Introduction

As can be seen, the logistics management of a company implicitly involves the supply chain, limited to internal functions such as the storage flow over planning, execution and control; This will be efficient in the external flow from the treatment of origin to the point of consumption given to goods, services and information, both from basic companies and industries. 1. The proper organization and management of chains provides companies with competitive advantages by reducing manufacturing costs and benefiting from the resources, skills and talents that each specific area of the world has to offer (supplies, manufacturing, design), but integration and gradual progression to value networks has also created a global interdependence that poses many challenges for the future 2.

Growing digitalization and automation trends are changing the way sourcing is carried out, from inventory management through all the processes involved in the chain, to collaboration with suppliers. In recent decades, supply has been characterized by massive globalization and widespread use of technologies to optimize processes, the search for supplies around the world and the configuration of increasingly complex supply networks. 2. In the global landscape, particularly in Latin American countries, logistics is executed as an organized process that requires implementing a flow of tangible and intangible materials, whose work begins with the reception of the planning until reaching an end that satisfies the customers. 1. These markets, considered emerging, are full of opportunities were understanding the dynamic context and responding quickly to changes is the key to success. 3.

Within the local context, emerging businesses, known as small or medium-sized companies with a short time of experience and a small position in the market, can be commonly seen and have a great participation in the area's economy. 4. In these businesses, supply chain management can be considered inefficient, both due to the magnitude of the activities and the actions of the actors and the development of the processes that influence it. 3. For example, if suppliers fail to comply, procurement becomes less efficient; the lack of innovation in production and distribution hinders growth in the market and; The inadequate use of resources by the workforce hinders the achievement of the organization's goals. 5.

Even so, various studies show that SMEs tend to be more agile and respond to unpredictable changes effectively compared to their larger competitors. 3,4. It is common for small and medium-sized companies to be considered more agile than large corporations due to their size and more flexible structure, this allows them to be faster in making decisions, implementing new projects and adapting to market changes. In addition, SMEs tend to have a closer relationship with their customers and suppliers, thus, they have the ability to better respond to their needs and challenges. However, they also lack market knowledge, access to international credit and financial resources to innovate, which is even more challenging in emerging economies, where the business environment is volatile and dynamic. 3 This is why proper supply chain management becomes vital as it has a significant impact on the company's performance and, in turn, on its competitiveness. 6.

The pandemic caused by covid-19 altered consumption patterns rooted in the culture of each country 7. In this sense, producers and those who offer services locally, with adequate planning and risk management, had the opportunity to sustain their economic activity, by becoming the first source of access to food and health products, among others. 8. This has been a challenging period for many local producers who, over time, have demonstrated their resilience and ability to adapt by facing obstacles and continuing to offer high-quality products to their communities.

Studies from the time of the pandemic show growth in purchases from local merchants in both consumers and institutional suppliers 8. Small and medium-sized local producers adapted in various ways to overcome obstacles, including diversifying products and sales channels, starting to deliver at home and offering the option to purchase through virtual channels; increasing local agricultural production, promoting sustainable agriculture and encouraging producers to expand their operations; collaboration with other local companies, as a method to improve efficiency and reduce costs and; innovation in marketing and promotion, using social networks and other online tools to improve their efficiency and reach a wider audience.

With the above, and with the premise that SMEs represent 90% of the business sector and contribute around 50% of the world's gross domestic product 5, governments and industries should incorporate modern supply chain management concepts to test how applicable they are 9. Characterizing the state of logistics and supply chain management in emerging businesses constitutes support for drawing development strategies at the business, academic and public-economic order levels 10. This study seeks to identify the percentage of business competitiveness of emerging businesses in the city of Bogotá based on their logistics performance.

