Introduction

Green Waste (GW) includes tree and shrub clippings, dead leaves, grass clippings, and soil from municipal parks, gardens, and residences, among other sources. The GW fraction is an important fraction of municipal solid waste and is characterized by a predominance of lignocellulosic matter (i.e., 27% to 57% cellulose, 11% to 55% hemicellulose, and 3% to 22% lignin on a dry basis) 1, which requires long times to degrade in nature 2. In recent decades, GW generation has increased, which is associated with urban development and the expansion of urban green spaces 3. In 2017, the world generated approximately 2 billion tons of municipal solid waste (MSW), with GW representing approximately 11% 4. In Colombia, according to the Ministerio de Vivienda, Ciudad y Territorio (MVCT) and the World Bank (WB), by 2021 in cities with more than 5,000 subscribers of Municipal Solid Waste (MSW) management services 267 thousand tons of waste related to urban cleaning were generated, with GW representing the largest portion 5. The final disposal cost of GW can be significant and variable. In the case of Latin American and the Caribbean (LAC) countries, such as Brazil, it can range from US $22.0/ton in the southeast to US $63.0/ton in the northeast. In Colombia, the average cost is US $10.36/m3 (6.

The impacts of GW on the environment not only affect the landscape, but also increase the risk of fires and contribute to the production of greenhouse gases (GHG) such as methane 3.

Composting is a biotechnological alternative used for the treatment and valorization of GW. The resulting product is an amendment or support material that can be reincorporated into agricultural production processes or used as a soil improver, thus promoting the principles of the circular economy 7. In addition, this biotechnology contributes to solving the problem of final disposal of GW, helping to minimize greenhouse gas emissions associated with this materials 8. Furthermore, GW often exhibits low levels of micropollutants, facilitating their treatment by biological processes and favoring the generation of products that meet quality standards for use in agriculture 9.

Although composting is an applied technology for GW treatment, it presents challenges due to the low degradability of lignocellulosic substances 10. Moreover, if the process is not properly operated and controlled (e.g., oxygen supply, moisture content, nutrient balance), the process can be slow (e.g., between 90 and 210 days), require large treatment areas 9, generate unpleasant odors 11 and produce a low quality product that makes it commercially unattractive. This is further complicated by the variable composition of GW, which depends on the predominant vegetation, the season, and aspects related to its collection 9.

Due to the challenges associated with the composting of GW, several strategies have been employed to improve its treatment and by-products, including (i) operational changes in the process such as Two-Stage Composting; (ii) pretreatment, including fraction separation and particle size reduction; (iii) addition of bacterial inoculums, such as bacteria and fungi; (iv) co-composting with amendments and support materials; and (v) incorporation of additives such as biochar, zeolites, among others 12. Each of these strategies has either improved or had antagonistic effects on the composting process. This highlights the need to further understand these strategies to define operational conditions based on the study context.

Considering the challenges to improve GW composting and the strategies identified in different contexts for its optimization, this article synthesizes the results of several studies developed in Colombia that have evaluated strategies for the improvement of GW composting. The investigations considered were developed by the authors of this paper, some of which are not published, while others have been presented in about 10 publications (4, 9, 12-19). This article addresses aspects such as the identification of the physicochemical characteristics of GW, the evaluation of the effect of the implementation of strategies to improve the process and product quality, and finally reflects on research perspectives to continue strengthening the implementation of composting in MSW management in developing countries such as Colombia. The perspectives raised aim to contribute to the continuity of research in this field in developing countries.

Fundamentals of the Composting Process

Composting refers to the biological degradation of organic waste and has four stages (mesophilic, thermophilic, cooling and maturation) involving temperature changes from room temperature to 70°C, which is essential for the sanitization of the product. Microbial consortiums carry out this process in a predominantly aerobic environment, resulting in a stable by-product with no pathogenic load that can be applied to the soil; substances such as carbon dioxide (CO2), water steam (H2O), nitrates (NO3 -) and sulfates (SO4=) are also produced 20.

