1. Introduction

Functional foods are produced for the purpose of providing health and nutritional value. The Food and Drugs Administration (FDA) recommends using substances such as antioxidants, phytochemicals, and dietary fibers in food compositions 1. Non‐starch polysaccharides (NSP) are recognized as dietary fibers 2. A fiber-rich diet is characterized by biological benefits such as improving colon health, lowering the risk of chronic diseases, and protecting the cells from oxidative damage. Additionally, the fermentation of the dietary fibers results in short-chain fatty acids that are beneficial to human health 3.

However, such positive biological effects are provided by certain dietary fibers which may not have the same effect and depend on fiber sources and processing methods 4. Fruit fibers contain low amounts of phytic acid and bioactive molecules such as antioxidants 5, and phenols. Characteristics such as higher water-holding capacity, solubility, and fermenting ability in the intestine have given higher qualities to fruit fibers 6.

Apple pomace is a by-product of the fruit juice industry and comprises peel, seed, stem, and pulp tissues. This by-product contains dietary fibers, polyphenols, vitamins, and organic acids that can benefit human health 7,8 and have high potential as a dietary source 3. The main components of apple dietary fiber are pectin (5.50-11.70 %), cellulose (7.20-43.60 %), hemicelluloses (4.26-24.40 %), lignin (15.30-23.50 %), and gums 9. Apple peel (APE) and Apple pulp (APU) powders have high amounts of soluble and insoluble dietary fiber; therefore, they can be used to enrich food products.

Baked products are well-known food types to humans and have a key role in feeding people worldwide. Among most of them, wheat flour usually is the main ingredient in processing. However, can be replaced with partially dietary fibers to produce enriched products. Nowadays, enriched products such as bread, cakes, and biscuits are available in stores. Some of the criteria that consumers consider when choosing foods include taste, convenience, price, and other characteristics, such as health 10. Replacing a part of wheat flour with functional ingredients to produce enriched products can change properties such as stability, texture, and taste 11,12.

Sing et al. produced high-quality enriched muffins using 6 % concentrate of black carrot dietary fiber and 0.5 % xanthan gum 13. O’Shea et al. utilized orange juice pomace (up to 8 %) to increase the dietary fiber content of bread 14. Using carrot pomace powder to produce cakes resulted in a product with optimal density, hardness, and sensory scores 15. Also, the application of apple pomace in biscuits showed low glycemic index levels as a partial substitution of wheat flour in cake elaboration and produced a healthy food product 16.

2. Materials and methods

2.1. Materials

Apple peel and pulp, separately produced as residual wastes of juicing, were dried for 3 hours in the oven (60 °C). The dried pulp and peel were ground and sieved using a 60 µm mesh. Then, the samples were placed into plastic lid packages and stored in a refrigerator at 4 °C. The packages were kept at room temperature for 12 hours before use.

2.2. Methods

2.2.1. Chemical analysis

The moisture and ash content of the APE, APU, and wheat flour were determined according to methods 6540:1980 and 5984:2002 17. The lipid content was tested according to the Soxhlet method 18, and the protein content was determined following the modified Lowry method 19. The fiber content was assessed upon method 32-07.01 20.

2.2.2. Water holding capacity

The Sudha et al. methods, with some modifications, were used to quantify the water-holding capacity of the powders 21. One gram of each sample was dissolved in 15 ml of distilled water in a 50 ml falcon tube. Next, the samples were kept at room temperature for water absorption. After 24 hours, the samples were centrifuged at 15,000 g for 20 minutes. Next, the upper clear liquid phase was removed. The lower part was weighted to determine the water-holding capacity (g/g) by measuring the weight difference between the sample residue and the initial sample.

2.2.3. Oil absorption capacity (OAC)

OAC was analyzed based on the methods developed by Ktenioudaki et al. with slight modifications 22. One gram of each powder was mixed with 15 ml sunflower oil in a 50 ml falcon tube. Next, the samples were kept at room temperature to absorb the oil. After 24 hours, the samples were centrifuged at 15,000 g for 20 minutes. By removing the upper oil phase and weighting the residue, the oil absorption capacity was determined by calculating the weight difference.

2.2.4. pH

One gram of each APE and APU powders were dissolved and homogenized in 200 ml water using a mixer. Next, the mixture was filtered using a filter, and the pH was determined at 24.0 ± 0.3 °C using a pH meter (Jenway-3020-UK) with method 02-52 20.

2.2.5. Bulk density

Fifty grams of each sample was poured into a 250 ml graduated cylinder with slight shaking to measure the sample volume 20.

