1. Introduction

Mango (Mangifera indica L.) is an important tropical fruit in terms of production, consumption (attractive aroma and flavor), and nutritional value. It is rich in minerals, carbohydrates, and carotenoids, being in the ranking of the most commercialized fruits in the world [1,2]. Its main world producer is Asia, which accounts for about 74.30% of the global mango production [1].

Brazil is a major producer of mango due to its edaphoclimatic conditions. This fruit is one of the most exported in the country, with a record shipment in 2019: 221,913 thousand tons, meaning an increase of 30% in relation to the volume of the previous year. Although present in several Brazilian states, mango production is more representative in certain regions, the main one being the São Francisco Valley, Pernambuco/Bahia [3].

Despite this importance, growers face a huge challenge with postharvest losses of the fruit, which result from the biochemical processes and physiological deterioration that occur during ripening. These processes reduce moisture content and lead to the appearance of wrinkles and wilting, substantially reducing the commercial value of fruits [4,5].

The use of biodegradable coatings based on polysaccharides, lipids, and proteins arises as an attractive technological alternative to minimize these losses with a view to prolong the shelf life of fruits. This alternative enhances the conservation of fruits and vegetables by reducing gas exchange and water loss between food and the environment, preserving texture and nutritional value and thus improving the commercial aspect [6].

Several studies have used biodegradable coatings to improve the postharvest quality of mangoes. For example, [7] observed the maintenance of mango quality after coating with chitosan. In addition, [4] evaluated the effect of edible coatings based on cassava starch and chitosan on the postharvest life of ‘Tommy Atkins’ mango. The authors observed an increase of 3 days in shelf life and lower respiratory rates.

In this context, this study evaluates the effect of a low-cost biodegradable coating formulated with potato starch, rice starch, cassava starch, and gelatin on the postharvest quality of ‘Tommy Atkins’ mango for export.

2. Materials and methods

Tommy Atkins’ mangoes were harvested at maturation stage 2 and selected according to the uniformity of color, size, and the absence of mechanical and physiological injuries. These fruits were grown in an orchard belonging to the company Special Fruit - Importação e Exportação LTDA, in Petrolina city, Pernambuco State, Brazil. Potato and rice starch were provided by the company Agrícola Horizonte LTDA. Cassava starch (brand Amafil) was purchased commercially. Type A gelatin and sorbitol were purchased from the company Ingredientes-online.

To prepare the 5% gelatin coating (5% GEL), 5 g of gelatin was hydrated in 100 mL of distilled water for 1 hour, and then heated to 85 °C for 10 minutes. To maximize the plasticization of coatings, sorbitol was added at 5% the gelatin mass (0.25 g). The solution was subjected to magnetic stirring until complete homogenization, and then reserved.

To prepare the suspensions made of potato starch - POT, rice starch - RIC, and cassava starch - CAS, 3 g of each was added to 100 mL of distilled water and sorbitol at 10% the starch mass (0.3 g). The suspensions were then heated to 85 °C in a water bath for different times (5 minutes for CAS, 3 minutes for POT and RIC).

The reserved gelatin solution was added separately to each starch suspension, forming three different coatings: 5% GEL/CAS; 5% GEL/POT; and 5% GEL/RIC. Afterwards, the same methodology was used to obtain coatings containing 10% gelatin (10% GEL) combined with potato, rice, and cassava starch. The only difference was the amount of gelatin used (10 g), with a proportional amount of sorbitol. The following coatings were thus obtained: 10% GEL/CAS; 10% GEL/POT; and 10% GEL/RIC. This methodology was used by [8].

The experiment was conducted at the Agricultural Products Storage Laboratory of the Federal University of Vale do São Francisco in Juazeiro city, Bahia State, Brazil. The fruits were sanitized in a hypochlorite solution (0.01%) for 15 minutes and placed at room temperature until complete drying. The coatings were applied by immersion, in which the fruit was immersed for one minute in the coating solution, staying at room temperature until complete drying. For the control treatment, the fruit was immersed in distilled water for 1 minute. Rigid polystyrene trays were used as packaging materials in which the fruits were stored under ambient conditions (25 ± 3 ºC and 65 ± 5% RH), in a laboratory bench, for 10 days. Four fruits per treatment were randomly sampled every two days [9].

