1. Introduction

Peach palm (Bactris gasipaes) is a fruit consumed since pre-Colombian time in tropical areas ranging from the Amazon to Costa Rica, cooked fruits are eaten, or products such as flour, preserves, jams, chips and fermented beverages are produced [1,2]. Yuyama et al. [3] reported that the peach palm is one of the more complete tropical foods due to its nutritional value because it has high contents of protein, essential amino acids and unsaturated fatty acids. Notably, this fruit has high contents of β-carotene, vitamin A, calcium, phosphorus and iron [1]. Carotenoids are molecules obtained in photosynthetic tissues, and chemically known as hydrocarbon carotenes (lycopene and β-carotene) or xanthophylls (lutein, β-cryptoxanthin, and zeaxanthin) [4]. These compounds are important in the human diet because they are associated with protection against cancer and some degenerative diseases (e.g., cataracts, age-related macular degeneration and Alzheimer's Disease), as reported antioxidants and pro-vitamin properties [5]. The extraction of carotenoids of plant tissues conventionally is performed by solid-liquid extraction (maceration and Soxhlet), which are laborious, time consuming and require high volumes of organic solvents (acetone, hexane, acetonitrile, tetrahydrofuran, and petroleum ether) [6,7]. Situation has led to study new non-conventional methods that can reduce the extraction time, the process temperature and solvent consumption and contribute to higher extraction efficiency and lower energy consumption compared to conventional extraction methods [8]. Currently, extraction techniques such as ultrasound, offer greater efficiency in the extraction of bioactive compounds, because this technique is very simple and economical, making it an alternative to the conventional techniques [9]. The high efficiency of ultrasound extraction is mainly attributed to its mechanical effects, cavitation increases the temperature and pressure facilitating the phenomena of mass transfer by increasing the solubility and diffusivity of the solvent in the extraction matrix, as has previously reported by Chandrapala et al. [10] and Junjian et al. [11]. The ultrasound technique has been used in the extraction of carotenoids in plant materials, such as tomato [12,13], citrus peels [14], oil palm [15], carrot [16,17], red grapefruit [18], annatto seeds [19], papaya waste [20], peach palm peel [21], and pomegranate wastes [22]. Despite these works, studies are still limited, where vegetable oils are used as solvent in the green extraction of carotenoids by ultrasound. This paper aims to study the effect of various parameters such as extraction time, solid to solvent ratio, and extraction temperature which affects ultrasonic-assisted extraction (UAE). Hence, the main aim of this work is to optimize the various above-mentioned parameters for the extraction of carotenoids from dry peach palm peel using soy oil as extraction solvent.

2. Materials and methods

2.1. Materials chemicals and materials

The high quality β-carotene standard (95-99%) was provided by Sigma Aldrich. At a local supermarket was purchased refined soy oil. The absorption spectrum of the extracts was measured in a spectrophotometer (Jenway 6320D spectrophotometer, USA.). The refined soy oil had a peroxide index of 0.94 Meq O2/kg and an acidity percentage (oleic) of 0.28%.

2.2. Obtaining ß-carotene extract ultrasonic-assisted extraction total carotenoid from dried peel

Dried peel preparation and the extraction were conducted as the report Ordóñez-Santos et al. [21]. Peach palm fruit (Bactris gasipaes) peel was separated with a knife, peel was oven dried at 60 °C until the moisture level was constant (11 % w/w), and reduced to particle size of 0.25 mm. Dry peel dispersed in 4 mL of soy oil, and the extraction was performed at different temperature, extraction time and solid to solvent ratio. UAE was performed in an ultrasonic bath system (Ultrasonic Cleaner mrc DC 150 H, with 40 kHz frequency and maximum power of 150 W, the internal dimension: (300 mm × 155 mm × 150 mm). The carotenoid yield (mg/100 g dried peel) was calculated using the molar extinction coefficient of 10.6*104 M-1cm-1 for β-carotene in soy oil at 464 nm, according to Ordóñez-Santos et al. [21]. Ultrasound assisted extraction was compared with the Soxhlet and maceration, conventional extraction methods. Soxhlet extraction was performed following described by Zaghdoudi et al. [23], modifying the methanol by hexane as solvent extractor for 6 hours, the solvent evaporated using nitrogen. Extraction by maceration proposed by Li et al. (2013) modifying the sunflower oil by soy oil as solvent extractor for 6 hours. The actual power dissipated in the ultrasonic bath was 75-90 W, which was determined by calorimetric method reported by Kiani et al. [24].