2.2.6. Cake production

APU and APE powders were used separately in three levels (10, 20, and 30 %) to prepare the cake samples. Another cake sample was produced with only wheat flour as a control. The used amounts are shown in Table 1. The cake samples were made by blending ingredients, including sugar, milk, egg, and commercial emulsifier, and using an electric mixer for 4 minutes under fast speed to reach a foam-like mixture. Next, flour and baking powder were slowly added to the compound at a slow mixer speed. After 1 minute, the generated dough was poured into a cake pan and placed in the oven at 180 °C for 20 minutes.

Table 1. Formulation of prepared cakes

| Ingredients | Control | APU-10 | APU-20 | APU-30 | APE-10 | APE-20 | APE-30 |

| Wheat flour | 100 | 90 | 80 | 70 | 90 | 80 | 70 |

| Apple powder | 0 | 10 | 20 | 30 | 10 | 20 | 30 |

| Egg | 130 | 130 | 130 | 130 | 130 | 130 | 130 |

| Sugar | 60 | 60 | 60 | 60 | 60 | 60 | 60 |

| Emulsifier | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Baking powder | 2.8 | 2.8 | 2.8 | 2.8 | 2.8 | 2.8 | 2.8 |

Based on weight (g)

2.2.7. Specific volume

The cake volume was calculated using colza seeds based on the displacement principle. Subsequently, weight (g) and specific volume (cm3/g) were determined 20.

2.2.8. Colorimetry

Three colorimetric parameters, including a*, b*, and L*, were investigated. Parameter a* indicates the green to the red color range, b* delineates the blue to the yellow color range, and L* represents cake lightness. The crust and crumb of the cakes were separated, and the samples were placed in an imaging box with 10 lamps to prepare the samples for the test. Imaging was carried out using a digital camera (Canon, EOS 450D). Also, the measurement of color parameters was done using the Image processing toolbox in MATLAB (v 9.4, 2018a) software 23.

2.2.9. Textural analysis

The texture analysis was conducted using the reference method 20 with a texture analyzer (Brookfield CT3-10 kg, US) equipped with an aluminum probe (36 mm diameter) and a loading weight of 5 kg. The cake crust was separated, and then the crumb was examined by slicing 2×2×2 cm cubes to analyze the texture. The required pressure to compress the cubes to 40 % of the original height was calculated using the device in the following conditions: pre-test speed = 1 mm/s; speed during the test = 1.7 mm/s; post-test speed = 10 mm/s.

2.2.10. Sensory analysis

Seventeen trained panelists carried out sensory analyses of the cakes on a five-point hedonic scale (1 dislike very much to 5 like very much). The parameters to evaluate were aroma, texture, taste, odor, and appearance; an overall quality score was computed as the average of the five traits. Mean score values for sensory evaluations of cakes were used 24.

3. Results

3.1. Chemical analysis of powder

In the chemical analysis results (Table 2), it was found that all three samples showed statistically significant differences (p<0.05). The wheat flour had higher moisture, 13.42±0.18 %, than APU and APE, but the ash content was less than in other samples. APU and APE had 3.27±0.05 % and 1.58±0.04 % protein which were significantly lower than the wheat flour (p<0.05). The insoluble fiber of the wheat flour (5.89±0.05 %), significantly lower than APE (38.12±0.04 %), and APU (33.71±0.05 %) (p<0.05). The dietary soluble fiber of APE and APU were 19.24±0.07 % and 13.89±0.03 %, respectively.

Table 2 Chemical composition of wheat flour, APU and APE powders (DWB).

| Chemical composition (%) | Moisture | Ash | Protein | Fat | Insoluble dietary fiber | Soluble dietary fiber |

| wheat flour | 13.42±0.18 a | 0.63±0.01 c | 10.11±0.08 a | 1.08±0.12 c | 5.89±0.05 c | 2.32±0.00 c |

| APU | 8.81±0.11 b | 1.62±0.06 b | 3.27±0.05 b | 2.43±0.08 b | 33.71±0.05 b | 13.89±0.03 b |

| APE | 7.70±0.09 c | 1.97±0.02 a | 1.58±0.04 c | 4.25±0.14 a | 38.12±0.04 a | 19.24±0.07 a |

DWB = Dry weight basis

Values in the same column with the same letter are not significantly different (p<0.05).