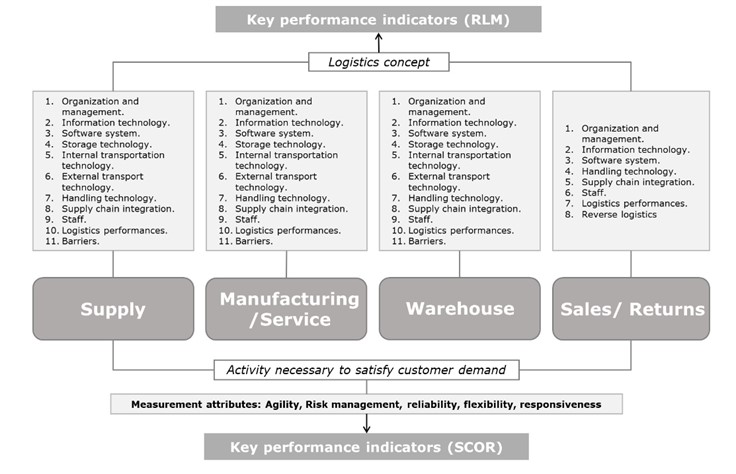

Two reference models were used as instruments for measuring competitiveness of supply chains in emerging businesses. The first, the SCOR (Supply Chain Operations References) model 11, whose characteristics allow selecting the relevant logistics processes to be evaluated and the basic attributes rooted in the proper functioning of each of them, such as agility, reliability, response capacity, risk management and reliability. This model focuses on the continuous improvement of the supply chain, through the definition of processes, metrics, best practices and technologies to support supply chain management.

The SCOR model is a tool for presenting, analyzing and configuring supply chains and focuses on five key areas: planning, sourcing, production, delivery and return, and provides a common language for supply chain management. This instrument is designed to evaluate the supply chain in terms of the effectiveness and efficiency of sales and operational planning 12. It works across industries using universal definitions that apply to any link in the chain. Using the SCOR model, companies can judge how far along a process is in the chain and how much it aligns with their business objectives 11.

On the other hand, the competitiveness of the processes is evaluated through the components of the Competitive Logistics Reference Model (LRM) 10. The LRM is defined as a set of concepts and practices that a company must apply to increase its competitiveness under international standards 10. This model, initially developed for the National Learning Service (SENA) by the International Research and Technical Assistance Center “John F. Kennedy” (CIATI-JFK) and the Logistics and Production Management Laboratory (LOGESPRO), includes thirteen measurement factors that allow identifying the competitiveness of the logistics processes of companies. The LRM focuses on the identification of customer needs and the alignment of logistics processes for satisfying these requirements effectively. This model highlights four key areas of logistics: customer service, demand planning, inventory management and transportation. Its objective is to help companies diagnose their main problems and establish a strategic and operational standard to which supply chains should aspire.

Methodology

In broad terms, the SCOR model focuses on improving efficiency and reducing costs in the supply chain 12, while the MRL model focuses on improving competitiveness and creating value for the customer through supply chain management. For this reason, it was decided to use the two models in the search to identify opportunities for improvement from the analysis of the processes and operations of the supply chain, taking into account the business perspective and that of the client, addressing efficiency and competitiveness. Figure 1.

The application of surveys based on these instruments allowed us to characterize emerging businesses in the city of Bogotá. To carry out this study, a representative sample of emerging businesses in the Colombian capital was selected. This figure is related to the data from the chamber of commerce on the existing MSMEs in the city, in its June 2022 report, which indicates the existence of 428,886 registered businesses (86% of the jurisdiction of the Chamber of Commerce of Bogotá, in the Cundinamarca region). Of the total businesses, 12.9% (approximately 55,563 businesses) belong to the food and pharmaceutical sectors, the object of study in this research.

With the application of the sample size formula, selecting a confidence level of 90%, a study of at least 271 companies is necessary; with this, the conclusions obtained can be considered statistically valid.

Table 1 shows the rating ranges used for the analysis of each of the components of both models, using a scale from 0 to 100%, with zero being the lowest rating and one hundred being the expected result.

Table 1 Rating scale

| Compliance percentage | Assessment | Analysis | Description |

|---|---|---|---|

| 0% - 38% | Very bad | Problem | The process is not identified with the attribute description; therefore, it does not exist. |

| 39% - 53% | Bad | Weakness | The process is minimally identified with the description of the attribute, that is, there is an idea of what should be done, but it is not implemented. |

| 54% - 69% | Regular | Opportunity for improvement | The process is partially identified with the description of the attribute, that is, it is implemented, but there are errors in its execution that must be improved |

| 69% - 84% | Well | Opportunity for improvement | The process is significantly identified with the description of the attribute. The activities are organized; however, it can still be improved. |

| 85% - 100% | Very good | Strength | The process absolutely identifies with the description of the attribute. The development of this is considered to be in an advanced state. |

The evaluation must be totally objective, taking into account the answers given by those in charge of each process, complementing the data collected by the researcher through direct observation and information derived from other activities and processes assigned to the organization.

