Introduction

Tanning is the process by which animal hides are converted into leather 1,2, offering flexibility and immunity to bacterial attack as its main characteristics 3. Currently, the conventional tanning process uses chromium as the main input, accounting for 85-90% of leather manufacturing in terms of use 4,5,6. This implementation is due to its efficiency, versatility, availability and relatively inexpensive price 7 and, consequently, makes it one of the main pollutants of the tanning industry, causing considerable deterioration of ecosystems and human health 3,8. For this reason, there is a market trend towards the substitution of chromium by more environmentally acceptable products 9,10. As an alternative, vegetable tanning is a process derived from obtaining tannins from plants, leaves, wood, bark, branches, seeds, roots or fruits 10,11,12. This option provides less environmental pollution by generating biodegradable residues that can be used in the production of fertilizers 13, and offers the leather greater stability in molding properties, tear resistance, air permeability and strength 9. Tannins can be extracted with different solvents such as water, ethanol, acetone and methanol, or mixtures of them in different proportions, with water being the most economical solvent 14.

Taking into account these investigations, the mango seed (Manpngera indica L.) is the object of study as a tannin carrier, which can potentially be applied in the tanning process 7. It should be noted that mango is the second most traded tropical fruit worldwide and the fifth in terms of production 15. In Colombia, this tropical fruit species originating from India is considered one of the main agricultural products of the Magdalena Medio and Santander regions due to its adaptability 16. However, the residues associated with this crop are mainly the peels and seeds, which constitute 20% to 60% of the total mass of the fruit 15, for this reason, several researchers proceed to give it an added value and a sustainable use for tanning and extraction of tannins 7, this because it has been shown that the mango seed is a good source of polyphenols 15,16,17, an essential source for vegetable tanning. Therefore, solvent extraction is the technique commonly used to obtain polyphenolic extracts. The most commonly used solvents include methanol, ethanol, acetone, ethyl acetate, dichloromethane, hexane, isopropanol, and acetonitrile 18; however, mixtures of ethanol or acetone with water (between 50% and 99.5%) are the most commonly used extracts for mango seed 17.

On the other hand, sheep production in the country has traditionally been marginal and artisanal in nature, with regionalized production where consumption is of a cultural nature 19, developing mainly artisanal products and informal marketing 20, in which meat production stands out, being part of the subsistence of families in rural areas 20,21. The main sheep breeds are the Katahdin, Santa Inés, Pelibuey, Dorset, Dorper, and Hampshire, which are used for having better productive yields compared to the native animals 22. Although sheep production is growing, there are still several challenges to overcome, such as poor management by producers, the level of training of many sheep breeders, low investment in research, development of new products and lack of adequate training, together with scarce and inadequate infrastructure for slaughter 19. This situation results in a deficient technological level in terms of handling the conservation and storage of skins 21.

Having said this, the importance of sheep in the agroindustrial sector can be determined for a potential application in the tannery industries, since these are in charge of treating animal skins 23, to avoid its putrefaction. In addition, several studies indicate that sheep hides can be used for the manufacture of gloves, shoes, bags and carpets 24,25,26; however, it is evident that the use of chromium salts in this industry has significant environmental consequences 12, especially because of the large volumes of water with organic and chemical waste that are discharged into bodies of water 6.

Therefore, in this research, the extraction and quantification of tannins present in the seed of the mango (Manpngera indica L.) was carried out to later use it as a potential tanning agent in the skin of sheep of the Santa Inés breed, in order to generate sustainable alternatives of use and generation of added value to the by-products and agricultural residues of the territory of Magdalena Medio Santandereano.

Methodology

Environmental Conditions and Project Location

This research on the extraction and quantification of tannin was carried out at the Science Laboratory of the Santa Lucía Research Center of the Instituto Universitario de la Paz - UNIPAZ, located 14 km from Barrancabermeja, Colombia. The tanning process of sheep skin was carried out in the Academic Unit Agroindustrial Plants located in the Santa Barbara neighborhood in Barrancabermeja, Colombia, with environmental conditions of 86 meters above sea level, temperature of 32°C and relative humidity of 82%.

