1. Introduction

The evaluation of jobs, aimed at determining dysergonomic risk factors translates into the need to design and maintain a safe job for the worker, taking on the work of the Industrial Engineer from an ethical and labor productivity perspective.

In Colombia, in the micro-establishment sector by the year 2010, 56.30% corresponds to the trade sector, 33.83% services and 9.8% to the industrial sector [1].

Organizations in charge of managing occupational risk (ARL) in Colombia, in 2016 paid 9,347 compensation for work-related accidents and 4,828 for work-related illnesses, which represents a high rate of morbidity concernign work-related injuries [2].

Skeletal muscle injuries are a serious problem for the labor sector and the government because they are one of the main causes of absenteeism, disability costs, loss of labor productivity and problems in society and the family after all it affects the health of the worker, which should be an ethical and moral responsibility of college professors, area managers, workers unions and the worker himself, they should be guarantors of ensuring working. However, in Colombia by 2010, they accounted for 85% of cases of occupational diseases [3].

Several investigations have been carried out on occupational diseases or skeletal muscle injuries [4-14] performing ergonomic evaluations in order to determine the prevalence of risk factors to musculoskeletal injuries, their etiology, incidences and consequences conditions for the prevalence of their health.

This research assesses the disergonomic risks to which workers are exposed in three small and medium-sized enterprises located in Bogota.

In Colombia, there is a legal framework to regulate industry concerning occupational health and pursues the objective of providing adequate working conditions for job performance, in order to ensure the health of persons linked to the work, among they can be cited in Resolution 2400 of 1979, Law 9 of 1979, Resolution 2013 of 1986, Decree 1072 of 2015, Resolution 1016 of 1989, Law 1562 of 2012, Decree 1443 of 2014, Decree 1072 of 2015, Resolution 1111 of 2017, Resolution 0312 of 2019. Colombian Technical Guide GTC 45, which corresponds to resolutions emanating from different government institutions such as the Ministry of Labour, Ministry of Health and Social Protection. These laws provide support for research aimed at this type of project, in order to comply not only with the ethical but normative codes governing work in Colombia.

2. Methodology

This research was developed through a cross-sectional study, of a descriptive type, framed in a project of the Management of Technological Innovation and Productivity (GINTECPRO) research group of the Universidad El Bosque, in three small and medium size enterprises (SMEs) located in Bogotá, belonging to the sectors: metalworking [15], plastic [16], timber [17], to determine the disergonomic risk factors to which the workers of the companies evaluated are exposed. For this purpose, a non-probabilistic sample was selected, at the discretion of the researcher, according to the selection criteria: company classified as small or medium, belonging to the city of Bogotá with repetitive processes, high manual content with viab biomechanical demands, and that will provide access to researches.

The evaluation was carried on in 48 jobs, in which 76 persons work according to the description shown in Table 1.

Table 1 Distribution of jobs and number of workers per company.

Source: Author based on Castañeda, Ruge $ Zambrano (2019); Manrique & Otero (2019) and Aponte, Otalora & Perez (2019).

The company of the metalworking sector, located in Bogotá, is responsible for the rectification of engines that work with diesel, gasoline, and gas; is considered a medium-sized enterprise. Its processes are carried out with machinery of manual, automatic and semi-automatic type. In it work 32 workers distributed in 15 jobs, referred to as follows: cylinder burnishing, torque, butt brushing, crank grinding, lathe machining, valve tester, valve slashing, welding, pressing for shirts, rectification of bench circles, rectification of large blocks, rectification of small blocks, radial drilling, rectification of cylinder heads, washing pumps.

The plastics company, located in Bogotá, produces high-density polyethylene packaging. This company evaluated 24 jobs, including 31 workers, who work in the production area. The jobs considered were: sealant, mill, 2- and 5-liter blowers (4 jobs), injection of 125 T (2 jobs), 125 T injection (2 jobs), Injectors 255 T (2 jobs), injection 305 T (2 workstations), offset printer (4 positions), screen printing (4 positions), pad printing, flaming machine.