3.2. Dietary fiber analysis of cakes

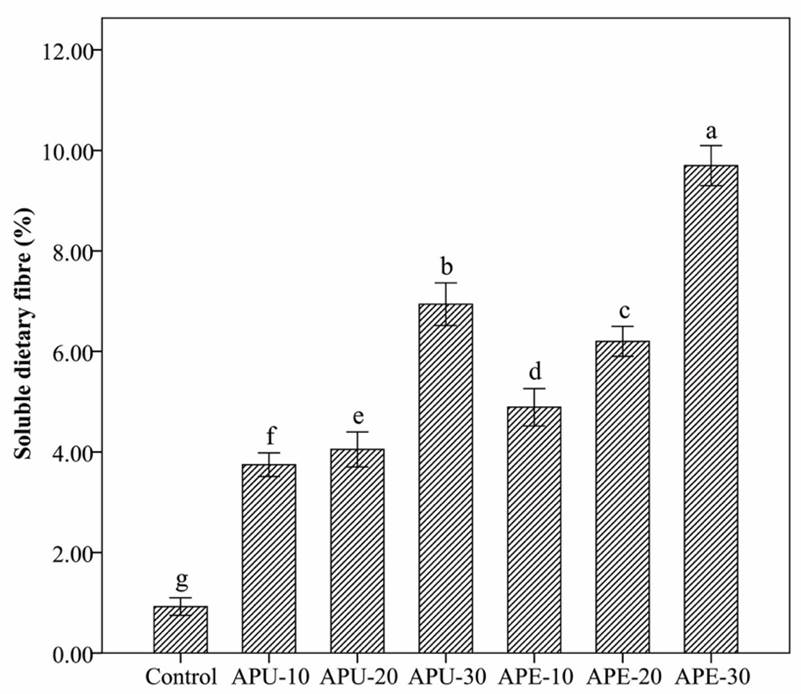

In this research, seven treatments of the samples (three different levels of percentage replacement of APU and APE powders and a control sample) were prepared and examined for chemical properties. Figure 1 shows that replacing the wheat flour with APU and APE powders significantly affected the amount of soluble dietary fiber (SDF) and insoluble dietary fiber (IDF) in the cakes (p<0.05). Data comparison showed that the control sample contained the lowest amount of SDF (1.03±0.12 %), IDF (3.58±0.21 %), and total fiber, while APE-30 had the highest SDF (9.87±0.53 %) and IDF (17.64±0.79 %). However, by increasing the percentage of APE or APU powder in the cakes, the amounts of IDF and SDF were significantly increased from 11.61±0.81 to 17.64±0.79 % and 3.84±0.44 to 9.87±0.53 %, respectively (p<0.05).

3.3. Functional and physiochemical properties of APU and APE powders

The wheat flour, APE, and APU powders were analyzed using a pH meter (Table 3). According to the results, the APE contained a lower pH level (4.31±0.02) than the APU powder (4.97±0.01). Additionally, the pH levels of both powder types were significantly lower than the wheat flour (6.35±0.02) (p<0.05).

Table 3 Functional and physicochemical properties of Wheat flour, APU, and APE powders.

| Sample | pH | Water absorption capacity (g/g) | Oil absorption capacity (g/g) | Bulk density (g/l) |

| wheat flour | 6.35±0.02 a | 4.71±0.12 c | 1.14±0.09 c | 503.4±2.5 a |

| APU | 4.97±0.01 b | 6.69±0.10 b | 2.19±0.07 b | 438.6±3.7 b |

| APE | 4.31±0.02 c | 7.26±0.13 a | 2.32±0.03 a | 421.1±4.9 c |

Water absorption capacity (WAC) is a practical parameter in food products such as bread, cakes, and macaroni. Table 3 shows that APE with 7.26 ± 0.13 (g/g) contained the highest value, and the wheat flour with 4.71±0.12 (g/g) had the lowest. The Oil absorption capacity (OAC) of the APE and APU powders were 2.32±0.03 (g/g) and 2.19±0.07 (g/g), respectively, and significantly higher than wheat flour (p<0.05) (Table 3). The obtained bulk density for the wheat flour, APU, and APE were 503.4±2.5 (g/l), 438.6±3.7 (g/l), and 421.1±4.9 (g/l), which were significantly different (p<0.05).

