Pasta is a product obtained from a dough composed of semolina and water, which is subjected to mixing, extrusion, and dehydration processes (in some cases). The quality of spaghetti depends not only on the quality of the raw materials but also on the processing conditions (Giannetti et al. 2014). Good quality pasta is resistant to cooking, firm, and has low adherence. Pasta is also known for its low nutritional value and dietary fiber content. Durum wheat semolina used in pasta can be enriched with legume flour to produce more nutritious but still high-quality pasta (Ahmad et al. 2018). Because of that, research into spaghetti has focused on three main aspects: extrusion conditions, total or partial replacement of semolina with non-conventional flours, and drying conditions.

The first aspect is important because it influences the final quality. It gives the product greater stability during storage and affects physical characteristics, such as color, texture, cooking quality, and sensory quality. The second aspect can increase nutritional quality since pasta is considered an unbalanced food because of its low contents of fat, dietary fiber, and protein with biological value (lysine and threonine deficiency). Several studies have been carried out on the formulation of spaghetti with unconventional flours (Ahmad et al. 2018; Fiorda et al. 2013; Gull et al. 2015; López-Mejía and Morales-Posada 2020). Various studies have reported the use of dehydrated and ground squash pulp as a partial substitute for wheat semolina due to its contents of protein (4.91-9.63 g 100 g-1), dietary fiber (3.72-35.32 g 100 g-1), minerals (6.01-7.39 g 100 g-1) (Aziah Noor and Komathi 2009; Aydin and Duygu 2015; Mirhosseini et al. 2015), carotenoids (2.82-9.20 mg 100 g-1), and phenolic compounds, as well as its high antioxidant activity (Que et al. 2008) and pleasant orange color.

Different studies have shown that various benefits are obtained by replacing conventional flour with pumpkin pulp flour in pasta formulation. One of the most outstanding is the significant nutritional contribution this plant material provides to the product. Pumpkin pulp presents high alpha and beta-carotene (pro-vitamin) content and high antioxidant capacity (López-Mejía et al. 2020; Buzigi et al. 2021), reducing the risk of degenerative diseases, cardiovascular diseases, cataracts, and certain carcinomas (Buzigi et al. 2021). Moreover, it has been mentioned that it increases the mineral and fiber content, especially the soluble type. Furthermore, pumpkin pulp can help improve important sensory attributes, such as color as it increases redness (a*) and yellowness (b*) due to carotenoid pigments. An increase in flavor acceptance has also been reported. The texture remains acceptable and similar to the samples where wheat was not substituted as long as the DSP (dehydrated squash pulp) addition level in the formulation does not exceed 25-30% (Mirhosseini et al. 2015; Novita Indrianti et al. 2021). However, the partial or total replacement of wheat flour with this vegetable flour remains challenging because some adverse effects on the quality of the pasta are observed. Among them is the decrease in the amount of protein and starch, thus lowering the gluten concentration, which is also interrupted by the presence of fibers. This leads to the absence of a stable network that allows the trapping of starch granules, which leads to increased cooking losses, decreased cohesion and elasticity, and increased adhesiveness. Thus, formulated pasta dough with 50% or more non-wheat flour does not have an appropriate texture for the laminating process (Mirhosseini et al. 2015; Novita Indrianti et al. 2021).

The last aspect, regarding drying, is important because the dehydration process induces the polymerization of the protein network, which, by forming strongly and continuously, prevents the release of the starch exudate and reduces the stickiness of the pasta. Additionally, the drying temperature induces changes in the starch structure, which presents greater damage in dry pasta dried at low temperatures, influencing the adhesiveness and hardness. For this reason, it is considered that pasta dried at high temperatures has a higher cooking quality than pasta dried at low temperatures (Masato et al. 2021), which is one of the most important characteristics for consumers. However, in fortified pasta with alternative flours as an important source of β-carotene, low temperatures (30-60 °C) should be considered to increase the retention of the bioactive compound (Larrosa et al. 2016). Despite the importance of this unit operation in the final quality of spaghetti, few studies that analyze the effect of drying temperature in pasta made from wheat semolina fortified with vegetable flours of high nutritional value have been carried out. Therefore, the aim of this research was to evaluate the effect of low-temperature drying on the properties that determine the quality of spaghetti enriched with dehydrated squash pulp at different levels (5, 10, 15, and 25 g DSP100 g-1 of flour).

