I. Introduction

Currently in Colombia, an increasing problematic caused by the invasive plant Ulex europaeus is becoming evident. This plant is one of the 100 most damaging invasive plants in the planet [1]. The species; due to its resilience, germination capacity in complex locations, elevated growth and reproduction rates due to spores, represents a threat to native Colombian ecosystems such as those found in the rural areas of Cundinamarca and Boyacá [2]. In 2018, the Ministry of Environment and Sustainable Development decreed that it was the involved departments’ responsibility to search for efficient mechanisms to fight this problematic because besides being harmful to the environment, it is showing to be hazardous to the general wellbeing of the populations whose farmland and potable water are in contact, and are affected by, the common Gorse [3]. In the Ministry’s resolution, control, gathering, mitigation and eradication methods for the previously mentioned plant are described. However, no alternatives for its disposal are proposed once the plant is cut, crushed and transported to its final destination. The resolution only considers the incineration of the organic waste in order to avoid leaving remains that may result in new sprouts. Likewise, it is possible that different alternatives that may have more benefit and a positive social impact are not being considered.

Like many other countries around the world, Colombia is facing a growing energetic and environmental crisis. Due to the approach that has been used as of today concerning environmental policies such as the preservation of ecosystems, reduction of environmental impact and investigation in renewable energy sources, every moment; it is becoming more difficult to depend solely on traditional methods to supply the country’s energetic needs [4]. In addition to limitations that the hydrocarbon industry is suffering, for example the prohibition of “fracking”, it is foreseen that the country is going to have a decrease in investments intended for exploration, resulting in an increase in the price of fuel. Consequentially, it is expected that the productive potential of petroleum in the country decreases [5]. Considering this, it is important to revise which alternatives can be proposed in order to obtain new fuel options, using the available resources that are present in Colombia.

Previous studies about common Gorse (Ulex europaeus) have shown that it possesses usable properties in the energetic scope [6, 7]. After conducting thermo gravimetry tests, Lizarazo [6] evidenced that, due to the elemental compositions, the material contains a high carbon percentage that is viable for fuel purposes. Additionally, Osorio [7] added information to Lizarazo’s investigations. Beyond corroborating the elemental composition, Osorio offered an approximation to the plant’s heat value and the composition of the essential oils that might explain the Gorse’s flammability; these investigations yield a better concept of the unique properties that the plant possesses. These studies, besides being supported by the analyses executed by Milquez- Sanabria [8], generated a deeper concept around the usefulness of the Gorse, and presented evidence of how this plant may become an opportunity, instead of a threat.

Based on the presented context, this article investigates the viability of producing a solid biofuel for industrial and domestic consumption, with the purpose of providing support to the advantages that will arise when the common Gorse becomes an energetic harvest. The article is structured in the following way: in section 2 the methods and materials are illustrated, in section 3 the results are described, section 4 contains result discussions and in section 5 the conclusions and approach towards future projects are established.

II. Methods

The process that was executed during the investigation consisted in analyzing an alternative for integral benefit using the Ulex europaeus; in other words, from the gathering process to the final product delivery. The geographical areas in which the sampling would take place were established in the mountain path near Tausa (Cundinamarca) because of the availability of the Gorse in said area. However, the same investigation could be conducted in other geographical areas in future opportunities in order to compare results and establish if they can be replicated independent of the geographical precedence of the plant.

Figure 1 shows the sequence of stages proposed for the attainment of solid biofuel. It is notable that this project investigates the generation of two products: ground plant and briquettes. The project is based on the hypothesis that the shape of the first product may be useful for industrial consumption, and the second one for domestic use. The proposed stages are:

1. Gathering: following the protocols proposed by Resolution 684 to avoid propagation [3];

2. Shredding and packaging: in a possible future scenario for the utilization of the plant, the material must be transported from the fields to a processing center. For this reason, the shredding process is suggested, it generates a volume reduction, it decreases probability of seed propagation and decreases transportation fees.

3. Grinding: necessary for the homogenization and consequentially, ease the blending and material extrusion.

4. Blending: reintegration process of the different parts of which the Gorse is composed. This, with the objective of obtaining an initial approach of the log/foliage percentages that generate the most added benefit.