Raw Materials and Reagents

86 mangoes (Manpngera indica L. ) (equivalent to 13.000 grams) were collected wild in the village El Llanito, belonging to the district of Barrancabermeja, as the main source of vegetable tannins. As tanning material, two sheep skins of the breed Santa Inés (Ovis aries) were acquired from the Finca El Quinal, located in the village El Veintisiete of the municipality of Carmen del Chucurí (Colombia). Analytical grade ethanol (70%) was used as a solvent for the extraction of vegetable tannins, using gallic acid as a standard for quantification. In the tanning process, sodium chloride (NaCl) was used with a purity of 99%, 98% sulfuric acid, formaldehyde (3%) and castor oil, all of them analytical grade.

Pre-treatment

Mango fruits were selected at maturity, and then the fruit was pulped manually in order to release the whole kernel, which was free of defects and visible fungi. A total of 86 seeds were taken with a total weight of 2.150 grams, which were then selected and dried in a Memmert oven reference UN55 at 50°C for 48 hours until a moisture content of 11,53% was achieved 16. Afterwards, the dry seeds were milled in a Trapp grinder, reference JTRF400, obtaining a flour with a particle size of approximately 1 mm using a 20 mesh sieve.

Extraction of Plant Tannins

For the extraction of vegetable tannins present in the mango seed, the methodology described by Paz-Díaz et al. 2, Basantes Basantes et al. 3 and Palencia-Blanco et al. 27 with some modifications was used. Thirty grams of mango kernel flour were weighed and diluted in 150 mL of extractant solution varying the volume 70% Ethanol/30% water and 50% Ethanol/50% water, performing three 3 replicates for each experiment. Subsequently, the solutions were left in constant agitation for 15 minutes at 60°C, then at rest and in the absence of light for 4 days. Afterwards, the supernatant liquid obtained was removed and filtered under vacuum with Whatman No. 40 paper in order to purify the sample. Finally, the solutions were rotoevaporated in an IKA RV 10 rotoevaporator at a pressure of 175 mbar, 100 rpm and a temperature of 60°C for 20 minutes in order to separate the solvents (ethanol-water) and obtain the tannin extract, which was stored at 4°C.

Qualitative analysis of Plant Tannins

Two drops of 5% ferric chloride solution were added to 1 mL of the extracted sample and allowed to stand for 5 min. Then, drops of the extracted samples were applied on a cotton, and a reading was taken by means of the formation of dark green, as investigated by several authors 7,12,28.

Quantitative Analysis of Plant Tannins

The total polyphenol content was quantified according to the methodology described by Palencia-Blanco et al. 27 and Priscila et al. 29. In summary, the concentration was obtained by means of the UV-Vis spectrophotometry technique, in which the extracts were diluted 1:10 and direct reading of absorbance at 280 nm was performed, using distilled water as blank. A calibration curve was constructed using gallic acid, 0,25; 0,5; 2; 4 and 5 ml was prepared in a 10 ml volumetric balloon and was volumetrized with distilled water to obtain concentrations of 0, 5, 10, 20 and 40 ppm. Finally, the total tannin content was determined in relation to the calibration curve obtained and expressed as mg gallic acid equivalents per g of sample (mg GAE/g). The UV-Vis spectra and quantitative measurements were recorded in a Thermo Scientific Genesys 10 S UV/Vis Spectrophotometer.

