Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

Revista de Arquitectura (Bogotá)

Print version ISSN 1657-0308On-line version ISSN 2357-626X

Rev. Arquit. (Bogotá) vol.24 no.1 Bogotá Jan./June 2022 Epub Sep 03, 2022

https://doi.org/10.14718/revarq.2022.24.1.4064

Technology, environment and sustainability

Manual concrete manufacturing by means of mechanical suspension for application in popular habitats

1 Universidad Nacional de Colombia sede Medellín (Colombia) Facultad de Arquitectura Escuela de Construcción Arquitecto constructor, Universidad Nacional de Colombia. Medellín (Colombia) Doctor en Proyectos, Universidad Internacional Iberoamericana. San Francisco de Campeche (México) https://scholar.google.es/citations?hl=es&user=vUYHN2wAAAAJ cmbedoya@unal.edu.co; mbedoya2000@yahoo.com

This paper presents a methodology for the manual preparation of concrete mixtures using the principle of mechanical suspension, with which concrete mixtures were obtained with optimal performance in terms of compressive strength, porosity, density and void percentage. Destruction tests of cylindrical samples were performed at 7, 14, 28 and 56 days of age; porosity, bulk density and voids according to ASTM C-642; Scanning Electron Microscopy (SEM) with chemical probe analysis; and ultrasonic pulse velocity (UPV) measurements. The results allow to conclude that it is feasible to manually make concrete mixtures without increasing the consumption of cement, optimizing the behavior of the material in terms of durability, since a homogeneous material was obtained with a better dispersion of the cementing material, which qualifies its rheological conditions. This work was granted an Invention Patent, with number 16136903, and both the author and the Universidad Nacional de Colombia have donated this process to society so that it can be carried out in territories such as Latin America, Africa and Asia, that share self-construction processes, with advice from academic and social work centers. It can also be used in works that require making small quantities of concrete for mixing adjustments.

Keywords: cement; concrete; construction materials; durability; sustainable construction; traditional architecture

Este artículo da a conocer una metodología para la confección manual de mezclas de concreto mediante el principio de suspensión mecánica, con el que se obtuvieron mezclas de concreto con un desempeño óptimo en cuanto a resistencia a la compresión, porosidad, densidad y porcentaje de vacíos. Se hicieron ensayos de destrucción de muestras cilíndricas a 7, 14, 28 y 56 días de elaboración; porosidad, densidad Bulk y vacíos según ASTM C-642; microscopía de barrido electrónico (MBE) con análisis de sonda química, y mediciones de velocidad de pulso ultrasónico (VPU). Los resultados permiten concluir que es factible confeccionar manualmente mezclas de concreto sin aumento del consumo de cemento, lo que optimiza el comportamiento del material en cuanto a durabilidad, ya que se obtuvo un material homogéneo con mejor dispersión del material cementante, que cualifica sus condiciones reológicas. A este trabajo se le concedió Patente de Invención, con el número 16136903, y tanto el autor como la Universidad Nacional de Colombia han donado a la sociedad dicho proceso, para que pueda ser llevado a cabo en territorios como Latinoamérica, África y Asia, que comparten procesos de autoconstrucción, con asesoría de centros académicos y de trabajo social. También puede ser empleada en obras que requieran elaborar pequeñas cantidades de concreto para ajustes de mezclas.

Palabras clave: arquitectura tradicional; cemento; construcción sostenible; durabilidad; hormigón; materiales de construcción

Introduction

In Colombia, and generally in Latin America, informal construction is growing more and more (Turner, 2018, p. 69), so it is a fact that an important part of the cities materializes behind the back of municipal or governmental planning. In addition to representing a social and environmental problem, given that habitability standards such as educational or recreational facilities are not met, the quality of construction is sometimes not of optimal quality, or to be so, cost overruns must be assumed, as it is the case of manufacturing concrete and mortar, since this composite material is one of the most used for the consolidation of the built habitat.

In the absence of mechanical technologies for the preparation of mixtures using ordinary Portland cement (OPC), most of the time informal builders make mortars -for brick and plastering-and concrete -for columns, beams, and slabs- by manually mixing the materials (Aguwa, 2010, p. 60). Essentially, the following materials are used in small works: fine and coarse aggregates, Portland cement for general use, and water.

