1. Introduction

1.1. State of the art

Environmental pollution is a serious issue that must be addressed as soon as possible. Polyethylene Terephthalate (PET or PETE) is considered a serious environmental problem that need to be studied in order to decrease its environment impact. According with INEGI [1], 44.646 million tons of urban solid waste were generated in Mexico by 2017; of which around 10% was classified as plastic waste. Carcaño [2], made an important prediction based on a study of supply-demand of PET products, establishing that the demand of PET products is going to be higher. One way to decrease this problem can be by implementing "green building". These alternatives provide the opportunity to reuse toxic products and developed new building techniques, hence solid waste or polluting products can be integrated into useful structural elements that can even improve the building processes and also contribute to the mechanical properties of the structural elements. In order to understand the mechanical properties of concrete containing PET waste, several manuscripts have been conducted taken into account parameters such as elastic modulus [3-5], flexural tensile strengths [6-8], impact resistance [10], fresh and hardened properties of concrete [11] including abrasion resistance [9]. This research is presented as a structural context where PET-profiles were used as an alternative structural reinforcement, and also a probabilistic model is used to estimate the PET contribution in terms of exceedance of the rupture modulus.

2. Main scope

The main objective of this paper is to be the first national incursion on the subject of sustainable development through a prototype proposed to be implemented in the highway infrastructure. Here, the results are presented in order to assess the importance of using a PET-profiles matrix within concrete beam-type specimens where the flexural properties of concrete specimens reinforced by a soft pre-tensioned PET-profile matrix placed on in specially designed molds should be increased. PET-profiles settled as a fiber matrix with soft pre-tensioned condition could have advantages in structural members in some precise applications, as for instance, structural support for road safety barriers. Laboratory Tests are performed using a universal machine (WDW-200E) in order to estimate the tensile strength capacity of PET profiles with different width, number of "knots" and other conditions. The desired PET profile is chosen and the concrete mixture is designed under the ACI standard guidance [17]. The main stage is to estimate the flexural properties of reinforced concrete beams by including pre-stressed PET-profiles in order to develop a sustainable prototype that can be used in the highway infrastructure which are basically designed with a specified compressive strength of concrete (f'c=30MPa).

2.1. The research process will cover the following phases

Analyze the mechanical and physical properties of the PET-profiles with different width, different number of "knots" and also many other conditions.

Perform Bending tests of concrete beams with loads in the thirds of their length.

Perform Bending tests of concrete beams including pre-stressed PET profiles in a unidirectional fiber matrix.

Perform bending tests of concrete beams with pre-stressed PET-profiles placed on a bidirectional fiber matrix in a mesh form.

In this paper a probabilistic assessment is used to estimate the PET contribution of the rupture modulus [12]. Here, the beam-type specimens are casted with concrete with a (f'c=30MPa) complying with NMX-C-159-ONNCCE-2004 [13] and NMX-C-160-ONNCCE. 2004, MEXICO: ONNCCE [14]. These standard codes are used for the preparation of test specimens. In order to estimate the flexural strength capacity of beam-type specimens, it is worth to mention that, the molds are built with a cross section of 0.15 x 0.15 m and length equal to 0.60 m, made of wood. The wooden molds will include different aluminum accessories necessary to hold the PET-fibers, then it is possible make a soft pre-stressing, see Fig. 1.

3. PET-profiles: Tensile strength capacity

The PET-profiles and/or PET-threads were tested one by one in blocks with similar geometric properties in order to estimate an average of the tensile strength capacity and deformation of each block. The PET-profiles were cut and prepared from recycled PET-bottles coming from commercial sodas. In Table 1 to 6, valuable information is given obtained for PET-profile with different width (Table 1), number of "knots" (Tables 2) and also other properties were analyzed such as for instance the temperature effect. It is worth to mention that the tensile strength was estimated in a Universal Testing Machine (WDW-200E),

The necessity of workability, when the PET-profiles are implemented in the wooden molds is very important. For this reason and according with the tests results given in Table 1, it was decided to use PET-profiles with 3.5 x 10-3 m of width. On the other hand, knotted PET-profiles have the "anchorage" function working together with concrete; these knots will be like the corrugations in the steel rods. In this study, Knotted PET-profiles are the most viable option granting the anchorage between PET-Profiles and concrete, see Fig. 1.