The process consists of two stages: mineralization and humification 21. During the first stage, mesophilic aerobic microbial consortiums transform rapidly degradable macromolecules such as carbohydrates, proteins, and lipids into simpler organic and inorganic compounds. This leads to oxygen consumption, carbon dioxide emission, and the generation of energy that is released as heat 20. This stage produces substances, such as ammonia (NH3) and short-chain volatile fatty acids, with phytotoxic potential. These substances are subsequently consumed by microorganisms present in the process, including bacteria of the genus Pseudomonas, Bacillus, Thiobacillus, Enterobacter, actinobacteria such as Streptomyces, and filamentous fungi of the genus Aspergillus, among others 22,23. The presence of these microorganisms depends on the substrate type and operational conditions that affect the autochthonous biomass of the process (18). The rate of degradation increases with temperature, reaching thermophilic values (> 45ºC), which promotes the reduction of pathogens and the selection of thermophilic microorganisms 24. Microbial activity remains high until nutrient concentrations, especially nitrogen, and easily degradable organic matter decrease 21.

During the second stage of the process, the more complex substances are degraded, resulting in a decrease in temperature and an increase in pH to slightly alkaline values until the end of the process 25. At this point, the thermophilic microbial population decreases, and mesophilic microorganisms and actinobacteria become predominant, which are characterized by the slow degradation of starch, cellulose, hemicellulose, and lignin, substances that are precursors for the formation of humic compounds 24.

The substrate transformation induces high metabolic activity in the microbial consortiums, leading to changes in process conditions and subsequent stages of exponential growth, stationary growth, and succession of organism groups 21. The process involves several groups of microorganisms with established roles in organic matter degradation, including bacteria, fungi, actinobacteria, protozoa, and annelids. The first three groups are mainly responsible for rapid consumption of organic waste, while the others contribute to the transformation of organic structures, facilitating their availability as a source of carbon for bacteria (21, 22).

The most relevant parameters in the process are chemical characteristics of the substrates (total organic carbon-TOC and nutrients such as nitrogen and phosphorus), moisture, pH, oxygen, substrate porosity and process temperature, which have been widely identified in previous research 20,22,26,27.

The primary byproduct generated during the process is compost. Compost is characterized by stabilized organic matter that is compatible with plant growth and exhibits partial humification 21. Compost presents physicochemical properties that determine its characteristics and uses, including TOC, NTotal and Ninorganic, pH, electrical conductivity (EC), cation exchange capacity (CEC), macro- and micronutrients, moisture content, water holding capacity (WHC), bulk density and particle size.

Identification of physicochemical characteristics of green waste

The physicochemical characterization of GW represents a challenge for the valorization of this type of waste due to the fact that the material that arrives at the composting facilities usually has a high variability in its composition due to factors such as the climatic and geographical conditions of the generation sites (e.g., the abundance of dry leaves in summer and the abundance of grass in winter) 28. Authors such as Reyes-Torres et al. 9) indicate that in Latin American and Caribbean (LAC) countries such as Colombia, grass clippings are the predominant GW material in both summer and winter, with proportions of 71% and 45%, respectively. Similarly, Vandecasteele et al. 29 indicate that in composting facilities, climatic conditions influence the development of the composting process.

Despite the variability in substrate composition (e.g., type of organic material constituting the GW), GW typically contain green and dry leaves, branches and grass clippings, and finally roots and soil fractions 9. It is important to mention that few reports specify the physical composition of the material used in the studies, which makes it difficult to monitor the influence of the material on the GW composting process 9,13,18. Considering the diversity of materials that constitute GW, these can be divided into two fractions: the green fraction refers to leaves and grass clippings, while the brown fraction corresponds to branches, hedge clippings, roots and trunks 9. This type of classification provides information on the physicochemical quality of GW and could help in the selection of appropriate materials (co-substrates) to improve their biological treatment process.

The physical composition of GW affects the physicochemical properties, which in turn affects the composting process 30. Therefore, it is important to develop studies that relate the physical composition of GW to the physicochemical quality of this type of waste. This would help to identify conditions for process optimization and contribute to improving the quality of the final product 29.