The procedure used for decades consists of: 1) dry and mix the aggregates until homogeneity is achieved; 2) add the cement to the aggregates and mixing until homogeneity is achieved; 3) elaborate a sort of volcano with this mixture of aggregates and cement to pour the water into the center and make the final mixing until either mortar or concrete is obtained. These steps and their order apply equally in Europe, Asia, and Africa, either because small volumes are made, or because doing so obeys informal constructions.

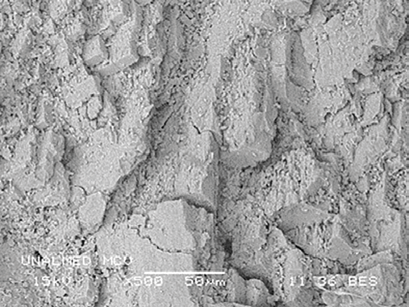

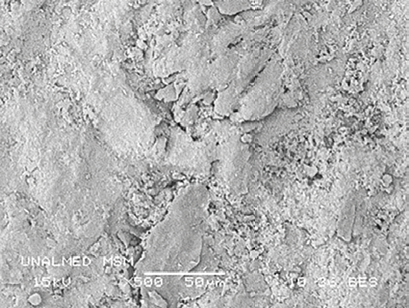

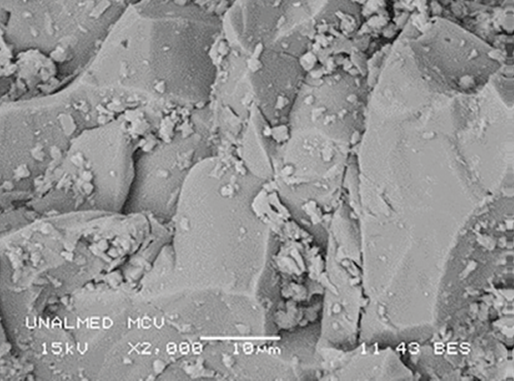

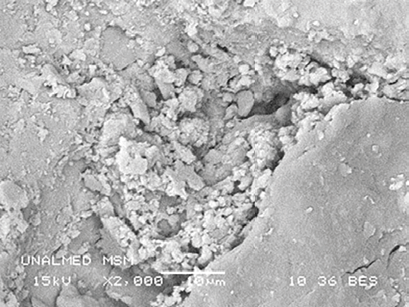

Although it is said that there is homogeneity in the mixture of aggregates and cement in a dry state, this is not entirely true. On the contrary, as it could be verified by this research through MBE images, neither cement dispersion nor aggregate coating is achieved in an optimal way, which also affects the strength and durability aspects.

In addition, the decision is often made to add more cement than calculated to make up for the deficiency of manual mixing, which increases the cost per cubic meter of mortar and concrete, precisely for the communities with the lowest monthly income, and which, due to outsourcing and the supply chain with intermediaries, pay the most expensive cement on the market.

Based on the above, this article explains how a manual mixing methodology used for more than ten decades, inherent to the existence of modern Portland cement was rethought by proposing a new succession of stages in the mixing of its components and, thus, a better dispersion of cement, which contributes to the improvement of intrinsic characteristics of the material, such as lower porosity, lower absorption and greater activation of the cementitious material in the mixture.

Methodology

The raw materials and methods used for the concrete mixtures are described below, as well as the tests and discussion of the results obtained. The concrete made with a conventional manual mixing procedure was called MCV, and the concrete made with a mechanical suspension mixing procedure was called MSM.

Selection of raw materials

Natural aggregates from quarries were used. Table 1 shows the characteristics of the coarse and fine aggregate.

Table 1 Characteristics of the aggregates used.

| Variable | Coarse aggregate | Fine aggegate |

|---|---|---|

| Maximum size (mm) | 19.05 | - |

| Maximum siza (mm) | 2.87 | 2.74 |

| Fineness modulus | 7.20 | 3.30 |

| Absorption percentage(%) | 1.28 | 3.00 |

Source: own elaboration (2020).

The cement used was CPO, or general-purpose cement, whose characteristics are shown in Table 2.

Preparation of mixtures by MCV and MSM

The mixtures were made at the Construction Laboratory of the Universidad Nacional de Colombia, Medellín. Two concrete mixtures were designed: one called conventional manual mixing (MCV), and the other called manual mixing with mechanical suspension (MSM). A slump in the range of 5 cm to 7.5 cm was sought, using an A/C ratio of 0.52 in the two mixtures. The slumps are shown in Table 3.