The company of the timber sector is dedicated to the manufacture, distribution, and sale of wood furniture for the hom, is located in the town of Tunjuelito in the city of Bogotá. The production area of the company is distributed in 10 jobs in which 13 workers work: joinery (cutting, brushing and assembly) with 6 workers; upholstery (cooking, cushioning and stapling) this area has 3 workers; sanding and painting with 4 workers distributed in the positions called restoring, sanding, painting and finishing.

In the first stage, the Nordic questionnaire was applied [18], in each of the companies. This method is a standardized questionnaire for the detection and analysis of skeletal muscle symptoms, the authors of the instrument divided it into two parts, the first of these has a series of questions related to the identification of the areas of the body where the worker has felt discomfort; while the second inquires about the time in which the worker has felt the discomfort, if the worker has been evaluated by a health care professional and if he has had these symptoms in recent periods. The questionnaire was applied to the 76 workers and the data were tabulated for processing and further analysis.

The Laboratory of Economics and Sociology of Labor method (L.E.S.T) method was also administered, evaluating the five variables set by the method in each of the companies: the physical environment, physical load, mental load, psychosocial aspects and working time.

And finally, the Rapid Entire Body Assessment (REBA) [20] method was applied to determine biomechanical risk levels due to inadequate or forced postures demanded by jobs.

The real-time filming technique [21] was used for analysis in the REBA method.

For the administration of the methods described above, all the workers involved were informed of the objectives of the study, the scope and methodology to be followed were explained, and the voluntary nature of participation in the investigation. In this regard, workers who voluntarily participated in signed informed consent.

3. Results and discussions of results

3.1. Nordic questionnaire results

After applying the Nordic questionnaire in the metalworking company, it was found that, of the 32 workers, 39.58%, claim to have been incapacitated for muscle-skeletal discomfort, while 23.44% of them claim to have missed work for suffering from the same discomfort, without the need for a medical consultation.

In the plastics sector company, the population evaluated consists of 31 workers, who work in the production area, of which 72% of the disabilities that were generated in recent months have been linked to disergonomic and Psychosocial problems.

In the company in the timber sector, the questionnaire was applied to the 13 workers who work in the production area, these workers were incapacitated in a range of 31% to 38% per area, according to data from the last year, due to back pain at 46% and pain in the arms with 27%.

The results of the application of the Nordic questionnaire are tabulated in Table 2.

Table 2 Percentage of incidence per body area referred by workers according to the questionnaire.

Source: Author based on Castañeda, Ruge & Zambrano (2019); Manrique & Otero (2019) and Aponte, Otalora & Perez (2019)

As evidenced in the above results, according to the Nordic Questionnaire applied to the workers of the three companies assessed, the body regions most affected, as the workers themselves refer are, the lumbar back region, hands/wrists and shoulders.

In the metalworking sector, workers refer to inadequate movements, bad working practices regarding posture, prolonged standings and the lack of tools to facilitate the performance of heavy lifting, as the factors causing discomfort. Workers carry out their work with back lateralized and tilted forward, executing lifts greater than 22 kg., concerning to psychosocial risk, workers said that the main factors within the working environment are stress and excessive workloads

Workers in the plastics Company refer their discomfort mainly to repetitive movements, inadequate posture, prolonged standings and stress, factors to which they are exposed due to their workplace.

In the case of the timber sector, they attribute the inconvenience to prolonged standing, load handling, poor postures required by work and repetitive movements, as well as stress.

The previous findings show that bad postures, prolonged standing, and stress, according to the perception of the workers, are the transversal causes in the three companies associated with the inconvenience referred by the workers.