Table 1 identifies the physicochemical characteristics of GW, showing the high variability of this type of waste in eight Colombian cities, in parameters such as moisture (ranging from 20% to 78%), TOC (ranging from 26% to 43%) and TN (ranging from 0.65 to 2.75%).

Table 1 Physicochemical Characterization of GW in Colombian Cities

| Parameter | Versalles15 | Piedecuesta19 | Bucaramanga4) | Valledupar 31 | Pamplona 32 | Cali33) | Cali-Rural34 | Palmira35) |

|---|---|---|---|---|---|---|---|---|

| Moisture (%) | 78 | 27.3 | 63 | 70 | 70 | 20 | N.R | N.R |

| pH (Units) | 8.04 | 6.9 | 7.5 | N.R | N.R | 7.23 | 7.0 | N.R |

| TOC (%) | 36.91 | 26.6 | 29.87 | N.R | N.R | 27.3 | 43.18 | 31.15 |

| TC (%) | 2.45 | 1.2 | 0.65 | N.R | N.R | 1.16 | 2.75 | 1.91 |

| C/N | 15.04 | 22.2 | 46.19 | 70 | 35 | 24.41 | 15.7 | 16.30 |

| TN (%) | 1.27 | N.R | 0.25 | 0.08 | N.R | N.R | N.R | N.R |

| KT (%) | 1.18 | N.R | 0.62 | 0.26 | N.R | N.R | N.R | N.R |

| Lignin (%) | N.R | 35.1* | 40.80 | N.R | N.R | N.R | 2.67 | 10 |

| Cellulose (%) | N.R | N.R | 12.43 | N.R | N.R | N.R | 35.78 | 31 |

| Hemicellulose (%) | N.R | N.R | 15.47 | N.R | N.R | N.R | 19.26 | 29 |

* Corresponds to lignocellulosic fraction; N.R: Not reported

Evaluation of strategies to improve the process and product quality of GW composting

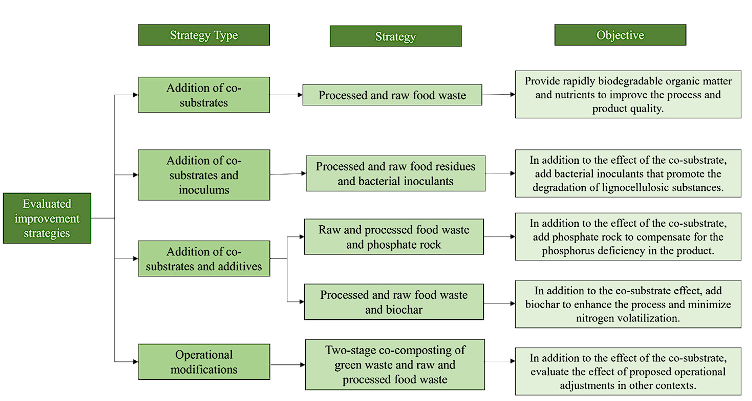

Considering that GW is characterized by a low content of macro- and micro-nutrients and a high concentration of recalcitrant compounds (lignin), which influence the quality standards required for the final product, the duration of the composting process and, therefore, the land requirements, gas emissions and the generation of low quality products 12, it is necessary to identify strategies to improve the composting of GW 9. Figure 1 shows the strategies that have been evaluated in several studies conducted by the authors of this paper and that have shown improvements with respect to composting only GW.

Table 2 shows the characteristics of the different studies conducted and summarizes the main results obtained.