MATERIALS AND METHODS

Materials

Fresh squashes (Cucurbita moschata var. Bolo verde) were purchased in a local market (Cavasa, Candelaria, Palmira, Valle del Cauca, Colombia) and processed to obtain dehydrated pulp. They were conditioned and dried following the methodology reported by López-Mejía and Morales-Posada (2020). The milled durum wheat semolina used was of Italian origin (La Molisana) with a protein ratio of 14 g 100 g-1. All reagents mentioned in this study were analytical grade (95 and 99% v v-1).

Spaghetti preparation

The base spaghetti formulation consists of two components: flour (wheat flour and/or dehydrated squash pulp) (65 g 100 g-1 mix) and distilled water (35 g 100 g-1 mix). The incorporation of DSP was added in the following amounts: 5, 10, 15, and 25 g 100 g-1 of flour. Each component was weighed on a precision balance (Mettler Toledo, PB1502, Switzerland) and mixed manually to achieve a uniform appearance. Subsequently, distilled water was added, and the mixture was kneaded for 15 min until an elastic mass was obtained, which was left to rest for 1 h. Next, the dough was cut with a manual machine (Imperia, Italy, 2015) and length=150.50±0.55 mm.

Spaghetti drying

The drying operation was carried out in a climatic chamber (Memmert, ICH 260L, Germany) under two conditions [Temperature (°C)/Relative Humidity (RH)]: Condition 1) 50 °C/50% RH (30 min) (stage I), 50 °C/70% RH (6 h) (stage II) and 40 °C/50% RH (12 h) (stage III); and Condition 2) 50 °C/50% RH (30 min) (stage I), 60 °C/70% RH (6 h) (stage II) and 40 °C/50% RH (12 h) (stage III). Each drying condition was carried out in triplicate, with an initial load of 300±1 g (moisture content of 35±0.70 g 100 g-1).

For each condition, drying ramps were used, carried out in three stages. Stage I was called pre-drying, where the moisture content of the spaghetti was reduced by up to about 20%; this was carried out at a low temperature to avoid cracking the surface and for a short time to prevent the development of fungi. Stage II was called drying and was carried out at a higher temperature than the pre-drying and lasted approximately 5 to 6 h until a moisture content of 12±1 g 100 g-1 (w.b.) was achieved. Stage III was called stabilization and consisted of keeping the spaghetti at low temperature and relative humidity conditions to stabilize it for later packaging and storage.

Spaghetti quality

Proximal analysis

Moisture, protein, dietary fiber, fat, and ash contents were determined using AOAC (2005) methods. They were measured in triplicate and expressed on a dry basis.

Total carotenoid content and color

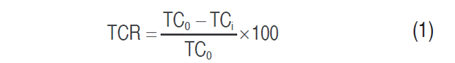

The quantification of total carotenoids (TC) (µg g-1) (dry-based) was performed in fresh, dry, and cooked spaghetti in triplicate. Absorbance at 450 nm (Abs450) was measured on a spectrophotometer (Jenway, 6320D, United Kingdom). The TC concentration concerning the β-carotene concentration was calculated using the equation of Lambert-Beer, with a coefficient of β-carotene in hexane / of 2,592 (Rodríguez-Amaya 2001). The percentage of total carotenoid retention (TCR) was calculated by the difference from the initial content (fresh spaghetti) (equation 1).

Where TC0 is the total carotenoid content before spaghetti processing (drying and cooking) and TCi is the total carotenoid content after spaghetti processing (drying and cooking).

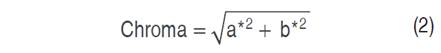

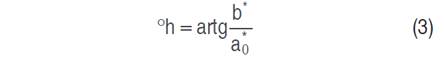

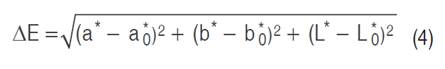

The color parameters CIELAB, L* (luminosity: 0-100); b* (color coordinate which indicates yellow + and blue -); a* (color coordinate which indicates red + and green -) were measured using a colorimeter (Konica Minolta, CR-400, Japan) previously calibrated (Y=89.5, X=0.3166, and Y=0.3347). The Chroma (equation 2), tone angle (h°) (equation 3), and color difference regarding dry spaghetti ΔE (equation 4) were calculated. /, / and / were measured in fresh spaghetti; and L*, a*, and b* were measured in dry spaghetti.

