INTRODUCTION

The identification of deceased persons is a fundamental human right since all individuals have an identity in life that must be clearly established at the time of death for social, cultural, religious, judicial, legal, and economic purposes. In civilized societies, legal life is acquired with civil registry and the end of it is indicated with a death certificate, and this why it is very important to verify the identity of corpses or human remains 1)(2.

In the scientific-forensic investigations into death, the work during the necropsy medico-legal documentation should involve the collection, analysis, classification, and interpretation of data by forensic experts, prosecutors, and judicial investigators, which include dentists, since the careful examination of soft and mineralized tissues -including teeth- that make part of the stomatognathic system provides physical evidence that helps establishing the person′s identity 3)(4. However, this process may be blocked by the condition of the human remains due to different cadaveric phenomena or events pre-, peri and post-mortem associated with the cause of death. One of the challenges to the scientific, academic and technical forensic science experts is the case of individuals who have been burned, charred or incinerated, whose visual recognition is difficult because of facial alterations or bad conditions of finger pads, or because obtaining enough sequences of deoxyribonucleic acid (DNA) is unlikely 5)(6.

Since a person′s positive identification requires the irrefutable correlation of physical post-mortem features with records of those same characteristics ante-mortem, teeth and the materials used in dental treatments are a critical source of information, due to their property of resisting high temperatures 7)(8)(9)(10, and to the relative protection provided by perioral tissues facial muscles, maxillary bones and jaw, periodontal tissues and the tongue 11.

This is why, taking into account the classification of body burns (1. Superficial burns, 2. Destroyed epidermis areas, 3. Destruction of epidermis and dermis and necrosis areas in underlying tissues, 4. Total destruction of skin and deep tissues, and 5. incinerated remains)12, dentists are called upon to assist and guide the identification of individuals in the last three categories, by comparing postmortem records with ante-mortem dental clinical history records. These comparisons or correlations are usually made with dental treatments such as prosthetic restorations and fillings, given the great resistance of dental tissues and dental materials -including composite resin restorations-5)(13)(14)(15. In general, when dental materials (including composite resins) are subjected to high temperatures, they may suffer changes in color, texture, fissures and cracks, fractures, dimensional stability and shattering.

Thus, after recording the postmortem dental data of a corpse or human remains, and by having evidence that suggest their possible identity, the next step is to get relevant dental records in order to make dental comparisons ante- and postmortem, which, according to the American Board of Forensic Odontology 16, and supported by national and international laws, allows establishing identity in a particular case as positive (total coincidence), possible (compatibility), insufficient (inadequate available information), or exclusive (inconsistency and incompatibility)17)(18.

Composite resins are dental biomaterials used in dental restorative procedures. They consist of a mixture of polymerizable resin (organic component) mixed with particles of inorganic fillers (inorganic component) and the elements to bond them 19. Composite resin components are normally distributed as follows (percentages change per manufacturer): 1. Resin matrix consisting of hydrophobic dimethacrylates of high molecular weight (Bis- GMA -bisfenol-a-glicidil metacrilato-) and low molecular weight (TEGDMA -triethylene glycol dimethacrylate- and UDMA -urethane dimethacrylate-) and monometacrylates (IBOMA -isobornil methacrylate- and THFMA -tetrahidrofurfuril methacrylate-); 2. Polymerization inhibitors, such as MEHQ (4-methoxyphenol); 3. Color stabilizers, such as benzophenones, benzotriazoles and phenyl salicylate, which absorb UV light; 4. Filling particles of 0.04 microns (micro-fillers) to more than 100 microns (macro-fillers), which provide dimensional stability to the matrix resin (by reducing polymerization shrinkage, decreasing coefficient of thermal expansion and increasing hardness), such as crystal quartz, colloidal silica, lithium and aluminum silicate, aluminum silicate barium, strontium and aluminum silicate; 5. Opacifiers, such as barium, strontium, zinc, zirconium, and ytterbium; 6. Bifunctional adhesion agents that bond the resin matrix to filler particles, such as epoxy agents, vinyl, and silanes (vinyl-trietoxi silane or metacriloxipropiltrimethoxy silane); 7. Polymerization initiators, such as heat-activated benzoyl peroxide, tertiary amines (chemically activated) and canforoquinones (activated by ultraviolet light); and 8. Pigments that provide tooth-like shades, such as organic oxides (barium fluoride)20)(21.

