1. INTRODUCTION

According to European Environmental Agency [1], plastic-particularly plastic waste-has a significant impact on climate and environment, plastic waste in most cases, was not handled in a sustainable way. In recent past years, plastic waste has been a problem environmentally, in land and water bodies. Negative impact of plastic has resulted to bans or restrictions on usage of one or more types of plastic in various countries/regions.

This research evaluates the compressive strength prediction for plastic as partial replacement of fine aggregate in concrete using artificial neural networks (ANNs) and based on data from previous experimental research. The application of accurate prediction models for green concrete could promote usage and quality control of sustainable building materials. Chandwani et al. [2] study on modeling slump of ready-mix concrete showed that usage of ANN methodology-developed in MATLAB 2011b and trained using Levenberg-Marquardt algorithm-was superior to regression models for problems having various independent variables. Comparative analysis of genetic programming and artificial neural networks (ANNs) techniques-trained using Levenberg-Marquardt algorithm-applied for compressive strength prediction with and without fly ash, indicated that ANN model was most reliable according to Chopra et al. [3]. Al-Swaidani and Khwies [4] research

using ANNs established in MATLAB and trained by Levenberg-Marquardt backpropagation on concrete containing volcanic-scoria as cement replacement, 0 % (control) to 35 %, indicated that ANN models were not only practical for compressive strength prediction but also highly efficient for water permeability prediction and porosity, the model performing better than multi-linear regression. In Revathy et al. [5] study, mean absolute percentage error (MAPE) represented the model performance and root mean square error (RMSE) represented the error between experimental and predicted results, for neural network models generated to predict compressive strength and fresh properties of flowable concrete, using MATLAB. Revathy et al. [5] indicated using 34 data set for training, 8 for validation and 8 for testing, for neural network using BFGS quasi-newton back propagation training algorithm. Sathyan et al. [6] used random kitchen sink algorithm and regularized least square algorithm, the two-application come together in the grand unified regularized least square (GURLS) tool bar in MATLAB, the training data had 32 datasets and to measure model accuracy, 8 test dataset were used, for modeling hardened stages of self-compacting concrete.

According to Chunchu and Putta [7] study, recycled high impact polystyrene could be replaceable up to 30 per cent for natural river sand (by volume) for production of eco-friendly durable and flowable concrete. According to Soboji and Owamah [8], low density polyethylene (LDPE) plastic waste recycling in concrete is environmentally friendly, it should be encouraged. The concept of plastic waste mixing in concrete could be a very environmental friendly method of solid waste disposal in landfills as indicated by Dharmaraj and Iyappan [9]. Waste utilization from rice processing/production for construction could provide alternative sustainable materials, while reducing the burden of solid waste according to Ngandu [10], likewise for re-used/ recycled plastic waste for construction.

The development of accurate models for prediction of concrete incorporated with recycled plastic aggregates could provide a cost-effective tools for specifications, co des of practices, quality control and/or policy guideline. Accurate machine learning tools for modeling concrete with alternative sustainable materials could be less time consuming and more environmentally friendly as compared to experimental trials/mix designs.

Development of predictive model using data from different experimental research dataset could result to a versatile and generalized model with reasonable accuracy of concrete characteristic. This study aims at evaluating prediction of compressive strengths for concrete with plastic- mainly waste/recycled plasticas partial replacement or addition of fine aggregates. The four (4) input variables included water: binder ratio; con trol compressive strength (Mpa); % plastic replacement or additive by weight and plastic type. Plastic type were classified and allocated numerical values. The output variable was the compressive strength for concrete having plastic aggregate as partial replacement or addition of fine aggregate.

1.1 Plastic/ plastic waste properties, applicability and effect

According to Jabtoñska etal. [11], study on Polyethylene terephthalate (PET) bottle washing waste indicated bulk density of 602.3±63.2 kg/m3, specific density of 1.27±0.14 kg/dm3 and CaO-16 % weight, SiO2-10.32 % weight, Al2O3-4.49 % weight and loss of ignition-61.2 % weight. Study by Saikia and Brito [12] recycled PET aggregates including coarse flakes (PETpc), fine fraction (PETpf) and plastic pellets (PETpp) were reported to have 24 hours water absorption of 0.18 %, 0.25 % and 0.1 % respectively, bulk densities of 351 kg/m3 (PETpc), 555 kg/m3 (PETpf) and 827 kg/m3 (PETpp), with fine aggregate indicated 0.2 % of 24 hours water absorption and 1441 kg/ m3 bulk density. Dharmaraj and Iyappan [9] study used low density polyethylene (LDPE), for partial replacement of fine aggregate, that were grinded (or) shredded (or) pulverized, with specific gravity reported at 0.89, while that of fine aggre-gate was indicated at 2.7. Soboji and Owamah [8] indicated specific gravity of 0.92 for LDPE. According to Adejumo and Jibrin [13] study, waste plastics obtained from old/discarded waste plastic tanks in Maitumbi, Nigeria, indicated specific gravity of 2.22, while sand's was reported at 2.63.