Cooking quality

The spaghetti cooking tests were carried out in triplicate for each formulation, according to AACC International Methods (AACC 66-50.01 2010) with some modifications. The tests consisted of immersing 25 g of dried pasta in 300 mL of distilled boiling water (98 °C). The cooking time was the time it took for the spaghetti to be cooked al dente (representing pasta with some presence of ungelatinized starch in the inner core). The weight gain (water absorbed by the structure) was determined by the weight difference before and after cooking and was reported as a gram of water 100 g-1 of sample. Finally, the solids lost by cooking were evaluated. After cooking, the water level was brought to the initial volume. The dry matter was determined from a sample of 25 mL of cooking water subjected to 105 °C to a constant weight in a furnace (Raypa, EV-50, Spain). The result was expressed as g of solids 100 g-1 of sample.

Texture analysis

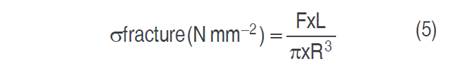

Fracture tests were carried out on dry spaghetti, and double-cycle compression tests were performed on cooked spaghetti using a texturometer (Shimadzu, EZ-S Test, Japan). The fracture test was performed by incorporating a segment of dry spaghetti on a bending bridge (lower broken core jig 346-51818-01) with an opening of 4 cm, and a compression force was exerted in the center with a probe (toothed pushrod B 1 pc 346-51814-02) at a speed of 30 mm min-1 until fracture. The samples consisted of cylinders (1.91±0.15 mm x 70±5 mm) of dry spaghetti (MC=9.10±1.07 g 100 g-1). The breaking force was measured as the maximum peak and the distance at which the sample fractured. The breaking force (σfracture) was calculated using equation 5. The diameter of the sample (1.91±0.15 mm) was measured with an electronic digital calibrator (Mitutoyo, Japan). For the double compression cycle test, the same probe was used. For each test, four strands of spaghetti al dente with a diameter of 2.50±1.05 mm were used. The samples were placed perpendicularly to the probe in a base cutting test jig (346-51817-01). The speed of analysis was 30 mm min-1, reaching 100% compression. Through the analysis, six textural parameters were obtained: fracture (N mm-2), hardness (N), cohesiveness (dimensionless), elasticity (dimensionless), gumminess (N), and chewiness (N). The graphs were processed with Origin 8.0 (USA).

Where L is the distance between the two supports of the bending bridge (mm); R is the radius of the spaghetti sample (mm); and F is the maximum force at the fracture (N).

Sensory analysis

The spaghetti samples cooked al dente were subjected to sensory evaluation by a semi-trained panel of 20 people (9 women and 11 men), aged between 23 and 50. For this analysis, evaluators were selected based on their health status, availability, and fondness for the product (ICONTEC: GTC 165, 2007). Once pre-selected, they underwent screening tests for basic tastes, odors, and colors, and were subjected to paired, duo-trio, and triangular tests with problem substances. The outcomes of these tests were scrutinized using sequential analysis according to ICONTEC: NTC 5278 (2004). Upon selecting the panelists, trials were conducted with the type of sample and test to be applied, ensuring that the results were consistent. Attributes such as color, brightness, odor, elasticity, adhesiveness, firmness, and taste were evaluated in 8 g samples served at room temperature (28 °C) on white polystyrene plates in an illuminated and odor-free space. The rating scale was from 1 to 5, where 5 meant "I like it a lot," 4 "I somewhat like it," 3 "I neither like nor dislike it," 2 "I somewhat dislike it," and 1 "I dislike it a lot." To qualify elasticity, the evaluator was asked to take a piece of spaghetti with both hands and exert contrary forces until it split. For adhesiveness, two pieces of spaghetti were joined and then separated. Finally, firmness was evaluated as the necessary force exerted by the teeth to divide the sample. In this analysis, the attribute was acceptable when the rating was greater than 3. The intent to purchase was estimated by asking the panelists if they would buy the product, to which they responded with "yes," "no," or "maybe," and a comment section was included. Each spaghetti formulation was evaluated on a different day.

Experiment design and statistical analysis

A completely randomized factorial design was carried out to analyze the effect of the drying temperature and the addition of DSP on the spaghetti quality characteristics. A two-way analysis of variance and Tukey's test (P<0.05) were developed using SPSS. For this purpose, the data were subjected to tests of normality and homogeneity in order to ensure statistical inference. Furthermore, a Pearson correlation test was carried out to analyze the correlation between the percentage of DSP on humidity content and the correlation between sensory attributes evaluated in the product.