5. Extrusion: for the generation of briquettes. However, in future opportunities other mechanical processes that require a smaller energetic investment may be evaluated.

An additional drying stage was observed during the process between the shredding and grinding stages that generates efficiencies during grinding. However, a detailed study about its effect is recommended for future projects.

A. Methods

In this section, the steps implemented for the investigation of the attainment of solid biofuel made from the plant Ulex europaeus are illustrated. The main objective of the project is to define a log/foliage percentage that allows the establishment of a satisfactory balance between the heat value of the product and the best possible use of the plant.

For this, the first step was the characterization of the log/foliage percentage of the Gorse from Tausa. Following this, samples of the ground material with different log/foliage percentage were generated. Finally, some of these samples were extruded for the generation of briquettes. The following is the experimental methodology in detail:

Step 1: Gathering of the Ulex europaeus Samples: 10 samples of the Gorse were gathered following the protocol established in Resolution 684 [3].

Step 2: Separation of the Log and Foliage: The foliage was separated (thorns, leaves, seeds and fruit) from the log of the Gorse for posterior weighing and characterization of weight distribution of the common Gorse from the Salitre de Tausa- Cundinamarca mountain path.

Step 3: Shredding (Chipper): The log and the foliage were shredded separately and the approximate volume reduction reached was measured.

Step 4: Characterization of the Log/Foliage Percentage: The gathered samples were weighed separately in order to determine de total weight percentage occupied by the log and the foliage.

Step 5: Grinding (Blade Mill): The log and foliage were ground separately in order to homogenize and so, ease the blending and extrusion of the material.

Step 6: Blending: Using a blender, the required quantities were blended until an adequate homogenous mix was obtained for the production of the solid biofuel. Samples containing different log/foliage percentages were generated.

Step 7: Extrusion (Single Screw Extruder): Some of the samples were inserted in an extruder for the generation of briquettes.

Step 8: Execution of Proximate and Ultimate Analysis: Characteristic samples were selected and sent to be analyzed in the laboratory, with the purpose of determining: elemental composition, heat value, volatile material, ash, Sulfur, fixed Carbon and humidity. This was done in order to understand the behavior of the resulting material and to be able to conclude if the material is adequate as a solid biofuel.

B. Sample Analysis

In order to calculate the log/foliage percentage, the population was treated as a random variable and the random error theory was used [9].

where N is the number of samples analyzed, and 𝑥 𝑃𝑅𝑂𝑀 and 𝜎 , the average and standard deviation, respectively.

The obtained results in the proximate and ultimate analyses are based on ASTM certification and were implemented with the following methods:

Proximate:

-

· Total Humidity: ASTM D3302/D3302M-15

· Ashes: ASTM D3174-12

· Volatile Material: ASTM D3175-17

· Fixed Carbon: ASTM D3172-13

· Sulfur Content: ASTM D4239-17 Method A

· Net Heat Value: ASTM D5865-13

C. Implementation of the Experimental Methodology

As per indicated in Resolution 684 [3], the Gorse requires careful handling since it’s fruit tends to expel seeds by means of spore propagation (plant ejection) once it reaches maturity. This implies that the plant must be packed in situ, because any means of transportation will only foster the plant’s seed propagation.

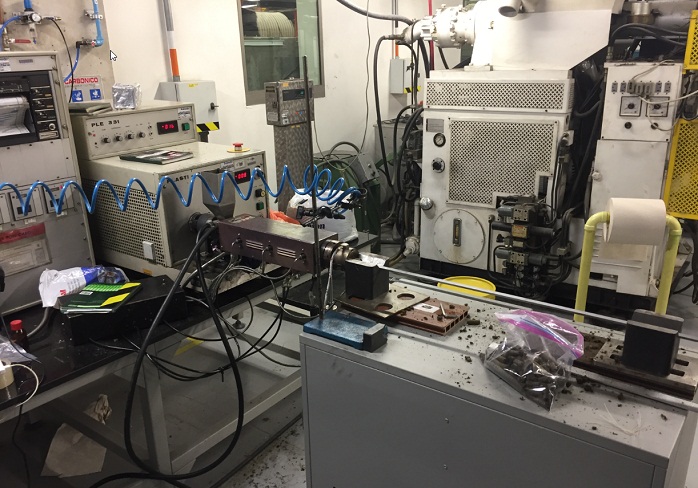

Taking this into account, the chipper used (Figure 2), counted on superior safeguards on the inlet shaft and with a direct exit towards the packing, in order to avoid undesired propagation at the moment of the plant’s shredding.