Tabla 2 Characteristics of the different experiments and results of the final product

| Strategy | Proportion of substrates | Type of process | Scale | Treatment assessed | Type and quantity of additive | Process time | Characteristics of the final product |

|---|---|---|---|---|---|---|---|

| Co-substrate | 50% GW + 30% RFW + 20% PFW | CC | Laboratory (100 kg per unit) | T1: 100% GW T2: 60% GW + 40% RFW T3: 50 GW + 30% RFW + 20 % PW | N.A | 67 | pH: 7.60 Moisture: 54.6% EC:1.62mS/cm TOC: 23.1% TN:2.4% C/N:10.5 TP:0.8% GI: N. R |

| Co-substrate and Inoculum | 50% GW + 32.5% RFW + 2.5% RAP + 13%Sd + 2% PR | CC | Pilot (120 kg per unit) | T1: with inoculum T2: without inoculum T3: Only GW | Microbial inoculant (Bacillus sp. :4.85 X 105 UFC mL-1 Paenibacillus sp: 1.44 X 105 CFU mL-1) | ND | pH: 8.4 Moisture: N.R EC:1.5mS/cm TOC: 25.4% TN:1.7% TP: N.R C/N:14.9 GI: 95.8% |

| Co-Substrate and Additive | 48% GW + 32.5% RFW +2.5% +PFW + 13%Sd + 2% PR | CC | Laboratory (40 kg per unit) | T1: 100% GW T2: 50 % GW + 32.5% RFW + 2.5 % PFW+ 13% Sd + 2% PR T3: 48% GW + 32.5 % RFW + 2.5% PFW+ 13% Sd+ 2% PR+ 2% Bch T4: 45% RV+ 32.5% RAC +2.5% RAP + 13% As + 2% RF+ 5% Bch | 2% of Biochar | 43 | pH: 6.93 Moisture: 55.28% TOC: 31.35% TN:1.30% EC:0.16mS/cm TP: 2.14% C/N:24.1 GI: 137% |

| Co-Substrate and Additive | 48% GW + 21% RFW + 18% PFW + 13% Sd | CC and TSC | Pilot (250 kg per unit) | T1: TSC + 15 % PR T2: CC + 15% PR T3: CC | 15% PR | 90 | pH: 7.72 Moisture: 27.97% TOC: 12.21% TN:0.73% TP:7.33% EC:0.13mS/cm C/N:16.57 GI: 163% |

| Operational modification | 46% GW + 19% RFW + 18% PFW + 13% Sd | CC and TSC | Piloto (200 kg per unit) | T1: TSC T2: CC | 4% PR | 73 | pH: 8.36 Moisture: 44.2% EC:0.2mS/cm COT: 29.04% C/N:18.68 TN:1.55% TP:4.19% GI: N.R |

a Proportion of substrates with the best results in the experiment; b The treatment with the best results in the final product; N.A: No Additive; Bch: Biochar, N.R: Not reported, RFW: Raw Food Waste; PFW: Processed Food Waste; PR: Phosphate Rock; Sawdust; COT: Total Organic Carbon; TN: Total Nitrogen; PT: Total Phosphorus; GI: Germination Index; EC: Electrical Conductivity. ND: No Data, T: Treatment; TSC: Two-Stage composting, CC: Conventional Composting.

Addition of co-substrates

The incorporation of co-substrates in biowaste composting has been effective in reducing the process time and improving the quality of the final product 36,37. In the local context, Oviedo-Ocaña et al. 16 and Oviedo-Ocaña et al. 14 evaluated the effect of co-substrates available in the study area. The co-substrates selected were processed and unprocessed food waste (FW), which is a novel strategy given that these wastes are generally used as the main substrate. The mixture of both substrates, due to their physicochemical characteristics, allowed to obtain recommended values for the beginning of the composting process in several parameters (e.g. TOC, TN, pH, moisture).

The addition of these co-substrates allowed GW composting to reach temperatures in the thermophilic range in a shorter time and to reach higher temperatures compared to GW composting without co-substrate. It was also effective in maintaining temperatures in the thermophilic range for a longer period (19 days) compared to the biowaste alone treatment (9 days). The cooling phase of the process was also characterized by a shorter duration and room temperature was reached between 8 and 14 days faster than the GW-only treatments. This showed that the addition of raw and processed FW provides greater effectiveness to the composting process with better conditions for sanitizing the final product. In addition, it contributes to the simultaneous solution of the management of two organic fractions of MSW, such as GW and biowaste.