Results and discussion

Although the term supply chain is relatively new, companies have always put it into practice through their different productive areas 6,13. To carry out the characterization of this research, four specific phases of the chain were taken into account: supply, from which the raw materials and all the inputs necessary to carry out the manufacturing or be able to provide the service are obtained; production or manufacturing, whose procedure transforms all inputs into finished products; storage, which deals with the way in which finished products are maintained and retain their characteristics before leaving the company, and; distribution and sale, where the product is transferred for marketing directly to the client or to the points of sale 5.

While today, real-time data is widely available and data-driven approaches are emerging, organizations and especially small and medium-sized ones lack the expertise to identify critical points in their processes and the logistics applications that should be used to increase efficiency in their daily operations and, therefore, the competitiveness of their processes 14. Through the attributes that make up each reference model used for the study, the efficiency of each process is measured and then an approximation is given to the general competitiveness of emerging businesses in the area. The approximate results of each phase are presented below. Table 2.

Table 2 Evaluation results

| Attribute | Provisioning | Manufacturing/ Production | Store | Distribution/ Sales |

|---|---|---|---|---|

| Agility | 68% | 90% | 86% | 62% |

| Reliability | 95% | 91% | 82% | 84% |

| Answer's capacity | 90% | 85% | 87% | 94% |

| Reliability | 84% | 93% | 86% | 81% |

| Cost and asset management | 81% | 73% | 91% | 63% |

| Risk management | 89% | 75% | 78% | 59% |

| Logistics concept | 86% | 92% | 68% | 76% |

| Logistics organization | 86% | 74% | 69% | 78% |

| Handling technology | 72% | 96% | 86% | 98% |

| Storage technology | - | - | 71% | - |

| External transport technology | 76% | - | 80% | 98% |

| Internal transport technology | - | 67% | 88% | - |

| software technology | 82% | 83% | 90% | 74% |

| Human talent | 79% | 94% | 96% | 84% |

| Supply Chain Integration | 91% | 80% | 86% | 74% |

| Environmental barriers | 72% | 93% | 86% | 69% |

| Reverse logistics | 85% | 87% | 85% | - |

Provisioning

In the chain, procurement connects all the activities necessary to obtain the raw materials, products and by-products necessary for manufacturing 15. Its main objective is to reduce or eliminate waste associated with the acquisition of materials. 15. For this stage it is important to have well planned and coordinated regarding the availability of materials, the amount of costs and the time they require 16. The supply function impacts the company's strategy because its management affects the total cost and the timely satisfaction of customer needs 15.

Sourcing in emerging businesses can work in a variety of ways depending on the structure and objectives of the company. Generally, these variations come from the sector and economic activity, together with the strategic management approaches that define the required standards and make the organization's decisions. Some of the items included are:

Identification of suppliers: It must be assured that they are reliable and have high quality standards. Typically, emerging businesses look for suppliers who offer a good product at a competitive price.

Negotiation and agreements: after identifying potential suppliers, businesses seek to choose the one with the best quality-price conditions. In this sense, they usually agree on supply quantities that meet their needs and requirements.

Demand planning: as a key aspect of supply, as it allows emerging businesses to anticipate the needs of their customers and ensure they have sufficient supplies available.

Quality control.

