Introduction

Sorghum [Sorghum bicolor (L.) Moench] is one of the important cereal crops in the semi-arid tropics globally for providing human food, animal feed and raw materials for industrial use. In the present context of global climate change the crop is likely to become more important due to its adaptability to high temperature, water scarcity and saline conditions (Sanchez et al. 2002; Brouk and Bean 2011). Its tolerance of drought and saline conditions makes sorghum a valuable feed resource for growing on saline soils in arid and semi-arid regions (Fahmy et al. 2010).

India contributes 16% of global sorghum production and traditionally sorghum is grown both as fodder and grain crops in all states of India, with 3 southern states (Maharashtra, Karnataka and Andhra Pradesh) accounting for nearly 75% of sorghum's cultivable area and 85% of total sorghum production. It is grown as green fodder in the rainy season (July to mid-October, Kharif season) and later for grain as a food-feed crop.

Apart from producing grain as food for humans plus non-ruminant and ruminant livestock, sorghum residue (stover) is an important source of dry roughage for ruminants in the tropics, including India. The nutritive value of sorghum stover in terms of protein, energy and digestibility is low and stover is unable to provide a maintenance diet for ruminants. In view of the growing importance of crop residues for livestock feed, improving the nutritive value of sorghum stover is an important object-tive in the tropics (Rattunde et al. 2001). Blümmel and Reddy (2006) reported substantial variation in the fodder value of sorghum stovers and supported the concept of genetic enhancement to improve dual-purpose sorghum cultivars. Genetic variability in sorghum for various nutritional traits has been reported (Youngquist et al. 1990; Singh et al. 2014). There is a paucity of systematic information on nutritive value of improved forage sorghums for ranking of forage cultivars (Akabari and Parmar 2014) and also for selecting genetic material for use in sorghum improvement programs.

There is a need to quantify the genetic diversity of available sorghum cultivars in terms of nutritive value for use in breeding sorghum varieties or hybrids with higher stover value without compromising grain yield (Rattunde 1998; Hash et al. 2000). With this objective, a total of 11 sorghum cultivars were screened for variability in protein, carbohydrate and dry matter digestibility to select parents for subsequent use in sorghum breeding programs.

Materials and Methods

Production, sampling and processing of sorghum stovers

Eleven sorghum cultivars (SP 18005A x 220-2,3,6,7; PC-5; GGUB44 x SSG-59-3; ICSV-700; CSV-17; NRF-526; FM-1; SPV-1616; PVK-809; UPMC-503; and HC-308), selected on the basis of diverse genetic backgrounds, use and yield (stover and grain; Table 1) were grown at the research farm of Indian Institute of Millet Research, Hyderabad, India, in a randomized block design with 3 replications in plots of 5 x 4 m spaced at 45 cm between rows and 15 cm between plants within rows. A basal dose of 80 kg N and 40 kg P/ha was applied, with a further 40 kg N/ha 30 days after sowing. The variation in number of days to grain ripening since planting varied among cultivars: CSV-17 matured in 100 days and ICSV-700 matured in 122 days with the remainder intermediate. Yields of grain and stover were measured following grain harvesting and a composite stover sample was taken from each replication of individual cultivars for chemical analysis. The stover samples were dried in a hot-air oven at 60-65 °C for 96 h to constant weight. Dried samples were then ground through a 1-mm sieve using an electrically operated Willey mill and subsequently stored in plastic containers for laboratory analysis.

Chemical analyses

Dry matter (DM), crude protein (CP), ether extract (EE) and ash concentrations of sorghum stover samples were estimated as per procedures of AOAC (2000). Fiber fractions, namely neutral detergent fiber (NDF), acid detergent fiber (ADF), cellulose and lignin, were determined following the detergent method of Van Soest et al. (1991) using Fiber Tech analyzer (FibraPlus FES 6, Pelican, Chennai, India). Heat-labile a-amylase and sodium sulphite were not used in NDF solution. Lignin (sa) was determined by dissolving cellulose with sulfuric acid in the ADF residue (Van Soest et al. 1991). Cellulose was estimated as the difference between ADF and lignin (sa) in the sequential analysis and hemicellulose was calculated as difference between NDF and ADF concentrations.