Concrete with granulated plastic as partial replacement of sand indicated lower compressive strength after 28 days curing in comparison to the control specimen as indicated by Adejumo and Jibrin [13]. According to Thorneycroft et al. [14], generally, plastics substitution in concrete mix cause reduced compressive and tensile strength due to reduced bond strength between the cement matrix and plastic and also failure due to plastic itself and performance could be improved through chemical treatment of plastic aggregated, the study indicated that the most efficient plastic aggregate should be rough, irregular, sufficiently small but with simi lar grade as sand it replaces. According to Saikia and Brito [12] PET-aggregate incorporated concrete specimen had significantly lower resultant compressive strengths and the tensile strength to compressive strength ratio observed for all specimen having PET-aggregate were higher compared to conventional concrete, hence incorporation of PET- aggregate increases toughness behavior. According to Bolat and Erkus [15] the tendency of decreasing compressive strength by increase of polyvinyl chloride (PVC) ratio as aggregate replacement was attributed to decrease in adhesive strength between PVC surface and cement paste and the hydrophobic nature of PVC, that may resist water necessary for cement hydration from entering the concrete specimen structure during curing. According to Gopi et al. [16] study, compressive strength decreased with increase in % of PET as fine aggregate partial replacement was attributed to increase in porosity of concrete and concrete proper bonding not taking place and the PET incorporated concrete indicated better performance for compressive strength up to 10 % fine aggregate replacement, compared to those partially replaced with polypropylene (PP), attributed to the PET size being near sand gradation. In Gopi et al. [16] study, compressive strength decrease for PP as partial replacement of river sand was attributed to size and shape of PP flakes.

Utilization of waste such as plastic waste as fine aggregate substitution could reduce the demand and negative impacts of sand mining while reducing the quantity of solid waste, while adding value to plastic waste. Reduced slump values of concrete mixes with waste plastic, partial replacement of sand indicated that it can be applied for situations requiring low-degree workability e.g., pre-cast bricks, partition wall panels and so forth, however there was increased workability when superplasticizer was added to waste plastic incorporated concrete in Rai et al. [17] study. Employment of PET discarded plastic bottles in concrete is an efficient promising approach of getting rid of such waste as indicated by Shubbar and Al-Shadeedi [18].

2. MATERIALS AND METHODS

2.1 Review and Dataset

Review dataset from previous experimental studies, for plastic partial replacement or additive of fine aggregate in concrete was used for this study, with 44 datasets from 8 sources, used. Table I shows the data from review, used for the predictive model and the modifications made on the source data. The % plastic replacement or added was based on weight.

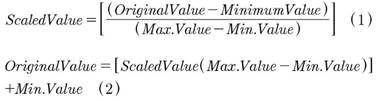

Table I indicates, the compressive strengths used for this study from reviews ranged between 66.8 MPa (adopted from Al-Hadithi, and Alani [19] study) and 14.02 MPa (adopted from Gopi et al. [16]) for the concrete having partial replacement of fine aggregate with plastic and the percentage of plastic replacement or addition were between 0.86 % (adopted/modified from Shubbar and Al-Shadeedi [18] study) to 45.19 % (adopted/modified from Bolat and Erkus [15] study) by weight of fine aggregate. Hasanzade-Inallu et al. [24] used ANNs implemented using MATLAB R2019a, to have different input and output variable to ranges that were similar, each variable was normalized by substraction of its minimum, then divided by its range and the output must be de-normalized by the reverse process. According to Henigal et al. [25], better comparison and avoidance of influence of greater value parameters, data are normalized, with data normalization scaled within the range (0,1), equation (1) is used for normalization the output is de-normalized to actual values according to equation (2).

