Introduction

The exposure to chloride ions is the main cause of degradation of the concrete reinforced structures. Chloride ions dissolved in water can permeate through concrete; this could lead to various defects of the structure such as corrosion of reinforcement, cracking and spalling (Aguirre & Mejía de Gutiérrez, 2013; Fernández & Palomo, 2009). The presence of capillary pores and air voids influences concrete permeability to a large extent. Therefore, a durable concrete should have low permeability. An excess of water, expressed as a high water/binder ratio, produces an increase in the amount of capillary pores when evaporation happens, especially those connected with the exterior (Delagrave, 1996; Mehta & Monteiro, 1998). Additionally, during the life service of concrete, the high porosity compromises the physical-mechanical properties of concrete and its permeability (Detwiler & Mehta, 1989).

Therefore, to assess the durability properties of concrete, it is necessary to study the transport mechanisms of fluids and substances from the outside and into the material by some tests such as permeability, porosity and absorption.

To enhance the ability of concrete to withstand the different mechanisms of degradation such as the chloride permeability or the sulfates attack, it's necessary to involve supplementary cementitious materials, which partially replace the Portland cement. These are responsible for the pozzolanic reaction characterized by the consumption of calcium hydroxide Ca(OH)2, allowing them to form calcium silicate hydrates (CSH) (Talero, 1986). The rising of this phase, promotes lower porosity, and an improvement in durability and resistance properties (Mehta & Monteiro 2006; Taylor, 1967).

Metakaolin (MK) is a type of calcined clay which is one of the most used and studied supplementary cementitious materials. MK is obtained by the calcination of kaolinitic clay at a controlled temperature of 700°C. It presents a high reactivity and excellent pozzolanic properties, due to its chemical composition, amorphous structure and high specific surface (Caldarone, 1994; Kakali et al., 2001; Razak & Wong, 2005; Torres et al., 2007). It has been demonstrated that when MK is used as a partial replacement of cement, it accelerates the hydration of Portland cement and reduces the content of calcium hydroxide in the concrete mix, while it improves permeability resistance and shows lower values of porosity, water absorption and sorptivity ((Asbridge et al., 2001; Borosnyói, 2016; Caldarone, 1994; Khatib & Clay, 2004; Mejía de Gutiérrez et al., 2004)). This material has been recommended for use in the production of ultra-high performance concretes and self-compacting concrete (Badogiannis et al., 2015; Tafraoui et al., 2016).

On the other hand, a residue of the petrochemical industry, called spent fluid catalytic cracking catalyst (FCC), has been studied in the last few years. This industrial residue comes from the catalytic cracking units, which can be found in petroleum refineries. Once the catalyst loses its natural activation properties, it is replaced by a new one, and the product is assumed as a waste material (Agamez, 2006). The FCC is mainly composed by silica and alumina. It can be useful as raw material for the elaboration of new materials. Once an FCC's catalyst is disposed in the refining process, there is the possibility of incorporating it in the production of mortars and concrete as pozzolanic additions (Antiohos et al., 2006; Pacewska et al., 2002a; Payá et al., 1999; Payá et al., 2001a; Payá et al., 2003; Torres et al., 2012a).

Different authors have reported that the reactivity level of the FCC is as high, as the one of pozzolan type, and act as an accelerator for the hydration of cement. This is evident in short periods of curing. In Portland Cement added with FCC, a greater production of CSH and a lower one of calcium hydroxide were found. This was due to the high reactivity of the material (Borrachero et al., 2002; Jung-Hsiu et al., 2003; Pacewska et al, 2002a). Similar results have been found by Trochez et al., 2010; Torres_et al., 2012b, showing that the residue of the catalytic cracking catalyst presents a high reactivity. This assertion results evident in the consumption of calcium hydroxide, which comes from cement hydration. That behavior was optimized with the percentage represented by the addition, and the curing time. Additionally, in the evaluation of the hydration process of cement with FCC, it has been reported as principal products, the CSH gel, ettringite, CAH and CASH; compounds similar to the ones reported in the MK-Cement system (Payá et al., 2003).