Carbohydrate and protein fractions

Total carbohydrates (tCHO) of stover samples were calculated as 100 - (CP + EE + ash). Carbohydrate fractions in the samples were estimated as per Cornell Net Carbohydrate and Protein (CNCP) system (Sniffen et al. 1992), which classifies carbohydrate fractions according to degradation rate into 4 fractions, viz. CA - rapidly degradable sugars; Cb1 - intermediately degradable starch and pectin; Cb2 - slowly degradable cell wall; and Cc -unavailable/lignin-bound cell wall. Structural carbohydrates (SC) were calculated as the difference between NDF and neutral detergent insoluble protein (NDIP), while non-structural carbohydrates (NSC) were estimated as the difference between tCHO and SC (Caballero et al. 2001). Starch in samples was estimated by extracting stover samples in 80% ethyl alcohol to solubilize free sugars, lipids, pigments and waxes. The residue rich in starch was solubilized with perchloric acid and the extract was treated with anthrone-sulfuric acid to determine glucose colorimetrically using glucose standard (Sastry et al. 1991). A factor of 0.9 was used to convert glucose into starch (mg %).

The CP of stover samples was partitioned into 5 fractions according to the Cornell Net Carbohydrate and Protein System (CNCPS; Sniffen et al. 1992) as modified by Licitra et al. (1996). Neutral detergent insoluble protein (NDIP), acid detergent insoluble protein (ADIP) and non-protein nitrogen (NPN) were estimated following the standard method (Licitra et al. 1996). For NDIP and ADIP, samples extracted with neutral detergent and acid detergent solutions, respectively, were analyzed as Kjeldahl N x 6.25 using semi-auto analyzer (Kel Plus Classic-DX Pelican India). For NPN estimation, samples were treated with sodium tungstate (0.30 molar) and filtered, and residual nitrogen was determined by the Kjeldahl procedure. Non-protein nitrogen of the sample was calculated by subtracting residual nitrogen from total nitrogen. Soluble protein (SP) was estimated by treating the samples in borate-phosphate buffer, pH 6.7-6.8, consisting of monosodium phosphate (Na2PO4.H2O) 12.2 g/L, sodium tetraborate (Na2B4O7.10H2O) 8.91 g/L and tertiary butyl alcohol 100 mL/L and freshly prepared 10% sodium azide solution (Krishnamoorthy et al. 1983). The N estimated in the residue gives the insoluble protein fraction. The SP was calculated by subtracting insoluble protein from total CP.

Intake, digestibility, energy, feed value

To calculate DM intake (DMI), digestible dry matter (DDM), relative feed value (RFV), total digestible nutrients (TDN) and net energy (NE) of the stovers for different animal functions, i.e. lactation (NEl), weight gain (NEg) and maintenance (NEm), equations given by Undersander et al. (1993) were used. Digestible energy (DE) and net energy (NE) values were calculated using equations of Fonnesbeck et al. (1984) and Khalil et al. (1986), respectively. The in vitro dry matter digestibility (IVDMD) was estimated using the 2-stage technique of Tilley and Terry (1963) by incubating 0.5 g of sample in inoculum of sheep maintained on a mixed grass hay-concentrate diet.

Minerals

Samples of sorghum stovers were wet-digested with 3:1 HNO3:perchloric acid mixture, cooled and filtered through Whatman 42 filter paper. The aliquot was used for estimation of calcium (Ca), copper (Cu), zinc (Zn), iron (Fe), cobalt (Co) and manganese (Mn) using an atomic absorption spectrophotometer (Varian AA 240) against their standards. Phosphorus was estimated colori-metrically using Barter's reagent according to AOAC (2000).

Statistical analysis

Data were subjected to analysis of variance of SPSS 17.0 to test the differences between sorghum cultivars for chemical composition, carbohydrate and protein fractions, energy values, digestibility and mineral concentrations.

Variable means were compared for significance at P<0.05 level (Snedecor and Cochran 1994).