Ngandu [10] used 51 (70.83 %) training dataset, 10 (13.89 %) validation/checking dataset and 11 (15.28 %) testing dataset. In this study, the overall dataset of 44 was divided into three, including:- 31 No. (70.45 %) datasets are used for training, 6 No. (13.64 %) for validation or checking and 7 No. (15.91 %) for testing.

The Dataset were multi-randomilised, while the average values of variables for overall and the three categories of dataset were checked to ensure that no extremely biased dataset occur.

The four (4) input variables included water: binder ratio; control compressive strength (Mpa); % plastic replacement or additive as fine aggregate by weight and plastic type. Plastic type were classified and allocated numerical values. The output variable was the compressive strength concrete having plastic aggregate as partial replacement or addition of fine aggregate.

2.2 Artificial Neural Network (ANN)

The study used Artificial neural network with four input variables, one output variable and one hidden layer. Various trials were conducted for varying number of nodes in hidden layer, between 1 to 21 and/or varying iterations.

The networks were developed in OCTAVE 5.2.0 a free software according to Eaton et al. [26]. Illustration by Oman [27] on developing a neural network on octave assisted in development of the networks utilized in this study, that adopted the backpropagation algorithm, to train network with a goal of minimizing cost. Tangent activation function were used for both the hidden and the output layer and the learning rate was keep constant at 0.06. Activation function formulas were in accordance to GeeksforGeeks [28] and Gupta [29] (https://www.analyticsvidhya.com).

The RMSE was the main indicator used to evaluate or check the performance of the artificial neural networks trials. Also the absolute factor of variance (R2) was calculated for the ANN models. After training the networks, validation/check dataset was used to indicate how well the particular models had trained, as indicated by normalized RMSEs hence majorly used in determining models to proceed to the test dataset.

The architecture of the network is as shown in Fig. 1, with 3 layers:- input layer with 4 nodes, 1 hidden layer and output layer with 1 node.

2.3 Evaluation of Network(s)

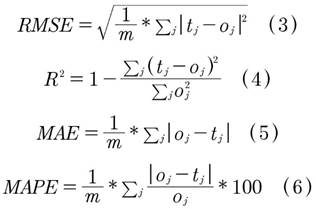

RMSE and R2 were calculated by OCTAVE and, the RMSE used to evaluate/check the performance of models, for normalized data. The RMSE, R2 were also calculated by libreoffice calc spreadsheet. Zhang et al. [30]examined the deviation between predicted and experimental values using RMSE, mean absolute percentage error (MAPE) and absolute factor of variance (R2), the equations (3) and (4). Chandwani et al. [31] used six different statistical performance for evaluation that included mean absolute error (MAE) and mean absolute percentage error (MAPE) as shown in equations (5) and (6). Ngandu [10] used the RMSE, R2, MAPE and MAE for evaluation of model.

Where: o: Experimental Value; t:- Predicted value; m:- total no. in the group

Selection of model was based on the RMSE value. RMSE, R2 , MAE & MAPE were determined for the de-normalised dataset of the selected model.

The percentage differences between the compressive strengths for both experimental and predicted values and control/reference or target strengths (control strength) were calculated based of equation (7). The dataset were clustered based on % plastic replacement or addition as fine aggregates and percentage averages those differences were calculated.

3. RESULTS

The Table II, shows the structure for the selected ANN model, based on the relatively low RMSE exhibited for the three datasets, selected from various networks trials, ranging between 1 to 21 nodes for the hidden layer.

The RMS, R2 MAE and MAPE % values for the selected model is as shown in Table III.

Fig. 2, illustrates the graph for the 44 experimental datasets and the predicted values of compressive strengths.

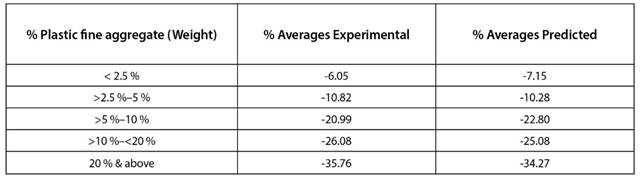

The average percentage differences for compressive strengths of experimental and predicted data, based on the control strength values and clusters of % plastic by weight are shown in Table IV.