FCC presents pozzolanic characteristics comparable to Metakaolin (Borrachero et al., 2002; Payá et al., 2001b; Pinto et al., 2007; Soriano, 2008; Trochez et al., 2010). Given the similarities of these two materials, a pilot program was developed in order to assess some properties that are influential in durability, including the total absorption, porosity, initial superficial absorption and capillary absorption. Concrete mixes were elaborated with partial replacement of FCC regarding Portland Cement (0 %>, 10 %>, 20 % and 30 %>) and their behavior was compared with concrete mixes containing 20 % of MK, at different curing ages.

Experimental Procedure and Materials

Materials

Portland Cement (PC) was used for concrete preparation. Spent fluid catalytic cracking catalyst (FCC) and Metakaolin (MK) were used as supplementary materials. FCC was supplied by a Colombian petroleum company (Ecopetrol, Cartagena). The chemical and physical characteristics of these materials are presented in Table 1.

Table 1 Chemical and physical characteristics of the FCC, MK and cement used

| Characterístics | Cement (PC) | MK | FCC |

|---|---|---|---|

| Chemical composition ( %) | |||

| SiO2 | 19,43 | 53,38 | 48,09 |

| Al2O3 | 4,00 | 43,18 | 41 ,57 |

| Fe2O3 | 3,61 | 0,43 | 0,91 |

| CaO | 64,46 | 0,05 | 0,22 |

| MgO | 1,52 | 0,35 | 0,13 |

| K2O | 0,39 | 1 ,11 | 0,09 |

| TiO2 | 0,34 | 0,59 | 0,85 |

| Loss on Ignition | 2,58 | 0,52 | 2,19 |

| Physical characteristics | |||

| Density (kg/m3) | 3,13 | 2,50 | 2,63 |

| Average Particle Size (μίτι) | 16,07 | 7,53 | 18,00 |

| Pozzolanic Activity index, | 92,9 | 97,4 | |

| 28 days | |||

Source: Authors

The chemical composition of the FCC was determined by X-Ray Fluorescence (XRF) using a Philips MagixPro PW-2440 spectrometer fitted with a rhodium tube. In this table is observed that the FCC is composed almost entirely by silica and alumina, with a chemical composition similar to Metakaolin. The pozzolanic activity was determined according to ASTM C618 standards; it requires a minimum pozzolanic activity index of 75 % at 28 days of curing to consider a material as a pozzolan. All the raw materials were used under that parameter.

The FCC used in this study is partially amorphous, and its crystalline components are a faujasite type zeolite, kaolinite and quartz. In contrast, the MK used in this research, is predominantly of amorphous shape, with traces of quartz as the only crystalline phase (Torres et al., 2012a, Torres et al., 2012b; Trochez et al., 2010)

Preparation of concrete mixes

A control concrete mixture (0 % addition) was made along with four concrete mixtures added with the proportions shown in Table 2. In these four mixes, the cement was partially replaced with the addition, 10, 20, 30 % FCC and 20 % MK. The coarse aggregate had maximum nominal size of 12,7 mm, nominal density of 2 668 kg/ m3, unit weight of 1 542 kg/m3 and absorption of 3,0 %>. Sand had nominal density of 2 679 kg/m3, unit weight of 1 667 kg/ m3, absorption of 2,1 % and a fineness modulus of 2,84. A constant water-to-binder ratio (w/b) of 0,5 was used. Therefore, it was necessary to incorporate a high efficiency superplasticizer, due to the reduced workability of the mixtures. It is noted, that the binder is represented by cement addition. This w/b was selected, based on the durability requirements specified in the Colombian Earthquake Resistant Construction Code NSR-10, item C.4.2. Specimens were cured in water saturated with Ca(OH)2 at room temperature for periods up to 180 days.