This study used five commercial systems that are widely used in the dentistry worldwide (Z100 3M-ESPE®, Z250 3M-ESPE®, Z350 3M-ESPE®, Brilliant NG Coltene-Whaledent®and TPH3 Dentsply®). Due to their biological, aesthetic, and physical properties, as well as their relatively low cost and easy handling, composite resins have become the preferred restorative biomaterial to restore the morpho-functional characteristics of dental mineralized tissues that have been altered. Similarly, this study used five composite resin colors (A1, A2, A3, A3.5 and B2) that are frequently used in aesthetic restorations 22)(23. Since the use of composite resins as restorative materials in dental cavities -regarding dental amalgam- has been increasing in recent decades 24, as they play a critical role in the identification process providing a greater number of matching markers during the antemortem-postmortem forensic correlations 25, and because they are highly resistant to high temperatures 7)(8)(9)(10, the purpose of this study was to establish in-vitro parameters on the behavior of five commercial composite resin systems at high temperatures, allowing forensic experts to determine that it is actually a composite resin and not another dental material based on specific macrostructural changes in each temperature range, which may constitute evidence markers to eventually contribute to the process of forensic dental identification in the case of or burned, charred, or incinerated corpses of human remains.

MATERIALS AND METHODS

This was a descriptive, pseudo-experimental invitro study using a stereo microscope to analyze the behavior of 375 disks made of five commercial composite resin systems of (Z100 3M-ESPE®, Z250 3M-ESPE®, Z350 3M-ESPE®, Brilliant NG Coltene-Whaledent®and TPH3 Dentsply®) which were subjected to high temperatures (200, 400, 600, 800 and 1000 °C). Five colors (A1, A2, A3, A3.5 and B2) were used in all the systems, except for Brilliant NG Coltene-Whaledent®(dentin -A1/B1, A2/B2, D3/A3 and A3.5/B3- and enamel -A2/B2-).

Preparation of composite resin disks

An aluminum matrix, acetate sheets and glass vials were used to produce five disks simultaneously, each measuring ten millimeters in diameter by four millimeters thick. To make each disk, the composite resin (specific brand and color) was packaged using the technique of oblique increments of 2.5 millimeters which were polymerized -each increment- by 40 seconds with a light curing lamp (Spectrum 800 Dentsply®) using a normal power of 550 mW/cm2-recommended by the manufacturer and verified at the time of manufacturing each disk in the radiometer included with the lamp- until completely sealing the cavities in the matrix. Although not all disks were polished, the inhibited layer was removed with a cotton swab moistened with water and pumice. Once the stage of polymerization was over, the disks were removed from the matrix.

Management and conservation of samples

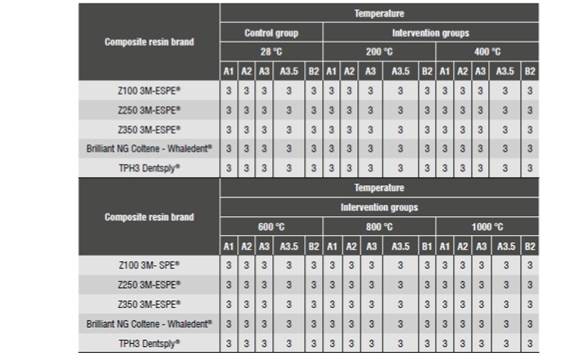

Once the composite resin disks were manufactured, each was placed in an opaque plastic container and kept at relative humidity and room temperature (28 °C). Prior application of high temperatures, each disk was taken a digital photograph with a Leuchtturm® 1.3-megapixel stereo-microscope at 15X. The disks were sorted out in the six groups (a control group -at room temperature- with 75 disks, and five intervention groups -subjected to high temperatures- with 375 disks in total) according to the commercial systems, the shades and the temperature ranges (Table 1).