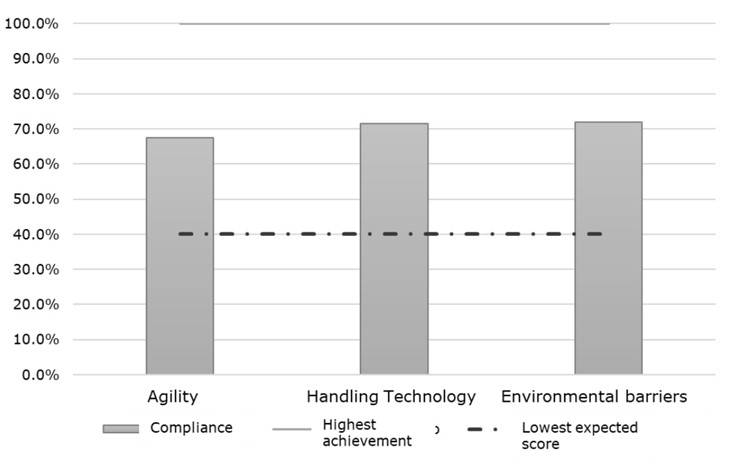

In the adaptation of the reference models, there are fifteen attributes applicable to the supply phase, each of them and their result are detailed in table 2. Given the rise of supply chain sustainability, the supply task of both products and services must demonstrate their contribution to the growth of sales and market share through their relationship with the quality and innovation of the products, but also on their impact on the environmental characteristics of the product and the responsible production processes 15. Figure 2.

Based on the evaluation, it was found in the process that agility, mainly in supplier compliance, requires improvement. Companies must be aware of the correct treatment of all procedures, since a seemingly simple error such as poor supplier selection can lead to major problems within the organization 5. Opportunities for improvement are also found in the “handling technology” and "environmental barriers” parameters. In the former, without the appropriate workforce, there can be mistakes that alter the characteristics and quality of the products. 11. Taking into account the limited scope and limited budget that SMEs have, the quality of the products must be ensured from the raw materials and their treatment 17.

Regarding environmental barriers, Bogotá, being the capital of the country, brings together all kinds of people, with different cultures, traditions and beliefs that converge in a single environment 18. Due to these differences, demonstrations, whether in opposition or in favor of certain political, economic and social aspects, have become part of the city's daily activities. This seems not to be relevant for logistical activities, until mobility becomes difficult in the city due to mass marches or road blockades as a method of protest. This is when the transfer of supplies becomes difficult and the lack of information to avoid setbacks or resolve them quickly directly affects the logistics process 18.

Manufacturing or Production

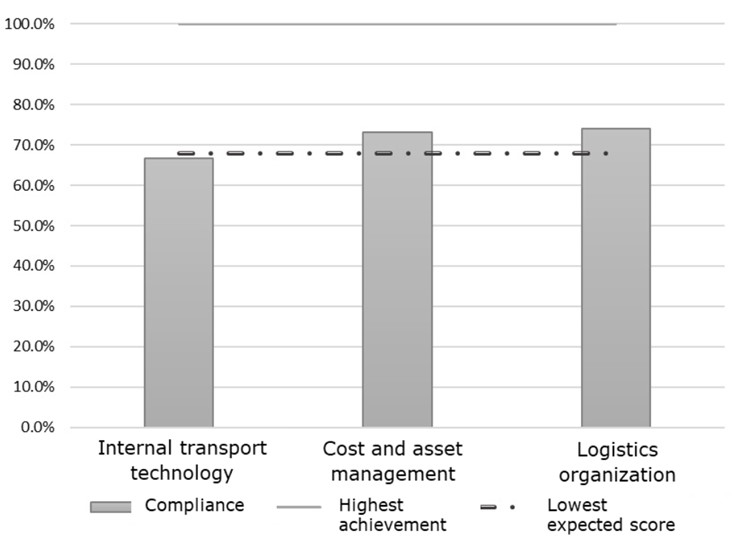

Within the chain processes, manufacturing includes all processes related to the creation and production of the product. That is, the operations necessary for the transformation of raw materials into products and their mass production. The optimization of the industrial process plays a deciding role in the standardization of operations and, therefore, in a more agile and effective cycle 16. According to the reference models used, this phase of the chain adapts to thirteen of the attributes used for the study. A regular score was found in them regarding internal transportation technology. Figure 3.

In the production stage, a series of procedures are carried out, which depending on the way in which they are executed, can help minimize work times and, consequently, reduce process costs, and achieve an efficient and effective supply chain 5. During the interviews with those in charge of this process, it became evident that, due to the conditions and customs associated with the size of the business, it is not usually considered important to obtain some means of internal transportation of goods. This results in constant losses of product that is categorized as damaged or obsolete 19.

