Introduction

Food of animal origin is a relevant source of foodborne diseases; among them, meat is one of the main food vehicles for biological hazards to humans 1. Due to its physical and chemical characteristics, meat can favor the growth of pathogenic microorganisms such as Salmonella spp., Escherichia coli O157:H7, and other potential foodborne disease carriers or related toxins, which makes meat a food of major risk to public health 2,3,4 and for which its handling requires adequate safety practices. Indeed, it has been estimated that 14.8% of foodborne disease outbreaks in Colombia were caused by consuming meat and meat products 5.

Microbial contamination of meat can occur during the slaughter process, which inevitably takes place in transforming live animals into meat. Most of this contamination comes from dirt, dust, and feces associated with the animal's skin, which encounters the carcass when removed 6,7.

Several decontamination methods have been reported to reduce the microbial contamination of carcasses: physical (e.g., hot water, steam, steam vacuuming), chemical (e.g., organic acids, chlorine, acidified sodium chlorite, polyphosphates), and biological (e.g., bacteriophages, bacteriocins) 8. However, the most effective carcass decontamination techniques are nonbiological, with chemicals, acids, steam, and hot water washes being the most effective 1.

Chemical decontamination involves the application of a chemical substance at some point during slaughter. The most commonly used and extensively studied substances for chemical decontamination of carcasses are low molecular weight organic acids (e.g., lactic, acetic, citric, fumaric) and other chemicals such as chlorine, acidified sodium chlorite, peroxyacids, and trisodium phosphate 8.

Several studies worldwide, including two Colombian studies, have investigated the effect of chemical decontamination and bacterial reduction of beef carcasses 9,10,11,12,13.

Nevertheless, the characterization of decontamination procedures of beef carcasses in abattoirs is scarce, with few studies characterizing these procedures among other food safety practices 14,15. This lack of reliable information on decontamination procedures of beef carcasses in any country constrains the possibilities for evaluation and improvement, which represents a risk of contamination of meat with pathogenic microorganisms of public health concern 16. In addition, this undesirable contaminated meat also affects productivity 17 since the ineffectiveness of microbiological risk control leads to commercial and economic disadvantages for slaughterhouses 17,18. The decontamination process chosen by the slaughterhouse to guarantee meat safety and reduce the risk of biological hazards must be validated according to government regulations and their preferred methods under specific production conditions and circumstances 8,19,20.

In 2019, the Colombian cattle slaughter was 3,407,750 heads, of which 96.4% were intended for national consumption. Of this number, the province of Antioquia provided the highest proportion, with 541,003 heads (15.88%) 21, making the decontamination characterization procedure highly relevant in this province to reduce the risk of contamination with pathogenic microorganisms of public health concern. Therefore, this study aimed to characterize the decontamination procedures of beef carcasses in slaughterhouses located in the province of Antioquia (Colombia).

Materials and methods

Ethical considerations

This study has the approval of the Committee for Animal Experimentation (Act Nr. 133, June 2th, 2020) and of the Committee of Bioethical of the University Research Headquarters (CBE-SIU) (Act Nr. 20-110-905, June 26th, 2020). Both committees of the Universidad de Antioquia, Colombia.