Application of high temperatures

This procedure was based on the technical scientific protocol established at the Department of Odontostomatology of University of Pavia (Italy),7) as well as the studies at the School of Dentistry of Universidad del Valle (Colombia)9.

The suggested in vitro model for this study is conducted in an oven and not in direct flame, bearing in mind that in different literature reports the maximum temperature reached is 1000 °C -while some reports have raised the temperature up to 1200 °C 7, no significant differences are reported compared the 1000 °C-, a peak reached after 25 to 30 m. and then kept at approximately 500 °C until all of the oxygen is consumed or all organic material is reduced to carbon (carbonization) or to compounds of calcium, phosphate, silica or other mineral nutrients (incineration). In addition, this in situ "flask effect" is comparable to the effect of perioral tissues, facial musculature, bone tissue, and dental and periodontal tissues 11.

The composite resin disks in the intervention groups, corresponding to each temperature range, were placed on individual trays for refractory coating (Cera-Fina® Whipmix®) to facilitate handling and were subjected to direct heat in a muffle furnace (Thomas Benchtop Thermolyne®) previously calibrated to five different temperature ranges (200, 400, 600, 800 and 1000 °C) with an increment rate of 10 °C per minute from an initial temperature of 28 °C up to each proposed temperature. For example, the three Z100 3M-ESPE®disks color A1 were introduced, each in its respective tray, in a temperature range of 28 °C to 200 °C, leaving the furnace to cool down to room temperature in order to remove the trays with disks. Then, the three Z100 3 M-ESPE®disks color A2 were introduced, each in its respective tray, in a temperature range of 28 °C to 400 °C, leaving the furnace to cool down to room temperature in order to remove the trays with disks. This process was repeated successively for each brand and disk color for the remaining temperature ranges: 600, 800 and 1000 °C.

Observation of samples

As a preparation for describing the behavior of the composite resin disks of five commercial systems subjected to high temperatures, two authors were trained in observation of changes in the control group (bearing in mind the following variables: color -the shade of each resin as brown, black, grey and powder white-, texture -roughness and porosity- fissures and cracks -crackled surface appearance-, fractures -loss of continuity in disk-, dimensional stability -size increase- and shattering -fragmentation-) in order to have bias control bias and to achieve consistency in observation criteria. The degree of reliability was estimated by means of the Kappa test using version 6.0 of the Stata®software and its findings determined intraobserver (0.91 and 0.91) and interobserver (0.88 and 0.93) standardization for both observers respectively.

Statistical analysis

The analysis of frequencies was conducted with version 22.0 of the IBM SPSS Statistics®software in order to determine the relative frequency (%) of the macroscopic changes in the sample. The following variables were considered: temperature, color, texture, fissures and cracks, fracture, dimensional stability and shattering.

RESULTS

The five composite resin commercial systems of (Z100 3M-ESPE®, Z250 3M-ESPE®, Z350 3M-ESPE®, Brilliant NG Coltene-Whaledent® and TPH3 Dentsply®) showed very similar behavior in each temperature range (Table 2). Surface macroscopic changes were evident at 15X (Figure 1, Figure 2, Figure 3, Figure 4 and Figure 5) in terms of color, texture, fissures and cracks, fracture, dimensional stability, and shattering of composite resin disks subjected to the action of high temperatures. It should be noted that each figure corresponds to a commercial system of composite resin; the first column corresponds to disks in the control group which were not subjected to high temperatures and, moving from left to right, each column corresponds to temperature ranges starting from 200 up to 1000 °C. Similarly, the rows correspond to shades; row 1 shows shade A1, and from top to bottom the table lists shades A2, A3, A3.5, and B2; except for Brilliant NG Coltene- Whaledent® with shades from the first column topdown as dentin -A1/B1, A2/B2, D3/A3 and A3.5/ B3- and enamel -A2/B2-.