RESULTS AND DISCUSSION

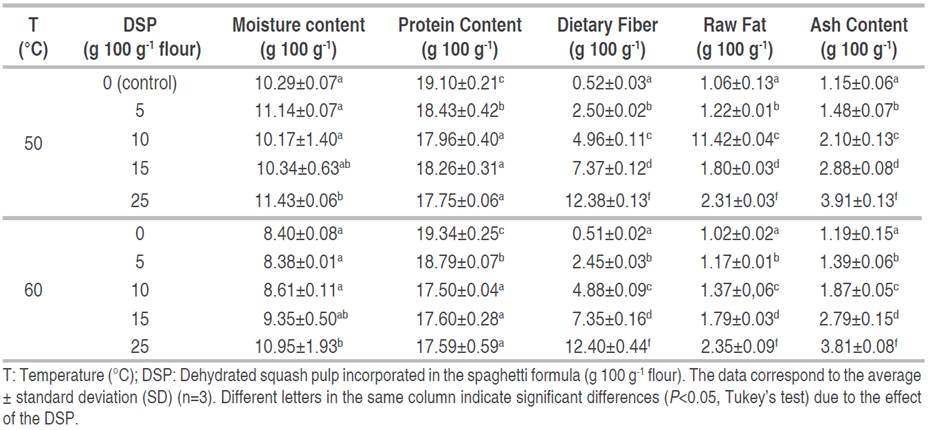

Proximal analysis

The DSP flour was characterized by obtaining values of moisture content (13.08±0.07 g 100 g-1), dietary fiber (30.02 g 100 g-1), protein (13.87±0.05 g 100 g-1), ash (8.89±0.10 g 100 g-1), total carotenoids (452.04 µg g-1), phenolic compounds (415±9.19 mg GAE 100 g-1), and CIE L* a* b* coordinates of L*=71.50±0.03, a*=13.60±0.30, and b*=34.72±0.16. According to the analysis of variance, temperature only had a significant effect on the moisture content (P<0.05), while DSP had a highly significant effect on all parameters measured in the proximal analysis (P<0.0001). The interaction between the factors did not significantly affect these variables. According to the homogeneous subset test carried out with the DSP factor, when analyzing the moisture content, there were no significant differences between the control and DSP-5, DSP-10, and DSP-15. At the same time, DSP-25 was significantly higher than the control. This result was attributed to a higher proportion of hydrophilic compounds provided by the DSP (carbohydrates and proteins). This could be corroborated using the Pearson correlation test, in which a value of r=0.457 was obtained (P<0.05). Finally, the moisture content values obtained for each formulation were found to have a maximum value of 13% (d.b.).

For a fixed drying time of 6 h, an inversely proportional relationship was evident between the drying temperature and moisture content (Table 1), which could be corroborated by the Pearson correlation test performed, which revealed a highly significant value of r (r=-0.556) (P<0.01). The moisture content decreased when the drying temperature increased from 50 to 60 °C. This result is related to the increase in collision energy between molecules due to the increase in temperature, which increases the diffusivity of the water toward the surrounding medium.

Table 1 Physicochemical properties of the spaghetti on a dry basis as a function of % DSP and drying temperature.

Concerning protein content, it was observed that DSP-10, DSP-15, and DSP-25 were not significantly different, although they were significantly lower than the control. At the same time, DSP-5 was significantly higher than all DSP formulations but lower than the control. In contrast, fat increased significantly from 1.17 to 2.35 g 100 g-1, which indicated the contribution of fatty acids that raw vegetable material provides to the formulation. A similar trend was evidenced for ash content due to the richness in minerals such as calcium, phosphorous, potassium, and zinc that DSP provides to the formulation (Ponka et al. 2015). This trend was also observed for dietary fiber: up to 25 times higher in DSP-25 than the control.