Preparation of conventional manual mixing

The MCV mixture is the procedure used worldwide for manufacturing mortars and concretes at a small scale. It has the following stages:

The aggregates are prepared and mixed in a dry state until a uniform mixture is obtained, as shown in Figures 1 and 2.

Then a kind of volcano is made, to pour the cement in the center of the aggregates, and it is stirred until obtaining a homogeneous dry mixture with a predominant gray color, as seen in Figure 3.

Finally, water is poured over the aggregate-cement combination and stirred until a wet mixture is obtained, which is poured into the cylindrical specimens, as shown in Figures 4, 5 and 6.

Manual mixing with mechanical suspension

The MSM mixture is the proposal of this work. It modifies the mixing process of the components and, as will be seen in the section corresponding to the results and their discussion, has an impact on the behavior of the concrete, both in the fresh and hardened states. Its stages are:

The necessary amount of water is prepared, and the cement is gradually deposited in the container containing it, as shown in Figure 7.

It is mixed until the cement is dispersed in the water, resulting in a mechanical active suspension, as shown in Figure 8.

The fine aggregate is introduced into the active mechanical suspension and stirred until a homogeneous mixture is obtained, dispersing the grains among the fluid paste, as shown in Figure 9.

Finally, the coarse aggregate is poured and stirred until the concrete mixture is obtained, ready for placement or pouring into the cylindrical specimens, as shown in Figures 10 and 11.

Source: own elaboration (2019). CC BY

Figura 9 Pouring of fine aggregate into the mechanical suspension.

Source: own elaboration (2019). CC BY

Figura 10 The coarse aggregate is mixed with the paste obtained by mechanical suspension.

The same design and dosing of materials was used for both mixtures since the study was not on the substitution of conventional material, but on the mixing methodology. Material consumptions are shown in Table 4.

Strength and durability tests

Cylindrical samples of 10 cm in diameter and 20 cm in height were made and then immersed in a curing tank with lime-saturated water at a temperature of 23 + 3 2C, as shown in Figures 12, 13, and 14. The samples were taken to the hydraulic press to determine their resistance to compressive stress at ages of 7, 14, 28, and 56 days. Hardened concrete samples were also analyzed to determine their behavior in terms of absorption, bulk density, and porosity. For these analyses, ovens according to ASTM C-642, electronic press for compressive failure, and ultrasonic pulse velocity equipment were used.

Results

Compressive strength tests

Fifteen concrete samples were made for each of the mixtures, for a total of 30, using cylindrical specimens 10 cm in diameter and 20 cm in height. Three specimens were taken per mixture for each failure age, according to NTC 1377, equivalent to ASTM C192M (Icontec, 1994). The results are shown in Table 5.

Table 5 Resistance to compressive stress.

| Mixture | Resistance to compressive stress (MPa) | |||

|---|---|---|---|---|

| MCV | 7 days | 14 days | 28 days | 56 days |

| 1 | 14,28 | 18,35 | 22,02 | 24,90 |

| 2 | 14,82 | 18,13 | 21,85 | 24,75 |

| 3 | 14,53 | 18,28 | 21,95 | 24,55 |

| Average | 14,54 | 18,25 | 21,94 | 24,73 |

| MSM | 7 days | 14 days | 28 days | 56 days |

| 1 | 14.15 | 18.76 | 22.25 | 25.18 |

| 2 | 14.62 | 18.45 | 21.90 | 24.79 |

| 3 | 14.27 | 18.20 | 22.40 | 24.63 |

| Average | 14.35 | 18.47 | 22.18 | 24.87 |

Source: own elaboration (2020).

The MCV mixture was taken as a reference, to make a percentage comparison in terms of compressive stress behavior, assuming, then, that the MCV mixture is 100%, as shown in Table 6.

Table 6 Comparative behavior to compressive stress.

| Mixture | Compressive stress comparison (%) | |||

|---|---|---|---|---|

| 7 días | 14 días | 28 días | 56 días | |

| MCV | 100,00 | 100,00 | 100,00 | 100,00 |

| MSM | 98,69 | 101,21 | 101,09 | 100,57 |

Source: own elaboration (2020).

An average of the compressive strength at the four failure ages showed that the MSM mixture was 100.39%, compared to the control mixture, which was the MCV, indicating a slightly higher performance or in favor of the MSM; however, statistically, they are considered identical. The positive aspect of this result is that the new mixing methodology behaves following the requirements of the mixture design parameters, without negative effects, and reaching the performance resistances of ordinary concrete made in popular sectors, which are in the order of 21.0 MPa, according to NSR-10 (Decree 926 of 2010).