2.3. Experimental design

Optimization of UAE parameters of total carotenoid extraction from dry peel was done using Response Surface Methodology (RSM). A five-level-three-factor, central composite rotatable design consisting of seventeen experimental runs was employed including three replicates at the center point. The extraction factors were temperature (X1, °C), extraction time (X2, min) and solid to solvent ratio (X3, g/mL).

The actual and coded levels of the independent variables are given in (Table 1), and second-order polynomial equation which includes all interaction terms was used to calculate the predicted response in the following eq. (1).

Table 1 Independent variables and their levels used for in a Central Composite Rotatable design.

Source: The Authors.

where Y is the response variable, ß0, ßi, ßii, and ßij values represent corresponding regression coefficients, and Xi and Xj are independent variables (i ≠ j). The analysis of variance (ANOVA), the mean values were considered significantly different when p < 0.05, regression analysis and plotting of response surface plots, allowed establishing the optimal conditions for total carotenoids. Statistical analysis was performed by using Design Expert program (10.0. version).

3. Results and discussion

3.1. Response surface optimization

The effect of the factors evaluated in ultrasonic of total carotenoids extraction can be seen in Table 2. The range of total carotenoids extracted peach palm peel, experimental values between 44.20- 166.43 mg/100 g dried peel. Table 3 shows the statistical analysis of the response surface, linear, quadratic, and interaction effect of the three study factors (extraction temperature, extraction time, and solid to solvent ratio). The significance level model (p <0.01) shows that this can be applied to monitor the optimization of the extraction process. Temperature, extraction time, solid to solvent ratio, and the quadratic effect of factors statistically influenced of total carotenoids extraction (Table 3). As shown in the Table 3, Lack of Fit was not significant (p> 0.05) in the mathematical model proposed; this ensures suitability to predict the variations within the system. The experimental values showed a good fit with the empirical regression equation Y= 159.09 - 25.33X1 - 12.98X2 + 19.40X3 + 10.32 X1X2 - 12.63X1X3 + 2.27X2X3 - 27.27X2 1 - 21.89X2 2 -24.36 X2 3, as they presented the value of the coefficient determination r2 was 0.9466 and r2 adj = 0.8780 (Table 3).

Table 2 Central composite rotatable design matrix and response values for total carotenoids

Source: The Authors.

Table 3 Analysis of variance (ANOVA) for the fitted quadratic polynomial model for optimization of extraction parameters

r2=0.9466. r2 Adj=0.8780, a*(p < 0.05); **(p < 0.01) and ***( p < 0.001), and NS= Not significant.

Source: The Authors.

Source: The Authors.

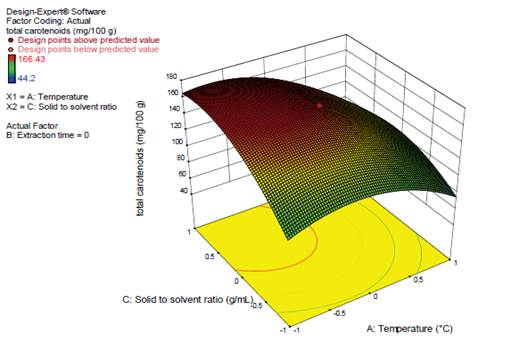

Figure 1 3-D response surface of extraction temperature and extraction time on the content of total carotenoids.

3.2. Response surface and contour plots

Fig. 1, the response surface generated by the effect of extraction time and temperature on the extraction of total carotenoid concentration is presented. It is noted, that increasing the temperature significantly reduces total carotenoids concentration and a quadratic temperature effect is evident. Guadarrama-Lezama et al. [25] report that the temperature is a factor which can accelerate the process of oxidation polyunsaturated fatty acids present in oil, which in turn, have co-oxidation reactions in carotenoids. Moreover, temperatures below increase the extraction of carotenoids; this probably associated to the reduction of viscosity and increased solubility of the pigment which allowed improved mass transfer, this situation has been previously described by Yolmeh et al. [19].