Firmness analysis (N) included the use of a digital penetrometer (Instrutherm PTR-300). Whole mangoes were perforated in the median region and on both sides of each fruit using a uniform force with a 6 mm tip. The result was obtained and expressed in Newtons (N). Weight loss (%) was quantified by a semianalytical balance (BEL Engineering) with a minimum capacity of 0.5 g and a maximum of 5200 g.

Total soluble solids (TSS) was obtained through direct reading on a digital refractometer (Hanna Instruments, model HI 96804), with a scale in degrees Brix, according to the methodology of the Adolfo Lutz Institute [10]. Total titratable acidity (TTA) was analyzed using the acidimetric method, also according to the methodology of the Adolfo Lutz Institute [10]. The TSS/TTA ratio was calculated by the ratio between TSS and TTA [10].

Delta absorbance (DA) index was obtained using a portable spectrophotometer (DA-meter®, Turoni, Italy). It was estimated by the difference between the absorbance values measured at 670 and 720 nm [11], in both sides of each fruit in the sample. Colorimetry analysis considered color parameters in mango peel and pulp, determined using the Konica Minolta CR-400® colorimeter-spectrophotometer with the CIELAB color system, obtaining L*, a*, and *b values. Ascorbic acid content was determined by titration with Tillman’s reagent according to the methodology described in [10].

The experimental design was completely randomized, arranged in a 7x6 factorial scheme with four replications per treatment. The first factor corresponds to coatings (control - without coating; 5% GEL/CAS; 5% GEL/POT; 5% GEL/RIC; 10% GEL/CAS; 10% GEL/POT; and 10% GEL/RIC). The second factor corresponds to storage time (0, 2, 4, 6, 8, and 10 days), with analysis every two days. The data were subjected to analysis of variance (ANOVA) using the Tukey test at 5% probability with the aid of the statistical program ASSISTAT 7.7 [12]. In case of significant difference, the data were subjected to regression analysis through the SigmaPlot 10.0 program.

3. Results and discussion

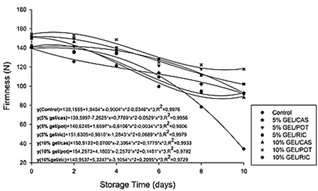

Analysis of variance showed a significant difference (p ≤ 0.05) between the coatings used and the total storage period, for all analyzed variables. Firmness decreased for all treatments, especially for the control Fig. 1. Changes in fruit firmness, and consequently in fruit texture, usually correlate with starch hydrolysis in sugar and the degradation of pectin in the cell wall during ripening [7]. Fruits coated with 10% GEL/POT remained with about 76.24% of their firmness at the end of the 10 days of storage, making it the most efficient treatment Fig. 1.

Source: The authors.

Figure 1 Firmness (N) of 'Tommy Atkins' mangoes with different types of coatings, stored under ambient conditions (25 ± 3 ºC and 65 ± 5% RH), in a period of 10 days of storage.

All treatments showed an increasing weight loss Fig. 2, corroborating with the study by [4]. However, the coatings were efficient in reducing weight loss. Fruits coated with 5% GEL/CAS and 5% GEL/POT better maintained their mass Fig. 2.

Source: The authors.

Figure 2 Weight loss (%) of 'Tommy Atkins' mangoes with different types of coatings, stored under ambient conditions (25 ± 3 ºC and 65 ± 5% RH), in a period of 10 days of storage.

Total soluble solids (TSS) increased for all treatments Fig. 3, corroborating with [13]. In that study, ‘Palmer’ mangoes had an increase in TSS during storage in all treatments, demonstrating that the ripening process was not totally interrupted by the coatings. The treatment with 10% GEL/RIC was more efficient in delaying the evolution of TSS, with average values of 6.60 °Brix at the end of storage.

Source: The authors.

Figure 3 Total soluble solids (°Brix) of 'Tommy Atkins' mangoes with different types of coatings, stored under ambient conditions (25 ± 3 ºC and 65 ± 5% RH), in a period of 10 days of storage.