Ovine Tanning Process

In the preparation of the skin for tanning, two raw skins with an average length of 1,3 meters long and a width of 1,1 meters, previously washed and fleshed, were used. Each skin was independently immersed in 3 L of 2% NaCl solution, in order to dissolve some globular proteins and avoid subsequent swelling. Then, the skins were rinsed with water and the fat was manually removed. Each skin was then added in a solution of 3 L of water with 1 mL of 10% sulfuric acid H2SO4 (%w/v) and remained at rest for 60 minutes in order to break the collagen fibers to subsequently add 10 mL of formaldehyde to 3% and fix the hair on the skin. After this time, the skins were rinsed with plenty of water to remove the acid and formaldehyde, and the epidermis was removed from the skin 2,30. For tanning, the skins were immersed in 3 L of tannin solution (20 mL of tannin extract in 1 L of water, corresponding to the mL of tannin extract from the extraction of the 50/50 and 70/30 %v/v concentrations) for 3 days, shaking twice a day for greater fixation of the tannin in the skin. The tanned skin was introduced in a solution with proportions of 90% water and 10% castor oil, with a mixture of 50 g of detergent per liter of prepared solution. Fatliquoring is done by massaging the oil solution mixture until it is completely absorbed by the surface of the skin and the fleshing side. Finally, the tanned skins are left in the shade to remove moisture from the skin and allow the tanning agent to bind further into the collagen fibers 2,27.

Evaluation of Physical-Mechanical Properties

Tensile strength, tear strength and elongation percentage were determined using a Muver Model 5053-5 dynamometer, where the maximum force reached until breakage was recorded (NTC-ISO 3376:2007; NTC-ISO 3377-2:2006). A GESTER GT-KC37A lastometer was used to measure of distension and strength of grain by the ball burst test. Finally, the shrinkage temperature was determined using a Binder KBF-S-115 climatic chamber. The values of the physical-mechanical properties were evaluated in both directions, longitudinal (parallel to the backbone) and transverse (perpendicular to the backbone) of the Santa Inés breed sheepskin (NTC 1042:1998; NTC 4683:1999). These parameters were used to evaluate the leather's capacity to resist the multidirectional stresses to which it is subjected in its practical uses 31.

Statistical Analysis

All measurements were performed in triplicate and the data were expressed as means ± standard deviations. ANOVA analysis and Tukey's test were applied for the optimum tannin concentration and analysis of the physical-mechanical tests of the tanned leather, in order to determine the significance of the results. The statistical study was carried out with TIBCO Statistica 13,5 Desktop Version 1,35 software.

Results and Discussion

Qualitative Analysis of Tannins

In the extraction process, ethanol was used as a solvent for the extraction and concentration of tannins. The studies showed that the two concentrations of ethanol (70% ethanol/30% water and 50% ethanol/50% water) are ideal for the extraction of tannins, giving a dark green coloration in the precipitate of the solution with mango kernel 7, which suggest the presence of condensed tannins, as well as Maryati et al. 12 and Sánchez-García et al. 32 that indicate that the addition of ferric chloride makes the tannin form complex compounds with Fe+3 ions. Similar results were obtained by Paz-Díaz et al. 2, who compared the solvents acetone, ethanol and methanol for the extraction of tannins from the fruit of the Piñón de Oreja tree; this research found that ethanol has a greater capacity to extract tannins in parts of plant material. The qualitative results of these investigations demonstrated the applicability of these plant material for use in leather tanning 28. In addition, according to the authors, for the tanning process to be effective, a pH range of 4 to 6 is necessary, which agrees with the present study 33. It should be noted that the temperature of the tannin extraction method in this research was 60°C in order to guarantee a higher extraction yield in the process and to avoid the degradation of the phenolic compounds that are important. This is in agreement with the work of Aguilar-López et al. 34 and Shirmohammadli et al. 35, who argue that the ideal temperature range during optimal extraction methods is between 50 and 60°C, since, at temperatures above these, tannins tend to degrade.