This result is consistent with the slump test of the mixtures in the fresh state, since, as shown in Table 3, the MSM mixture showed a higher slump compared to the MCV mixture. These slumps were 7.20 cm and 6.90 cm, respectively, which leads to infer that there is an optimal accommodation of the materials in the concrete matrix (Figueroa & Palacio, 2010). In this sense, the workability of the mixtures in a fresh state for small volumes was better in the case of the MSM mixture, where better lubrication of the components was noted at the time of stirring the materials, represented by a lower effort on the part of the participants in the manual mixing activity.

Durability tests

Although there are no significant differences between the two types of mixtures in terms of compressive strength, as shown in the previous section, this research is especially interested in their behavior in terms of durability, since the constructions referred to in this study, and the small volumes, between 0.25 m3 and 0.50 m3, are located in cities such as Bogotá, Medellín, Caracas, Mexico, and Santiago de Chile, which have high levels of atmospheric C02 (Rosas et al... 2010, p. 12), 2010, p. 12); thus, the performance of the material in a hardened state in these carbonate environments is an important aspect for the service life of CPO-based structures and coatings.

The tests performed were: standard test method for density, absorption, and voids in the concrete according to ASTM C642-06, as shown in Table 7; MBE, and ultrasonic speed, as shown in Table 8. The results are shown below.

Table 7 Density, absorption and voids of hardened concrete.

| Mixture | Absorption after immersion and boiling (%) | Dry Bulk Density (g/cm3) | Empty permeable pore volume(%) |

|---|---|---|---|

| MCV(1) | 9,90 | 2,11 | 21,60 |

| MCV (2) | 10,10 | 2,09 | 21,70 |

| Average MCV | 10,0 | 2,10 | 21,65 |

| MSM (1) | 9,50 | 2,11 | 20,90 |

| MSM (2) | 9,60 | 2,11 | 21,00 |

| Average MSM | 9,55 | 2,11 | 20,95 |

Source: own elaboration (2020).

Table 8 Ultrasonic Pulse Velocity.

| Sample | Sample moisture (%) | Speed (m/s) | Average speed (m/s) |

|---|---|---|---|

| MCV (1) | 13.25 | 3 911.0 | 3 903.5 |

| MCV (2) | 13.07 | 3 896.0 | |

| MSM (1) | 13.18 | 4 125.0 | 4 096.0 |

| MSM (2) | 13.10 | 4 067.0 |

Source: own elaboration (2020).

It can be observed that the MSM mixture has better behavior, or performance, than the MCV reference mixture. In terms of dry bulk density, the MSM was also superior. Regarding the values of absorption and porosity of the hardened concrete, both mixtures presented a behavior under the ranges exposed by different researchers; among them, D. K. Nekrasov, who asserts that concretes register porosities that oscillate between 20% and 30%, or Apórtela, who obtained average porosities of 23.3 % with limestone aggregates and an A/C ratio of 0.50. As for absorption, the values obtained for the two mixtures also fall within the range described by D. K. Nekrasov, which is between 10 % and 20 % (Olivares et al., 2004).