Table 1 Tensile strength capacity of PET-profiles with different widths and a length equal to 0.25 m and Thickness 4.5 x10-4 m

Source: The authors.

Table 2 Tensile strength capacity from knotted PET-profiles with a width 3.5 x10-3 m, length equal to 0.25 m and Thickness 4.5 x10-4 m

Source: The authors

Table 3 Tensile strength capacity from PET-profiles baked at 50 °C with a width 3.5 x10-3 m, length equal to 0.25 m and Thickness 4.5 x10-4 m

Source: The authors

Table 4 Tensile strength capacity from PET-profiles baked at 100 °C with a width 3.5 x10-3 m, length equal to 0.25 m and Thickness 4.5 x10-4 m

Source: The authors

Table 5 Tensile strength capacity from PET-profiles baked at 150 °C with a width 3.5 x10-3 m, length equal to 0.25 m and Thickness 4.5 x10-4 m

Source: The authors

Table 6 Tensile strength capacity of extruded Plastic-profiles made off with commercial plastic bags; length 0.15 m.

Source: The authors

Knotted PET-profiles provide similar tensile strength capacity than not knotted PET-profiles, see Table 2 where a total of 60 test specimens were tested in blocks each one with 10 specimens with similar knotted conditions in order to estimate an average of the tensile strength capacity and deformation of each block. Even, in this research work, the effect of temperature on the PET is reviewed since the particles of the material could be crystallized providing a change in their mechanical properties. The Tensile strength estimated from PET- profiles baked at different temperatures are presented in Tables 3 to 5 where 5 tests are reported for each time step and temperature, these number of tests were considered enough evidence to observe the behavior of the effect of temperature on PET-profiles.

The Plastic-profiles can be made off with recycled plastic material coming from commercial plastic bags, See Fig. 2 where extruded Plastic-profiles are shown. In Table 6, is clear that the deformation of the Plastic-profiles is greater than that experienced by the PET-profiles given in Table 1. In fact, the tests carried out under controlled laboratory test conditions proved that "Plastic-profiles", with circular cross-section, resist a certain tensile strength capacity without reaching their rupture, it means that the Plastic-profiles are working in the plastic zone area.

A considerable number of Tests were carried out with different diameters of extruded Plastic-profiles, see Table 6 where it is shown that the Plastic-profile of 5.75 x10-3 m in diameter has the highest tensile strength capacity.

It is worth to mention that for 1 kg of plastic material; the following material is required:

0.772kg of recycled Linear Low-Density Polyethylene (LLDPE).

0.154kg of recycled High Density Polyethylene (HDPE).

0.074kg. of recycled Low Density Polyethylene (LDPE)

The last three materials can be recycled from commercial plastic bags.

4. Concrete Beam-type specimens: Flexural strength capacity

The concrete was designed with a specified compressive strength of (f′c=30MPa) . The compressive strength of concrete is measured to ensure that the concrete satisfy the quality control. To measure the compressive strength of the concrete, cylindrical-test specimens of 0.15 x 0.30 m are prepared and stored until the concrete hardens. The whole testing procedure was carried out in laboratory test conditions following the standard codes, see [13-15].

Once the concrete mixture is designed and tested. The concrete is casted in molds made off wood with cross-section 0.15 x 0.15 x 0.50 m. Every PET-thread had knots every 0.02 m to provide traction and an additional pre-tension was induced (approximately - 1 kg per thread). A cast beam-type specimen with the PET-profile matrix is shown in Fig. 3.

Source: The authors

Figure 3 Beam-type specimen with PET-profiles settled in a bidirectional fiber matrix in a mesh form.