Table 2 Proportion of materials in concrete mixtures

| Mixture | Control | FCC-10 % | FCC-20 % | FCC-30 % | MK-20 % |

|---|---|---|---|---|---|

| Materials: | |||||

| Cement (kg/m3) | 380 | 342 | 304 | 266 | 304 |

| FCC (kg/m3) | 0 | 38 | 76 | 114 | 0 |

| MK (kg/m3) | 0 | 0 | 0 | 0 | 76 |

| Coarse aggregate (kg/m3) | 950 | 850 | 950 | 950 | 950 |

| Fine aggregate | 777 | 777 | 777 | 777 | 777 |

| (kg/m3) | |||||

| w/b ratio | 0,5 | 0,5 | 0,5 | 0,5 | 0,5 |

| Superplasticizer (L/m3) | 0,83 | 1,00 | 1,34 | 1,82 | 1,36 |

Source: Authors

Tests and methods

The test of absorption and porosity was made according to ASTM C642 - "Standard Test Method for Density, Absorption, and Voids in Hardened Concrete", in cylindrical specimens on 75 mm diameter and 150 mm high. The Initial superficial absorption (ISAT) test was developed under the specified in the BS 1881-208 "Testing concrete recommendations for the determination of the initial surface absorption of concrete" standard. The initial surface absorption rate is a parameter that allows the measurement of the amount of water that gets inside the concrete by time unit and surface. It is a very useful test for the determination of the absorption speed, in the coating zone of the structure. The measurement of this property was done on 150 mm diameter and 100 mm high cylinders, for all the mixtures in study, and the different stages of the test; stipulated in the experimental program. The capillary absorption test was done according to ASTM C1585 - "Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement concretes", over concrete slices 100 mm diameter, and 50 mm high, at curing ages of 28, 56, 90 and 180 days. In general, the samples were pre-conditioned by drying at 60 °C until constant weight was reached.

Results and discussion

Mechanical properties

The compressive strength at 28 days of curing was 46,6 MPa, 47,5 MPa, 40,0 MPa and 43,7 MPa for concretes added with 10, 20, 30 % FCC and 20 % MK, respectively. At 90 days the strength increased up to 51 MPa for concrete blended with 10 % FCC, this value was approximately similar to that reported for the control and added with 20 %% MK. At 180 days of curing, concrete added with 10 % FCC and 20 % MK were 6 % and 13 % higher than the control (Torres et al., 2014). These results show that the mechanical performance of the FCC is apparently comparable to the one of MK, as other studies have indicated (Paya et al., 2003). It is worth noting that 1 day of curing, the compressive strength of concrete with 20 % FCC was higher by 28 % than that reported by MK 20 %, indicating a greater reactivity at early ages, which is consistent with reports from other researchers (Anthiohos et al., 2006; Soriano, 2008;).

Water Absorption and Porosity

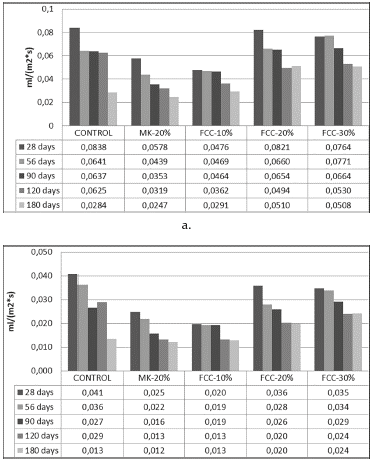

The porosity and absorption test is quite helpful for the evaluation of the open porosity of concrete (pore network that allows the circulation of the fluids), which is one of the main factors that modify the resistance and durability of concrete. The results of water absorption by total immersion obtained from the different studied mixes and evaluated by ASTM C642, are presented in Figure 1.

Source: Authors

Figure 1 Absorption and Porosity of the concrete mixes studied. a. Absorption, b. Porosity.