Once the samples were obtained, the material was ground in order to blend the required proportions. As can be observed in Table 1, the samples consisted of different log/foliage percentages and in both simple ground product and briquettes generated after an extrusion process. This with the objective of investigating the domestic and industrial alternatives. Finally, different compositions were evaluated so that a satisfactory balance between heat value and highest efficient plant use could be identified in at least one of them.

Table 1 Prepared and analyzed samples

| Sample | Content | Type |

| 1 | 100% Log | Briquette |

| 2 | 60% Log – 40% Foliage | Briquette |

| 3 | 60% Log – 40% Foliage | Ground Gorse |

| 4 | 50% Log – 50% Foliage | Briquette |

| 5 | 50% Log – 50% Foliage | Ground Gorse |

| 6 | 50% Log – 50% Foliage + 15% Olive Oil | Briquette |

Once blended, a sample of each composition was subject to an extrusion process. The extrusion process was selected since the synterization pressure and temperature had to be reached in order to produce the briquette [10]. Since the material was unknown, the extruder permitted the variation of the parameters in order to determine the optimum conditions for its manipulation.

In order to perform the extrusion process, the Brabender Plasti-Corder PLE 331 (Figure 3) machine was used and its temperature and pressure conditions were modified so that the level of compaction necessary for the material to maintain its shape after the process was executed was reached. It was found that, with a temperature of 80°C and a pressure of 900 psi, compact briquettes are obtained from samples that weren’t subject to the drying process. Some of the samples obtained are presented in Figure 4.

Finally, the samples were sent to the CQR Cotecna laboratory for the proximate and ultimate analysis.

III. Results

The obtained results are described in this section.

A. Volume Reduction

It was estimated that the Gorse gathered occupied an approximate volume of 0.19m3 (187,661cm3). This value was quantified based on the wheelbarrow used for the transportation of the material. Once the shredding process was finalized, the volume occupied by all the samples gathered was of 0.055m3 (55,000cm3). This value was obtained from the bag in which the samples were packed for transportation and handling. The volume reduction was calculated in the following way:

From the data obtained, there is evidence that once the material is shredded, the Gorse loses approximately 70% of its volume, allowing an efficient and easy transport. This is relevant to the study proposed due to the fact that it not only indicates the ease of material processing, but also the opportunity of cost reduction in transportation.

B. Log/Foliage Percentage

10 samples were analyzed in order to characterize the plants from de Salitre del Tausa mountain path, regarding the log/foliage percentage. The results are reported in Table 2.

Table 2 Results of weighing of gathered samples

| Sample | Log (kg) | Foliage (kg) | Sample Weight | Log % |

| 1 | 1.7 | 1.7 | 3.4 | 50 |

| 2 | 1.9 | 1.6 | 3.5 | 54 |

| 3 | 2.2 | 1.9 | 4.1 | 54 |

| 4 | 1.5 | 2.1 | 3.6 | 42 |

| 5 | 1.7 | 1.4 | 3.1 | 55 |

| 6 | 1.6 | 1.5 | 3.1 | 52 |

| 7 | 2.1 | 2 | 4.1 | 51 |

| 8 | 1.6 | 1.6 | 3.2 | 50 |

| 9 | 1.7 | 1.8 | 3.5 | 49 |

| 10 | 1.8 | 1.8 | 3.6 | 50 |

| Average | 1.78 | 1.74 | 3.52 | 50.6 |

| Total Weight | 17.8 | 17.4 | 35.2 |

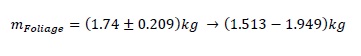

Applying Equation 1 (random error) and finding the standard deviation of the weight, the following is obtained:

A range of weights can now be calculated, log:

And foliage:

C. Proximate Analysis

In order to evaluate the samples produced, proximate analyses were performed on all of the samples. Tables 3 and 4 report the results of the proximate analysis for the six samples prepared with humidity and dried, respectively. In Table 4, Carbon [11] and wood [12] values are added as a comparison. The numbers of the samples correspond to those described in Table 1.

