Introduction

Economic efficiency in agriculture, which includes forestry, is reflected in a better production with the same number of resources or the same production with a lower number of resources. Better production refers to a greater quantity, better quality, higher diversity, or a mixture of the above. For economic efficiency, the prices of resources and products at the time of their measurement are important. It is also important to consider the physical, social, environmental, and political context of the agricultural production being analyzed. Globally, from 1990 to 2020, the increase in planted forest area was 123 million ha, reaching 294 million ha (FAO & UNEP, 2020). In Colombia, the registered area of commercial forest plantations for 2016 was approximately 470,000 ha (Martínez et al., 2016).

The cultivation and use of forest species in Colombia are mainly aimed at obtaining wood. However, other additional uses are gaining value, such as the use of forest residues. Proper management of forest residues brings some benefits, such as avoiding contamination in situ and the nearby ecosystems. Additionally, these residues constitute a good source of improvement that, in turn, can reduce the use of synthetic fertilizers (Arvanitoyannis et al., 2006).

If organic waste, including that of forest species, is subjected to a thermal conversion of biomass in an oxygen-limited environment, a solid, fine-grained, and porous product with a high content of organic carbon called biochar is obtained from the pyrolyzed material (IBI, 2013; Ippolito, Donnelly, & Grob, 2015). Biochar stands out for absorbing nutrients and water and reducing the bulk density of the soil (Lehmann, 2007; Reddy et al., 2013). Given its stability in the environment (Ippolito, Spokas, et al., 2015), biochar generates environmental benefits associated with the reduction of CO2 in the atmosphere through carbon sequestration in the soil increasing the organic matter content of the soil, and economic benefits by generating emission quantifiers for GHG or CERTS and carbon credits (Antle & McCarl, 2002; Lehmann et al., 2003; Post et al., 2004). These benefits have allowed biochar to be currently considered as an environmental alternative to the use of synthetic fertilizers in forestry production.

Forest crops such as Acacia mangium generate organic residues that are not yet being used properly. In the department of Meta, nine years after cultivation was established, 1 t of biomass was produced for every four usable trees (CONIF, 2013). Thus, in a plantation with a density of 400 plants ha-1, an average of 100 t ha-1 of biomass is obtained, whereas in the studied plot this biomass is obtained after 12 years under the same conditions. Of the total biomass, 40% remains in the field as waste, 40% remains in the sawmill as waste, and only 20% is used as wood (SIOC, 2018). These 80 t ha-1 of unused residue could be converted into 24 t ha-1 of biochar at an efficiency of 30%. The use of this biochar in the same forest crop to replace synthetic fertilizers could have consequent favorable economic and environmental effects.

The economic efficiency of biochar as an amendment was analyzed in a commercial forest plantation of A. mangium located in Colombia. This research studied the costs, income, and efficiency of labor, land (yield) and capital (profitability) for the use of biochar vs. the use of synthetic fertilizers in A. mangium to determine whether the application of biochar in the soil of an A. mangium agroecosystem is viable in economic terms, compared to the conventional agronomic practices of the same plantation.

Materials and methods

Location and characteristics of the study area

The study was carried out in the Planas village, located in the municipality of Puerto Gaitán, department of Meta (Colombia), (between 3°05' and 4°08' N, and between 71°05' and 72°30' W). The area has an average annual temperature of 30°C and a total annual rainfall of around 2,300 mm with a bimodal pattern. The soils that dominate the region are Oxisols and Ultisols. In the Planas village, the soils are Typic Troporthents, shallow and low in bases (IDEAM, 2013). In Planas, there is a commercial A. mangium crop belonging to an associative forestry company. At the time of the study, the A. mangium crop had an area of 2,100 ha in different stages of development. The first plantations were established in 2008. Between 2017 and 2018, a field trial was carried out on this company's facilities, which served as the basis for the elaboration of a doctoral thesis from which the data for the present article were taken (Reyes Moreno, 2018). Under the same edaphoclimatic conditions of the forest farm, two comparative forms of timber production with different nutrition models were considered: a "standard" crop (ST), with the use of a synthetic fertilizer ("Triple 15" or 15-1515: nitrogen (N) 15%, phosphorus (P2O5) 15%, potassium (K2O) 15%, YARA, Colombia) and an "optimal" crop (OP) with biochar and synthetic fertilizer applications. The biochar was applied once at the beginning, while the synthetic fertilizer was applied every year in both scenarios. A "real" analysis was performed for ST, and a projection, with data that came from a statistical analysis of response surface (Reyes-Moreno et al., 2019), was performed for OP of management and harvesting activities (pruning, thinning, and cutting). The first pruning was carried out in the first year of establishment and then every 15 months. The first thinning was performed in the fifth year and the second in the ninth year. The thinnings provided saleable timber. After the two thinnings, the crop was left with a density of 400 trees ha-1 until the time of cutting, which was carried out in year 12. The projected cultural activities of the trial were those corresponding to commercial cultivation and consisted of pruning and thinning. The first pruning was carried out in the first year of establishment, then every 15 months. The thinning was carried out in the fifth and ninth years. Thinning also provided saleable timber material. After thinning, the crop was left with 400 trees ha-1 until the time of cutting.