3.4. Physical characteristics

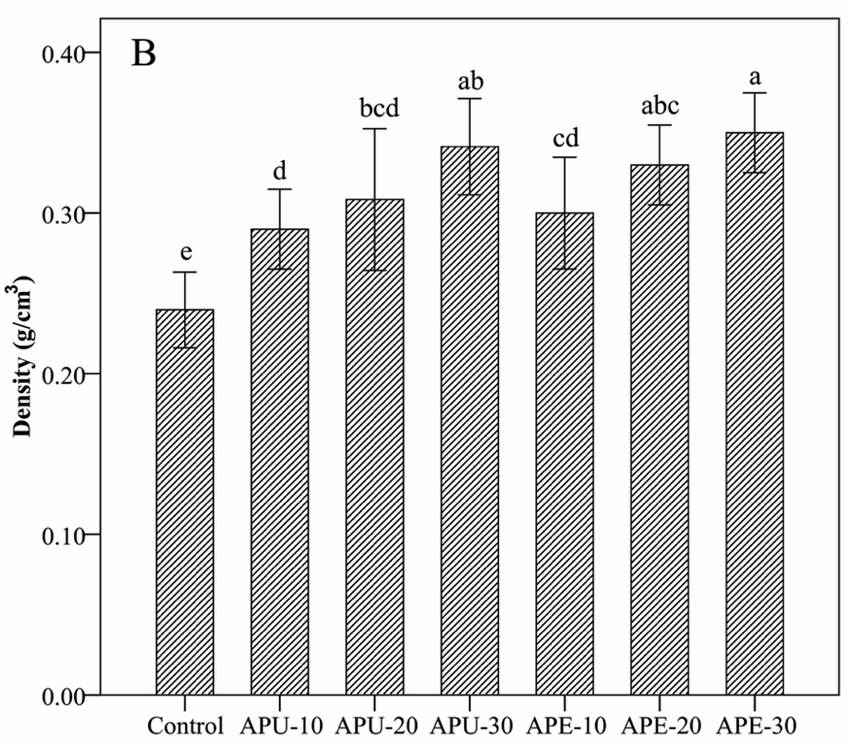

Figure 2 shows the physical characteristics of the control and enriched cakes. As the data indicates in Figure 2A, the volume of the samples were reduced significantly with the addition of APE and APU powder levels compared to the control (p<0.05). As can be seen in figure 2, the volume of the APU and APE samples ranged from 141 cm3 to 168 cm3, which were lower than that of the control sample (p<0.05). By increasing the APU or APE powder content in the cake formula (Figure 2B), the density of the samples was higher than the control sample (p<0.05).

3.5. Colorimetry

The effects of adding APU and APE powders on the cake color have been separately presented in Table 4. The highest lightness level of the cake core and crust were observed in the control sample; these parameters were 81.23±5.88 and 52.21±3.12, respectively. Among the enriched samples, the APU-10 sample showed no significant difference compared to the control (p>0.05). Evaluation of the cake crust showed that increasing the enrichment level did not significantly affect the lightness of the cake enriched with APU (p>0.05). The a* index demonstrates the color range of the samples from green to red. By increasing APU and APE, a* values increased from 1.38±0.16 to 3.01±0.22 and 1.59±0.18 to 3.82±0.25, respectively, in the cake core (p<0.05). The cake core in APE samples also showed higher a* index levels. The highest level of redness in the cake core was found in the APE-30 (3.82±0.25). Evaluation of the cake crust showed that the control sample had the highest redness with a value of 5.99±0.23. With the addition of APU and APE powders, the redness of the samples was reduced compared to the control sample (p<0.05). The b* index demonstrates the color range of blue to yellow in the samples. In the evaluation of cake cores, the enriched samples had less yellowness compared to the control sample (p<0.05), but they had no significant difference from each other (p>0.05). The yellowness index cake crusts dropped from 28.14±2.73 to 24.36±2.03 and 25.66±1.57 to 18.39±1.07 with increasing the level of APU and APE, respectively.

Table 4 Effect of different level of APU and APE powders on color parameters of enriched cakes.

| Sample | Core | Crust | |||||

| L* | a* | b* | L* | a* | b* | ||

| Control | 81.23±5.88 a | 1.02±0.11 f | 29.72±1.23 a | 52.21±3.12 a | 5.99±0.23 a | 31.22±1.98 a | |

| APU-10 | 77.41±5.01b | 1.38±0.16 e | 23.15±1.55 b | 49.87±3.98 ab | 5.81±0.41 b | 28.14±2.73 ab | |

| APU-20 | 72.29±3.95cd | 2.12±0.13 c | 23.97±1.38 b | 47.62±4.01 bc | 5.63±0.39 d | 27.09±1.61 bc | |

| APU-30 | 69.05±4.28 d | 3.01±0.22 b | 21.07±2.41 b | 47.35±5.28 bc | 5.70±0.35 c | 24.36±2.03 cd | |

| APE-10 | 73.71±6.43 c | 1.59±0.18 d | 23.81±2.04 b | 44.41±3.84 cd | 4.92±0.34 f | 25.66±1.57 bc | |

| APE-20 | 72.08±4.80 cd | 2.30±0.20 c | 22.97±1.81 b | 41.30±2.57 de | 5.08±0.31 e | 22.18±1.39 d | |

| APE-30 | 65.19±7.61 e | 3.82±0.25 a | 21.34±0.05 b | 38.97±3.91 e | 4.34±0.27 g | 18.39±1.07 e | |