Results

Grain and stover yields

Stover yields in the various cultivars varied from 7.61 t/ha (CSV-17) to 13.7 t/ha (SP 18005A x 220-2, 3, 6, 7), while grain yields ranged from 1.59 t/ha (FM-1) to 4.51 t/ha (SPV-1616) (Table 1).

Means followed by different letters within columns differ significantly at P<0.05 level.

Chemical composition

All chemical parameters varied (P<0.05) between cultivars. Crude protein was highest in SP 18005A x 2202, 3, 6, 7 and PC5 (6.6 and 6.7%, respectively) and lowest in UPMC-503 (3.7%; Table 2). The OM and EE concentrations in stovers varied (P<0.05), with ranges of 91.0-93.5% and 1.05-1.61%, respectively. NDF ranged from 55.0% (ICSV-700) to 68.2% (CSV-17), ADF from 35.3% (ICSV-700) to 43.1% (CSV-17), cellulose from 27.9% (ICSV-700) to 33.8% (CSV-17) and lignin from 4.33% (PVK-809) to 5.79% (CSV-17) (P<0.05).

Means followed by different letters within rows differ significantly at P<0.05 level.

CP - crude protein; OM - organic matter; EE - ether extract; NDF - neutral detergent fiber; ADF - acid detergent fiber.

Carbohydrate fractions

Concentrations of tCHO, NSC and SC of sorghum stovers differed (P<0.05) between cultivars (Table 3). Total carbohydrates varied from 88.6% (UPMC-503) to 83.3% (SP 18005A x 220-2, 3, 6, 7), while structural carbohydrates were highest in CSV-17 (66.4%) and lowest in ICSV-700 (53.6% DM). Similarly the carbohydrate fractions (Ca, Cb1, Cb2, Cc) differed significantly (P<0.05) across the sorghum cultivars. The highly degradable carbohydrate fraction (CA) was highest (P<0.05) in stover of ICSV-700 (30.3%) and lowest in CSV-17 (16.7%). On the other hand the slowly degradable carbohydrate fraction (Cb2) was lowest in ICSV-700 (53.8%) and highest in CSV-17 (66.4%).

Means followed by different letters within rows differ significantly at P<0.05 level.

tCHO - total carbohydrates; NSC - non-structural carbohydrates; SC - structural carbohydrates; CA - rapidly degradable sugars; CB1 - intermediately degradable starch and pectins; CB2 - slowly degradable cell wall; CC - unavailable/lignin-bound cell wall.

Protein fractions

The protein fractions Pb1, Pb2, Pb3 and Pc differed significantly (P<0.05) in stovers of the sorghum cultivars (Table 4). Lignin-bound/unavailable protein fraction PC was highest (P<0.05) in stover of SPV-1616 (36.8%) and lowest in ICSV-700 (20.4% CP).

Means followed by different letters within rows differ significantly at P<0.05 level.

PA - non-protein nitrogen; PB1 - buffer-soluble protein; PB2 - neutral detergent-soluble protein; PB3 - acid detergent-soluble protein; PC - indigestible protein.

Energy and its efficiency for animal functions

Energy value in terms of GE, DE, ME and TDN in stovers differed significantly (P<0.05; Table 5). Cultivar ICSV- 700 had highest concentrations of DE, ME and TDN (2.60 kcal/g DM, 2.13 kcal/g DM and 59.0%, respectively), while CSV-17 had the lowest (2.16 g/kg DM, 1.77 kcal/g DM and 48.9%, respectively). The energetic efficiency for different animal functions, viz. NEM, NEG and NEL, also differed (P<0.05) amongst the sorghum cultivars, with ranges of 1.13-1.42, 0.41-0.70 and 0.95-1.33 kcal/g DM, respectively.

Means followed by different letters within rows differ significantly at P<0.05 level.

GE - gross energy; DE - digestible energy; ME - metabolizable energy; TDN - total digestible nutrients; NEl - net energy for lactation; NEg - net energy for growth/gain; NEm - net energy for maintenance.