Now, it is possible to perform bending tests in order to estimate the flexural strength of concrete beams-type specimens with loads in the thirds of their length with and without PET-profiles embedded following a unidirectional fiber matrix or a bidirectional fiber matrix in a mesh form.

According with NMX-C-191-ONNCCE [15], the modulus of rupture is a material property obtained to determine the flexural strength of the concrete by the bending test of a beam. There are two types of failure in terms of the rupture modulus, when the fracture is presented in the middle third of the clearing, see Fig. 4 and when the rupture is not presented within the middle third.

Source: The authors

Figure 4 Concrete Flexural Resistance using a simple concrete beam with load in the middle third of the clearing. NMX-C-191-ONNCCE [15].

Therefore, on average, two beam-type specimens were casted per every test stage so that in total around 18 tests beam-type specimens were done obtaining the following results. In Table 7, the bending test results for beam-type specimens made of simple concrete are shown with loads in the thirds of their length.

In Table 8 and 9, the bending tests results coming from beam-type specimen whit pre-stressed PET profiles in a unidirectional and bidirectional fiber matrix are given, respectively.

Table 8 Main data obtained from Beam-type specimens made with PET-profiles placed in a unidirectional fiber matrix

Source: The authors

Table 9 Main data obtained from Beam-type specimens made with PET-profiles placed in a bidirectional fiber matrix (45°, Fig. 3).

Source: The authors

The average of the maximum load capacity and deformation are obtained from beam-type specimens casted at different ages; see Tables 7 to 9 where Fluctuated load capacity values are observed. The PET-profiles in a unidirectional and bidirectional matrix arrangement have influence in the flexural strength capacity of the beams-type specimens. In Tables 7 to 9, The deflection has also an considerable importance in the load capacity and modulus of rupture where a soft increment in the value are observed in beam-type specimens with PET-profiles settled in a uni and bi-directional matrix. It is because the beam-type specimens with PET-profiles can support more deflection. The influence of the PET-profiles is higher in the test specimens with a unidirectional arrangement than in a bidirectional matrix where the PET-profiles settled with a 45° angle could affect the behavior of the unidirectional PET-Profile arrangement which could work once the concrete have failed. In Tables 7 to 9, the rotation is estimated using the data of maximum load and deformation. It is easy to see that the PET-profiles provide a better rotation degree to the beam where, the beam-type specimens made with PET-profiles placed in a bidirectional fiber matrix placed to 45° have higher rotation and flexibility with similar flexural strength those beam-type specimens with a unidirectional fiber matrix.

In Table 2 is shown that a thread with 10 knots can resist a load of 135.97 N. But according to data in Tables 7 to 9, it is not easy to see the contribution of tensile and flexural strength. For this reason, it is necessary to analyze the Figs. 5-7.

In Fig. 5, the beam specimen reaches the maximum load and after that a fragile failure is presented. That is not the case for beam specimens with unidirectional and bidirectional PET fiber matrix where, the PET profiles provides a 62-63% average resistance after the failure of concrete, see Fig. 6 and 7. In Fig. 7, PET-profiles placed in a bidirectional matrix with 45° provide a 6.46% more compared to profiles settled in a unidirectional way. Therefore, PET-profiles settled in a bidirectional matrix with 45° provides around 69.31% more than a simple concrete beam after the fragile failure, it should be mentioned that these test specimens with PET-profiles shown a remarkable strength increase upwards compared to the profiles placed in a unidirectional way; showing a "constant" or linear contribution.

Source: The authors

Figure 5 Load-Deflection for a simple concrete beam loaded in the middle third of the clearing. NMX-C-191-ONNCCE [15].

Source: The authors

Figure 6 Load-Deflection for a beam-type made off concrete with unidirectional fiber matrix loaded in the middle third of the clearing. NMX-C-191-ONNCCE [15].

Source: The authors

Figure 7 Load-Deflection for a beam-type made off concrete with bidirectional fiber matrix loaded in the middle third of the clearing. NMX-C-191-ONNCCE [15].

