1. Introduction

Over time, different time periods have been defined through which human beings have contributed to their development and evolution, including the Stone Age, Bronze Age, Iron Age, Polymer Age, and Silicon Age, among others. However, it can be said that Feynman’s dream about the miniaturization of things has been consolidated in the Nanomaterials Age [1], related to the control of size, shape, and chemistry at the nanoscale (1 - 100 nm). Nanotechnology has been in a major landscape in the last years due to the different Nobel prizes given in this area. In 2016, the Nobel Prize in Chemistry was obtained by Jean-Pierre Sauvage, Sir J. Fraser Stoddart and Bernard L. Feringa "for the design and synthesis of molecular machines". Meanwhile, Moungi G. Bawendi, Louis E. Brus and Alexei I. Ekimov were awarded in 2023 “for the discovery and synthesis of quantum dots”. Although this is of primary importance for the academic and scientific community, nanotechnology is commonly believed to be a futuristic theme. Nevertheless, it is crucial to understand that the nanoworld is not phantasy but part of everyday life as it can be found in different applications and products, such as cosmetics, smart tv, food, among others.

In the fourth industry revolution, nanotechnology is part of convergent technologies alongside cognitive sciences, information technology and biotechnology, leading to the human evolution to a sustainable environment, narrowing the gap between how to manage natural resources and how to do it in a responsible way.

Today, this nanoworld is part of the oil and gas industry for several applications such as formation damage, drilling, improved oil recovery (IOR), secondary recovery, and enhanced oil recovery (EOR), among others [2-5]. Colombia is a pioneer key player for the implementation under real oilfield conditions with important results in terms of productivity and recovery increase, as well as processes optimization.

The development of nanofluids is currently integrated in search of greener operations with a lower environmental impact, which are optimized through machine learning strategies and neural networks, allowing the identification of critical factors for production and recovery with laboratory data, reservoir simulation and field applications. This is applied to productivity improvement and recovery operations and is integrated into the intelligent use and capture of CO2. Particularly, this strategy seeks to generate an impact in which other industries, such as cement, can be integrated to open a better panorama for carbon neutrality. In this way, there are several research focuses that include the analysis of CO2 emissions inside and outside the oil and gas industry, optimization in the management, treatment and transportation of these emissions, the viability of improved and enhanced oil recovery (IOR/EOR) processes with CO2 and flue gas, as well as understanding and optimizing the CO2 storage capacity in mature reservoirs and deep aquifers. The results obtained through laboratory tests under field conditions, as well as simulation processes, have made it possible to identify different strategic areas where decarbonization processes would be enhanced and a broader panorama would open towards the fourth industrial revolution in the oil fields to continue to contribute to meeting the objectives set out in the Paris Agreement.

2. Oil and gas industry and CO2 emissions

In the current context of the climate crisis, the development of innovative carbon capture, utilization and sequestration (CCUS) technologies is necessary [6]. In this sense, these technologies are considered key to achieving the goals set in scenarios of net zero carbon emissions by 2050 (NZE 2050) and the control of global warming.

In the oil and gas industry, different processes allow for improving productivity and increasing reserves at the well and/or field scale, called enhanced recovery processes (EOR), in which the injection of gas into the reservoir is included to increase the recovery of hydrocarbons. Thus, CO2 can become the fundamental input to apply this type of technology, with all the benefits that they entail, and at the same time, contribute to the reduction of the concentration of CO2 in the atmosphere. Additionally, all these processes focused on increasing productivity and EOR using CO2 would allow energy to be produced through the extraction of oil and gas. At the same time, this type of emissions would be reduced due to their injection, reinjection, and subsequent sequestration in the field. In general, it has been found that in these processes between 30 - 40% of the CO2 injected can be stored in the porous medium [7].

The use of CO2 in EOR technologies (CO2-EOR) has grown exponentially since the 1970s and has achieved commercial success [8]. The displacement of oil with CO2 can be classified as immiscible or miscible depending on the properties of the fluids and the pressure and temperature conditions of the reservoir [5]. However, some phenomena limit the efficiency of CO2-EOR technology, associated with the high mobility ratio between CO2 and oil, which leads to early gas eruption, gravitational segregation, channeling and viscous interdigitation of CO2, resulting in low sweep efficiency [9]. These limitations can be overcome by injecting chemical agents for mobility control, such as foams, which can also be formed from CO2 and used for EOR can decrease the relative permeability and increase the viscosity of the displacing phase, improving sweeping efficiency [10]. Gases of different chemical natures have been widely used for productivity and improved recovery processes [11-14]. One of the methods to improve sweeping efficiencies in recovery processes is using conventional CO2 foams, which present challenges associated with their stability, which can be overcome by implementing nanotechnology [15].

