1 Introduction

The search for new compounds that help improve the mechanical conditions of construction materials has led to the development of concretes with high mechanical properties, fire resistance, and impact resistance, through the use of nanomaterials [1], It is well known that cement is a material widely used in the construction industry, much of this material is used for the manufacture of concrete, which has many advantages to resist compressive loads, but very prone to cracking when exposed. to tension [2], This is why in recent years the use of new innovative methods such as the use of nanomaterials has made it possible to improve the properties of cementitious compounds; however, there are still some unforeseen issues with the dosages [3]. Currently, with the implementation of nanoparticles as an additional material in the designs of concrete mixtures, better results have been obtained in the fresh properties of concrete, since it improves its mechanical characteristics, in addition to positively influencing the increase in durability [4]. Now, in order to know the current advances in this field, studies on the influence of nanomaterials in different areas of the construction industry have been compiled [5].

Technologies to improve the properties of concrete have entered a stage, known as the era of smart concrete, it is in this where nanotechnology unleashed development in order to improve certain characteristics [6]. The manufacture of concrete with the addition of nanotechnology aims to have a higher density to reduce the number of pores it contains, thus reducing the attack of sulfates, as well as increasing its resistance to impact loads [7]. Nanomaterials speed up the hydration rate in the initial stage, increase the absorption of water due to its surface, reducing the free water available [8] Currently nanomaterials are constantly studied, due to the different applications in different areas that go from semiconductors to energy, textiles and construction. [9]. Recent research showed that a small addition of nanoparticles, carbon nanotubes (CNT) and nano titanium dioxide (TiO2), have improved the 28-day resistance of cement mortar when added in optimized amounts, and the same optimization for reinforced concrete, producing very good results. However, long-term resistance differs due to poor control of the degree of freedom of its valence electron, that is, nanomaterials tend to oxidize in the long term. [10]

Following the arrival of nanotechnology in India, considerable amounts of research have been found involved in the search for new and efficient materials on the nano scale (10 ^ (- 9) m) [11]. These materials may revolutionize construction in the not too distant future, in fact, it was nanotechnology that completely changed electronics and computing. So it is considered that this can also revolutionize the construction sector. Currently there are successful applications based on nanotechnology that would have been almost impossible without the use of nanoparticles [12].

Recent research studies the problems of the production of construction materials, particularly concrete, and their treatment through the use of nanotechnologies, the general mechanisms of formation of the structure of a set cement and the influence of a treatment of its components. [13]. In an undefined way on the modification of the properties of reinforced concrete, adding nanomaterials are still in a laboratory phase [14].

There are nanomaterials that have unusual properties, among them we have ultrafine powder, which has magnetic, mechanical, electrical and optical properties compared to traditional granular materials. Despite being a relatively new material, it has applications with promising results in construction, which is why it can be used to improve concrete performance, such as silica fume that provides better strength and durability due to its lower granularity and high activity [15]. However, its production is low and its price is high. Generally, silica fume is not considered when the strength of concrete is less than 80 MPa, with the increasing demand for concrete, nanotechnology has produced nanomaterials to replace silica fume, which are widely used in concrete due to their nano special effects [16].

The emergence of nanotechnology in the cement industry has already shown a notable impact on mechanical properties and reveal that nanomaterials improve the performance of reinforced concrete, resulting in High Performance Concrete (HPC) or Ultra High Performance Concrete (UHPC) and in turn, makes concrete durable [17].

In the construction sector, it is constant to deal with soils with unsuitable properties for civil engineering projects. Problem soils generally need special treatment to improve their properties [18], To improve certain characteristics, a process known as soil stabilization is used, normally it is carried out with chemical additives such as cement, lime, but which usually cause alkaline environments, due to the increase in Ph in the soil. [19], Therefore, new alternatives are currently being sought for soil stabilization, focusing on the use of nanomaterials to improve resistance to unconfined compression., [20,21] and the variation of the Atterberg limits, hydraulic conductivity, Ph, density and specific gravity [22].

Nanomaterials have a promising future, among the best known are: colloidal silica, bentonite and laponite, these present a satisfactory effect in mitigating liquefaction for sandy foundations, and the carbon nanotube has the ability to increase compressive strength without confining [23]. Colloidal silica is the closest market application, despite the advantages of nanomaterials adopted as additives for soil improvement, they are known for not causing interactions with different biological objects at the cellular level. Studies on nanomaterials as an additive to treat geotechnical problems in soils are very promising and may intensify the relationship between sustainable development and engineering [24].