Type and study design

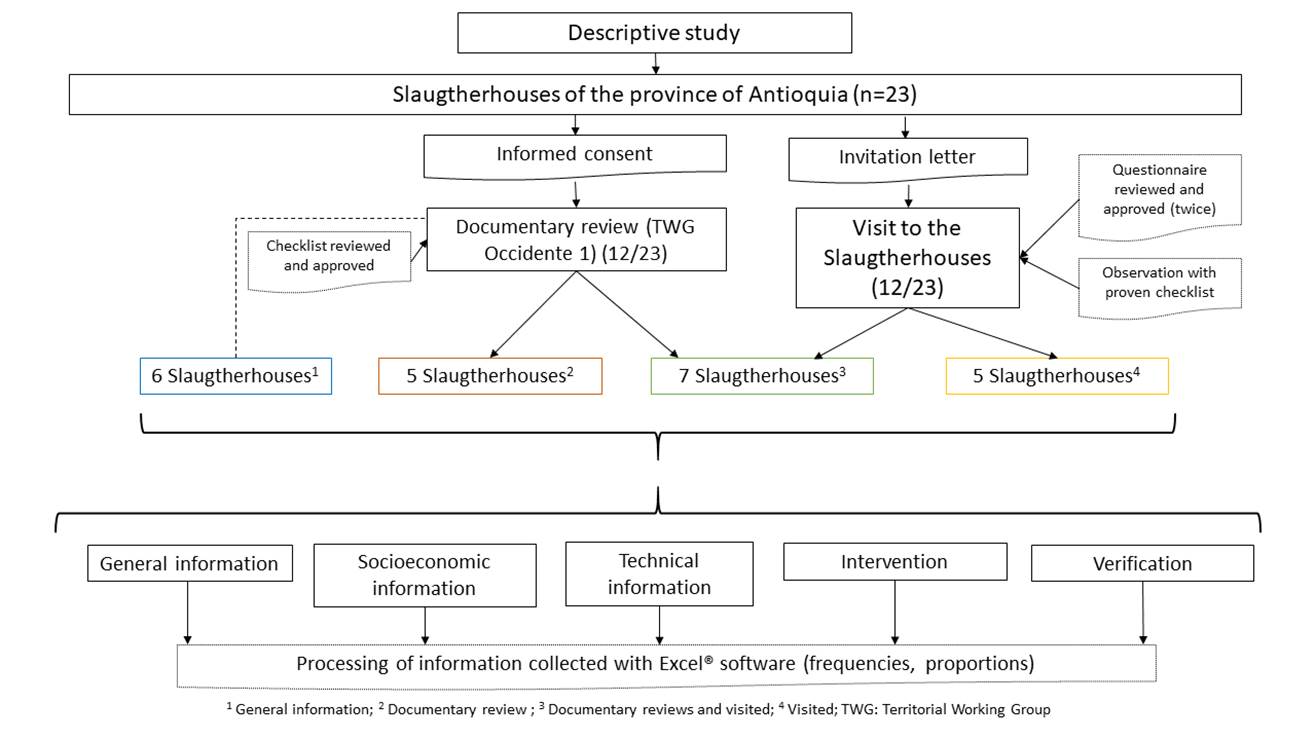

A descriptive study was conducted to characterize beef carcass decontamination procedures (Fig. 1). The characterization of beef carcass decontamination procedures was carried out in the 23 slaughterhouses registered and authorized by Invima in the province of Antioquia. Both primary (i.e., the information provided by the slaughterhouses themselves and by direct observation of the researchers during a visit) and secondary sources (i.e., the information provided by the Invima) were used. Several strategies were implemented to increase the likelihood of voluntary participation in cattle slaughterhouses. Information on the legal representative of the slaughterhouse (including email and telephone contact numbers in the Invima database and on the commercial pages) was collected to establish the initial contact. The abattoirs were then contacted by email through an invitation letter, and later phone calls were made to confirm the email arrival. Twelve cattle slaughterhouses agreed to participate and were finally enrolled in the study.

Documentary review from the Invima´s repository

Documentary information registered, authorized, and available in the Territorial Working Group (TWG) Occidente 1 repository, through informed consent, were collected and reviewed to identify the characteristics of each cattle slaughterhouse. For this purpose, a form was designed to collect general, socio-cultural, and technical information and for the characteristics of the decontamination procedures.

Visits to the slaughterhouse

A single visit was carried out between November 2020 and April 2021 to each of the 12 cattle slaughterhouses that agreed to participate in the study. During the visit, the characterization information of each slaughterhouse was collected through a questionnaire completed by the delegated and responsible person who attended the visit.

The questionnaire included five sections: 1) general information, 2) socio-cultural information, 3) technical information, 4) characteristics of the disinfection process, and 5) verification of the decontamination procedure. In addition, an open non-cooperative observation 22 of the routine decontamination procedure of carcasses was carried out during the same visit, using a form to record this specific information.