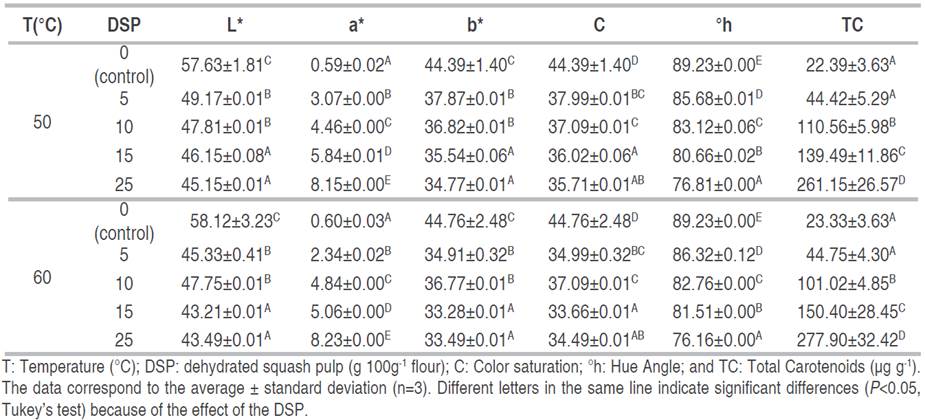

Color and total carotenoid content

According to the analysis of variance, the factors, both independently and in their interaction, had a highly significant effect on the color CIEL* a* b* coordinates (P<0.001). However, temperature did not have a significant effect on the total carotenoid content (P>0.05). A similar result was reported by Hidalgo et al. (2010), who found no significant loss of this bioactive compound during the drying of pasta. The greatest loss occurs during the extrusion process (a stage that was not considered in this study since it was handmade pasta). In contrast, DSP significantly influenced this variable (P<0.05). DSP had a significant effect on the total carotenoid content of the spaghetti. The added DSP is rich in carotenoid pigments, such as β-carotene, which provide functional properties and nutritionally enrich the product. The spaghetti obtained in this study had a total carotenoid content ranging from 44.42 to 277.90 µg g-1, and the total carotenoid content of DSP-25 was 12 times higher than that of the control.

Analyzing the values of the a* coordinate that expresses the reddish tones for positive values, it was observed that this increases significantly with the addition of DSP, presenting the highest value in DSP-25. On the other hand, the b* coordinate that expresses yellow tones for positive values decreases significantly with increasing DSP, lowering the yellow tone. This behavior is related to the increase in total carotenoid content in the formulation, reaching a value of 269.52 µg g-1 for DSP-25. The above is reflected in the values of °h and Chroma, since °h decreases, approaching orange tones, and Chroma also decreases, meaning that the color reduces its purity (Table 2).

Moreover, when analyzing the effect of temperature on these coordinates, a decrease in L*, a*, and b* was observed, indicating an increase in orange tones. This is attributed to a greater elimination of moisture, which leads to the carotenoids becoming more concentrated in the food matrix. The ΔE of the fresh samples decreases due to the effect of temperature, while it increases due to the effect of DSP (ΔE=17.77-23.88: 50 °C; 17.20-22.19 60 °C). It was noted that the DSP-25 spaghetti had a dark brown tonality, which could be attributed to the Maillard reactions caused by the thermal treatment and sugar-sugar-amino acid interactions.

Cooking quality

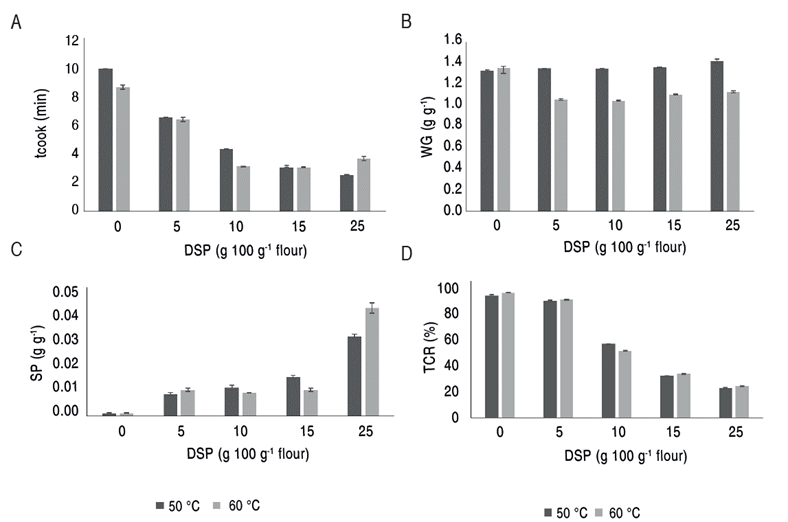

According to the analysis of variance, temperature did not have a significant effect (P<0.05) on total carotenoid retention (TCR) and solids lost in the cooking water (SP). In contrast, it significantly affected cooking time and weight gain (P<0.05). On the other hand, the DSP factor significantly (P<0.05) affected all response variables and the interaction between both factors (T * DSP).