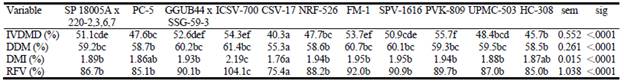

Intake, digestibility and relative feed value

The calculated values of DMI, DDM and RFV for stovers of the 11 sorghum cultivars varied significantly (P<0.05; Table 6) with ranges of 1.76-2.19%, 55.3-61.4% and 75.4-104.1%, respectively. In vitro dry matter digestibility (IVDMD) of stovers was highest (P<0.05) for cultivars PVK-809 (55.7%) and ICSV-700 (54.3%) and lowest for CSV-17 (40.3%).

Table 6 Predicted dry matter intake, digestibility and feed value of stovers from 11 different sorghum cultivars.

Means followed by different letters within rows differ significantly at P<0.05 level.

IVDMD - in vitro dry matter digestibility; DDM - estimated digestible dry matter; DMI - estimated dry matter intake; RFV - relative feed value.

Macro- and micro-minerals

Macro- and micro-mineral concentrations in stovers differed (P<0.05) across sorghum cultivars (Table 7). Stover from SPV-1616 had lowest Ca and P concentrations (216 and 39.9 mg/kg, respectively) with highest Ca in NRF-526 (398 mg/kg) and highest P in HC-308 (71 mg/kg). The concentrations of micro-minerals, viz. Cu, Zn, Fe, Mn and Co, ranged between 1.47 and 9.59, 14.2 and 35.5, 109 and 281, 46.5 and 112.5, and 1.74 and 5.44 ug/g, respectively.

Means followed by different letters within rows differ significantly at P<0.05 level.

Discussion

Grain and stover yields

The stover yields of high biomass lines SP 18005A x 2202,3,6,7, ICSV-700 and NRF-526 were higher, but not significantly so, than those of fodder and grain types SPV-1616 and PVK-809. This is expected because the high biomass lines were specially bred for higher biomass. On the other hand, the grain yields were higher in SPV-1616 and PVK-809 followed by CSV-17. The former two varieties were bred for maximizing grain yield with superior stover yield. Umakanth et al. (2012) observed that SPV 1616 showed high adaptability for grain and fodder yields and biomass, and hence better suited as a dual purpose sorghum variety. Sharma (2013) observed that CSV 17 was a good grain yielding variety that had least stover yield in western Rajasthan, India.

Chemical composition

Cereal stovers and straws are usually low in crude protein and rich in fiber concentrations, unable even to meet the minimum CP requirements (7%) for maintenance of animals and rumen microbes (Minson 1990), so there is need to supplement these stovers with protein rich leguminous forage or non-protein nitrogen or protein sources. In the present study CP concentrations (3.76.7%) of sorghum stovers are below the maintenance requirement for ruminants. Mativavarira et al. (2013) reported that CP concentrations of stovers varied (P<0.05) across cultivars and ranged between 5.6 and 6.6%, which supports our findings. Varietal differences for sorghum stover quality have been reported for protein and cell wall concentrations (Badve et al. 1993). Fiber fractions, viz. NDF, ADF, cellulose and lignin, are in general agreement with the earlier recorded values of Elseed et al. (2007) across 5 sorghum varieties. Crude protein, OM and EE concentrations of sorghum stovers reported by Misra et al. (2009) were on par with our results, while their NDF and ADF concentrations were higher than our values. Like the present study, variability in NDF, ADF, cellulose and lignin concentrations of sorghum stovers in different cultivars has been reported earlier (Garg et al. 2012; Hamed et al. 2015).