3.2. Laboratory of Economic and Sociology Labor method (LEST) results

When applying the LEST method, the physical environment was evaluated in the first instance for the three companies: concerning the thermal environment, the company that presents the greatest risk in this aspect for workers is that of the Plastic sector, in which 44% of the jobs are under conditions of significant harmfulness, due to the operation of machines that generate heat such as those in the injection and blowing areas.

Concerning the noise factor, the company that presents the most exposure with harmfulness to workers is the company of the metalworking sector, with 86.7% of jobs with harmfulness, the company in the plastic sector has 46% of jobs with harmfulness and 33% with strong discomfort for workers.

For lighting, the three companies have percentages of jobs with deficiencies in this variable, being that of the plastic sector the one that presents the greatest deficiency with 46% of jobs with harmful levels, followed by the company of the timber sector that presents 52% of jobs in strong discomfort condition.

About the static load, most of the jobs of the three companies present average discomfort for the worker; concerning mental load factors, the critical issue for the company in the plastic sector is the demand for time, in this case, all jobs have a level of average fatigue discomfort; for the company of the sector, the critical factors regarding mental load are attention and complexity and speed. While the metalworking company presents a satisfactory condition for this aspect.

3.3. Rapid Entire Body Assessment methods (REBA) results

In the metalworking sector company, the REBA method was applied in the 15 jobs, and it was found that 13.33% of them present a high level of risk, with a score of 8, these jobs are those called torque and radial drilling, while 86.67% of the positions represent a medium level of risk, of which 84.6% showed a score between 6 and 7, values that also require attention, see Fig. 1. These findings reflect that the performance of activities in the metal-mechanical sector company requires significant commitments due to lateralization and flexion of the neck and back between 20⁰ and up to 60⁰ respectively, as well as extensions in upper limbs for workers. There are also sudden and repetitive movements that cause repetitive posture changes.

Source: Castañeda, Ruge & Zambrano (2019).

Figure 1 REBA risk level by job in the metalworking company.

As shown in Fig.1, no job is at a low-risk level in the biomechanical evaluation carried out through the REBA Method, there are no jobs either above a score of 11, that is, with a very high-risk level.

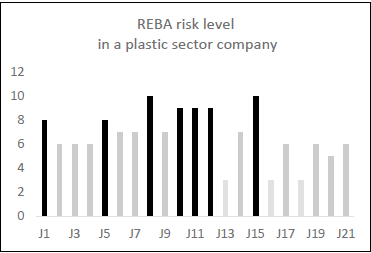

For the plastic sector company, 33.34% of the jobs present high-risk of skeletal muscle injuries with ranges between 8 and 10 points, these jobs are those referred to as sealer, blower injectors and offset printing; 52.38% a medium risk level also with a preponderance towards high values of the interval between 6 and 7, and 14.28% of jobs with a low level, see Fig. 2. These results are mainly due to unstable postures, neck and back flexion up to 20⁰ and 60⁰ respectively, repetitive use of hands and wrists, with flexion and lateralization of the same, and flexion of the arms at 60⁰. There are also rapid and abrupt changes in posture.

In the company of the plastic sector, there are no jobs with scoring levels greater than 11 or very high risk for skeletal muscle injuries, as shown in Fig. 2.

However, in the company of the wood and furniture manufacturing sector, the findings regarding the biomechanical valuation were the following: 43% of the jobs are at a high level of risk; while the remaining 57% have a medium level of risk, with a higher proportion of them with values of 7 points, which represents a considerable level of risk, Fig. 3. These results occur due to flexions of the neck and back in ranges of up to 20⁰ and 60⁰ respectively, rotation and lateralization of the back, repetitive movements in hands with the rotation of wrists, and extension of arms and forearms are also presented.

In the timber sector company, there are also no jobs with values higher than 11 points REBA risk level, nor jobs with low risk values for skeletal muscle injuries.

Right away in Table 3, there is a comparative table between the three companies, concerning biomechanical evaluation through the REBA method.