The improvements in the process are attributed to the favorable conditions of the substrate mixture for the beginning of the composting process (i.e. pH close to neutral, organic matter of fast degradation and C/N < 20), which could stimulate the biological activity of the microorganisms, increasing the mineralization of the organic matter and the availability of nutrients in the final product 37. However, the results in the final product showed phosphorus deficiency, so it is necessary to establish additional strategies such as the addition of additives.

Addition of co-substrates and additives

The use of co-substrates in combination with additives (i.e., phosphate rock or biochar) is another strategy that has been implemented to improve the composting of GW and the nutrient composition of substrates at the beginning of the process 28. Hernández-Gómez et al 13 evaluated a mixture of 48% GW, 21% unprocessed food waste, 18% processed food waste, 13% sawdust and 15% phosphate rock. The authors reported an increase in phosphorus concentration in the product quality; however, composting without phosphate rock showed a higher compliance with product quality standards. The results showed that it is necessary to adjust the phosphate rock concentration to reduce the process time compared to composting without phosphate rock and at the same time improve the product quality. In this regard, the reduction of the phosphate rock dosage from 15% to 2% in the initial mixture of substrates (i.e. GW, processed FW, unprocessed FW and sawdust) showed synergistic effects in the process, as reported by Soto-Paz et al. 18 and Oviedo-Ocaña et al. 19, and contributed to the increase of nutrients such as nitrogen and phosphorus in the final product.

On the other hand, biochar (Bch) is another additive that shows potential for GW degradation in composting. It is characterized by helping to generate an environment conducive to microbial growth due to its porosity, cation exchange capacity (CEC), and adsorption capacity 38. The main benefits of using Bch in composting are related to the increase in the rate of biodegradation and humification of organic matter, as well as the reduction of greenhouse gases and nitrogen loss. Regarding the final product, it helps to immobilize heavy metals present in soils, thus reducing the possibility of their uptake by plants 39,40. However, many of the studies have focused on the mixture of Bch and the final product (compost), since the mixture is more effective than Bch alone in terms of its impact on soil characteristics and the crop to which it is applied 41,42.

In previous studies developed by the authors Parra-Orobio et al. 4, two doses of Bch at 2% and 5% were evaluated in the co-composting process of GW and FW. The results showed that the 2% dose increased the biological activity during the active phase of the process. This increase was evidenced by a prolongation of the time of the thermophilic stage (up to six days), a greater reduction in the concentrations of hemicellulose (33.9%), cellulose (23.3%) and pathogenic organisms compared to the treatment without Bch. Concerning the final product, although there were no statistically significant differences between the treatments evaluated, the final product obtained with a 2% dose of biochar was characterized by a higher fertility index (4.5) and microbial conditions that facilitate its use as a soil improver.

Addition of co-substrates and inoculums

Although composting is a biological process where the organisms involved in the stabilization of the material develop naturally, it has been documented that the addition of inoculants increases the degradation rates of organic matter (OM) and reduces the time of the composting process 18. The addition of species, a consortium of several species or the simple use of mature GW compost are some of the alternatives.

Considering the presence of lignocellulosic materials in GW, some authors have used lignocellulose-degrading microorganisms as inoculums to facilitate the degradation of this recalcitrant 19. Table 3 shows the types of inoculums used in GW composting studies and the results on the duration of the process and the C/N ratio of the product, which were references for the studies developed in Colombia. It is highlighted that white rot fungi have been documented as one of the most efficient lignocellulose-degrading microorganisms. In particular, the species Phanerochaete chrysosporium is the most studied fungus in the composting of different types of lignocellulosic wastes, and has been used in several GW composting processes, individually and in fungal consortia 9.