Figure 4 Brilliant NG Coltene-Whaledent® composite resin disks subjected to high temperatures observed at 50X

In general, at 200 °C all composite resin systems behaved in the same way, with loss of brightness and visible white stains as common characteristics; at 400 °C disks turned brown due to initial combustion of organic matrix, with brown stains and surface fissures plus shallow cracks; at 600 °C the disks turned black due to combustion of organic matrix, white stains appeared with an increase in the pattern of surface cracks and deep cracks associated with initial thermal expansion, which in the case of TPH3 Dentsply®caused the shattering of disks; at 800 °C the disks were opaque and gray due to incineration of organic matrix, the surface got a crackled appearance due to an increase in surface fissures, some of the disks got fragmented by deep cracks, disk shape was altered by dimensional shrinkage and, in the case TPH3 Dentsply®the disks burst; finally, at 1000 °C the disks were opaque and white due to incineration of organic matrix, surfaces kept a crackled appearance by the increase in surface fissures, some of the disks got fragmented by deep cracks, disk shape was altered by dimensional shrinkage and, in the case TPH3 Dentsply®, disks dramatically changed their shape by thermal expansion and got a sponge aspect due to the amount of surface pores and deep perforations.

DISCUSSION

Before starting the discussion on the behavior of composite resin disks subjected to high temperatures, it is necessary to understand the distribution of components (classification according to size of filler particles) of the commercial systems included in this study. Filler particles are responsible for reducing polymerization shrinkage, water sorption and the coefficient of thermal expansion in resin matrix, increasing tensile, compression, and abrasion strength, besides the modulus of elasticity 20)(21. Using different manufacturing processes, filler particles can be of different sizes: microparticles starting at 0.04 microns and macroparticles starting at 100 microns and more 26.

Five composite resin systems were used in this study: 1. Z100 3M-ESPE®, which is a multi-purpose micro-hybrid composite resin whose organic matrix is composed of Bis-GMA and TEGDMA and whose inorganic component is zirconium filler particles treated with silane (coupling agent) measuring 0.6 microns in average (0.01 to 3.5 µm); 2. Z250 3M-ESPE®is a micro-hybrid universal restorative system whose organic matrix is composed of Bis-GMA, TEGDMA and UDMA, and whose inorganic zirconium component is treated with silane (coupling agent) measuring 0.6 microns in average (0.01 to 3.5 µm); 3. Z350 3M-ESPE®, which is a nano-hybrid restorative universal system with an organic matrix composed of Bis-GMA, TEGDMA, UDMA, and PEGDMA, and an inorganic component of silica filler particles of 20 nanometers, zirconia of 4 to 11 nanometers and zirconium clusters treated with silane (coupling agent) of 20 nm; 4. Brilliant NG Coltene-Whaledent®is a universal micro-hybrid composite resin whose organic matrix is composed of various methacrylates and with an inorganic component of amorphous silica filling particles of 0.6 microns in average (0.01 to 2.5 microns); and 5. TPH3 Dentsply®which is a universal nanohybrid restorative system with an organic matrix composed of Bis-GMA, TEGDMA, and Bis-EMA, and an inorganic component of filling particles of aluminum silicate, barium silicate, boron silicate, and barium fluoride of 0.1 microns and silica clusters measuring 15 nanometers in average (10- 20 nm) 21)(22.

Now that the composition of composite resin commercial systems has been explained, the discussion will focus on the variables considered in this study, i.e., changes in color, texture, fissures and cracks, fracture, dimensional stability, and shattering.