Regardless of the size of the company, companies must have tools that allow them to manipulate and move their products from one place to another, optimizing time and ensuring that, during handling, the finished product will maintain the expected characteristics in image and quality 19. Although it is true that for the fulfillment and achievement of business objectives on efficiency and competitiveness, the human factor plays an extremely important role since it largely determines the achievement of the same 19,20, it should not be expected or planned that all activities and their results depend solely on the workers 20.

Warehouse

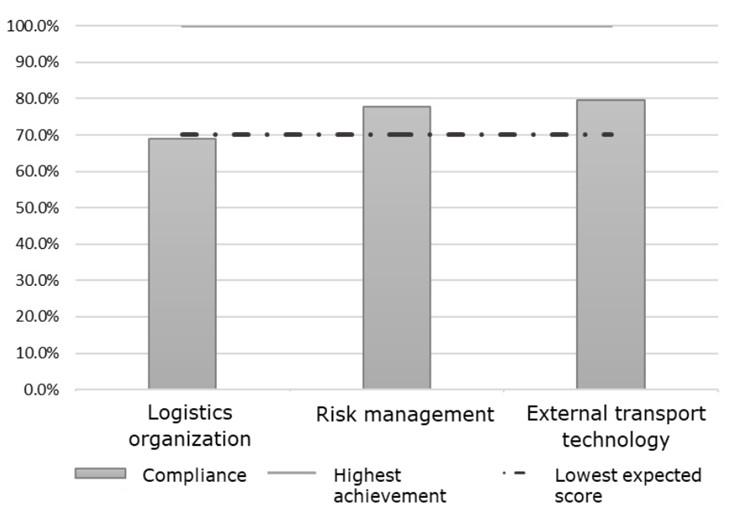

Managing warehouse and inventories is a critical element of any supply chain. The objective is to have the correct product in the right place and at the exact time and in addition to storing the merchandise, protect and preserve it properly within an established time period 21. The situation caused by the pandemic has further increased the importance of having effective warehouse control within companies, from the moment it begins with the acquisition of merchandise and its storage, and ends with the departure of the products to the customer, or to the point of sale 22. Various factors enter this phase that can make the difference between efficient management of the chain and the activity of a company, or the poor drift and unsustainability of a business 16. Figure 4.

The industry today is in a flexible and diverse manufacturing landscape where effective customer service depends largely on the correct logistics setup 2. The storage of raw materials or merchandise, totally or partially manufactured, is an economic factor of great importance 21. As happens in the links described above, in general in the SMEs under study a regular performance is observed in the logistics organization. This result is intertwined with performance in external transportation technology and from there, the constant uncertainty in taking risks.

Latin American companies, and even more so those that are emerging, must understand that logistics management and organization is the basis of business competitiveness 1. This is why, in addition to production costs, other concepts must be considered such as storage costs per unit of raw materials or elements in general that are stored for later use 1,23.

To improve warehouse efficiency, experts advise measuring and calculating locations, internal movements and relocations separately, since these tasks have different needs that vary depending on the type of product the company handles, the type of warehouse, or the way in which the products are converted into output (production, order preparation, dispatch, return, etc.) 9,23. If the needs for locations, internal movements and relocations have been planned, it will be possible to know what human and material resources are required at any given time 6,23.