Pre-test of the information collection instruments

All information collection instruments -questionnaires and forms, were pre-tested at a small scale to evaluate their effectiveness. In each case (i.e., documentary review from the Invima´s TWG Occidente 1 repository, characterization information of each slaughterhouse during the visit, and characterization of the routine decontamination procedure during the visit). Six experts in the field (one doctor of engineering and five veterinarians with long experience in beef abattoirs and postgraduate studies in the field of veterinary public health) evaluated the structure to ensure that all important issues were identified and covered, and to identify problems, such as unnecessary length, poorly worded, unclear questions, or allowance of subjective responses 23 (Figure 1).

Results

General characteristics of the slaughterhouses

According to the Invima repository, 23 cattle slaughterhouses in Antioquia were active and authorized during the evaluation period (July 2019 and April 2021). Seventeen paid for the permanent inspection service. Five conducted periodic inspections, and information was not obtained from one slaughterhouse because it was registered in another jurisdiction (i.e., Caribbean Coast-2 TWG). According to the origin of the working capital (type of company), 11 public, eight private, and four mixed slaughterhouses are in Antioquia. Following the sanitary authorization, five slaughterhouses can allocate their products for self-consumption, seven at the local level, nine at the national level, and only one has the authorization to export. In general, it was identified that most slaughterhouses have a slaughter volume of <50,000 heads per year (monthly average-based) (Table 1).

Table 1 Information of the slaughterhouses registered, open, and with sanitary authorization by Invima in the province of Antioquia (Colombia), 2019-2021

| Slaughterhouse | Municipality | State of operation | Inspected by | Type of inspection | Type of company7 | Destination of the carcass | Slaughter volume8 | Enrolled and visited during the study |

| 1 | Amalfi | Open | TWG Occidente 12 | Not permanent | Mixed | Self-consumption | <50,000 | Yes |

| 2 | Amagá | Open | TWG Occidente 1 | Permanent | Private | National | <50,000 | No |

| 3 | Andes* | Closed1 | TWG Occidente 1 | Permanent | Public | Local | <50,000 | No |

| 4 | Anorí | Open | TWG Occidente 1 | Not permanent | Public | Self-consumption | N.D. | No |

| 5 | Cañasgordas* | Open | TWG Occidente 1 | Permanent | Public | National | <50,000 | Yes |

| 6 | Caramanta* | Open | TWG Occidente 1 | Permanent | Private | Local | <50,000 | Yes |

| 7 | Caucasia | Open | Caribbean-2 Coast TWG | N.D. | Private | N.D. | N.D. | No |

| 8 | Ciudad Bolívar* | Open | TWG Occidente 1 | Permanent | Mixed | National | <50,000 | No |

| 9 | Copacabana | Open | TWG Occidente 1 | Permanent | Public | Local | <50,000 | No |

| 10 | Ebéjico | Open | TWG Occidente 1 | Not permanent | Public | Self-consumption | N.D. | No |

| 11 | Fredonia | Open 3 | TWG Occidente 1 | Permanent | Public | Local | <50,000 | Yes |

| 12 | Marinilla* | Open | TWG Occidente 1 | Permanent | Private | National | <50,000 | No |

| 13 | Medellín* | Open | TWG Occidente 1 | Permanent | Mixed | National | <100,000 | No |

| 14 | Peque | Open | TWG Occidente 1 | Not permanent | Public | Self-consumption | <50,000 | Yes 9 |

| 15 | Puerto triunfo | Open 4 | TWG Occidente 1 | Permanent | Public | Local | N.D. | No |

| 16 | Rionegro* | Open | TWG Occidente 1 | Permanent | Mixed | National | <50,000 | Yes |

| 17 | San Carlos | Open 5 | TWG Occidente 1 | Not permanent | Public | Self-consumption | <50,000 | Yes |

| 18 | San Roque* | Open | TWG Occidente 1 | Permanent | Private | National | <50,000 | Yes |

| 19 | Santa Rosa de Osos*6 | Open | TWG Occidente 1 | Permanent | Private | National and export | Between 50,000 and 100,000 | No |

| 20 | Sonsón* | Open | TWG Occidente 1 | Permanent | Private | National | <50,000 | Yes |

| 21 | Turbo* | Open | TWG Occidente 1 | Permanent | Private | National | <50,000 | Yes |

| 22 | Urrao | Open | TWG Occidente 1 | Permanent | Private | Local | <50,000 | Yes |

| 23 | Yarumal* | Open | TWG Occidente 1 | Permanent | Private | Local | <50,000 | Yes |