Based on this, a national strategy is proposed that allows for mitigating the effects of CO2 on the environment, with a view from the decarbonization of the oil industry through cost-effective solutions. Thus, different developments and proposals within the framework of said strategy are presented below.

3. Synergy with the cement industry

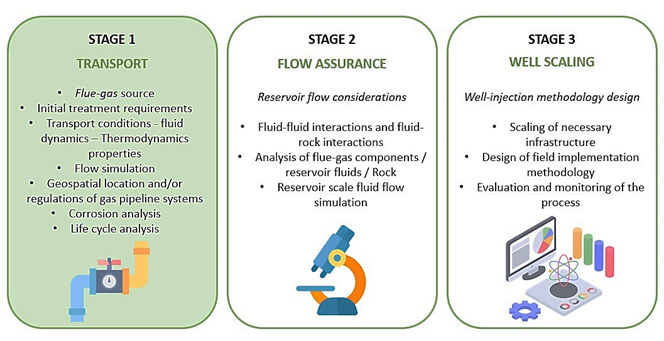

Today, 60% of the total emissions from cement production are generated mainly during the decarbonization of CaCO3 for clinker production, while the rest are attributable to combustion in heating systems [16]. Accordingly, various alternatives can be offered for applying CO2 utilization technologies enhanced with nanotechnology. The development of this line within the strategy is framed in the use of CO2 from the cement industry for its implementation in processes of improved oil recovery and/or increased productivity in Colombian fields. Therefore, research alternatives can also be evaluated and developed directly using the flue-gas streams generated in the cement industry to save costs associated with the separation of CO2. To carry out these developments, it is important to consider each of the necessary stages of the process in detail. Figure 1 presents a general overview of the stages to be considered, in which the transport processes are essential in a first approximation, from the strategic points of the transport of CO2 and/or flue-gas streams from the source to the fields of interest. Subsequently, in the second and third stages, the flow assurance of the EOR technologies is carried out with its respective component of evaluating fluid-fluid and fluid-rock interactions that will provide the critical determinants for possible implementation in the field.

Source: Own.

Figure 1 Stages to be considered in the process of cement industry-related CO2 used for EOR/IOR.

Thus, current the studies are focused on the first stage of transport (see Figure 1), considering as a particular case study the reservoirs of the Magdalena Medio Valley basin as potential fields for the application of CO2-EOR processes based on proximity with the cement industry in the same area. In this first stage, the considerations of the fluid dynamics of transport of the gaseous currents have been analyzed, including the respective thermodynamic analysis of fluids, the design considerations, and layouts of possible gas pipelines from the gas source to the oil field. Additionally, the respective flow considerations have been made through simulation processes and experimental analyses of possible corrosion scenarios based on transport integrity considerations; studies that would be complemented with a life cycle analysis to estimate the carbon footprint reduction associated with the process to demonstrate its environmental impact. Finally, the development of this line has promoted additional synergies between the cement and oil industries with the common goal of reducing their carbon footprint, thus contributing to the achievement of the country's goals in terms of reducing net CO2 emissions, with its reduction goal of 50% by 2030.

4. Smart storage

The current scenario of carbon emissions worldwide has encouraged the development of new strategies that allow the proper disposal and/or use of CO2. Different approaches are reported in the specialized literature, including the CCS and/or CCUS alternatives, which have shown a more significant impact. CCS is mainly based on the principle of capture and subsequent storage of CO2. Storage options are aimed at reservoirs that generate suitable conditions for CO2 capture, such as deep saline aquifers or depleted reservoirs. On the other hand, Carbon Capture, Use and Storage (CCUS) strategies focus on the use of CO2 in alternative processes to promote adequate disposal and/or the generation of byproducts of great importance.

The CCS process promises to mitigate industry CO2 emissions by 22% by 2035 [17]. However, its global implementation has been hampered mainly by technical-economic considerations related to two main stages: i) the efficient and economical separation of CO2 from the process combustion gases generally using solid absorbents), and ii) CO2 injection in deep geological deposits (> 800 m) under supercritical conditions in porous media. In this regard, a novel improved configuration of CCS (e-CCS) is proposed [18, 19]. The entire combustion gas stream is injected directly into the reservoir, which serves as a selective system for CO2 separation from another gas components. Another advantage is that shallow reservoirs (< 300 m) can be used, and CO2 storage is further improved by modifying the rock surface to improve molecular interactions. Therefore, this line of work seeks to develop and evaluate micro/nanomaterials obtained from Colombian organic waste and biomass for improved CO2 capture and storage processes e-CCS or conventional CCS in deep reservoirs.