Table 3 Results of the proximate analysis as received with humidity

| Sample | % Humidity | % Ash | % Volatile Material | % Fixed Carbon | % Sulfur | Heat Value (kJ/kg) |

| 1 | 15.41 | 0.71 | 70.53 | 13.35 | 0.11 | 1614 |

| 2 | 12.51 | 1.23 | 72.04 | 14.22 | 0.14 | 1878 |

| 3 | 24.08 | 1.09 | 62.58 | 12.25 | 0.07 | 1490 |

| 4 | 17.1 | 5.58 | 62.87 | 14.45 | 0.24 | 1594 |

| 5 | 40.8 | 4.89 | 45.76 | 8.60 | 0.22 | 1229 |

| 6 | 11.91 | 1.73 | 71.85 | 14.51 | 0.22 | 1938 |

Table 4. Results of the proximate analysis Dry Basic without humidity.

| Sample | % Ash | % Volatile Material | % Fixed Carbon | % Sulfur | Heat Value (kJ/kg) |

| 1 | 0.84 | 83.38 | 15.78 | 0.13 | 1908 |

| 2 | 1.41 | 82.34 | 16.25 | 0.16 | 2146 |

| 3 | 1.44 | 82.43 | 16.13 | 0.09 | 1962 |

| 4 | 6.73 | 75.83 | 17.44 | 0.29 | 1923 |

| 5 | 8.25 | 77.24 | 4.51 | 0.38 | 2073 |

| 6 | 1.96 | 81.57 | 16.47 | 0.24 | 2251 |

| Carbon | 18.27 | 43.44 | 30.69 | 0.82 | 3023 |

| Wood | 3.38 | 80.87 | 12.68 | 0.42 | 1744 |

D. Ultimate Analysis 50:50 Sample

The proximate analyses in the dry basic show values of heat value similar to those of the different samples. Because of this, it was decided to only evaluate sample 4 in a detailed manner, through an ultimate analysis due to the fact that this allows the plant to be used completely. The results obtained in the analysis are reported in Table 5.

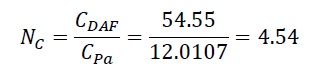

E. DAF Composition 50:50 Sample

The Dry Ash Free (DAF) composition was calculated based con the results of the ultimate analysis, in order to be able to determine the chemical composition of the solid biofuel that was generated. For the calculations of the DAF, the following approximation was used, for Carbon:

Applying the same procedure for the different elements, the following percentages were obtained and reported in Table 6:

Table 6 DAF Composition of Sample 4 (Briquette 50% Log- 50% Foliage).

| Sample | % S | % C | % H | % N | % O |

| Type | DAF | DAF | DAF | DAF | DAF |

| 4 | 0.36 | 54.55 | 7.06 | 1.20 | 36.72 |

From this percentage and the atomic mass, the number of moles present in the solid biofuel. The approximation, using Carbon as an example again, is reported as:

Applying the same procedure for the different elements, the following chemical composition is obtained:

IV. Discussions and Conclusions

The study executed came from the premise: “common Gorse possesses adequate properties for its use as a solid fuel, with purposes of low cost heat generation industrial and domestic scopes”. In this section, the results are discussed in order to evaluate the premise mentioned.

In Table 3, the As Received (AR) results of the samples are shown. However, as the purpose of this study is to evaluate the properties of the material, Table 4: Dry Basic (DB) will also be taken into account.

When the obtained results were analyzed, it can be observed that, regarding ash (remaining material after the burning process), the best alternative is the product consisting solely of log. When more components are added to the product, it tends to leave more residue behind itself.

The volatile material, because of indicating the difficulty, or lack thereof, of combustion presented by the product, demonstrated that with or without foliage the material can be ignited.

In Figure 5 an example of material burning is presented, it lit on fire easily and managed to maintain a flame after being briefly exposed to a heat source.

The sulfur content is considerably low in all of the samples. The maximum being of 0.38% in the 50:50 ground Gorse sample.