1Closed since November 2020; 2TWG: Territorial Working Group; 3Open since March 2020; 4Open since November 2020; 5Open since July 2020; 6Slaugtherhouse with authorization to allocate carcasses for export and the only beef slaughterhouse in Antioquia with Hazard Analysis Critical Control Point (HACCP) certification by Invima; 7According to the origin of the working capital; 8Heads per year (monthly average-based); 9Through virtual means; *Slaughterhouse subject to review of the beef carcass decontamination procedures in 2019, according to the TWG Occidente 1; N.D.: No data.

Documentary characterization of the beef carcass decontamination procedure

A 52.17% (12/23) of the slaughterhouses in the study had information on the decontamination procedures, identifying some sociocultural and technical features. Six slaughterhouses had personnel trained to perform the decontamination procedures, and 10 used carcass disinfection products. In the latter case, five plants used citric acid, two used lactic acid, the other two used peracetic acid, and one used a mixture of organic acids. It was evidenced that 66.67% of the slaughterhouses (8/12) used carcass disinfection products according to the product's technical data sheet, but only two used it in an adequate concentration for the intended purpose and consistent with scientific publications 18,33. It was also found that eight slaughterhouses had a documented carcass decontamination procedure; however, in six of these procedures, corrective actions were described when a non-conformity of the disinfectant solution was evidenced. Finally, eight slaughterhouses had a verification record of the microbiological results of the decontamination procedure (Table 2).

Table 2 Information registered in the Invima´s Territorial Working Group (TWG) Occidente 1 on the beef carcass Washing and Disinfection (decontamination) procedures in 12 slaughterhouses located in the province of Antioquia (Colombia), 2019-2021

| Slaughterhouse | The educational level of the person responsible for the quality area | Personnel trained to conduct the decontamination procedure | Chemical product used | Use of disinfection products according to the product's technical data sheet | Use of a decontamination product according to scientific publications | Documented decontamination procedure | Documented decontamination procedure, describing corrective actions when non-compliance is evidenced | Record of the verification of microbiological results of the decontamination procedure |

|---|---|---|---|---|---|---|---|---|

| 1 | Professional, DVM1 | No | Citric acid | No | No | No | No | No |

| 2 | N.D. | No | None | No | No | No | No | No |

| 3 | Professional, DVM1 | No | Citric acid | Yes | No | Yes | Yes | No |

| 4 | Technologist, FQC2 | Yes | Peracetic acid | Yes | Yes | Yes | Yes | Yes |

| 5 | Technologist, F3 | No | Citric acid | Yes | No | Yes | No | Yes |

| 6 | Professional, DVM1 | Yes | Citric acid | Yes | No | Yes | Yes | Yes |

| 7 | Professional, DVM1 | Yes | Organic acids | No | No | Yes | Yes | Yes |

| 8 | Technologist, F3 | Yes | NA | NA | NA | NA | NA | Yes |

| 9 | N.D. | Yes | Citric acid | Yes | No | Yes | Yes | Yes |

| 10 | Professional, IE4 | No | Citric acid | Yes | No | No | No | Yes |

| 11 | N.D. | Yes | Citric acid | Yes | No | Yes | Yes | Yes |

| 12 | Professional, DVM1 | No | Peracetic acid | Yes | Yes | Yes | No | No |

1DVM: Veterinarian; 2FQC: Food Quality Control; 3F: Foods; 4Industrial Engineer; N.D.: No data; NA: Not applicable (the information recorded by the TWG was related to the general decontamination program).