It consists of a novel initiative framed in a circular economy by synthesizing micro/nanomaterials derived from organic agricultural waste, including sugar cane, rice, corn and fruits. Several production chains in Colombia agriculture sector have problems, some related to waste management, and some producing regions have been vulnerable to violent conflicts.

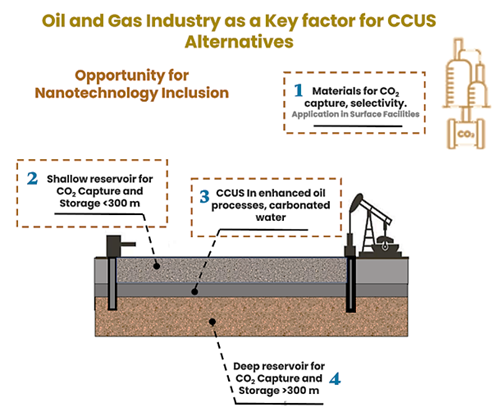

Thus, exploring other options for carbon capture, utilization, and storage processes has been possible, as described in Figure 2.

Based on fluid interaction processes under absorption/adsorption phenomena, CO2 capture processes in surface facilities are considered with the development of carbonaceous-based micromaterials derived from ground coffee waste to increase the selectivity of CO2 separation. On the other hand, regarding CCS processes, it is possible to propose two application scenarios: a) for shallow reservoirs with the inclusion of silica nanomaterials derived from rice husk to improve the capture capacity, also including the use of the combustion gas stream avoiding additional costs in the separation process [20] and, b) application in the steam injection process, which allows the capture of CO2 and its further conversion into valuable fuels during the catalytic decomposition of asphaltene in an atmosphere of steam gasification for shallow reservoirs, with additional effect on the crude oil by upgrading. Ceria nanomaterials were proposed in this case to generate a correct CO2 conversion [21]. Finally, the fourth application has been explored based on an experimental investigation of the effects of CO2 inclusion on the oil swelling phenomenon in the carbonated water system as an essential mechanism during the alternating water gas injection process (WAG).

5. Co2/Flue Gas Eor/Ior

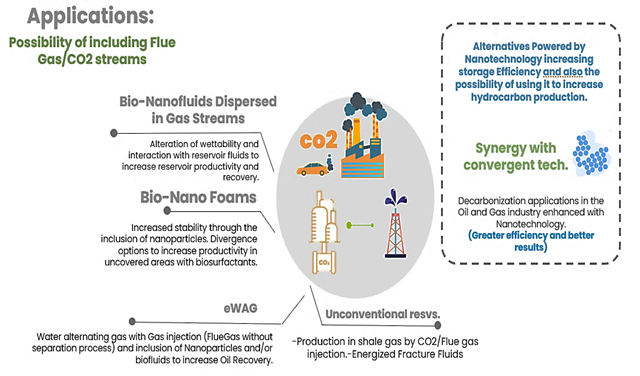

Several fronts can be developed regarding EOR/IOR processes, including using CO2 after surface capture, or flue gas [22]. Figure 3 summarizes some of these strategies. For example, this line within the strategy has focused on developing bio nanofluids to be injected dispersed into the gas stream. This is done to generate in situ capture of CO2 during IOR operations, such as formation damage inhibition or stimulation, and EOR operations with CO2 or flue gas, allowing an increase in stored CO2 of around 150% compared to the scenarios in the absence of nanofluids. Additionally, bio-nano foams generated with flue gas are proposed for divergence processes in the reservoir. The eWAG (enhanced WAG) processes allow the injection of an aqueous phase alternating with CO2 or flue gas, where both phases can be added with nanofluids, and the injection of carbonated water can even be generated. Likewise, during unconventional reservoir stimulation operations, energized fluids are proposed. Finally, during thermal recovery operations, the co-injection of steam and gas flow is proposed in the presence of nanofluids, which allows: i) upgrading of crude oil, ii) reduction of water consumption, iii) storage and selective use of CO2 and iv) greater recovery. Particularly, item III can occur through capture in the porous medium or through the catalytic conversion of CO2 by including bio-nanocatalysts.

6. Conclusions

The oil and gas industry is primarily responsible for decarbonizing its operations to meet the proposed emissions reduction goals. However, it is still in the planning and development stage of technologies that will allow this purpose to be achieved. In this way, different synergies have been proposed between industry, academia and the state that have allowed the generation of a national strategic plan for developing and applying new CCS and CCUS technologies. Different work fronts have evaluated different options experimentally and through simulation that allows effective decarbonization of the industry, not through compensation strategies, but through direct reduction of emissions. In this way, there is an undeniable commitment from the oil community to bring these and other solutions to TRL values greater than 7 in the short and medium term.