4. DISCUSSION

The ANN selected model, with 1 layer, 14 nodes and 320,000 iterations, had RMSE values of 1.786 Mpa, 1.661 MPa, 2.671 MPa and 1.311 MPa for the overall, training, validation/ check and testing datasets respectively. R2 values were 0.997, 0.998, 0.993 and 0.998 for the overall, training, validation/ check and testing datasets respectively. MAE values were 1.329 MPa, 1.302 MPa, 1.814 MPa and 1.033 MPa for the overall, training, validation/check and testing datasets respectively. MAPE values were 4.44 %, 4.35 %, 5.97 % and 3.51 % for the overall, training, validation/check and testing datasets respectively. Revathy et al. [5] reported MAPE values of less than 10 % for compressive strength, slump flow, v-funnel and L-box flow, thus an indication of very good performance. According to Tuntisukrarom and Cheerarot [32] study a high accuracy prediction ANN model, developed in MATLAB software, had acceptable error and reported RMSEs of 3.339 for training and 3.4569 for testing, among other model performance evaluations, for prediction of compressive strength behavior of ground bottom ash concrete. In this study, for the 3 dataset categories and the overall, MAPE values were below 6%, MAE were below 2 MPa, RMSE were less than 3 MPa and R2 were above 0.99. Also, the visual impression of graph, fig. 2, illustrates a good matching similarity between the expe rimental and predicted compressive strengths. Hence, the selected model showned good performance and accuracy in predicting compressive strength of partial replacement or addition of plastic as fine aggregate. Compressive strengths ranges from review data used in this study ranged between 66.8 MPa (adopted from Al-Hadithi and Alani [19] study) and 14.02 MPa (adopted from Gopi et al. [16] study) for the concrete with partial replacement of fine aggregate with plastic, a range of 52.78MPa. With consideration to range of compressive strengths inputs and evaluation values, the ANN model showed versatility and good generalization. Most datasets utilized recycled or waste plastic.

The % average differences for experimental values were -6.05 %, -10.82 %, -20.99 %, -26.08 % and -35.76 % for % plástic replacements or additives of < 2.5 %, >2.5 %-5 %, >5 %-10 %, >10 %-<20 % and > 20 % respectively, from the control strengths, indicating increasing % strength reduc- tion with increasing plastic proportion. For the predicted values, average differences were -7.15 %, -10.28 %, -22.8 %, -25.08 % and -34.27 % for plastic replacements or additives of < 2.5 %, >2.5 %-5 %, >5 %-10 %, >10 %-<20 % and > 20 % respectively, from control values, indicating increasing % strength reduction with increasing plastic proportion. Both experimental and predicted strength % differences from control generally showed that percentage strength reduction with increasing % plastic fine aggregate. According to Rai et al. [17], compressive strengths decreased with waste plastic ratio increase and strength increased by around 5 % after addition of superplasticizer. According to Gopi et al. [16] study, compressive strength decreased with increase in % of PET as fine aggregate partial replacement was attributed to increase in porosity of concrete and concrete proper bonding not taking place and the PET incorporated concrete indicated better performance for compressive strength up to 10 % fine aggregate replacement, compared to those partially replaced with PP, attributed to the PET size being near sand gradation.

5. CONCLUSIONS AND RECOMMENDATIONS

Majority data sources adopted for the study applied recycled or waste plastics as partial replacement or additive of fine aggregate in concrete. The selected model showed good performance and accuracy in prediction of plastic fine aggregate incorporated concrete with overall RMSE, R2, MAE and MAPE values of 1.786 MPa, 0.997, 1.329 MPa and 4.44 %. The errors were reasonably low despite the fact that dataset were gotten from different sources where physical, environmental and technological conditions and techniques are expected to vary, also the largest compressive strength value was more than 4 time of the smallest, from the review. The ANN model, showed versatility and good generalization, with consideration to the range of compressive strength input range. Also, the study indicate that the 4 input variable namely:- water: binder ratio; control compressive strength (Mpa); % plastic replacement or additive as fine aggregate by weight and plastic type, could have significant impact on strength of concrete with partial replacement/addition of plastic as fine aggregates.

Analysis of previous data in this study indicates that as the proportion of plastic increased, there was an increasing % compressive strength reduction from the control. The similar trend occurred for the selected predictive model.

The study recommends: Consideration on application of artificial neural networks (ANNs) models in prediction of green concrete, with partial waste plastic fine aggregate, that could be used extensively for quality control, policy guidelines, code of practice development and also as possible alternative for trial mix design.

Sustainable techniques such as development of low-cost, sustainable superplasticizers from recycled material and cost-effective technologies to adequately size and shape plastic for fine aggregate application should be sort, in an effort to improve compressive strengths of concrete with partial replacement of fine aggregate with plastic.