Characterization of the carcass Washing and Disinfection (decontamination) procedure

Twelve out of the 23 slaughterhouses allowed the visit; however, these 12 establishments differed from the 12 for which a record of information related to the carcass decontamination process was found during the documentary review of the TWG Occidente 1 records. Seven slaughterhouses were consistent with the information collected during the face-to-face visit and the documentary review from the TWG (Fig. 1).

Ten of the 12 slaughterhouses had a documented carcass decontamination procedure. In addition, it was evidenced that the 12 slaughterhouses visited had implemented chemical intervention in the process of obtaining carcass meat as a method to control pathogenic microorganisms. Regarding the chemical products used, it was identified that four slaughterhouses applied citric acid in concentrations of 0.10-0.15% (1000-1500 ppm), three of them used lactic acid in concentrations of 1.2-2% (12,000-20,000 ppm), three other slaughterhouses applied peracetic acid in concentrations of 160-210 ppm, and two used organic acid mixtures in concentrations of 0.02-0.12% (200-1200 ppm). In addition, eight of the 12 slaughterhouses used carcass disinfectants according to the product's technical data sheet but did no provided scientific support for the implemented procedure; therefore, no carcass decontamination procedure has been properly validated to date. Concerning the microbiological verification of the process, the study showed that nine of the 12 slaughterhouses sampled were positive for generic E. coli (indicator microorganism) and Salmonella spp. (pathogenic microorganism) (Table 3).

Table 3 Characterization of the carcass Washing and Disinfection (decontamination) procedure in the 12 slaughterhouses of study, located in the province of Antioquia (Colombia), 2019-2021

| Slaughterhouse | Municipality | QD | The educational level of the personnel responsible for quality | DP of decontamination | Chemical product used | Concentration (%) | Application of the disinfectant according to TS | Scientific support of the IP | Use of the decontamination product according to scientific publications | Microbiological verification of the decontamination procedure |

| 1 | Amalfi | No | NA | Yes | Citric acid | 0.10 | Yes | No | No | No |

| 2 | Cañasgordas | Yes | Technologist | Yes | Citric acid | 0.15 | Yes | No | No | Yes |

| 3 | Caramanta | No | NA | Yes | Citric acid | 0.15 | Yes | No | No | Yes |

| 4 | Fredonia | Yes | Technician | Yes | Organic acids | 0.12 | No* | No | No | Yes |

| 5 | Peque | Yes | Professional | Yes | Lactic acid* | 1.45 | No* | No | Yes | No |

| 6 | Rionegro | Yes | Technologist | No | Peracetic acid | 0.02 | Yes | No | Yes | Yes |

| 7 | San Carlos | Yes | Bachelor | Yes | Organic acids | 0.02 | No* | No | No | No |

| 8 | San Roque | Yes | Technologist | Yes | Citric acid | 0.13 | Yes | No | No | Yes |

| 9 | Sonsón | Yes | Technologist | Yes | Lactic acid | 1.21 | Yes | No | Yes | Yes |

| 10 | Turbo | Yes | Technologist | Yes | Peracetic acid | 0.02 | No* | No | Yes | Yes |

| 11 | Urrao | Yes | Professional | No | Lactic acid | 2.02 | Yes | No | Yes | Yes |

| 12 | Yarumal | Yes | Professional | Yes | Peracetic acid | 0.02 | Yes | No | Yes | Yes |

QD: Quality Department; DP: Documented Procedure; TS: Technical Sheet; IP: Implemented Procedure; NA: Not applicable; * slaughterhouse does not present a technical sheet of the disinfectant.