Carbohydrate and protein fractions

Carbohydrates constitute the main energy source of plants (50-80%) and play an important role in animal nutrition as a prime source of energy for rumen microorganisms (Van Soest 1994). In our study total carbohydrate concentrations of sorghum stovers varied between 83.4 and 88.6% DM, and exceeded the 78.5% DM reported by Das et al. (2015). Carbohydrate accumulation in fodder crops is influenced by several factors like plant species, variety, growth stage and environmental conditions during growth (Buxton and Fales 1994). Concentrations of SC and NSC differed (P<0.05) across the cultivars as suggested by Ferraris and Charles-Edwards (1986) and McBee and Miller (1990). Swarna et al. (2015), while evaluating the nutritive value of crop residues, found that Ca, Cb1, Cb2 and Cc concentrations in sorghum stover were 14.7, 1.12, 56.8 and 28.0% of tCHO levels, a pattern of carbohydrate fractions identical with our results. Relatively low Cc values (11.7-16.0% tCHO) in our study may be due to the lower lignin concentrations in our stovers than in theirs. In our results carbohydrate fraction Cb2 was highest in CSV-17 (66.4%) and lowest in ICSV-700 (53.8% tCHO). This is probably a function of the higher NDF and hemicellulose concentrations in CSV-17 and lower NDF and hemicellulose concentrations in ICSV-700. This was substantiated by the fact that forage with high NDF levels had higher concentrations of the Cb2 fraction, which is more slowly degraded in the rumen, impacting microbial synthesis and animal performance (Ribeiro et al. 2001). Higher hemicellulose concentrations result in higher concentrations of carbohydrate Cb2 fraction. Carvalho et al. (2007) reported that NDF concentration influences carbohydrate fraction Cb2 and forages high in NDF concentration usually have higher values of CB2. Values of carbohydrate fraction CC in our study (11.7-16.0 % tCHO) were generally lower than the 15.825.2% reported by Malafaia et al. (1998) for grasses.

Protein fractions (PB1, PB2, PB3 and PC) differed (P<0.05) across sorghum cultivars, which may be attributed to differences in concentrations of CP and lignin. About 5-15% of total forage N is bound to lignin, or rather, is unavailable to ruminal microorganisms (Van Soest 1994). Protein fraction Pc of stovers recorded in our study ranged between 20.4 and 36.8% CP, exceeding the above levels, probably due to variability in lignin concentrations. Forages, fermented grains and byproduct feeds contain significant amounts of fraction PB3 (Krishnamoorthy et al. 1983).

Energy and its efficiency

Energy density of roughages is a primary parameter influencing animal productivity. Stovers from the evaluated sorghum cultivars had adequate energy, except for CSV17 (ME 1.77 kcal/g), to meet the maintenance requirement of livestock (ME 2.0 kcal/g DM recommended for ruminants; ICAR 2013). The DE and ME concentrations in our study differed (P<0.05) across cultivars, being highest for ICSV-700 (2.60 and 2.13 kcal/g DM) and lowest for CSV-17 (2.16 and 1.77 kcal/g DM). The range of values for DE (2.16-2.6 kcal/g DM) and ME (1.77-2.13 kcal/g DM) are similar to the 2.142.51 kcal DE/g DM and 1.76-2.05 kcal ME/g DM recorded by Neumann et al. (2002), the 1.70-2.00 kcal ME/g DM reported by Garg et al. (2012) and the 1.6-1.72 kcal ME/g DM reported by Mativavarira et al. (2013). The variation in TDN concentrations in our study (59.0% for ICSV-700 to 48.9% for CSV-17) is a function of differences in fiber concentrations, as fiber is often used as a negative index of nutritive value in the prediction of total digestible nutrients and net energy. Sorghum stover TDN concentrations of 46.5-56.5% reported by Garg et al. (2012) cover a similar range to our findings, while Beef Magazine (2015) suggests TDN concentrations of sorghum stover are about 54% and Neumann et al. (2002) reported TDN of silage made from sorghum hybrids between 54.4 and 62.2%. Studies on the net energy efficiency of sorghum stovers for animal production functions is limited and values for NEM, NEG and NEL reported in Beef Magazine (2015) for sorghum stover of 1.06, 0.40 and 1.06 kcal/g DM corroborate our results.

Mean values of NEm, NEg and NEl reported by Bean et al. (2011) for hay made from the second cut of 32 sorghum hybrids were 1.13, 0.59 and 1.21 kcal/g DM, i.e. within the range of energy values for sorghum stovers recorded in our study.