As shown in the Table 3, the timber sector company has the highest percentage of jobs with high-risk levels, given its high content of manual jobs and the repetitive movements that make the activities of this sector, a great potential of risk of musculoskeletal injuries in workers. The company in the plastic sector also has a significant number of jobs with a high level of REBA risk, also due to repetitive movements and flexions of the neck and back due to the poor design of the jobs that force the adoption of inappropriate postures of the workers of the organization, and finally, the company of the metalworking sector, which has the lowest rate, however above 50 percent of jobs have an average REBA risk levels. By the shown jobs must be intervened with both engineering and administrative solutions to reduce biomechanical risk levels.

Table 3 Comparative table of biomechanical risk levels, according to the REBA method.

Source: Author, adapted from Castañeda, Ruge & Zambrano (2019); Manrique & Otero (2019) and Aponte, Otalora & Perez (2019)

Table 4 shows the different biomechanical risk factors present in the small and medium-size enterprises (SMEs) evaluated, which establishes the characterization of these factors in them.

Table 4 Characterization of risk factors in the companies evaluated.

Source: Author, based on Castañeda, Ruge & Zambrano (2019); Manrique & Otero (2019) and Aponte, Otalora & Perez (2019).

As can be seen in the Table 4, the common biomechanical risk factors in the three companies assessed are flexion and lateralization of the neck and back, repetitive movements and flexion/extension of the upper limbs and sudden changes in posture.

A comparison was established between the data obtained from the Nordic questionnaire and those obtained by the REBA method, finding that, in the case of the metalworking company, workers perceive greater discomfort in the back/lumbar area, neck and shoulders, however, the results of REBA method generates critical conditions for the neck, the back/lumbar area which corresponds to the workers perception , but also yields the hands/wrists as a critical area instead of the shoulders, as shown in Table 5.

Table 5 Comparison between the results of the Nordic questionnaire and REBA method.

Source: Author based on Castañeda, Ruge & Zambrano (2019); Manrique & Otero (2019) and Aponte, Otalora & Perez (2019).

Concerning the company of the plastic sector, it can be observed that there is a concordance in two of the body areas where workers report feeling discomfort and the data generated by the REBA method, these are wrists and hands and lumbar back region, however, there is a discrepancy in the third critical zone since workers perceive the neck and the REBA methodology refers to the elbow as the third factor with greater biomechanical commitment. See Table 5.

A concordance evaluation between the Nordic Questionnaire was carried out, with the participation of 76 workers and the results determined by the REBA Method applied to the jobs, in order to establish whether there is agreement between both methods, establishing as a null hypothesis H0= methods do not show concordance and as a hypothesis of the researcher H1 = the methods have concordance, for which the null hypothesis is rejected in case of a p-value <0.05.

For this, the Statistical Package for the Social Sciences (SPSS), version 25 was used, applying the Cohen´s Kappa statistic. Table 6 shows the results obtained for the shoulder.

Table 6 Crosstable of concordance between the Nordic Questionnaire and the REBA Method, evaluating the shoulder.

Source: Author from the SPSS program, version 2 licensed for Universidad El Bosque.

In this sense, it can be seen in Table 6 that there are 41 cases in which both methods agree with the “Yes”, that is, in 41 cases the workers expressed through the Nordic Questionnaire to have presented shoulder discomfort, as well as in 41 workers evaluated with the REBA Method found a risk of skeletal muscle injury of joint involvement, there are also 29 cases of concordance in which both methods agree that they have not presented shoulder ailments (Nordic Questionnaire) and do not present a risk for shoulder skeletal muscle injury (REBA method).

On the other hand, there are 6 cases of disagreement between the two methods, in which, 6 cases showed shoulder ailments, while with the evaluation of the REBA Method no risk was observed for the joint.

Concerning the value of the Cohen Kappa statistic, a value of 0.839 was obtained, which represents a very good agreement between both methods, with a significance level of 0.00, which is less than 0.05.