On the other hand, the direct observation of the decontamination procedure during the visit allowed us to identify that the 12 visited slaughterhouses implemented this process; nevertheless, none of the slaughterhouses recognized the combination of methods or the multiple obstacles strategy, and none had implemented the Hazard Analysis Critical Control Points (HACCP) safety assurance system. From a quality point of view, it was identified that seven slaughterhouses carried out prior verification of the disinfectant concentration and monitored the concentration during the workday or shift. Regarding the technique or mode of application of the disinfectant, it was observed that all the slaughterhouses applied the disinfectant by spraying with manually operated devices, five slaughterhouses had an exclusive operator for the carcass decontamination procedure, one slaughterhouse knew the pressure of the equipment used for the application of the disinfectant solution, and none of them knew the applied volume of disinfectant solution per carcass. When reviewing the documentation of the slaughterhouses visited, it was found that six had the documented procedure to carry out the carcass decontamination, evidencing a lower number of slaughterhouses than initially indicated such procedure when the questionnaire was applied during the visit. Four slaughterhouses were also identified to perform the carcass decontamination activities described in the documented procedures; therefore, the decontamination procedures need to be correctly validated, according to the results. However, seven slaughterhouses have laboratory records of microbiological results of the carcasses.

Factors determining the selection of the Washing and Disinfection (decontamination) procedure.

Based on the information collection instruments -both from primary and secondary sources, and what was observed during the visit, the factors that determined the selection of the carcass decontamination procedure in the slaughterhouses of the study were the type of company, slaughter volume, and lack of financial resources.

Discussion

The current study characterized the beef carcass decontamination procedures routinely used in slaughterhouses. The response rate obtained was lower (52%) when compared to similar studies using comparable methodologies 14,15. Although several efforts were made to increase the response, the voluntary participation in the research and some pre-existing prejudice against sharing information on safety procedures with academia led to the response rate obtained.

The five slaughterhouses that did not have a permanent official inspection could get access to this critical inspection service provided by territorial entities taking advantage of the regulations and guidelines issued by the Ministry of Health and Social Protection 24,25) similar to the inspection system of other countries, such as Mexico, USA, and Canada, with federal and state inspection 14,26,27,28. Some authors have suggested a relationship between the reduction in the prevalence of pathogens in the final product and access to an official inspection, resulting in microbiologically safer carcasses 26.

More than 90% of the slaughterhouses were small and/or very small plants, similar to others found in previous studies 14,15,27,28. It was hypothesized that slaughterhouses with higher slaughter volumes -at least 80,000 cattle/year (6,700 cattle/month), can invest in aspects related to ensuring product safety, as suggested by other studies 14,27. Due to their size, very small slaughterhouses have a low income and limited financial resources, so they save on aspects such as performing validation studies of the decontamination process used, acquiring technological resources such as automated intervention systems, and training personnel.

According to national health regulations, the personnel responsible for the operation must understand and conduct the activities under their responsibility 3,29. Continuous training in aspects associated with carcass decontamination should be reinforced in slaughterhouses since personnel training is essential to produce safe food 15,30.

The use of chemical products such as citric acid, lactic acid, peracetic acid, and a mixture of organic acids in carcass decontamination has also been identified by other researchers for the control of pathogenic microorganisms in meat 31,32,33,34. Although the substances used in the decontamination process vary between slaughterhouses, sprinkling organic acids was also evidenced in a previous study 14.

According to our results, citric acid is the most commonly used product at concentrations between 900 and 1,500 ppm (0.09-0.15%), which is consistent with the product's technical data sheet (i.e., 900-3,000 ppm). However, the concentrations at which the product was being applied were well below, compared to other studies, where 2% citric acid was not enough to significantly reduce pathogens 34,35. In the current study, it was established that three of the 12 slaughterhouses visited applied lactic acid at concentrations between 1.2 and 2%; however, previous research has recommended the use of lactic acid at concentrations between 2 and 4% to obtain reductions greater than one logarithmic unit 6,27,31.

Three of the studied slaughterhouses used peracetic acid at concentrations between 160 and 210 ppm, which is the recommended maximum concentration of 220 ppm 36. However, another study reports that it is not an effective intervention according to what is recognized 35.