Fig. 5 shows a tests specimen with fragile failure, it is because the PET profiles are not included. In Fig. 6 and 7, the contribution of the PET profiles are working once the concrete fail. Therefore, the curves in the figures show that the tests specimen is holding strength and lead to a ductile failure.

Fig. 8 shows that PET-profiles have the characteristic to keep the concrete fragments confined due to the action or anchoring provided by knotted PET profiles. Therefore, the PET-profiles inclusion in the concrete can be useful in structural support for road safety barrier where the car impact can spread small concrete fragments and the PET-profiles or PET-threads could keep the concrete fragments confined. Future work can be planned where impact tests and energy dissipation can be carried out, since the PET profiles has the ability to confine the concrete particles where the main objective of this project is to save the life of the road users and protect the environment.

5. Probabilistic estimation of PET-profiles contribution

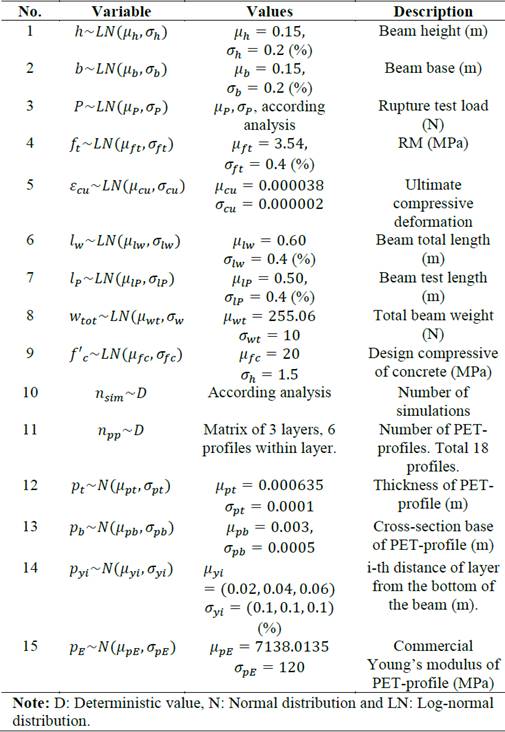

In this section, a probabilistic approach is proposed to evaluate PET-Contribution in terms of capacity and failure. In Table 10, the stochastic variables are enumerated. It is worth to mention that PET contribution affects more the vicinity of flexural failure stage when these profiles are delaying the Rupture modulus (RM) while the flexural beam upper compression block is increasing (or decreasing) to balance the flexural capacity. Therefore, the rupture modulus test considers an early state during beam behavior before tension-cracking condition where it is always expected a sudden and brittle beam failure.

Table 10 Stochastic variables and models for Probabilistic simulation of PET-contribution before flexure rupture

Source: Taken from [12]

The values shown in Table 10 are based on preliminary test studies which have been carry out in [12] where a modulus of rupture of 3.54MPa was obtained for a beam-type specimen made of 20MPa and beams including pre-stressed PET profiles in a unidirectional fiber matrix a modulus of rupture of 3.788MPa was estimated, which clearly is compatible with the results presented in Tables 7 to 9 where Beam-type specimens with a compressive strength of 30MPa which have been tested.

Eq. (1) is used to estimate the tension stress in the bottom fiber where rupture is taking place:

Where  and

and  are the inverse Hognestad’s stress-deformation model for nonconfined concrete and simple numerical modification of Hognestad’s stress-deformation model for nullifying tension stresses in the lower part of the beam, see reference [16]. The first term in

are the inverse Hognestad’s stress-deformation model for nonconfined concrete and simple numerical modification of Hognestad’s stress-deformation model for nullifying tension stresses in the lower part of the beam, see reference [16]. The first term in  is the flexural normal stress

is the flexural normal stress  and the last is a Young’s modulus that is calculated using a former ACI contribution [17]. The total weight of the specimen is considered as uncertainty. The variable

and the last is a Young’s modulus that is calculated using a former ACI contribution [17]. The total weight of the specimen is considered as uncertainty. The variable  is the distance to the section fiber in which one is interested on. Thinking in the top or bottom layers,

is the distance to the section fiber in which one is interested on. Thinking in the top or bottom layers,  .