In the same way, the concordance evaluation was carried out, through the Statistical Package for the Social Sciences (SPSS), using the Cohen Kappa statistic, between the Nordic Questionnaire and the REBA Method, for each of the body zone evaluated: elbow, neck, back, and hand. The values obtained are shown below in Tables from 7 to 10.

Table 7 Results of the evaluation of concordance between the Nordic Questionnaire and the REBA Method for the elbow.

Source: Author from the SPSS program, version 25, licensed for Universidad El Bosque.

Tabla 8 Results the evaluation of concordance between the Nordic Questionnaire and the REBA Method for neck.

Source: Author, from the SPSS program, version 25, licensed for Universidad El Bosque.

Table 9 Results of the evaluation of concordance between the Nordic Questionnaire and the REBA Method for the back.

Source: Author, from the SPSS program, version 25, licensed for Universidad El Bosque.

Table 10 Results of the evaluation of concordance between the Nordic Questionnaire and the REBA method for hand

Source: Author, from the SPSS program, version 25, licensed for Universidad El Bosque.

The above tables show concordance between both methods with 77.7% for the elbow, 84.2% for the neck, 93.4% for the back and 69.7% for the hand.

However, the results of Cohen's Kappa statistic and the p-value for the shoulder, elbow, neck, back and hand are shown in Table 11.

Table 11 Results of the Kappa statistic and the p-value for the Nordic Questionnaire and the REBA Method

Source: Author, from the SPSS program, version 25, licensed for Universidad El Bosque.

The Cohen Kappa statistic values show agreement between both methods evaluated, for the elbow and the hand, there is a moderate concordance whose Kappa value is 0.545 and 0.402 respectively, the hand being the one with the lowest value of the statistic; for the neck, they show a good concordance with the statistic value of 0.665 and for the back a very good concordance, with a Kappa value of 0.846.

All variables have a p value of 0.000 less than 0.05 which shows a statistically significant result.

4. Conclusions

After evaluating the biomechanical risk through the methodologies used, it can be seen that the lack of adequate furniture and poor designs of jobs, as well as the lack of adequate tools or devices indicated, contribute to jobs creating significant commitments to suffer from musculoskeletal injuries for the workers.

When applying the Nordic questionnaire, the most affected areas of the body, as reported by the workers, are the back/lumbar area, hands/wrists and shoulders, attributing bad postures, prolonged standing and stress as common causes of these discomforts. for the three companies evaluated.

Regarding the physical environment, it was found that temperature is a critical factor for the company in the plastic sector, while noise is a factor that is harmful to both the company in the metalworking and plastic sector; in relation to lighting, the three companies present percentages of jobs with harmfulness and inconvenience, is that of the plastic sector the most critical in this regard.

Concerning to the physical load, the variable that is affected in the three companies is the static load, representing average discomfort; in relation to the mental load factors reflected, the demand for time, attention and complexity and speed are cited.

About the results of the REBA method, in the three companies, there are important postural commitments with medium and high risk levels in 95% of the jobs, which must be corrected immediately, being the common biomechanical risk factors in the companies evaluated the flexion and lateralization of the neck and back, repetitive movements and flexion / extension of the upper extremities and sudden changes in posture

Concordance was found between the Nordic Questionnaire and the REBA Method when applying both methods to the 76 workers who work in the 3 companies of the metalworking, plastic and timber sectors, with Cohen Kappa statistic values between 0.402 and 0.846, with which It can be concluded that the inconveniences that workers perceive through the Nordic Questionnaire were objectively validated with the application of the REBA Method and it is demonstrated that both methods are concordant, a showing a statistically significant result.

It is important to continue researching in other companies in the sectors evaluated in order to increase the data and be able to provide more information on the evaluation of risk factors for musculoskeletal injuries in SMEs in Bogotá, as well as expanding the sectors evaluated.