Total titratable acidity (TTA) decreased for all treatments Fig. 4A, with uncoated fruits showing the greatest reduction, around 71.43%. Fruits with 10% GEL/RIC showed greater acidity, with an average concentration of 0.75 g.100-1 at the end of storage, showing a small increase of 0.06 g.100-1 between the sixth and eighth day of storage, as observed by [13]. The TSS/TTA ratio was higher for the control treatment Fig. 4B, also corroborating with the aforementioned author.

Source: The authors.

Figure 4. (A) Total titratable acidity (TTA) and (B) TSS/TTA ratio of 'Tommy Atkins' mangoes with different types of coatings, stored under ambient conditions (25 ± 3 ºC and 65 ± 5% RH), in a period of 10 days of storage.

Ascorbic acid content decreased for all treatments. Notwithstanding, the decrease was smaller for coated fruits, mainly for those coated with rice starch. For 5% GEL/RIC, the loss was 3.94%; for 10% GEL/RIC, 2.95%. Thus, the loss was lower for the composition with higher gelatin content Fig. 5.

Source: The authors.

Figure 5 Ascorbic acid of 'Tommy Atkins' mangoes with different types of coatings, stored under ambient cnditions (25 ± 3 ºC and 65 ± 5% RH), in a period of 10 days of storage.

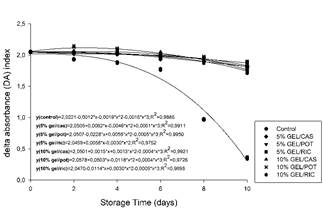

The delta absorbance (DA) index tends to decrease with advancing maturation, possibly due to the reduction in green color resulting from chlorophyll degradation [11]. The control treatment had the greatest reduction in DA index during storage, indicating fruit ripening and change in peel color Fig. 6. Among the coatings, 10% GEL/RIC promoted a greater change in fruit color, which may reflect chlorophyll degradation [14].

The color of fruit peel changed during storage. The control showed a reduction in green color Fig. 7, with an increase in a* value due to chlorophyll degradation and carotenoid synthesis during ripening [15]. Coated fruits showed the opposite behavior, with an increase in green color possibly due to the influence of coating on the mango metabolism, causing anthocyanin degradation and maintaining chlorophyll content [16].

Furthermore, yellow-orange tones and brightness increased for all treatments, given the increase in b* Fig. 8A and L* Fig. 8B values, respectively. Gelatin contributed to the increase in brightness. Therefore, on the second day of storage, the fruits had greater brightness than the control Fig. 8B, which corroborates with [8]. However, as the L* brightness also correlates with increased fruit brightness, the control showed a substantial increase in carotenoid content between the eighth and tenth day, making fruit peel more yellow and with lighter tones [17].

Source: The authors.

Figure 6 Delta absorbance (DA) index of 'Tommy Atkins' mangoes with different types of coatings, stored under ambient conditions (25 ± 3 ºC and 65 ± 5% RH), in a period of 10 days of storage.

Source: The authors.

Figure 7 Color peel a* of 'Tommy Atkins' mangoes with different types of coatings, stored under ambient conditions (25 ± 3 ºC and 65 ± 5% RH), in a period of 10 days of storage.

Source: The authors

Figure 8. (A) Color peel b*, (B) brightness L* of 'Tommy Atkins' mangoes with different types of coatings, stored under ambient conditions (25 ± 3 ºC and 65 ± 5% RH), in a period of 10 days of storage.

Fruit pulp became more orange-red as a result of storage for all treatments, given the increase in a* value Fig. 9A. This corroborates with the study by [18]. The b* value also increased for all treatments Fig. 9B, as observed by the aforementioned authors. The coatings increased pulp brightness Fig. 9C, mainly 5% GEL/POT and 5% GEL/RIC. This effect may be related to the higher water content retained in the pulp, improving the reflection of the light incident [17].

4. Conclusion

The application of biodegradable coatings did not extend the shelf life of ‘Tommy Atkins’ mango during storage days. Notwithstanding, the treatment preserved fruit mass and firmness, delayed ripening by reducing total soluble solids, delayed the decrease in total titratable acidity, decreased chlorophyll degradation in the peel, and increased pulp and peel brightness.