According to the observations, color changes in the composite resin disks can be associated to different levels of organic matrix combustion as temperature increases. At 200 °C, in comparison to the control group, the disks lose brightness due to surface combustion associated with the persistence of free radicals of the inhibited layer produced during polymerization (usually of peroxides)27. At 400 and 600 °C the disks turn initially brown and then black due to carbonization of organic matrix and there are stains initially brown and then white that are associated to manipulation of composite resin and instruments marks during the elaboration of disks. While manufacturers of composite resin systems do not usually specify a melting point, it should be noted that temperatures up to 100 °C are required for monomers to fuse with each other and form polymer chains, in a process known as thermal polymerization or heat curing.19) The monomers most commonly used in commercial composite resin systems (Bis-EMA, Bis-GMA, TEGDMA, and UDMA) begin to volatilize at 125 °C 28, until reaching melting point at 200 °C 21. At 800 and 1000 °C disks are gray and white respectively, and turn opaque due to incineration of organic matrix, except for disks of the Brilliant NG Coltene-Whaledent®and TPH3 Dentsply®systems, which are bright and with isolated black spots associated to a higher content of organic matrix. Therefore, in terms of color, this study observed the same changes reported by Merlati et al 7, Moreno et al 9, and Vásquez et al 29, who were able to determine the temperature at which resin disks were subjected to by means of surface color change, associated with different levels of initial combustion, charring, and incineration of organic matrix. However, it is not possible to establish differences between the five commercial systems or the colors taken into account in this study.

Concerning texture, it should be noted that the composite resin disks were not polished once the curing process was completed, so the smooth nature of their surface was provided by acetate strips covering them inside the matrix during final light curing according to the protocol. Thus, starting at 400 °C there were irregular pigmentations associated to those produced by instruments during the elaboration of disks using the oblique increments technique, resulting in a streaked appearance, which changes from brown (carbonization) to white (incineration) as temperature increases and fades at 800 °C. Another fundamental aspect that must be considered is that, from 800 °C (of from 600 °C in the case of TPH3 Dentsply®), the disks surfaces show a network of fissures that provides them with a crackled appearance which can be interrupted by deep cracks and fissures or fractures and disk fragmentation. At 1000 °C, disks of the Brilliant NG Coltene-Whaledent®and TPH3 Dentsply®systems are melted, porous and with deep perforations. With the exception of this last feature, Merlati et al 7, Moreno et al 9, and Vásquez et al 29) reported the same aspects in terms of composite resins texture.

Basically, as temperature increases, the composite resin systems experienced two reactions: the first occurs between 600 and 800 °C and involves thermal expansion of disks, which is noticeable in convex surfaces associated to carbonization of organic matrix by evaporation of components, creating gaps in between filling particles, the fissure pattern that produces the crackled look, and shallow cracks as a result of thermal shock. The second reaction occurs at 1000 °C and consists on thermal contraction as a result of incineration of organic matrix, causing the filling particles to regroup and lead to reduction in disk size, deep cracks, cohesive fractures, and fragmentation depending on the degree of incineration. These phenomena, described by Merlati et al 7, Moreno et al 9, and Vásquez et al 29) in composite resin dental restorations, occur in all disks except in the Brilliant NG Coltene-Whaledent®and TPH3 Dentsply®commercial systems, where disks are melted, porous and with deep perforations, suggesting that organic matrix polymers are not fully incinerated but reach their melting limit as well as their boiling point and then, once temperature decreases, they solidify and show the described aspect.