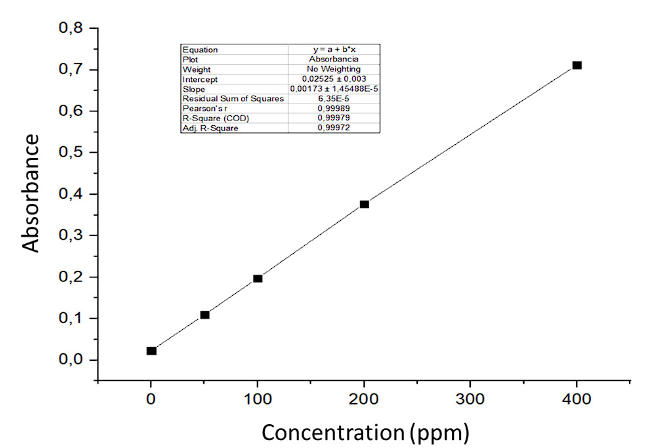

Quantification of Tannins

Figure 1 shows the calibration curve for gallic acid obtained from the UV-VIS spectrometer with a correlation coefficient equal to R2= 0,9998. From this calibration curve, three samples were obtained for each of the tannin concentrations, yielding an average of 110,1±4,5 (50/50) and 105,5±3,7 (70/30), where significant differences (Tukey's test p<0,05) were observed between the two treatments.

The results of quantification of phenolic compounds expressed in gallic acid show that the highest concentration in the extraction of tannins in the mango kernel occurs with the 50/50 ethanol/water solution with an average result of 110,1 mg GAE/g, this indicates that the sample with a greater amount of water extracts a higher value in polyphenols, besides ethanol extracts a great variety of phenolic compounds that are more soluble in this water-ethanol mixture 36.

Research carried out by Doris et al. 7, Mwaurah et al. 15, and Salazar-Beleño et al. 16 report concentrations present in mango seed in the range of 18,1 to 200,3 mg AGE/g, being similar to that obtained in this work with concentrations of 110,1 with solvent Ethanol/Water 50%/50%. These values are higher in terms of polyphenol content investigated by Correa et al. 37, where they quantified tannins from mango seed resulting in 19,2 mg EAG/g by means of methanol solvent, it should be noted that these differences in phenolic content are possibly due to the type of crop, geographical location and extraction methods applied 38.

Determination of Tensile Strength and Elongation Percentage

Table 1 shows significant statistical differences (p<0,05) in the values determined for tensile strength in sheep hides depending on the cutting mode. For these treatments, the tanning concentrations 50/50 vs 70/30 (% v/v) were evaluated, being the values for the parallel direction cut of 12,7 MPa and 11,3 MPa and for the perpendicular direction cut the values of 7,3 MPa and 10,5 MPa, respectively. These differences in tensile strength in the parallel and perpendicular shear types may be due to the fact that sheep skin has a lower content of collagen fibers and, therefore, tends to be less thick in the bending areas, such as the belly and neck 21.

Table 1 Tensile strength and percentage of elongation with vegetable tanning

| Cutting direction | Concentration | Traction (MPa) | Elongation (%) at 100 N load | Elongation at break (%) |

|---|---|---|---|---|

| (% v/v) | ||||

| Parallel | 50%-50% | 12,7 ± 0,3a | 3,2 ± 0,4a | 11,7 ± 0,5a |

| 70%-30% | 11,3 ± 0,2b | 6,0 ± 0,3b | 17,7 ± 1,1b | |

| Perpendicular | 50%-50% | 7,3 ± 0,5a | 5,7 ± 0,9a | 45,6 ± 4,1a |

| 70%-30% | 10,5 ± 0,8b | 5,9 ± 0,6a | 35,2 ± 6,5a |

a,b Different letters indicate statistically significant differences in the Tukey test, p < 0,05

These results are similar to those found by Mojo-Quisani et al. 31, who report that the tensile values in sheep leather are between 5,5 MPa and 10,2 MPa, so that the results obtained in the present investigation significantly surpass the results obtained in previous investigations, which demonstrates a considerable advance in the field of vegetable tanning. On the other hand, it is evidenced that the elongation at break of the tanned hides with tannins (50/50) in parallel and perpendicular cut was 11,7 and 45,6 %, respectively, while the hides tanned in concentration of 70/30 show values of 17,7 and 35,2 %, these results according to the international standard UNE-EN ISO 3376 (UNE-EN ISO, 2021), considers that an optimum value of elongation at break is in the range of 35% to 80%, Under this standard it was found that tanned hides with tannins (50/50) and (70/30) are within the permissible limits of the standard, being considered of good quality, but nevertheless the parallel cuts are below the permitted range, indicating that tanned hides outside these values tend to be rigid at the time of use, needing to have certain elasticity and characteristics for their confection 27.