.

With the inclusion of PET-profile, the bottom stress  and top stress

and top stress  may change with the hand of the stress diagram of a supposed plain remaining face. In Fig. 9, it is shown the case 9-a where PET-profiles are not included. Also, the condition of PET embedded is considered in 9-b and 9-c. In the Fig. 9-b, it is shown the case in which any reinforcing fibers (general case) are contributing to the tension wedge force and as a result, the compression force should increase in a manner of an area increasing. In the case of Fig. 9-c, the condition of a reinforcing soft fiber is prevailing. In the former case, the fibers are reducing concrete area at tension wedge and hence, the tension force should increase (with an increasing of tension wedge area). Previous cases in Fig. 9-b, 9-c, can be the cases of PET-profiles. The diverse behavior depends directly on the Young’s modulus of PET-profiles as theory is describing but also any initial pre-tensioning of PET-fibers (as is the case) according the PET variety and conditions.

may change with the hand of the stress diagram of a supposed plain remaining face. In Fig. 9, it is shown the case 9-a where PET-profiles are not included. Also, the condition of PET embedded is considered in 9-b and 9-c. In the Fig. 9-b, it is shown the case in which any reinforcing fibers (general case) are contributing to the tension wedge force and as a result, the compression force should increase in a manner of an area increasing. In the case of Fig. 9-c, the condition of a reinforcing soft fiber is prevailing. In the former case, the fibers are reducing concrete area at tension wedge and hence, the tension force should increase (with an increasing of tension wedge area). Previous cases in Fig. 9-b, 9-c, can be the cases of PET-profiles. The diverse behavior depends directly on the Young’s modulus of PET-profiles as theory is describing but also any initial pre-tensioning of PET-fibers (as is the case) according the PET variety and conditions.

Source: [12]

Figure 9 Effects of PET-profiles. (a) Stress diagram without PET-profiles. (b) Stress diagram with PET-profile and increasing of compression wedge area. (c) Stress diagram with PET-profile and decreasing of compression wedge area.

Assuming the behavior in Fig. 9-b, the PET contribution may be positive for increasing RM or generating cases where σb is less than σt . The experimental data of the beams in this work, confirm this belief. In order to include in the eq. (1) with the variation of df and using:

where c is the compression wedge depth, FC is the Compression resulting force, fi is the fiber force, b is the cross-sectional base and σb is the bottom tension stress. The signs ± are referring to soft-fibers (+, sign) and acting-fibers (-, sign), respectively. Using the eq. (2), it is possible to calculate (1) and estimate the modification of the stress profile. When the eq. (1) is modified by (2), it is possible to simulate by Monte Carlo technique and then find the positive or negative contribution of the PET-profile.

The limit state equation can be described by:

where  is the vector of stochastic and deterministic parameter shown in Table 10 and

is the vector of stochastic and deterministic parameter shown in Table 10 and  is the stochastic variable representing the maximum tension stress at the bottom line of the cross section and

is the stochastic variable representing the maximum tension stress at the bottom line of the cross section and  is the bottom stress calculated with

is the bottom stress calculated with  using the eq. (3) as

using the eq. (3) as  .

.

6. Application case

In Table 11, the results are shown which they basically address the tests made in beam-type specimens with simple concrete (f'c=20 MPa), where two different molds were used: a conventional 0.15 x 0.15 x 0.45 m and other with 18 holes to introduce the PET-profiles which have been carry out in [12].

From Table 11, it is possible to see an increase of reliability (β) for specific values of P, coming from expected forces for particular compressive strength of concrete in specific tested beams. And also low reliability β-values are referring to the tension cracking condition from the fact that this condition is not preventable. However, it is more important to be concentrated in the difference between beam’s reliability indexes (β) with and without PET-profiles. The differences are mainly what this work is about.