Carbon nanoparticles can be used as a superplasticizer additive that increases the tensile and flexural rupture properties of concrete. [25]. Nanotechnologies are currently considered the most active, with innovative science and useful applications in the construction sector, it has been shown that nano-materials have their application in rigid pavements, with results of improvements in their compression, flexural and modulus properties. elasticity, there is the possibility of improving the properties of cement bricks by using Nanomaterials such as Nano Alumina NA, Nano Ferrite NF and Nano Copper NC [26]

The substitution of natural aggregates in concrete mixtures, as a source of solution to global warming generated by concrete waste extracted from constructions, on roads in cold regions with constant snowfall, the use of hydrophobes is recommended in the maintenance of the pavement, which has greater efficiency, reducing the adherence of ice to the structural mat, reducing the risk of accidents [27]

The asphalt that is used in the paving of roads, is usually prone to failure due to cracking or in any case due to deformations caused by traffic and / or environmental factors. [28], For example, the formation of grooves in the asphalt surface usually occurs due to exposure to high temperatures, which soften the asphalt binder, therefore the properties of this material play a fundamental role in the final performance of the pavement layer. [29,30] while cracking usually occurs due to a hardening of the asphalt binder due to low temperatures [31], therefore the performance and duration of the asphalt layer depends a lot on the development and / or behavior of the binder in the face of traffic loads and climatic changes; Based on these problems, different techniques or methods have been proposed to modify the asphalt binder in order to counteract the aforementioned problems, among them the use of polymers and nanomaterials stand out [32].

Although the modification of the properties of the binder through the use of polymers has provided satisfactory results, but its high cost represents a disadvantage for its application [33], While the application of nanomaterials for the modification of the properties of the binder have a lower cost of between 20-30% approximately, and have shown that they can help combat several problems related to the behavior of the mixture, studies show that the use of Nanomaterials such as Nanosilica, leads to a reduction in ductility and penetration value, increases the softening point resulting in a higher viscosity compared to common asphalt [34].

It is known that asphalt is a material very prone to aging when it is exposed to heat, oxygen and solar radiation, the asphalt binder as it ages becomes more rigid and brittle, losing the adhesion of the aggregates, triggering pavement failures, shortening its lifespan [35]. During the aging process, physical reactions occur (evaporation of light components), and chemical reactions (oxidation, dehydrogenation, isomeration, etc.) [36]. Recent studies show that nanomaterials improve viscoelastic responses, resistance to high temperatures, resistance to aging of asphalt binders [37]

According [38], The use of Nanosilica in the asphalt binder improves the anti-aging properties and resistance to deformation, this change is due to intermolecular forces in the asphalt.

Soil stabilization, which involves improving shear strength, increasing stiffness and decreasing plasticity, as well as reducing volumetric change [39], They are commonly treated with chemical additives such as the application of lime, cement or industrial waste such as fly ash, although their results are positive [40], they carry the disadvantage of being highly polluting products, which is why they are currently looking for more environmentally friendly materials. [41]. For this reason, studies are currently being carried out on the application of nanomaterials to improve problem soils. [42], which show promising results, such as carbon nano tubes (CNT) that due to its fine structure, high strength and modulus of elasticity, elastic and ductile behavior, make it a suitable material to be used in soil stabilization. [43], Although its application to be used as a soil stabilizer is still in the laboratory study stage, but it is already known that it can increase the plasticity index, increase the compression and swelling index as well as increase the resistance to hydraulic conductivity.

2 Nanomaterials

2.1 Nanosilica

It is an element that can be dispersed in water, but it agglomerates in an alkaline solution because the calcium ions available in the solution of the pores will be adsorbed on the surface of the NS [44], which will trigger flocculation. Has the ability to accelerate the hydration process and pozzolanic reactions [8,45]. With characteristics similar to silica fume or micro-silica, the use of this nanomaterial in concrete mixtures increases the water requirement in the design, reducing slump and an increase in viscosity, thus reducing the workability of the concrete mix. [46], but it improves the mechanical response of the mixtures after hardening. This improved performance can be attributed to the acceleration of heterogeneous nucleation, the better packing of these mixtures, and the reactivity of the particles at these sizes. [47].