Determination of Tear Resistance

The tear resistance of leather refers to the amount of force (measured in Newton, N) required to make a cut in a leather sample in a specific direction (NTC-ISO 3377-2:2006). The evaluated results are shown in Table 2, where the impact of the two concentrations of vegetable tannin tanning agent on sheepskin is observed, according to the specifications of the international tear strength standard UNE-EN ISO 3377-2 (UNE-EN ISO, 2016a). In this case, sheepskin tanned hides with vegetable tannins exhibit an average tearing strength of 57,9 N (50/50), while those tanned hides with a concentration of 70/30 show an average tearing strength of 41,9 N. The values obtained here far exceed the quality standards established by the international standard UNE-EN ISO 3377-2 (UNE-EN ISO, 2016a) which correspond to 30 N.

Table 2 Tear resistance in Vegetable Tannin Tanning

| Concentration (%) | Cutting direction | Thickness (mm) | Tear (N) | Average tear (N) |

|---|---|---|---|---|

| 50%-50% | Parallel | 1,3 ± 0,10a | 44,9 ± 3,6a | 57,9 |

| Perpendicular | 1,2 ± 0,02a | 71,1 ± 7,3a | ||

| 70%-30% | Parallel | 1,2 ± 0,08a | 28,1 ± 2,7b | 41,9 |

| Perpendicular | 1,8 ± 0,15b | 55,7 ± 6,1a |

a,b Different letters indicate statistically significant differences in the Tukey test, p < 0,05

According to this standard, the leathers obtained with these values have a strongly constituted fibrillar structure, which makes them highly resistant to fracture, since their strength exceeds the minimum value. This indicates that these leathers are suitable for use as shoe linings, meeting the minimum requirements for tear resistance established in the standard 35,39. On the other hand, Oliveira et al. 21, argue that sheep hides intended for chamois leather should meet a minimum tear strength requirement of 15 N. Likewise, Negussie et al. 40 report maximum tensile strength values of 30,4 N in chrome-tanned sheepskins. These research results indicate that sheepskin hides of the Santa Inés breed treated with tannins extracted from mango kernels (Manpngera indica), exhibit outstanding characteristics that make them ideal for application in various leather industries.

Measurement of Distension and Strength of Grain by the Ball Burst Test.

Table 3 shows the results obtained in the ball burst test, which was carried out to evaluate the distension and strength of the grain layer in tannin-treated hides. The analyses performed indicated that no significant differences were observed between samples (p> 0,05). It was observed that the average final distension using vegetable tannins was 13,2 mm (50/50) and 10,6 mm (70/30), while the grain layer strength values showed final breakage results of 37,4 daN (50/50) and 48,3 daN (70/30).

Table 3 Distension and strength of grain by the ball burst test on tannin-tanned leather

| Concentration | Initial | Final | |||

|---|---|---|---|---|---|

| (%) | Test tube | Tear (daN) | Distension (mm) | Tear (daN) | Distension (mm) |

| 50%-50% | 1 | 14,4 | 8,7 | 44,9 | 13,6 |

| 2 | 11,6 | 7,5 | 32,6 | 13,2 | |

| 3 | 19,3 | 9,4 | 34,9 | 12,9 | |

| Average (mm) | 15,0 ± 3,9a | 8,5 ± 1a | 37,4 ± 6,5a | 13,2 ± 0,3a | |

| 70%-30% | 1 | 32,6 | 8,2 | 44,6 | 9,5 |

| 2 | 34,1 | 8,4 | 43,7 | 9,7 | |

| 3 | 24,7 | 8,2 | 56,8 | 13 | |

| Average (mm) | 30,4 ± 5,1b | 8,2 ± 0,1a | 48,3 ± 7,3a | 10,6 ± 1,9a | |

a,b Different letters indicate statistically significant differences in the Tukey test, p < 0,05