In this paper, the tests are made in beam-type specimens with simple concrete (f'c=30MPa). This is done mainly for structural applications mainly for a Highway Safety barrier prototype complying with the standard code "NMX-C-159-ONNCCE-2004" [13], where two different molds were used: a conventional 0.15 x 0.15 x 0.50 m and other with 55 holes to introduce the PET-profiles in a matrix with 5 layers with 11 threads every layer. Every PET-thread had knots every 0.02 m to provide traction and an additional pre-tensioning was induced (approximately 1 kg per thread). Beam-test specimens without PET-profiles has a Rupture modulus in average equal to 3.60MPa and Beam-type specimens made with PET-profiles placed in a unidirectional fiber matrix has an estimated Rupture Modulus around 5.54MPa (see Table 8) and 3.90MPa with PET-profiles placed in a bidirectional fiber matrix (45°, Table 9).

National Road Accident Statistics is widely addressed in [18]. In fact, injuries caused by traffic accidents are still among the ten leading causes of death in Mexico, in 2014, 15,886 deaths were registered. Therefore, a rate of 13.3 deaths per 100 thousand inhabitants is estimated. According with above, the possibility of a car accident is high and should be taken into account carefully.

7. Highway safety barrier prototype

Car accidents are presented due to various conditions and it is easy that the vehicles lose their trajectory causing accidents that endanger the lives of passengers and other road users. For this reason, the development of new technologies in this area is important. In consequence, road safety barriers are installed and designed in accordance with strict technical criteria, in order to achieve maximum efficiency avoiding major damage to road users. Highways have mostly road safety barriers dividing the main lanes. Due to the above, PET profiles can be added to the safety barriers potentializing considerably the PET recycling.

Safety barriers with PET-profiles matrix is an initial prototype as a proposal that need to be studied in detail, see Fig. 10 and 11. The initial model has PET-profiles placed in a bidirectional matrix where PET-profiles are settled with 0.15 m between each one following the vertical direction of the cross section, this arrangement is an initial purpose thinking in easy enabled and placed inside the mold of the safety barrier. For future investigations, it is recommended to conduct impact studies to determine the effectiveness of the proposed model and determine the release of energy as presented in the prototype. Therefore, the PET-profiles inclusion in the concrete can be useful in structural support for road safety barrier where the car impact can spread small concrete fragments and the PET-profiles or PET-threads could keep the concrete fragments confined.

Source: The authors

Figure 10 Pure bending device built according to the NMX-C-191-ONNCCE [15] standard.

Source: The authors

Figure 11 Pure bending device built according to the NMX-C-191-ONNCCE [15] standard.

8. Conclusions

Green building is the opportunity to reuse toxic products and developed new building techniques in such a way that polluting products can be integrated into useful building elements that can even improve the building processes and also contribute to the mechanical properties of the structural elements. Therefore, this paper is an initial addressing PET-profiles reinforcing for failure structural states. In fact, it is presented experimental tests of a PET-profile matrix as tension reinforcement of beams made of concrete under pure flexural test. It was shown that PET-profiles used in unidirectional and bidirectional fiber matrix with soft pre-tensioned condition could have advantages in structural members in some precise applications, as for instance members impose to impact such as road safety barriers implemented in the highway infrastructure where PET-profiles inclusion in the concrete can be useful in structural support when a car impact can spread small concrete fragments and the PET-profiles or PET-threads could keep the concrete fragments confined and also the PET-fibers can be helpful in the vicinity of cracking failure condition, having three main aspects: a subtle increasing rupture modulus, crack mitigating in the failure plane and providing an additional plastic PET-capacity after failure. From the structural reliability perspective, PET-threads have influence, rising the reliability levels for expected forces for a particular compressive strength of structural members. It is worth to say that the stochastic model match properly with the experimental test.