Values in the same column with the same letter are not significantly different (p<0.05)

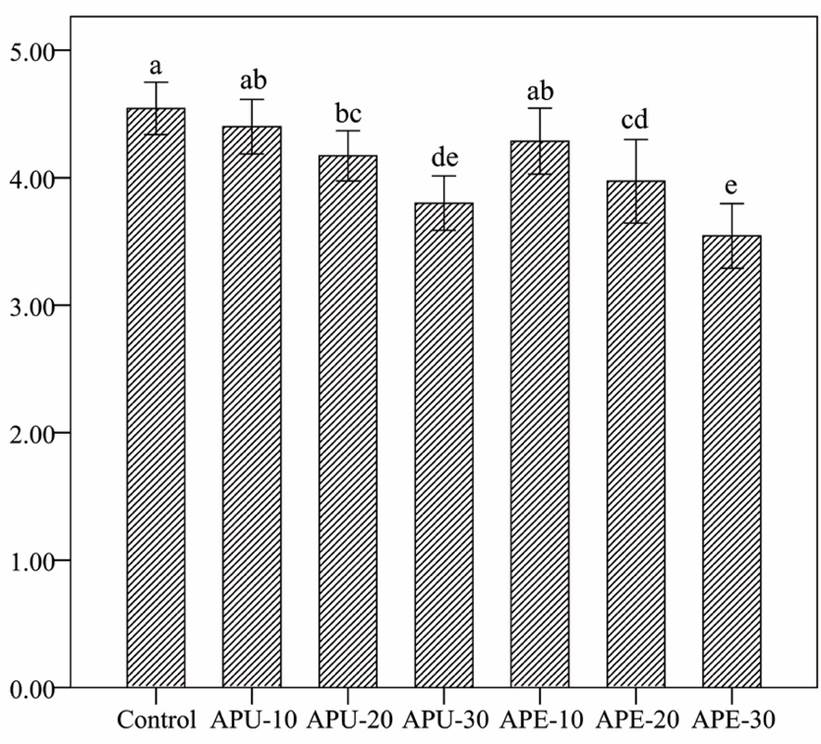

3.6. Textural properties

The results (Table 5) showed that hardness, gumminess, and chewiness of the samples increased significantly (p<0.05), which were higher in all samples compared to the control. However, in equal enrichment levels, the samples enriched with APE had higher levels of hardness, gumminess, and chewiness compared to APU. The APE-30 sample had the highest level of hardness (6.24±0.13 N), gumminess (4.48±0.16 N), and chewiness (4.44±0.10 N.mm). In the evaluation of springiness, no significant difference was found between the enriched and control samples. However, the springiness of APU-30 and APE-30 samples were 1.08±0.13 (mm) and 1.07±0.12 (mm), which had a significant difference compared to the other samples (p<0.05). The APU-30 and APE-30 samples had the lowest cohesiveness compared to other samples (p<0.05).

Table 5 Effect of different level of APU and APE powders on textural parameters of enriched cakes.

| Sample | Hardness (N) | Gumminess (N) | Chewiness (N.mm) | Springiness (mm) | Cohesiveness | Adhesiveness (N.s) |

| Control | 1.61±0.06 g | 1.29±0.05 g | 1.31±0.11g | 1.01±0.06 b | 0.80±0.02 ab | 0.39± 0.01 b |

| APU-10 | 2.82±0.13 f | 2.14±0.10 f | 2.17±0.10f | 1.00±0.00 b | 0.83±0.01 a | 0.39±0.01 b |

| APU-20 | 3.32±0.17 e | 2.55±0.15 d | 2.70±0.10d | 1.02±0.03 b | 0.82±0.01 ab | 0.40±0.01 b |

| APU-30 | 4.54±0.15 c | 3.52±0.19 b | 3.42±0.13 c | 1.08±0.13 a | 0.79±0.00 b | 0.40±0.01 b |

| APE-10 | 4.26±0.17 d | 2.39±0.21 e | 2.52±0.24e | 0.99±0.02 b | 0.79±0.01 b | 0.46±0.18 a |

| APE-20 | 5.39±0.26 b | 3.22±0.09 c | 3.79±0.11b | 1.02±0.02 b | 0.80±0.01 ab | 0.40±0.01 b |

| APE-30 | 6.24±0.13 a | 4.48±0.16 a | 4.44±0.10a | 1.07±0.12 a | 0.79±0.01 b | 0.40±0.01 b |