Intake, digestibility and relative feed value

From a livestock production view point, intake and digestibility are the main criteria in breeding programs for quality improvement in most cereal fodder crops. Dietary fiber concentration, its digestibility and rate of degradation in the rumen are the most important forage characteristics that determine DMI (Roche et al. 2008). The differences in predicted DMI levels we recorded (1.76-2.19%) may be attributed to differences in NDF concentrations. The NDF concentration of CSV-17 was 68.2%, which exceeds the 60.0% usually considered as the threshold likely to significantly reduce intake in ruminants (Zewdu 2005). Mahanta and Pachauri (2005) recorded DMI between 1.84 and 2.55% for sheep fed silage from 3 sorghum cultivars ad lib. Relative feed value of hay from second cut of 32 sorghum hybrids ranged between 106 and 126 (Bean et al. 2011), which exceeded the 75.4-100 we recorded. We attribute the lower RFV of stovers in the present study to their lower quality relative to the whole plants examined at a younger age by Bean et al. (2011), i.e. higher NDF and ADF concentrations as these influence the intake and digestibility of a fodder. Forage containing 41% ADF and 53% NDF is considered to have an RFV of 100 and RFV values decrease as the concentrations of NDF and ADF increase with crop maturity.

The variability in digestibility values may be attributed to differences in cell wall concentrations. Elseed et al. (2007) reported effective degradability of dry matter of stovers from different cultivars between 44.4 and 67.7%, which covers a similar range to our IVDMD and DDM values. Bani et al. (2007) recorded an inverse relationship between forage fiber fractions and DM digestibility, while Barriere et al. (2003) and Seven and Cerci (2006) indicated that nitrogen concentration and cell wall poly-saccharides determine the digestibility of a crop. The IVDMD of sorghum stover of 53.3% reported by Misra et al (2009) is consistent with our stover IVDMD values. The lower concentrations of NDF, cellulose and lignin in ICSV-700 and FM-1 could explain their higher IVDMD and DDM values (Tovar-Gomez et al. 1997; Zerbini and Thomas 2003), while the highest lignin concentration (5.79%) in stover of sorghum cultivar CSV-17 may explain the lowest IVDMD and DDM values for this cultivar.

Macro- and micro-minerals

Forages neither contain all the required minerals nor are they present in adequate quantity to meet animal requirements (Vargas and McDowell 1997). Calcium and phosphorus constitute the major portion (up to 70%) of the body's total mineral elements, play a vital role in almost all tissues in the body and must be available to livestock in proper quantities and ratio (McDowell et al. 1993). The Ca concentrations that we found, 215-343 mg/kg, should fulfill the maintenance requirements of ruminants (270-570 mg/k; NRC 2001), but P and Mg concentrations in stovers were low (39.9-71 and 42.958.6 mg/kg) and unable to meet the critical levels (220 and 120-220 mg/kg) recommended for ruminants. While the Ca concentrations in sorghum stover/straws reported by Ramesh et al. (2014) and Garg et al. (2003) are more or less similar to our values, P concentrations reported by these workers are higher than our values. Misra et al. (2015) reported P and Mg concentrations in sorghum stovers (N = 31) similar to ours. The concentrations of Cu (1.47-9.59 ug/g), Zn (14.2-35.5 ug/g) and Fe (109-281 ug/g) recorded in our study were within sorghum stover values reported by Ramesh et al. (2014) and Misra et al. (2015). The low concentrations of many minerals in straws and stovers are probably due to maturity and possible transfer of nutrients to seeds. Mineral concentrations in feeds and fodders are influenced by a number of factors (soil pH, soil type, plant species, stage of growth and harvest, crop yield, intensity of agriculture system, climate, fertilizer rate etc. (British Geological Survey 1992; McDowell et al. 1993).

The results from this study revealed significant variability in apparent nutritive value of the sorghum stovers tested. This indicates that there is considerable potential for selecting appropriate genotypes to include in breeding programs to improve stover quality. While stovers of all genotypes had adequate energy to meet ruminant maintenance requirements, protein concentrations were low and quite variable. While there is potential to improve stover quality by breeding, care would need to be taken to ensure grain and stover yields did not suffer as a result. Feeding studies with animals would throw more light on the predicted feed intakes and digestible dry matter values reported in this study.