Although in the Colombian context the implementation of inoculums in the degradation of lignocellulosic wastes such as GW has been carried out 43-46, few studies have reported their application in the composting process of this type of substrates. One of the studies that has advanced in the identification of bacterial inoculums in GW composting is the study developed by Soto-Paz et al. 18, who first isolated and identified, from a GW composting process, bacterial strains that had the greatest potential to degrade lignocellulosic substances. Subsequently, they evaluated and selected two of the strains with the highest lignocellulose degradation (Bacillus sp. F3X3 and Paenibacillus sp. F1A5) inoculated in the co-composting of 50% GW, 32.5% raw FW, 2.5% processed FW, 13% sawdust and 2% phosphate rock at laboratory scale (i.e. 250 mL reactors). The bacterial strains had concentrations of 4.85*105 CFU g-1 of Bacillus sp. F3X3 and 1.44*106 CFU g-1 of Paenibacillus sp. F1A5. The combined effect of co-substrate addition and inoculation resulted in a 37% reduction in lignocellulose content compared to the treatment without bacterial inoculation.

Table 3 Inoculants used in GW composting.

| Inoculants | Type | Composting time achieved with inoculant addition (days) |

|---|---|---|

| Fomes fomentarius | Fungal consortium | 86 |

| Trametes versicolor | ||

| Phanerochate chrysosporium | ||

| Efficient FW Microbials | Microbial consortium | 49 |

| Cellulose | Application of enzymes | 21 |

| GW compost | Compost as inoculant | 22 |

| Trametes versicolor | Fungal species | 86 |

| Phanerochaete chrysosporium | Fungal species | 86 |

| Anoxybacillus sp | Bacteria | 36 |

| Bacillus shackletonni, Streptomyces thermovulgaris y Ureibacillus thermosphaericus | Bacteria | 180 |

| Trichoderma sp | Fungal species | 28 |

| Aeromonas caviae sp., Shinella sp., Rhizobium sp., Corynebacterium pseudotuberculosis sp., Streptomyces clavuligerus sp | Microbial consortium | 60 |

On the other hand, Oviedo-Ocaña et al 17, following up on the results of the previously reported study, evaluated the conditions for optimizing the inoculation process at laboratory scale (120 L reactors) finding that the combined effect of the addition of co-substrates (raw and processed FW, sawdust and phosphate rock) and bacterial inoculants contributed to reduce the composting process time to 13 days compared to the GW-only treatment. In addition, the inoculant treatment produced a more stable product as evidenced by its respirometric index (RI: 2.9 gCO2 kgSV-1d-1) compared to the GW-only treatment (RI: 4.5 gCO2 kgSV-1d-1).

Finally, Oviedo-Ocaña et al. 19 analyzed the effect of inoculation and co-substrates on a semi-pilot scale (100 kg piles on wet basis); the addition of bacterial inoculants in the cooling phase of the co-composting process (i.e., same substrate mixture of GW and FW) was evaluated, where a reduction in processing time between 4 and 13 days was obtained compared to the GW mixture treatment. The results indicated that the bacterial inoculant contributed to increased lignocellulose biodegradation (29.1%) compared to the biowaste only treatment.

Regarding the final product, in the same study, Oviedo-Ocaña et al. 19 showed that it complied with the quality standards of the Colombian regulations (NTC 5167) and the Chilean regulations NCh 2880, with a pH of 8.3, TOC of 24.8%, total TN of 1.32% and germination index (GI) of 98.8%. These results show potential for the use of the final product for agricultural purposes as an amendment material. However, it is recommended to perform nutrient release capacity tests for nitrogen and phosphorus 47.

Operational modifications

Recent studies in GW composting have evaluated operational strategies to improve organic matter degradation. One of these strategies is two-stage composting (TSC), which has a phase in which the substrates are confined in a container (oxygen is supplied by passive aeration). The confinement favors the increase of temperature gradients that accelerates the biodegradation process. Subsequently, the material in process is removed from the container and piles are formed (second phase) to continue the biodegradation process under local environmental conditions. According to Zhang et al. 48, this operational change represents a reduction in process time (i.e. between 73 and 90%) and an improvement in product quality.