Values in the same column with the same letter are not significantly different (P<0.05)

3.7. Sensory characteristics

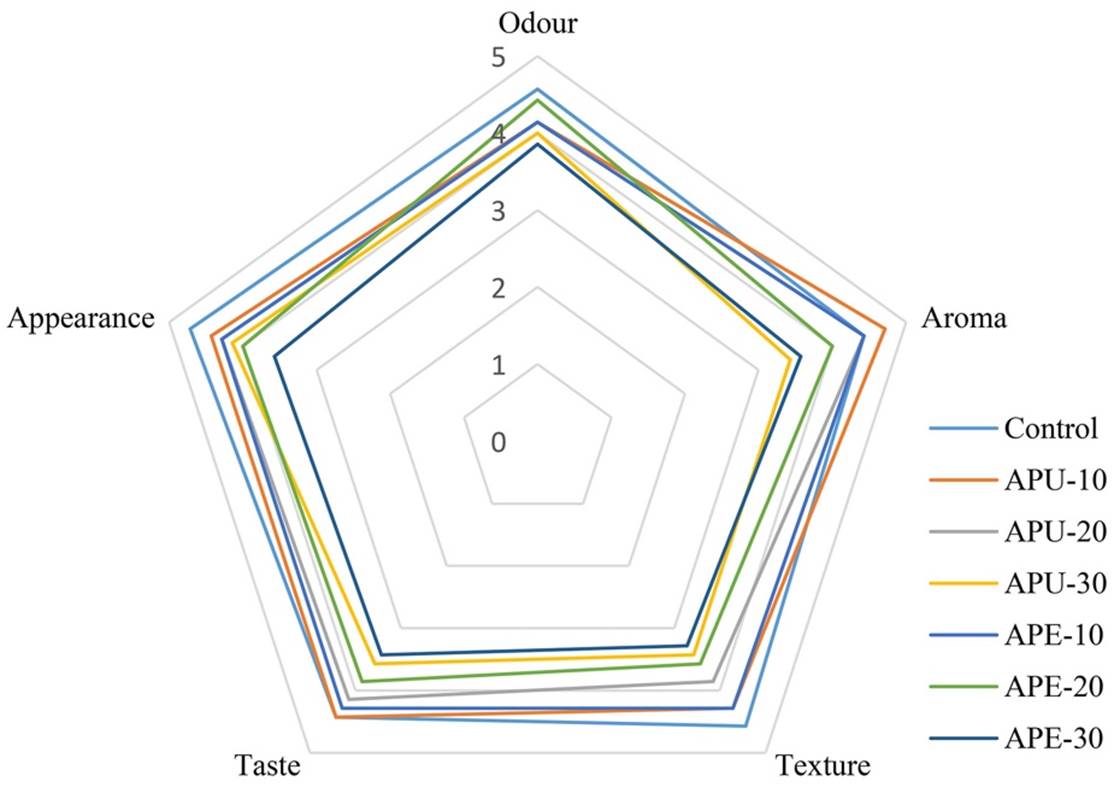

The sensory evaluation showed that the cake prepared with APE-30 had the lowest score in terms of appearance, texture, taste, and odor parameters (Figure 3). The control sample obtained the highest total score (Figure 4). However, the samples prepared with APE-10 and APU-10 were not significantly different from the control sample (p>0.05).

Figure 3 Sensory characteristics of seven samples prepared with increasing level of APU and APE powders, scale from 1 (extreme dislike) to 5 (extreme like).

4. Discussion

4.1. Chemical analysis of powder

Noor Aziah et al.25 reported 2.65 and 5.73 % for soluble and insoluble fiber of wheat flour, respectively. In this research, the soluble and insoluble fiber content of wheat flour were 2.32±0.00 % and 5.89±0.05 %, respectively. The APU and APE powders contained a higher percentage of soluble and insoluble fiber than the wheat flour (p<0.05). The measured insoluble fiber in APU and APE powders were 33.71±0.05 % and 38.12±0.04 %, respectively, indicating that APE powder contains a higher percentage of insoluble dietary fiber than APU powder. The APE powder, also contained more soluble dietary fiber (p<0.05). In Skinner et al.26 research, the content of soluble and insoluble dietary fiber in apple pomace powders were 13.5-14.6 % and 33.8-60.0 %, respectively. This broad difference in the amount of apple pomace can be associated with the difference in apple cultivars and dietary fiber extraction methods. In similar research, the content of soluble and insoluble fiber of apple pomace were 14.6 % and 36.5 % 21, respectively, which was consistent with the findings of this research as they also investigated peel and pulp powder. Regarding the function of fibers in the human diet, it can be stated that APU and APE as a source of soluble and insoluble fibers can improve the quality of food products.