It was identified that in most of the slaughterhouses of the study, the method of application of the decontamination product was manual. This type of application is less effective in reducing microbial populations 34. Considering that most of the slaughterhouses in Antioquia are small or very small -many in the latter classification, it is unlikely that the automated application mode was one of the most used since the latter is more suitable for larger slaughterhouses slaughter volumes 15. One explanation is the cost of such equipment and production needs, which makes it more likely to be used by larger slaughterhouses since they have more resources to implement these technologies.

In most of the slaughterhouses visited, it was observed that the operator responsible for the carcass decontamination procedure is not exclusively responsible for conducting this activity, which may increase fatigue. In addition, during the direct observation of the decontamination procedure, the slaughterhouses indicated that they were unaware of the disinfectant volume and application pressure. Other research has reported volumes ranging from 250 to 473 mL per carcass 37, and better results have been reported when using 2 to 3 L per carcass 34 and an application pressure range between 10-123 psi 18,38. Therefore, and in accordance with what has been pointed out in other studies, in addition to the concentration of the disinfectant, several specific variables of the process must be controlled, such as operator fatigue, pressure or lack of spraying of the product, the volume of the disinfectant applied, time of exposure to the disinfectant, and coverage area of the carcass with the spray, since these factors significantly influence the efficacy of carcass decontamination treatments 31,34,41.

According to what was observed, most of the slaughterhouses in the study have implemented an intervention method to control pathogenic microorganisms. In Antioquia, the most used method is washing carcasses with water at room temperature (average 19.9 °C) and sprinkling organic acids. Although it is recognized and accepted that an intervention is effective when it achieves at least a logarithmic reduction 27, and although the effectiveness of this decontamination procedure has been demonstrated, washing with water at room temperature and spraying with organic acids is the least effective alternative since it reduces only 1 to 1.5 logarithmic units 27,39. Hot water carcass washing was not used in the slaughterhouses study, an intervention that, like chemical disinfection, has increased over time as a pathogen control strategy in the US 15. Other studies have found that the combination of hot water washing (<55 °C) followed by organic acid spraying resulted in additional reductions of 0.2 to 0.5 and of 0.5 to 1.9 log units for E. coli O157: H7 and S. typhimurium, respectively, which are pathogenic bacteria of interest in meat 6,35,15,40. Furthermore, this strategy could reduce the bacterial load due to cross-contamination and is suggested for small and very small slaughterhouses 26. Therefore, it is considered a viable alternative to improve the conditions of the carcass decontamination procedures, according to the features of the slaughterhouses located in the province of Antioquia.

As discussed above and considering that none of the slaughterhouses visited acknowledge implementing the multi-barrier strategy -including a good preventive intervention such as supplier control, the multi-barrier approach significantly improves results and is more effective than a single intervention is used 14,41,42. Combining washing with hot water (<55 °C) followed by spraying with organic acids would be a practical and acceptable option for slaughterhouses in Antioquia.

Most of the slaughterhouses visited carried out a microbiological sampling of the carcasses to verify the effectiveness of the decontamination procedure, an aspect required according to Colombian health regulations 3,29. However, process control could be improved and monitored through well-designed sampling plans. Therefore, it is agreed to state that although the good manufacturing practices are essential for properly carrying out the slaughter process, pathogen sampling and control plans can help filter contaminated products during the transformation process, stimulate improvements in cleaning and disinfection procedures, and reduce consumer risk and financial costs associated with rejected products by improving product safety 43. In addition, to achieve control of pathogens in carcasses, sanitary standards require the interventions used to destroy and prevent the growth of pathogens to be validated under manufacturing conditions 3,29. Therefore, it is recommended that the beef carcass decontamination procedure chosen by the slaughterhouses must be validated under the local environments and conditions of each one, as has been recommended in other research works 11,41.

Conclusion

Although it was established that at least one decontamination procedure, such as chemical disinfection, is implemented in the slaughterhouses of study, this option is not supported by scientific or technical foundations. It is likely that, due to limited resources or low income, slaughterhouses are saving on technical factors, technology, and staff training and suitability. These findings support the need for improvements in the slaughterhouses of the province of Antioquia, including the improvement of surveillance programs to effectively reduce pathogens in the meat chain.