To evaluate the applicability of this operational modification, Oviedo-Ocaña et al. 14 evaluated the effect of TSC on the process and product quality during co-composting of GW and FW, using sawdust as the support material and phosphate rock as an additive. The results showed similar process conditions between two-stage composting and traditional composting (i.e., in terms of process time, temperature, VS, pH, and EC). In addition, the final products resulting from both treatments did not show statistically significant differences. Despite the lack of statistical differences in the final product between the two treatments, traditional composting was characterized by lower nutrient content (Ntotal: 1.55%; Ptotal: 4.19%) and lignin content (28.6%) than two-stage composting (Ntotal: 1.76%; Ptotal: 4.75% and lignin 30.3%). Therefore, this study concluded that the TSC was not an effective strategy in the analyzed study context and recommends the evaluation of other additional complementary strategies to improve GW composting.

Use of co-substrates

The use of co-substrates has shown benefits in improving the physico-chemical properties of GW; however, it is necessary to study the effect of other co-substrates from the agro-industry that can contribute to close the nutrient cycles in the framework of the circular economy. This can be supported using multi-criteria tools that consider aspects such as substrate characteristics that allow the selection of suitable co-substrates or additives to improve the composting of green waste.

Use of microbial inoculums

The use of microbial inoculants has shown positive results in GW composting at various scales (laboratory, semi-pilot, and pilot). Other studies also show that the use of different types of bacterial strains, fungi or mixtures of both, evaluated at different concentrations, generally have a positive effect on lignocellulose degradation compared to the control treatment (i.e. between 15 and 30%) (see Table 3). The challenges identified in this study show that it is necessary to continue the research that considers the use of different microbial strains and relies on molecular biology techniques to identify the taxonomic groups involved and their succession dynamics, to understand their role in the process of mineralization and humification of OM and their interaction with the native microbial communities.

Regarding the use of microbial inoculants, there are two challenges to increase their application in Colombia. On the one hand, the inoculants need to be evaluated on a real scale, so it is necessary to analyze incubation times to achieve maximum growth of microbial communities. On the other hand, it is necessary to preserve the microbial inoculant to avoid its potential contamination. Therefore, research on microbial inoculants in full-scale composting plants should be continued and the effects on process and product quality should be analyzed at this scale. In this way, it is possible to contribute to the search for solutions for the management of the organic fraction at the urban level and to reduce the amount of organic waste disposed in landfills. This is crucial in Colombia, where approximately 63% of landfills are nearing the end of their useful life 49.

Use of additives

Regarding the use of biochar in GW composting, it is recommended that future research (i) evaluates the effect of biochar produced with different biomasses; (ii) scales up the process (e.g., full scale) to analyze the effect of biochar addition on the degradation of lignocellulosic substances and the quality of the final product; iii) monitors the effect of biochar addition on the microbial community; iv) incorporates parameters that allow a better understanding of the effect of biochar addition on nitrogen dynamics during the co-composting process; and v) compares the effect of adding biochar at different stages of co-composting (e.g. mesophilic and thermophilic) on the process and the quality of the final product.

Evaluation of the quality of the product

It is necessary to assess the availability of nutrients such as nitrogen and phosphorus in the final product by evaluating soils and plant growth at the laboratory scale (e.g. pots) and at plot level. This is useful to define the rate of application of the product to the soil and the time required for its application. This aspect is fundamental to determine which type of crop is more suitable to be used according to the agronomic characteristics of the product.

Use of optimization tools in GW composting

Finally, a growing trend is to optimize the process through a modeling and simulation approach using artificial intelligence and machine learning tools 50. This aims to predict aspects such as process stability, maturity, gas emissions, among others. Therefore, research is needed to develop new models that integrate different elements of the operational strategies, allowing a more detailed understanding of the process at a lower experimental cost.

Conclusions

Based on this reflection, the following conclusions are presented:

The evaluation of alternatives to improve process and product quality in the documented studies has been effective in reducing process times, improving the physicochemical properties of the final product, and better product quality standards compliance.

Research development should continue, especially, in the following areas: evaluation of operational options such as mixing additives (e.g. inoculants and biochar), adaptation of laboratory tests to evaluate in situ material stability, evaluation of improved products in production systems, evaluation of the effect of product (compost) application on soil (mineralization) and plant growth.

Research and development of full-scale projects in the context of smaller populations can be useful to improve the performance of lignocellulosic waste composting facilities such as GW.