The biochar was obtained from the same plantation according to the methodology of Jouiad et al. (2015). Thinning and pruning residues from the commercial A. mangium plantation were subjected to slow pyrolysis with a residence time of 14 h and temperatures between 350°C and 400°C in two pyrolytic furnaces (made with local technology) located in the same plantation.

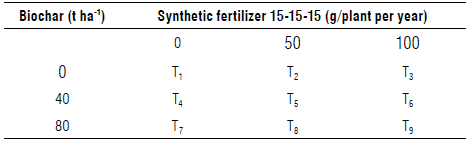

The field information was obtained in two different phases: during the nursery phase, which lasted three months (April to June 2017), and during the initial growth phase in the field with a duration of one year (July 2017 to July 2018). The field trial consisted in a comparison of the effects of synthetic fertilization and the application of biochar on the growth and biomass gain of the A. mangium crop, allowing a projection of future production. The treatments with three replicates are shown in Table 1.

Estimated volume of OP wood

Estimates of the wood volume in OP were made using the volume equation of a truncated cone, using the height and radii of the lower and upper bases of the trunk (Eq. 1). Measurements were carried out with a caliper for the radii and tape measure for the height. This approach was confirmed with a destructive pilot sampling to discard the use of the form factor and use the convenience of the truncated cone instead of the oblique one, since it is the most similar three-dimensional geometric shape in practice for the age of the plantation. For the process of optimizing the volume of A. mangium wood, two applications of fertilizer were carried out to the soil, each at two concentrations, adjusting a second order model design. In the model, two treatment levels were used, namely 40 and 80 t ha-1 of biochar and 50 and 100 g of synthetic fertilizer per plant. Finally, in this analysis, data were obtained for the application of 63.1 t ha-1 of biochar at transplanting (seeding) and 84.4 g/plant per year of synthetic "Triple 15" fertilizer. This was done once at crop establishment (Reyes-Moreno et al., 2019).

where A = area, Π = 3,141592, and r = stem radius.

Estimated volume of wood in the standard system (ST)

Projected timber production in the ST was calculated through a nonlinear regression developed from the information collected in the above-mentioned trial. To calculate the projection of wood volume (Tab. 2) in the ST, a nonlinear regression was used (Eq. 2):

where V was the estimated volume (cm3/plant), E(V\t) was the expected value of the volume given the explanatory variable associated with time (Ln is the natural logarithm), and t was time in years.

In the ST crop, 100 g/plant per year of synthetic fertilizer was applied as a crown at the base of each tree.

TABLE 2 Projection of the volume of wood produced (m3 ha-1) during a cycle under the standard production system in a 600-ha crop of Acacia mangium.

The plant density in the plantation in the first year was 1,000 plants ha-1.

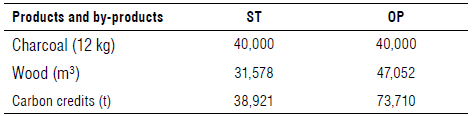

Apart from logging, the plantation provides indirect services associated with carbon fixation. The carbon credits corresponded to one metric ton of CO2 verified by an entity governed by ICONTEC standards. Regarding the carbon reservoir, biomass above ground was considered (only living wood), where 240,000 t were quantified with a value per ton of 15,000 Colombian pesos (in 2018).