These results are similar to those obtained by Basantes Basantes et al. 3, who tanned goat skins with aqueous extracts of Tara espinosa (Caesalpinia spinosa), obtaining a distension of 10,2 mm. When comparing the distension and resistance of the grain layer in the ball burst test on hides with the two types of tanning, it was found that both meet the criteria of the international technical standard UNE-EN ISO 3379 (UNE-EN ISO, 2016b), which requires a minimum of 7,5 mm to be considered as friction-resistant hides. Consequently, it can be inferred that sheep leather tanned with vegetable tannins complies with this requirement. Furthermore, these findings provide relevant information on the mechanical properties of tannin-treated hides, which is of great interest to the leather industry, as it contributes to improving the quality and applications of these livestock raw materials.

According to Palencia-Blanco et al. 27, it is relevant to consider that the resistance of the grain layer implies applying force in a central point of the leather, which increases the stress in that area until it breaks. The greater physical-mechanical characteristic, the greater the leather's capacity to resist bacterial attacks, inadequate conservation, inappropriate oiling and excessive stretching. Consequently, greater resistance in this property is essential to guarantee the durability and quality of the leather.

Determination of Leather Shrinkage Temperature

Table 4 shows the results obtained in the shrinkage temperature test for tannin-tanned hides. The analyses indicated that no significant differences were observed among the samples (p>0,05). That is, tannin-treated hides did not show statistically significant variations in terms of its shrinkage temperature.

Table 4 Contraction Temperature of Leather in Tannin Tanning.

| Concentration | Test tube | Water volume (mL) | Shrinkage temperature (°C) |

|---|---|---|---|

| (%) | |||

| 50%-50% | 1 | 350 | 62 |

| 2 | 350 | 62 | |

| 3 | 350 | 59 | |

| Average | 61 ± 1,7a | ||

| 70%-30% | 1 | 350 | 60 |

| 2 | 350 | 60 | |

| 3 | 350 | 59 | |

| Average | 60 ± 0,6a | ||

a,b Different letters indicate statistically significant differences in the Tukey test, p < 0,05

It is worth mentioning that the shrinkage temperature is that at which a perceptible shrinkage occurs when gradually heating a leather submerged in an aqueous medium; therefore, it is recommended that the leather supports a higher shrinkage temperature because it measures the thermal stability of the fibrillar structure of the leather 41. In the tanning process, the thermal stability test is one of the most important aspects to guarantee the quality and durability of the leather over time. During this research, the leather tanned with tannins extracted from mango kernel obtained an average shrinkage temperature of 60°C, which is lower than the standard limit (75°C) for the manufacture of leather products according to the international standard UNE-EN ISO 3380 (UNE-EN ISO, 2016c). This indicates that the crosslinking reaction between the leather (collagen fibers) and tannins (seed) was weak, implying that the leather would not be as durable over time 42, a higher resistance to shrinkage temperature will mean a better degree of stabilization and resistance to degradation. However, the results suggest that the shrinkage temperature of the leather may vary according to the tanning method used and the orientation index of the collagen fibrils. According to Nasr et al. 43, in the vegetable tanning process, the shrinkage temperature is below 70°C, although some incidences may occur in the pickling process, presenting a high shrinkage when subjected to the boiling water test 44.

Conclusions

The extraction of mango seed tannins (Manpngera indica) was achieved with qualitative results that reported the presence of condensed tannins in the extracts. For the extractions carried out with the concentrations of solvents (ethanol-water), it was found that the 50%/50% ratio gave the best results. The study considered the use of ethanol as solvent for the tanning extract due to its low cost, its compatibility with the principles of green chemistry and its ease of use.

It was observed that the extraction of tannins from mango seed could be a sustainable alternative for vegetable tanning in the leather of smaller species such as goats. Regarding the international standards (UNE-EN ISO) for leather quality, favorable results were obtained in the final physico-mechanical tests such as tensile strength, elongation percentage, tear resistance, distension, and rupture. These are essential to determine functionality in Santa Inés sheepskin (Ovis aries). However, the shrinkage temperature was not as favorable, falling below 70°C, highlighting an aspect to improve in operational processes like pickling.