4.2. Dietary fiber analysis of cakes

Kim et al.27 used Opuntiaa humifusa powder in enriched sponge cakes, which resulted in a linear increase of fiber and a reduction of carbohydrates and calories in the produced samples. Some research has shown that the use of green banana flour 28, green tea powder 29, mango peel and pulp flours 25, and apple pomace 30,31 also increased the fiber levels in the baked product. In this research, the samples enriched with APU contained lower amount of fiber compared to the corresponding samples that were enriched with APE (p<0.05).

4.3. Functional and physiochemical properties of APU and APE powders

In Moazezi et al.7 research, the pH levels of wheat flour and apple pomace were reported to be 6.1 and 4.6, respectively, which was consistent with this research. Due to the higher acid content of APU and APE compared to the wheat flour, in the preparation of the enriched cakes, the pH of the dough is lower than that of ordinary cakes. Masoodi et al.32 linked the pH reduction in the samples enriched with apple pomace power to the high surface area and acidity of the pomace.

Water absorption capacity (WAC) indicates the potential of a food product to bond with water 33, 34. All three samples displayed significant differences compared to each other. Kumar and Saini 35 reported WAC and oil absorption capacity (OAC) of the wheat flour at 0.46 (g/g) and 1.19 (g/g), respectively. In this research, WAC and OAC of wheat flour were 4.71±0.12 (g/g) and 1.14±0.09 (g/g). The OAC is the potential of flour proteins to make physical bonds with fat/lipids through capillary absorption. This property is of primary importance since lipids, as preservatives of aroma and taste, can increase mouth feel sense, especially in bread and other cooked food products 36,37. Higher OAC in APU (2.19±0.07 g/g) and APE (2.32±0.03 g/g) than the wheat flour (1.14±0.09 g/g), indicated the higher bonding potential and preservative feature of the pomace types in food products. High OAC can be due to other components present in apple peel and pulp which contribute to hydrophobicity 38. In some research on apple pomace 21,39, the bulk density was reported at 520 (g/L) and 429.5 (g/L), respectively, which could be consistent with the present study.

4.4. Physical characteristics

The volume of the cake is influenced by the mixture of air in the dough and the capacity of the dough to retain the gases released from the baking powder system. The volume reduction in the enriched cake with APU and APE may be linked with the interference of the fibers with the process of gas capturing within the cake matrix 40. In the case of replacing flour with cellulose, several researchers stated that it weakened the capacity of the gluten matrix to contain the released gases inside the cake 32,21. The density of the cake is an indicator of the dough capacity to contain air during mixing. Low density suggests many air bubbles within the cake texture. With the addition of APU to the cake formula (Figure 2B), the density of the samples was significantly increased from 0.29±0.04 (g/cm3) to 0.34±0.04 (g/cm3). Similarly, a decrease in volume and an increase in density were reported with the addition of fiber in the cake 21. Compared to the control, a rise in the density of the enriched samples can be due to the high level of fibers and the subsequent change in the viscosity of the dough. Proper density is associated with good aeration of the batter in mixing. An excessively low batter density also causes air to escape during the mixing and baking 41,42. Fibers, proteins, and sugars can increase the batter density because they can disturb the aeration process 43,44. Ayoubi et al.45 reported that adding Eleaagnus angustifolia (senjed) powder increased the density of the cake. In the present research, APU samples had more volume than the APE samples, indicating a higher amount of fiber in the peel powder. Noor Aziah et al.25 reported a specific volume reduction by replacing wheat flour with mango fiber in cakes. Similar findings concerning the volume reduction with the addition of spinach and avocado (Persea americana) puree 46,47 in cakes and APE in muffins 48 were consistent with the findings of this research.

4.5. Colorimetry

The color of the food products is a determining factor in their quality and heavily influences their marketability 49. Indeed, heat exposure generates the cake color 50. As stated before, the L* index indicates the product’s lightness. Based on the color analysis results, the highest lightness level of the cake core and crust were observed in the control sample. Increasing the enrichment level from 10 to 30% led to a decrease in L* index in the cake core. In the research of Kırbaş et al.51, it was found that the addition of apple pomace powder to the cake led to a reduction of the lightness level. An increase in the darkness and redness of the samples can be associated with the presence of more sugars in apple pomace compared to the wheat flour. Hence, the Maillard reaction between amino acids and sugars, as well as the caramelization of the samples, could have occurred more intensively (52,25,50. Jung et al.52) found similar results by adding apple pomace powder; in their research, the lightness of the cookie samples was reduced, while the redness level increased, which was explained by the darkness of apple pomace compared to the wheat flour.