Studied variables

The variables used were production costs, income and, therefore, profits and profitability. Additionally, the efficiency of labor and land use for the crops under study were compared (Tab. 3).

TABLE 3 Differences in production costs (millions of Colombian pesos in 2018) between a standard system (ST) and an optimal system (OP) (600 ha).

Table 4 shows the differences between the standard and optimal systems in terms of production.

Results

Production costs

Production costs by stages

Production in the entire cycle in OP is approximately 2% less expensive than in ST (Tab. 5). On average, 1 ha of the A. mangium crop costs approximately 30 million pesos per 12-year cycle (2.5 million pesos per year).

TABLE 5 Costs (millions of Colombian pesos in 2018) of production by stages. Standard system (ST) vs. optimal system (OP) of a 600-ha crop of Acacia mangium.

ST: 100 g/plant per year of 15-15-15 used for fertilization. OP: 63.1 t ha-1 of biochar plus 84.4 g/plant per year of 15-15-15 used for fertilization.

Production costs by factors

Direct costs, made up of inputs and labor, are 20% and 23% of total costs for OP and ST, respectively; indirect costs, made up of fixed assets, services and land, are 80% and 77% for OP and ST, respectively. Thus, this activity is high in demand for investment (capital), with a return in the medium (5 years) and long term (9-12 years). Fixed assets are the costs with the highest proportion (64-65%), followed by inputs (13-15%), services (10%), labor (7-8%) and land (4%) (Tab. 6).

TABLE 6 Costs (millions in 2018) of production by factors. Standard system (ST) vs. optimal system (OP) of a 600-ha crop of Acacia mangium.

Fixed assets (ST): seeder machine (1), chainsaws (3), tractors (3), vehicles (1), sawmills (1), finger machine (1), power plant (2), biochar furnaces (2) and facilities (3 houses, 4 cabins and a dining room).

Fixed assets (OP): seeder machine (1), chainsaws (3), tractors (3), vehicles (1), sawmills (1), finger machine (1), power plant (2), biochar furnaces (4) and facilities (3 houses, 4 cabins and a dining room).

Inputs (ST): pesticides 25 L ha-1/12-year cycle, synthetic fertilizer 900 kg ha-1/12 years, gasoline (18,500 gallons/12-year cycle). Inputs (OP): pesticides 25 L ha-1/12-year cycle, synthetic fertilizer 747 kg ha-1/12 years, gasoline (2050 gallons/12-year cycle). Workforce (ST): workers: 84 salaries/12 years. Labor force (OP): workers: 102 salaries/12 years.

Services (ST): consulting (6), maintenance (5), secretary (1), manager (1) and accountant (1). Services (OP): consulting (6), maintenance (5), secretary (1), manager (1) and accountant (1). Land: purchase of land.

Regarding production factors, OP and ST differ fundamentally in labor and the use of fertilizer and biochar. The OP uses more labor than the ST in harvesting and pyrolysis due to higher production, and the ST uses more labor than the OP in the annual application of fertilizer.

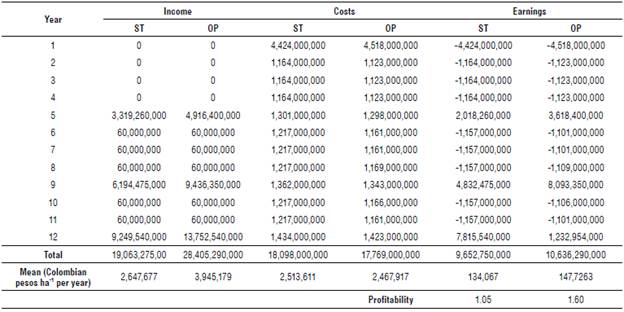

Income

Income from forestry is generated by producing charcoal, wood and by fixing CO2 (carbon credits). The main business is the production of wood.