Source: The Authors.

Figure 3 3-D response surface of extraction temperature and solid to solvent ratio on the content of total carotenoids.

Fig. 2, a significant effect in solid to solvent ratio to total carotenoids extraction is observed, carotenoid concentrations increased with increasing solute in the solvent and quadratic effect was observed in this factor. These results indicate that despite the increase of the solute, the solvent proportion remained higher, creating a concentration gradient, responsible for mass transfer, which allowed the diffusion of total carotenoids in the medium [18, 26]. This phenomenon has been previously observed by Sun et al. [14] and Purohit & Gogate [27] in the extraction β-carotene in carrots and orange by-product, in initial stages of extraction with ultrasound. Fig. 3 confirms the effect of the temperature and solid to solvent ratio of the level of total carotenoids extraction. The incidence of the quadratic effect of temperature and solid to solvent ratio is also observed (Figs. 2, 3).

The optimum extraction of total carotenoids peel peach palm with soy oil according to the analysis of response surface corresponded to a time of 28 minutes, temperature of 48 °C and solid to solvent ratio 0.0037 g/mL, allowed to obtain a maximum concentration of 151.50 mg/100 g dried peel. The values of optimization extraction were validated experimentally obtaining total carotenoids concentration of 149.35 ± 3.86 mg/100 g dried peel, which showed no significant difference (p> 0.05) with the value recorded in the optimization. Moreover, ultrasound extraction was compared with soxhlet and maceration techniques, considered conventional methods of extraction of carotenoids. Total carotenoid extraction (mg/100 g dried peel) by soxhlet was 168.8 ± 3.50; ultrasound was 151.50 ± 1.36, and maceration 113.40 ± 1.20. The extraction with soxhlet presented the greater extraction, however, these results show that the ultrasound technique by using vegetable oil is effective for extraction of total carotenoids in the by-product peach palm procedure since operation time was 28 minutes, no toxic reagents were used to the environment and water consumption is minimal in this technique, compared to extraction with soxhlet which requires excessive consumption of water in the cooling system, time continuous extraction of 6 hours, with high volumes of hexane or petroleum ether as solvent extractor. Moreover, maceration with soy oil is a technique that does not affect the environment, but the operating time and extraction yield is slow. Similar results reported Li et al. [16] who obtain higher concentrations of total carotenoids with ultrasound 334.75 mg β-carotene/L, compared to extraction by maceration 321.36 β-carotene mg/L in samples of carrot. Ordóñez-Santos et al. [21] report that by-product peach palm under the action of ultrasound, had higher levels of total carotenoids (163.47 mg β-carotene/100 g), compared to those who were not exposed to the ultrasound action (123.40 mg β-carotene/100 g). Li et al. [20] obtain higher level of extraction of lycopene in the skin of papaya samples with ultrasound (189.80 µg/g) against maceration (153.90 µg/g) and soxhlet (68.30 µg/g). Shisath et al. [28] and Tian et al. [29] report that the extraction yields obtained by ultrasound, is associated with the cavitation phenomenon caused by the propagation of pressure waves in the solvent. These authors report that the collapse of cavitation bubbles produced by micro-turbulence generates high-velocity inter-particle collisions and perturbation in micro-porous particles of the biomass which accelerates the eddy diffusion and internal diffusion. Shisath et al. [28] reports that due to cavitation, the cracks are developed in the cell wall which increases permeability of plant tissues facilitating the entry of the solvent into the inner part of the material as well as washing out of the extracts.

4. Conclusions

In this work the extraction variables, temperature and solid to solvent ratio statistically influenced the UAE of total carotenoids extraction from peach palm fruit peel. The extraction process that was optimized in the present research for obtain the highest extraction of carotenoids corresponded: 48 °C of temperature, 28 min of extraction time and of solid to solvent ratio of 0.0037 g/mL. This study indicated that the combination of ultrasound and soy oil can be considered as an alternative extraction of carotenoids to conventional methods, and should contribute to a green process for valorization of peach palm by-products.