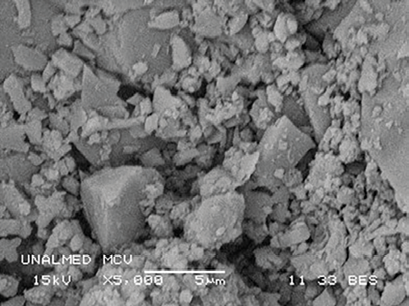

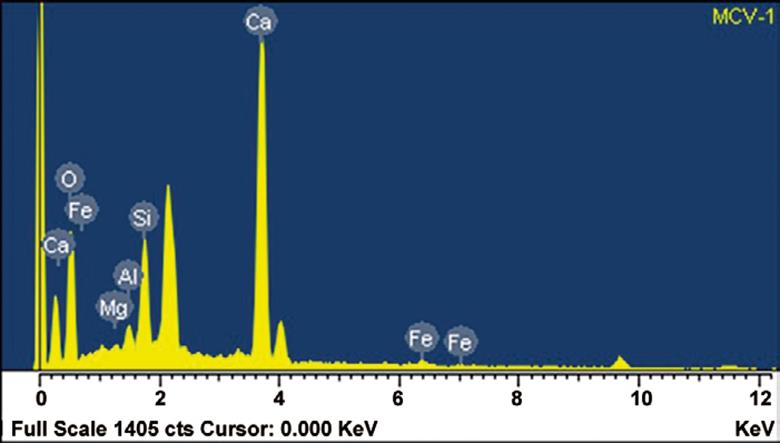

Scanning electron microscopy

As noticed in the MBE, (figures 15 - 20)the MSM mixture shows different behavior from that of the reference mixture MCV, since a more homogeneous, less porous surface topography is observed, to the extent that a better covering of the aggregates by the paste is evident. This means that the cement particles present a greater dispersion, and therefore the mechanical suspension covers, in a homogeneous manner, the inert filler material of the cementitious matrix. As the level of microscopic observation increased, noticeable differences were identified regarding the presence of pores and the exposure of aggregates in the hardened concrete, and to corroborate these findings, a reading was made using the chemical probe for micro-areas of the MBE, as shown in Figures 21 and 22.

Source: own elaboration (2019). CC BY

According to Figures 21 and 22, the presence of the components reported by the chemical probe for micro-areas coincides with the quality of the national cement used for the manufacture of CPO-based concrete (Tobón & Montoya, 2006). The presence of potassium (K) in the MSM coincides with a stage or phase of maturation of the cement paste of the concrete in a hardened state, but which is generally obtained by mechanical mixing, and not by manual mixing; this is an important achievement of the present research, since more complete hydration of the cement perhaps is being reached (Franus & Panek, 2015, p. 105).

Ultrasonic pulse rate

The results for the MCV and MSM mixtures are shown below. All cylindrical specimens were cured for 28 days, immersed in water saturated with lime; they were then dried for seven days at room temperature. The percent moisture content of the air-dried specimens was measured as well as the VPU, as shown in Table 8.

It is observed that the moisture content of the specimens is uniform in both mixtures. The MSM presented a higher PVU than the MCV, an aspect that is consistent with the characteristics of workability and initial slump, with the compressive stress resistance and with the porosity tests. If the value of the PVU of the MCV is taken as reference, then it is found that the MSM reaches 104.93%; that is, it is 192.50 m/s higher.

According to Malhotra, concrete with a PVU between 3660 m/s and 4575 m/s is considered good; below this range, it is considered fair and above this, it is considered excellent (Cruz et al., 2014). For the normal use, mixtures referred to in this research, which are between 21.0 MPa and 23 MPa, a performance in the range of 3660 m/s and 4575 m/s is considered optimal.

Discussion

The performance of the MSM samples was superior in all characteristics to that presented by the MCV, without requiring additives or an increase in the cementitious material to obtain such rheological qualification. For example, the compressive strength, although, statistically speaking, presented an identical behavior in both mixtures, remained superior in the MSM, which can be qualified as a positive aspect of the proposed methodology, since there is no negative effect on this physical-mechanical characteristic, and it follows the standards required for structural concrete with ordinary stresses, according to NSR-10.

The research was carried out in the urban context of Medellin (Colombia), a city that, like Bogotá (Colombia), Caracas (Venezuela), Mexico City (Mexico) and Quito (Ecuador), has a delicate problem of environments with a high presence of C02. Therefore, in addition to analyzing the behavior under compressive stress, it is necessary to study hardened concrete in terms of porosity. The higher the porosity and the volume of voids in the hardened concrete, the greater the possibility of carbonation and loss of passivation of the reinforcing steel, while the higher the density of the material, the less the possibility of leaching of dissolved C02. Under these characteristics, the MSM mixture performed better than the MCV.

Conclusions

The analysis using MBE allowed observing a better behavior of the microstructure of the hardened concrete in the MSM mixture. The images at different magnifications show a better coating of the aggregates by the paste, as well as a more homogeneous distribution of the paste on the surface. In turn, the chemical probe in micro-areas showed that in the MSM there is no negative affectation of its components; on the contrary, optimal activation of the cement was observed, in comparison with the MCV mixture, which was closer to a hydration maturity phase of a mechanically made mixture.