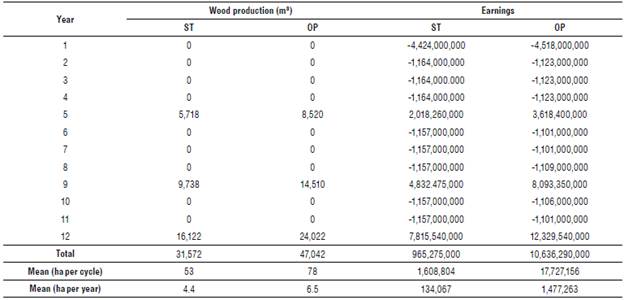

According to the projected yields, the OP obtains 47% more wood production (78 m3 ha-1) than the ST (53 m3 ha-1). The first harvest at year 5 generates 18% of the total wood production, the second at year 9 generates 31%, and the third at year 12 generates 51% (Tab. 7). The production of charcoal from year 5 generates income to cover part of the labor costs (Tab. 8).

TABLE 7 Wood production for a standard system (ST) vs. optimal system (OP) of a 600-ha crop of Acacia mangium.

TABLE 8 Income (Colombian pesos in 2018) by forest production for a standard system (ST) vs. optimal system (OP) of a 600-ha crop of Acacia mangium.

Economic efficiency of capital

The OP has higher income due to higher production and lower production costs due to less use of synthetic fertilizers. Its profitability is approximately 1.60 compared to 1.05 for the ST (Tab. 9).

Economic efficiency of work

The OP is also superior to the ST in terms of labor efficiency. Thus, a worker in the OP produces approximately 23% more wood than in the ST in a 12-year cycle (Tab. 10).

TABLE 10 Work performance (m³/worker) for a standard system (ST) vs. optimal system (OP) of a 600-ha crop of Acacia mangium.

A worker is active 44 h a week with a monthly salary of $900,000 Colombian pesos (in 2018). Year 1 is dedicated to the nursery and establishment. Years 2 to 8, 10 and 11 are dedicated to management. Year 5 is the first thinning and year 9 the second thinning (wood harvest). Year 12 is of wood harvest.

Economic efficiency of the land

The expected average production of wood ha-1 is 53 m3 and 78 m3 in the ST and OP respectively; that is, the OP is 47% more efficient in land use than ST. Additionally, OP earnings are approximately 10 times more than ST earnings (Tab. 11).

Discussion

The cost difference between the ST and OP systems is relatively small. The OP costs are 2% lower than ST for 185 USD ha-1. However, this small difference is part of the economic advantage of the OP system over the ST system. The application of biochar, like the application of fertilizers, has a cost. Although this study did not focus on this, Williams and Arnott (2010) give us an idea in this regard. Depending on the quantity (2.5 - 50 t ha-1) and the application method (broadcast-and-disk and trench-and-fill), the costs found were between 29 and 300 USD ha-1. The great advantage of using biochar is the increased yield; the OP system has 25 rrr3 more production (47%) than the ST system. Higher production and a lower cost lead to an even higher profit, with 60% in the OP system and only 5% in the ST system. The economic advantages of using biochar are also reflected in the efficiency of the use of land and labor resources. The OP system needs more work, but by producing more, it obtains 23% more wood per worker and 47% more per ha of land than the ST system. The economic efficiency of capital is measured through profitability. In our case, the difference between both systems is remarkable. In other studies, such as those of Maraseni (2010), positive results were also found with the addition of biochar. The researchers found that the income per kilogram of wheat went from USD$1098.84 to USD$1741 t ha-1 when biochar was applied to the soil. However, in other trials such as those of Ringius (2002), the financial returns of different agricultural practices with the application of various biofuels oscillated between 4.1 and -1.3, values below those found in this research.

Conclusions

The cost of producing A. mangium wood under an optimal system (with the use of biochar) is slightly lower than that of a conventional system (with the use of a synthetic-based fertilizer). The production cost in the optimal system includes the purchase of equipment and machinery for the pyrolysis of the organic remains of the plantation as well as the production and use of biochar as a basic addition. Fixed assets make up a large part of the costs.

The higher production of wood (about 50% more) in the optimal system (with the use of biochar) compared to the conventional system increases income and, therefore, profit. Thus, the economic profitability (cost-benefit ratio) of the A. mangium crop is 1.60 under an OP whereas under the ST it reaches only 1.05.

The efficiency of labor in the OP is 23% higher than in the ST. OP land efficiency is also higher since the OP produces 47% more wood per ha than the ST.

Thus, from the economic point of view, the OP production of A. mangium is more favorable than the ST production; thus, the system becomes an economic and environmentally friendly alternative to produce wood of this species.