Additionally, the fixed carbon content indicates de quantity of material of which the plant truly consists of, that can be exploited during combustion. In other words, it’s the percentage of material that will maintain and generate heat. As can be observed in Table 4, the 50:50 in briquette form contains the most content of fixed carbon in comparison to all the other samples analyzed and it exceeds the value of common wood by a significant margin.

Finally, the heat value demonstrated that the material possesses important properties. Beyod the low emission of harmful products for human beings, and the few solid residues that are generated when burnt, the material truly shows competitive energetic characteristics. Kitchen carbon, considered one of the best current alternatives of biofuel leaves a considerable amount of residue and depends on little volatile material for its ignition; this implies more time and costs for its cleaning and implementation. When comparing the results obtained, the material, in its best result (60:40 in briquette form) reached a value close to 70% of the carbon heat value. When compared to the energetic potential of other materials [7] used as solid fuels, the Ulex europaeus plant demonstrates a significant potential for its use as biofuel (Table 7).

Many of the materials described in Table 7 belong to the most used solid biofuels today, However, the costs associated to their transformation, gathering and acquisition make them hardly viable for mass use and this leads to them being labeled as unimportant.

Because of everything mentioned previously, the sample that deserves a more detailed study, and that represents the best use of the problematic would be samples 4 and 5. These use the material completely and without the need of additives such as oils. Besides, these samples count on the adequate characteristics for the generation of a solid biofuel for both domestic applications (after being synterized) and industrial use after its shredding and grinding.

The process that was carried out, even if it requires optimization in order to generate products with even more competitive characteristics, gave a general vision of the potencial that common Gorse has as a solid fuel.

The conclusions based on the previous analysis are listed in the following page:

1. The shredding is an imperative step, given that it not only facilitates the grinding process, but it also reduces around 70% of the volume that the plan occupies in its natural state, and makes it easier to handle during gathering.

2. Even though the composition and properties don’t vary greatly between the dry and wet samples, it is recommended to subject the gathered remains to a natural drying process. If optimum results are desired (fast and efficient drying process) an oven-based drying process can be implemented: Table 3 vs. Table 4.

3. Using the implemented procedures and all of the plant, without additives, competitive properties (as compared to common solid biofuels) were obtained.

4. The pressure and temperature parameters used in the generation of briquettes (900 psi and 80°C respectively) indicate that the process does not necessarily require heavy duty machinery such as the Brabender extruder. Given the findings, in future investigations it would be relevant to review several alternatives for the manufacturing of the briquettes. It is viable to base the initial trials in the studies carried out by Valderrama et al [14], when it comes to low cost manual methods for briquette manufacturing.

5. The feasability analysis provided an initial approach, to a possible process that would not only contain and avoid the random spread of Gorse, but also to create an opportunity to turn an environmental problematic into a 100% eco-friendly energy source.

6. The material can not only be used as briquettes, but also as ground material, and even pellet-like products [15]. Both ways demonstrate good heat generation properties; the only difference being the low production cost that the ground material would have over the briquette or pellet products

7. Taking into account the previsouly mentioned, it is recomended to use the entire plant (50:50 log/foliage ratio) and through this, take advantage of all the biomass available. In addition, with optimized processess this biomass source could become a unique energy source because it makes use of an invasive species, reduces the need of cutting down native trees for domestic use and generates clean energy.

Expanding on the context provided by the used research sources throughout the investigation, along with the findings that resulted from the analysis, the Ulex europaeus plant would have the potential to be considered as an alternative energy source. Due to its growth and resiliance properties, and considering the potential energetic values discussed along the article, the Gorse could possibly become an energetic crop guided towards the generation of both domestic and even industrial heat. However, it is necessary to carry out further investigation before making a definitive statement that it is possible to turn an environmental problematic into an energetic opportunity with added benefit. Some suggestions would be: (i) calculate the efficiency of the process: energetic consumption required in order to produce the solid biofuel versus the generated heat value; (ii) evaluate more efficient briquette manufacturing methods; (iii) look into a fullstream process that includes logistics costs and region dynamics, in order to evaluate the financial feasability of the proposed solution; (iv) take into account the possible environmental impact of the project and establish a procedure that is both efficient and optimizes its carbon footprint.