Another characteristic in favor of the MSM is its performance in the PVU test, being superior to that of the MCV, which indicates a lower air content inside the hardened mixture, and that urban contexts such as those already mentioned are detrimental to the durability and the physical-mechanical response of the concrete structures, since in the cities mentioned there are no freeze-thaw phenomena of stationary countries, so the mixtures are made without air inclusions and, on the contrary, looking for the lowest possible number of pores. In this sense, the VPU of the MSM was consistent with the results of porosity, density, and compressive strength, which allows concluding that there is a qualification of the compactness of the concrete, and this characteristic is relevant for the performance of hardened concrete, since it has already been proven that the lower the porosity of the material, the higher its mechanical strength, as well as its durability.

In general, it can be concluded that the MSM procedure is a contribution to construction with high population impact since it is aimed at small works that produce volumes between 0.25 m3 and 0.50 m3, where the highest consumption of cement and aggregates occurs, and in whose construction and self-construction processes the communities do not usually have access to mechanical means of mixing.

Consequently, more cement content is used to compensate for the absence of mechanized technologies that seek better compaction of the mixtures. Therefore, this methodology is presented as a contribution from the technical realm, as well as from the ecological and economic sustainability to the sustainable construction of urban and rural habitats. Hence, it is up to the academy, the construction guild, and the political-administrative administrations to contribute to its dissemination and massification

Acknowledgements

The author is grateful to the Universidad Nacional de Colombia, Medellin, for the support provided for the development of this research, as well as for the patent process before the Superintendencia de Industria y Comercio of Colombia (NP 16136903)

REFERENCES

Aguwa, J. (2010). Effect of hand mixing on the compressive strength of concrete. Leonardo Electronic Journal of Practices and Technologies, (17), 59-68. https://citeseerx.ist.psu.edu/viewdoc/down-load?doi=10.1.1.651.5943&rep=rep1&-type=pdf. [ Links ]

Cruz, R., Quintero, L. A., & Herrera, J. (2014). Evaluación del efecto de barras de refuerzo en concreto sobre las medidas de velocidad de pulso ultrasónico (VPU). Revista Colombiana de Materiales, (5), 107-113. https://revistas.udea.edu.co/index.php/materiales/article/view/19576. [ Links ]

Figueroa, T., & Palacio, R. (2010). Pathologies, causes and solutions of architecture concrete in Medellín. Revista EIA, 5(10), 121-130. doi:https://doi.org/10.24050/reia.v5i10.214. [ Links ]

Franus, W., & Panek, R. (2015). SEM investigation of microstructures in hydration products of Portland cement. https://pdfs.semanticscholar.org/d91f/8b-d9386a82457d5c0990b76a5a83a-3f046fa.pdf. [ Links ]

Instituto Colombiano de Normas Técnicas y Certificación (Icontec). (1994). NTC 1377 Elaboración y curado de especímenes de concreto para ensayos de laboratorio. Icontec. [ Links ]

Decreto 926 de 2010. Por el cual se establecen los requisitos de carácter técnico y científico para construcciones sismo resistentes Reglamento NSR-10. Marzo 19 de 2010. DO. 47656. https://www.adjurin.com/images/Pdf/5.Decreto_926_de_2010.pdf. [ Links ]

Olivares, M., Laffarga, J., Galán, C., & Nadal, P. (2004). Evaluación de la resistencia mecánica de un hormigón según su porosidad. Revista Materiales de Construcción, 54(273), 21-33. doi.org/10.3989/mc.2004.v54.i273.220. [ Links ]

Rosas, J., Rosas, D., & Morillón, D. (2010). Saturation, energy consumption, CO2 emission and energy efficiency from urban and rural households appliances in México. Energy and Buildings, 43, 10-18. doi.org/10.1016/j.enbuild.2010.08.020. [ Links ]

Sakai, K. (2009, 20 November). Recycling concrete: the present state and future perspective. Presented in TCG-JSCE Joint Seminar, Athens, Greece. https://businessdocbox.com/Green_Solutions/76590841-Recycling-concrete-the-present-state-and-future-perspective.html. [ Links ]

Tobón, J., & Montoya L. (2006). Análisis comparativo entre algunas materias primas minerales nacionales e importadas utilizadas en la industria del cemento. Boletín de Ciencias de la Tierra, (19), 57-72. http://www.scielo.org.co/pdf/bcdt/n19/n19a04.pdf. [ Links ]

Turner, J. (2018). Autoconstrucción. Por una autonomía del habitar. Pepitas Ed. https://www.pepitas.net/sites/default/files/libros/primeras_paginas/Turnerprimeras.pdf [ Links ]

Received: May 27, 2021; Revised: September 15, 2021; Accepted: October 26, 2021

text in

text in