2.2 Metacaolin

The use of metakaolin in the manufacture of concrete increases compressive and flexural strength when exposed to temperatures of up to 250 ° [8]

Metakaolin is a derivative of kaolin, as a result of dehydroxylation at temperatures of 800 ° C, when the bonds between the kaolin layers are broken, metakaolin is formed, and through a grinding process it is finally possible to obtain metakaolin [48].

2.3 Carbon Nanotube (CNT)

Nanotubes (CNT) have proven their value in construction materials and the motivation to find an effective solution to harness their long-term efficiency. Although CNTs were invented in 1991, their first patent was issued in 1996, and since then they have seen an exponential increase. [49], They are classified as one-dimensional materials, the main technique used for production is chemical vapor deposition. This method uses the catalytic transformation of carbon materials. CNTs are known to have excellent mechanical properties.

They are allotropes of carbon, with a cylindrical shape, they have high thermal conductivity, electrical and mechanical properties. In terms of improving flexibility and increasing strength, CNTs are the best nanomaterials [50]. It is an element that is composed only of carbon atoms, with elongated formations with a diameter of 1 to 100 nanometers and a length of 100 micrometers. Carbon nanotubes are perhaps one of the most promising nanomaterials, commonly used as a selective sorbent to remove organic and / or biological contaminants from streams [22]

3 Methodology

In this literary review, high impact databases such as Scopus, IOP Science, Science Direct and Ebsco were taken; From which a total of 86 articles could be selected, following a methodology that compiles scientific research in a blog and is classified under certain search conditions.

In Table 1 that shows the distribution by years of publications taken from 2016 to 2021: a total of 62 articles were obtained from the Scopus database, 9 from Science-Direct, 5 from Ebsco, 6 from IOP Science, and while in Table 2, the search by keywords in English is detailed: nanomaterials, concret, asphalt, cement, soils, mortar; with the respective database, in addition to the use of Boolean operators, in order to enrich the present investigation and Table 3 shows the filters used in the search.

3.1 Nanomaterials in construction

3.1.1. Nanomaterials in concrete

Before the year 1960, the only known binder material for the manufacture of concrete was Portland cement, but from the year 1970, chemical and mineral additives began to be studied and used. [51], Currently, the studies that use nonamaterials as a partial substitute for cement in the manufacture of concrete stand out.

In general, the participation of nanomaterials in concrete influences the fresh state. Improves mechanical properties and impacts durability properties, reducing porosity present in the concrete matrix [52].

Currently, Nanosilica has become a widely used material in the manufacture of concrete, due to the fact that they interact rapidly with the compounds that make up the mixture, causing physical and chemical interactions that influence the fresh and hardened properties of concrete [51].

The use of nanomaterials such as Nanosilica in the manufacture of concrete, can positively influence the potential to extend the useful life of the infrastructure, studies show that the use of nanomaterials improves the mechanical properties.

Table 4 details the use of nanomaterials in concrete.

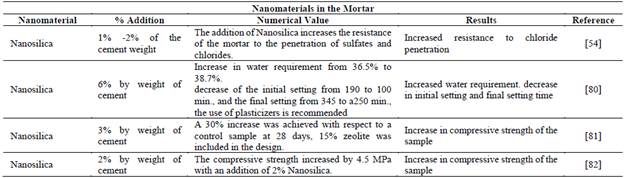

3.1.2. Nanomaterials in the Mortar

In mortar with nanotechnology inclusion, cement is the most consumed material behind water, and the most used is hydraulic (Portland cement). The main materials for making a mortar mix are water, sand and a cementitious material [53].

Cement is currently the subject of much criticism due to the environmental problems it causes during its production and use, due to the release of a large amount of carbon dioxide. Recent studies suggest that cement can be partially replaced with other materials without compromising the quality of the mortar [54]

The effects of nanomaterials on the characteristics of resistance to bending, compression, workability, chloride penetration and others, are widely studied today [55]. Additionally, research gaps and future prospects regarding the application of nanomaterials in mortars are discussed [25].

3.1.3. Nanomaterials in soil improvement

In the world of construction, it is ideal to have good soil for the construction of civil works, but in many cases this condition is not always present, so a method known as "soil improvement" is used, which consists of modify the properties of the soil by compacting it, replacing it with better quality materials or improving it through the use of chemical additives [56], Among the most used, cement and lime stand out, ranging in percentages from 3% to 20 " of the weight of the soil, due to the fact that the negative impact on the environment in which they are applied is high. New materials are currently being studied. with more environmentally friendly characteristics, among the new alternatives there are industrial by-products (slag, fly ash, rice ash, etc.), pusollanic materials (ash, pozzolana, silica fume, etc.) and those that are objects of this study: nanomaterials.