In general, all the samples have less than 5 %% absorption, which decreases along different curing ages (Figure 1a), as can be expected. A greater decreasing trend is noticed in the control sample and the one with FCC added at a 20 %. All samples of concrete with 180 days of curing, except the ones with 30 %% of FCC, have less than 1 % absorption; similar results have been reported by Mejía de Gutiérrez et al. (2009). It tends to be a smaller increase in the absorption of water as the percentage of FCC in the mix increases of 10 % at 30 %, at all curing times. The results vary between 3 % and 3,9 %, at 28 days of curing. The same behavior in total absorption has been reported for blended concrete with MK added between 0 and 20 %, with values between 4,2 and 5,4 %, respectively (Khatib & Clay, 2004).

A good behavior is presented in samples that have an addition of FCC-10 %, similar to the ones reported by Pacewska et al. (2002b), even showing lower values at 180 days, than the control samples and the MK-added samples. Reduced absorption and porosity for different samples in all test ages could be attributed to the outcome of additions on the filling effect and the pozzolanic action (thus modifying the concrete microstructure) (Detwiler & Mehta, 1989), which improves hydration of cement and pozzolanic reactions. This creates a denser microstructure with less pore capillary volume, thereby reducing the permeability. These results are similar to the reports about compressive strength, where the best performance (in the case of FCC) was the one of concretes with 10 % of addition.

On the other hand, the percentage of porosity has a significant influence over the mechanical properties and the durability of concrete. According to Neville & Brooks (1998) concrete's porosity can be modeled as a function that depends on different variables, like: water/binder relation, amount of cement, its hydration grade, the volume of trapped air, the amounts of fine and coarse aggregate; as well as their respective specific gravities.

Figure 1b presents the results of porosity for the different mixtures studied. As shown, the porosity percentage decreases with curing time. This is because while the hydration process happens, the pores size is reduced to 100 nm or less, thus they will lose their connections, therefore permeability decreases (Solis & Moreno, 2006).

The 10 % FCC-added, showed the best behavior since the second stage of the test, followed by the 20 % MK-added sample. When comparing the porosity percentages obtained in the various concrete mixtures under the judgment of the inspection manual named "Manual de Inspección, Evaluación y Diagnóstico de Corrosión en Estructuras de concreto Armado" (CYTED, 1997), it is observed that, according to the classification in all the stages of the test, the analyzed samples presented the common characteristic of a compact and high-profile concrete, as it showed an absorption below 5 % and a porosity below 10 %.

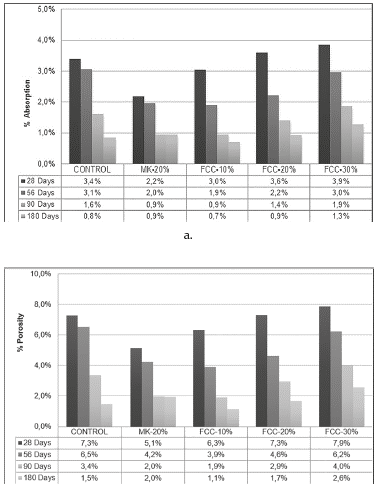

Initial Superficial Absorption (ISAT)

Figure 2 (a & b) shows the data of the readings taken at 10 and 30 minutes according to BS1881-208, which allows the study of the initial surface absorption of concrete. It is evident the decrease of the initial surface absorption rate, in the different stages of curing, for all the studied mixtures. It can be observed, that the 10 %>-FCC mixture, shows lower permeability levels at 28 days, than the one of 20 %-MK and the control simple. 180 days after, the results can be compared. In general, the samples added with MK and FCC-10 % present the best behavior. These additions have a high alumina content, which modifies the structure of the CSH gel, decreasing the permeability (Richardson, 1999).