Distribution and sales

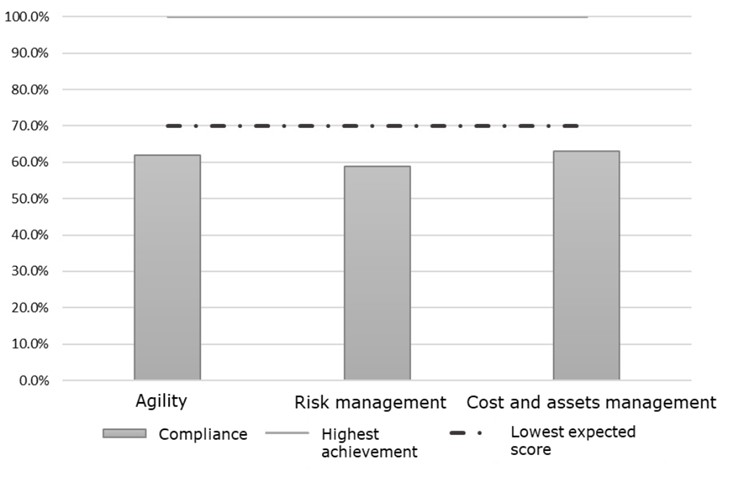

At this stage of the supply chain the product reaches the end customer. The objective, in addition to delivering to the final destination, is that the product reaches the customer in good condition and within the stipulated period (16). During the 2020 pandemic, due to strict confinement, manufacturing and logistics activities were suspended and, consequently, it affected supply and demand due to the restrictions imposed on merchants and retailers 24 Figure 5.

Beyond maintaining an adequate level of inventories, companies must have an efficient distribution and marketing process. This can be possible through agility and fluidity in the flow of information between manufactured products and market demand 25. Distribution becomes a determining factor in the supply chain since, to a large extent, it is what ensures customer loyalty. In the study companies, drawbacks related to risk management and in turn to asset management were observed, mainly due to the lack of tools that support their administrative activities.

The tools to manage distributions and sales found were spreadsheets, notebooks, word processors, among other inadequate options for logistics management. This results in longer delivery times than promised to the customer and, therefore, a decrease in reliability. If companies do not have the necessary material to carry out their activities, they demand longer work times, and quick but expensive solutions, which keeps at risk all the time, and at some point, it could become an unsustainable situation.

Discussion

Rapid changes in the retail environment are driving a structural change within companies that justifies the theoretical understanding of business competitiveness and its direct relationship with the sustainability of these companies 3,26,27. Emerging supply chains face fundamental changes in their environment, including imminent digitalization that helps new businesses adjust quickly and efficiently to market needs 26,28,29.

This study proves, as done in other research, that activities such as supply, production, storage and distribution are parts of a whole, which requires synchronization and integration to function efficiently and provide customers with quality products at affordable prices and in the shortest possible time, which adds value and allows any organization to increase its productivity and market share 5.

Small and medium-sized companies often face a series of challenges in their supply chains, including resource scarcity, due to } limited budget, which can make it difficult to efficiently manage their supply chains; lack of access to suppliers and markets, affecting the efficiency and quality of their chains; lack of flexibility, due to difficulties in adapting to changes in demand or changes in suppliers; lack of strategic planning and logistical control, which results in untimely deliveries and loss of customer loyalty 3,13,30,31.

The company must guarantee training and training programs for all personnel that cover the logistics system, from management, through handling, to the strategic and operational area. In addition, it must determine the main internal and external needs to reduce losses, deterioration, contamination and misplacements, mistakes and confusion that currently occur in the different processes of the company 10.

Conclusions

Supply chains in emerging businesses may face a number of challenges in their supply chains, including resource scarcity, lack of access to suppliers and markets, lack of flexibility, and difficulties in chain planning and control. However, many companies of this size have found creative ways to overcome these challenges and improve efficiency, demonstrating their resilience and adaptability.

The reference models used in the study allow the information to be organized logically and the performance of a company to be evaluated under certain standards for each of the links that make up the supply chain. Each of the instruments used for measurement constitutes a guide to carry out personal interviews with those in charge of each process within the organization. This is how it is possible to identify first-hand how adequately the processes are working and recognize the critical points that decrease productivity and business efficiency.

In the city of Bogotá, and specifically in emerging businesses, medium-low performances evident in the measurement factor corresponding to the logistics organization. This is mainly due to the fact that the process is not differentiated or subordinated to the highest level of management. Thus, the logistics process is not considered at the strategic or tactical level, it is only done at the operational level. From the results of the measurement, it can be concluded that, to guarantee adequate development and correct functioning of the logistics system, it must be planned and considered from the strategic management of the organization how resources will be managed and how business activities will be executed, always seeking to maintain the flows of information, materials, inputs and semi-finished or finished products throughout the chain.

Constant updating and training in technological resources and storage and transportation technologies is also of vital importance, taking into account the current global situation and market demands. Companies, regardless of their size, must guarantee safety and health conditions for their workers because, starting from there, as a side effect, they can increase their compliance in agility, reliability and provide a better response or greater promise of value to their end customer.