The use of nanomaterials for soil stabilization is currently being studied as an alternative to replace conventional methods, and one of the most common methods is the use of carbon nano tubes, although current studies are not extensive. knows that the use up to percentages of 1% increases the specific gravity, dry density, Ph, plasticity index, compression index and swelling in addition to reducing the hydraulic conductivity.

Table 6 details the use of nanomaterials in soil improvement.

3.1.4. Nanomaterials in Asphalt

The asphalt pavement, during its service stage, experiences many problems due to the loads to which it is subjected or to changes in temperature due to the variation of the climate [57], among the most prominent problems is the formation of grooves, deformations and cracks in the surface, these failures affect the serviceability, and require frequent maintenance [58].

The formation of furrows arises from the accumulation of constant deformations in the asphalt layer due to service loads and exposure to high temperatures [59], while the cracking begins due to fatigue, with small cracks that increase due to the constant repetition of loads to which it is exposed, and also due to the low temperatures experienced by the pavement, which cause a hardening of the binder, giving rise to to the formation of cracks [60].

The asphalt binder, which is the main component of the pavement, is a viscoelastic material [61], it is very prone to failure and is responsible for most of the problems that appear on the running surface of the asphalt layer [62], to improve the performance of the pavement, the properties of the binder must be modified [63]. The information that is known about the application of nanomaterials in this field is a bit scattered, therefore in this research work it will be synthesized in order to provide readers with the state of the art of research.

Table 7 details the use of nanomaterials in asphalt.

3.1.5. Nanomaterials in Cement

The use of chemical additives for the improvement of cement-based materials has grown currently [64], such as carbon nanotubes that help increase the flexural strength of elements made from cement [65], in addition to developing an increase in compressive strength up to 30% more than a sample with the addition of cement without additives [66]. Cement-based elements are brittle when subjected to tensile and bending loads, which trigger cracking. [67].

Table 8 details the use of nanomaterials in cement.

4. Conclusions

The use of nanomaterials in concrete is shown as a viable option, due to the results shown by different studies, so much so that, with relatively low addition percentages ranging from 0.15% to 4%, it is possible to increase the resistance to compression, impact resistance and sulfate attack, as well as increasing tensile strength with the application of nanomaterials such as carbon nanotubes.

The use of nanomaterials such as Nanosilica in soil stabilization achieves positive results in unconfined compression resistance tests, with an addition percentage of 0.1% of the soil mass, and during the first 7 days of curing the increase in the resistance is fast and subsequently the increase is gradual, on the other hand the stabilization with nanocalcium carbonate also achieves good results in the unconfined compressive strength tests, since with an addition percentage of 0.2% it is possible to increase the results , this value being the optimal content.

The use of Nanosilica considerably reduces the penetration and ductility in the asphalt, that is, the softening and viscosity of the binder is improved. In addition, the resistance to the formation of grooves is increased, and anti-aging properties improve, it should be noted that the dispersion of the nanomaterials within the asphalt mixture is important since it influences the final result, since the type of preparation is related that is done.

With the application of nanomaterials in the asphalt, it is concluded that in the tests of resistance to compression of an asphalt mixture with the addition of Nanosilica, it improves in humid and dry conditions, with an action percentage of 0.4% the resistance to traction, resistance to humidity and an increase in the modulus of rigidity is obtained. In the preparation of mortars, the uses of nanomaterials decrease the setting time, and influence the plasticity of the mixture, the smaller the nono material, the more water will be required in the design, so much so that with the use of Nanosilica increases the water requirement. To increase the fluidity of the mixture with the presence of nanomaterials, the use of plasticizers can be used, as long as they guarantee a correct dispersion and without limiting the performance of the nanomaterials.

Nanomaterials in the construction industry can be a good alternative from a sustainable point of view, in order to reduce the indiscriminate use of non-renewable resources used in the manufacture of materials used in construction, studies show that with the application of nanomaterials, positive results are obtained in the improvement of the mechanical properties of concrete such as increased compressive strength and tensile strength, in the stabilization of soils improvements are obtained in unconfined compressive strength and increased at the limit of plasticity in use to treat asphalt problems such as grooving, cracking and warping.