As previously explained, composite resin disks initially expand and then collapse due to thermal shock. In the Z100 3M-ESPE®, Z250 3M-ESPE®, and Z350 3M-ESPE®commercial systems, these changes in dimensional stability failed to break up the disks beyond the emergence of a network of fissures and deep cracks. This great resistance to the action of high temperatures may be associated to the composition of composite resins. The three commercial systems are classified as hybrids since they have particles of different sizes not exceeding 0.6 microns. Similarly, the content of filler particles is greater than the content of polymer matrix (Z100 3M-ESPE®66%, Z250 3M-ESPE®72,5% and Z350 3M-ESPE®78,5%)21)(22; therefore, when it is sintered and merged does not decrease disk volume as to affect its structural strength 30. In the case of the Brilliant NG Coltene-Whaledent®and TPH3 Dentsply®commercial systems, starting at 600 °C changes are dramatic, since there is surface fragmentation with loss of material continuity (cohesive failure) associated to a lower content of organic matrix, a minor content of filling particle -which is 58% for the TPH3 Dentsply®system- and with particles in nanometers. Concerning the Brilliant NG Coltene-Whaledent®system, the amount of filler particles is 65% of the volume, including particles of amorphous silica, which is much more soluble than the crystal form due to its porous structure, suggesting that an increase in temperature has the filling particles precipitate on a molten organic matrix altering the original shape. In their studies, Moreno et al 9) and Vasquez et al 29) explained that this initial phenomenon of thermal expansion and subsequent thermal contraction causes change in stability, fractures, fragmentation of composite resin fillings as well as their subsequent push out of the dental cavity, which is noticeable from 600 to 1000 °C.

The strategy of combining properties of organic and inorganic components has allowed to optimize the physical properties of composite resins; two of them are refractory characteristics -adapting to the various changes of the oral cavity and to food temperature without altering dimensional stability- and load strength -through a mineral reinforcement phase-, both provided by various inorganic filler materials such as silica and zirconium 31.

In this study, the Z100 3M-ESPE®and Z250 3M-ESPE®composite resin systems use zirconium as filling material, and Z350 3M-ESPE®uses zirconia and silica; while Brilliant NG Coltene- Whaledent®and TPH3 Dentsply®only use silica. Thus, according to the melting points of these two components (1700 °C for silica and 1900 °C for zirconium), the organic matrix is altered much faster than the inorganic matrix as temperature increases; and according to the amount of filling particles, the two last systems have a higher proportion of organic matrix, and therefore they are deformed when subjected to high temperatures.

CONCLUSIONS

The composite resin disks of the commercial systems included in this study presented changes in texture, fissures, cracks and fractures according to the temperature range to which they were submitted. Regarding dimensional stability and shattering, there were differences in disk behavior based on the classification of composite resins in terms of size filler particles treatment; thus, the Z100 3M-ESPE®, Z250 3M-ESPE®, and Z350 3M-ESPE®systems maintained structural integrity even if the surface had fissures, deep cracks or disk fracture, while the Brilliant NG Coltene-Whaledent®and TPH3 Dentsply®systems significantly changed their appearance.

In the case of color observations, all the commercial systems behaved in the same way, but it should be noted that opacity (200 °C), brown shade (400 °C), black shade (600 °C), gray shade (800 °C) and white shade (800 and 1000 °C) may be associated with different levels of initial combustion, charring, and burning of organic matrix; however, it was not possible to determine differences by color change among these commercial systems, as well as there were not apparent differences among composite resin shades.

Finally, in associating color changes with the macrostructural behavior of composite resin disks, it will be possible to identify the type of dental material used to make certain dental restoration, which is fundamental in ante-post mortem comparisons during the identification processes of dental forensics in the case of corpses or human remains that have been burned, charred, or incinerated. Similarly, these changes will allow estimating the temperature a composite resin restoration was subjected to, which is useful for medico-legal documentation.

The authors recommend performing further spectrometry analysis of the various commercial systems in order to quantify color, identify the behavior of molecular components of organic matrix components and microfillers, and use scanning electron microscopy to observe the microstructural changes that explain macroscopic changes (texture, fissures and cracks, fractures, dimensional stability and shattering) of composite resin disks.

text in

text in