Capillary Absorption

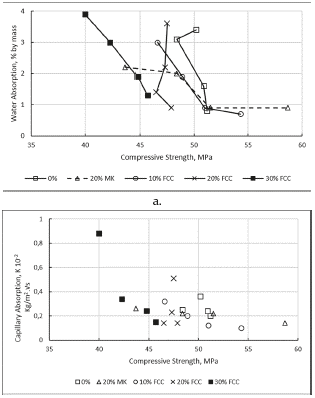

The capillary absorption is the relation between the mass of water by area unit that can absorb it in the capillary spaces, when the concrete is in contact with liquid water. It represents the effective porosity. This contact with water, also allows the entrance to the aggressive agents than can be found in the environment. With the data obtained of the change of weight of the sample (kg), the time (s) and the exposed area (m2), the capillary absorption coefficient (K) can be found; which is written in Kg/m2.Vs units. In Figure 3, the graph corresponding to the samples studied is shown.

It is important to notice the decrease in the capillary absorption coefficient, for all the ages of curing; it is observed a lower coefficient for the samples with additions of MK and FCC, in comparison to the control sample. It is noted the best behavior of the 10 %-FCC, because after 180 days of curing, presented 50 0% less superficial absorption in comparison with the control sample.

The lowest absorption coefficient of the MK and 10 %-FCC samples can be attributed to the higher density obtained in the material of high fineness that contains these additions. This allows the obstruction of the capillary pores. Also, the high reactivity in the additions, caused by the pozzolan activity, contributes to the refinement of the capillary pores of concrete (Dhir & Jones, 2002).

The concrete samples which had FCC additions, of 20 and 30 % as replacement of cement, after 28 days presented the highest capillary absorption coefficients, but it started decreasing, as the time of curing increased, thus finding at 180 days, lower values compared to the control sample. As the previous test, it is highlighted the lowest absorption coefficient, reported by 10 %-FCC and 20 %-MK. These results suggest that the presence of FCC causes changes in the pore network of concrete, and this refinement and/or blocking of them contribute to the reduction of the capillary porosity of the material, similar to what was reported in the presence of MK (Khatib & Clay, 2004).

As referring to permeability, Richardson (1999) suggests that the presence of alumina in the addition modifies the structure of the CSH gel, forming a sheet's structure which is more efficient for the filling of spaces, preventing the intercapillary connections that could connect pores. In comparison to the average Portland Cement pastes, which C-S-H gel structure forms needles, generating capillary nets that connect the pore system. This factor could explain the lower permeability that shows the pastes that contain MK and FCC. This analysis is consistent with the ones of other authors (Pacewska et al., 2000).

Relationship between absorption and compressive strength

The relationship between the total and capillary absorption and the strength is shown in Figure 4.

Source: Authors

Figure 4 Relationship between a. absorption by total immersion b. capillary absorption, and strength for concrete mixes.

It is observed that an increase of compressive strength is related with a decrease in the capillary absorption coefficient K. This same trend is observed for total absorption, however, it is not so clear. In both cases, it is noteworthy the concrete containing 20 %% MK, followed by FCC 10 %%. Although the highest percentage of absorption and capillary absorption coefficient are related to the mixture of least resistance (30 % FCC at 28 days curing), it is worth noting that these values change significantly with curing time (180 days), reaching lower ranks, similar to those of the mixtures of higher compressive strength.

Conclusions

The chemical and mineralogical composition of FCC are very similar to MK, thereby, the behavior of concrete added with these materials was comparable. The results of the test make evident a similar behavior of MK-20 % and FCC-10 % as an optimal replacement of cement, which results are comparable than the ones obtained with the control sample.

The results presented show that the pozzolan evaluated, in partial replacement of cement is a good alternative to produce concrete with a good durability, considering water absorption was less than 5 % and the porosity percentage less than 10 %.

In the study, the use of industrial residue demonstrates that the FCC could have a potential use as a partial replacement to Portland cement. These results may have a positive impact from an environmental point of view.