The APU-10 sample showed no significant difference compared to the control sample (p>0.05). Salehi et al.53 stated that the cake enrichment with apple powder led to a decrease in lightness, an increase in redness, and had no significant effect on yellowness.

4.6. Textural properties

The texture of food products is one of the most important factors that affect the acceptability of the product. Texture characteristics are influenced by cake volume, moisture level, and the interaction of different cake components 16. The texture tests are conducted either by instrumental analysis or sensory evaluation; however, the instrumental method is used frequently due to its accuracy.

Gumminess is calculated as hardness × cohesiveness 27, and chewiness is calculated as springiness × gumminess, and it is defined as the needed energy to disintegrate a food for swallowing 54. The results (Table 5) showed that with increasing the enrichment level, the hardness, gumminess, and chewiness also increased (p<0.05), which were higher than the control. Salehi et al. reported that adding apple powder to the cakes significantly increased cake hardness 53. According to Sudeh et al.21, the dietary fiber of fruits increased the hardness of the cake core. Ayubi et al.47 replaced wheat flour with senjed powder at different levels, increasing the cake texture hardness. Jung et al.52 researched on cookie samples enriched with apple pomace; high enrichment percentage decreased their hardness, which was associated with a low moisture level of the pomace.

Springiness is the measurement of elasticity level by determining the recovery level between the first and second compression cycle 27. In this research, APU-30 and APE-30 had higher springiness than other samples (P<0.05). Grigelmo-Miguel et al.55 found no significant difference in springiness by adding peach fiber to muffin samples. In research conducted by Kırbaş et al.51, the fiber addition reduced the cake springiness; however, the amount and type of fiber did not affect springiness. Noor Aziah et al.25 attributed texture changes in sponge cakes to interactions of fiber and gluten.

Cohesiveness determines the internal resistance of food structure and indicates the product’s strength to stick together 54. APU-30 and APE-30 had the lowest cohesiveness in all samples (p<0.05). In the research of Salehi et al. 54, the enrichment of cake using carrot pomace showed a reduction in cohesiveness. However, Rocha Parra 56 found that increasing the apple pomace level led to reduce cohesiveness in bread samples. Jun et al.57 found that applying apple peel flour reduced cohesiveness, whereas hardness and gumminess parameters in the samples significantly increased. Moreover, the control and three-gram enriched sample had no significant difference in adhesiveness.

Adhesiveness and cohesiveness parameters can be influenced by storage conditions, temperature, relative humidity, and packaging 58. In the present research, no significant difference was found in adhesiveness by adding pomace powders, except in the APU-30 and APE-30 samples, with the highest level of adhesiveness. This finding was consistent with the research of Kırbaş et al.51 since they found no significant difference in the addition of apple pomace in terms of adhesiveness.

4.7. Sensory characteristics

Consumers usually pay special attention to the sensory and visual characteristics of foods. Sensory analysis is an effective way to assess the acceptability of new food products. Our evaluation showed that the control sample had the highest score (4.57), but there was no significant difference between that and APU-10 or APE-10. In contrast, the APE-30 had the lowest score (3.72) due to the low score of APE-30 in appearance, texture, and taste parameters. The texture is an important characteristic and indicates the acceptability of the sensory quality of cakes. Based on the results, the control sample had no significant difference with APU-10 and APE-10 in texture scores. The aroma of the cakes enriched with APU-30, APE-30, and APE-20 had significantly lower scores than other samples (p<0.05). However, none of the panelists felt any aftertaste in sample APE-20. No significant difference was observed in the taste of the APU-10, APU-20, APE-10, and control samples. The evaluation showed that replacing a small amount of the wheat flour with APU or APE (10%) could improve the nutritional properties without significantly reducing the overall acceptance of the cake (P>0.05). These findings were consistent with the findings of some researchers 21,17,31 in different bakery products.

4. Conclusion

The results of this research demonstrated that a partial replacement of the wheat flour with apple pomace significantly increased the dietary fibers, especially insoluble fiber, compared to the control sample. The cakes prepared with APU-10 and APE-10 received the highest sensory scores after the control sample. APU and APE had the potential to use in the cake as a good source of dietary fibers.