The effect of DSP on the test of homogeneous subsets showed that TCR increased as the DSP value decreased in the formulation, reaching values of 90.4% for the control sample, while for DSP-25, it obtained values of 22.6%. This can be explained by the increase in the concentration of carotenoids in the matrix, meaning that these are more available to leach into the liquid cooking medium since it is also at boiling temperature. Likewise, the increase in DSP leads to a weakening of the network that forms the protein and starch, facilitating the loss of solids in the cooking water. Therefore, this decrease in TCR values is not necessarily related to degradation by the temperature of the cooking water. Indeed, Oduro-Obeng et al. (2021) mention an increase in the availability of these compounds due to cooking, which also increases their accessibility after consumption. Additionally, although it was not measured in this study, an isomerization of the pigment could have occurred, mainly due to the effect of the applied heat treatment and exposure to light, which also influences its bioavailability (Khoo et al. 2011).

Spaghetti cooking time varied from 3 to 6 min. This time was shorter than that reported by Minarovičová et al. (2018), who obtained values between 5.9 and 7 min. This difference depends on many factors, such as the level of substitution of wheat flour by DSP, the thickness of the spaghetti, the conditions of pasta production (extrusion and drying), the amount of starch, and the proportion of the rest of the components, such as protein and dietary fiber. Regarding the effect of adding DSP, a decrease in cooking time was observed when the level of DSP was increased. This behavior was similar for both drying temperatures (50 and 60 °C). However, the cooking time was greater in spaghetti dried at 50 °C using the lower contents of DSP (5 and 10 g 100 g-1 flour). Piwińska et al. (2016) observed no significant variation in pasta samples dried at different temperatures, reporting a cooking time of 6.50 min for each drying condition (50 and 60 °C). This response variable allowed us to detect that the DSP requires less cooking time (3-6 min) than the traditional formula (100% wheat flour) (8-15 min). Similar results were obtained by Padalino et al. (2013), who reported a cooking time of 7 min for spaghetti produced with yellow pepper flour (15% w w-1), and by López-Mejía and Morales-Posada (2020), who reported a decrease in cooking time due to the effect of adding DSP, reaching values of 5.12, 6.90, and 7.25 min. This may be due to the physical disruption of the gluten matrix caused by the fiber, facilitating water absorption and consequently decreasing cooking time.

Concerning weight gain, the values obtained (0.90-1.35 g g-1) were lower than those reported by López-Mejía and Morales-Posada (2020) (1.38-1.78 g g-1). The differences with other authors may be attributed to the particular characteristics of DSP since the dehydrated pulp used by Minarovičová et al. (2018) had a lower protein content (8.20±0.10 g 100 g-1) than the one used (13.87±0.05 g 100 g-1) in this study, which means that the obtained DSP can help to form a greater protein network, thus helping to maintain the integrity of the starch while it swells during cooking. On the other hand, the effect of DSP on weight gain was significant when the level of DSP was increased from 15 to 25 g 100 g-1. However, lower weight gain values were obtained for spaghetti dried at 60 °C. According to Piwińska et al. (2016), this behavior could be because temperature promotes a stronger protein network formation, further limiting starch swelling. In contrast, pasta with 100% wheat flour presents weight gain values of 1.76-2.02 g g-1 greater than those obtained in this study due to its high level of starch and gluten (Padalino et al. 2013).

Similarly, the solids lost in the cooking water were 0.01 and 0.045 g g-1 (Figure 1C), lower than those reported by Minarovičová et al. (2018) (0.05-0.07 g g-1). These values are desirable for the pasta to be considered high quality (0.07-0.08 g g-1) (Añón 2007). Regarding the effect of DSP, it was noted that the solids lost in the cooking water were not significantly different from the DSP-5, DSP-10, and DSP-15 formulations. However, DSP-25 had a significantly higher value (0.045 g g-1).

Figure 1 Spaghetti cooking quality as a function of the drying temperature and the percentage of dehydrated squash pulp. A. Cooking Time (tcook), B. Weight Gain (WG), C. Solids Lost by Cooking (SP), and D. Total Carotenoids Retention (TCR). Mean ± SD (n=3).

This result was associated with the solubilization of carbohydrates like starch and soluble fiber (pectin) due to the weakening of the network formed by gluten (Brennan 2008).

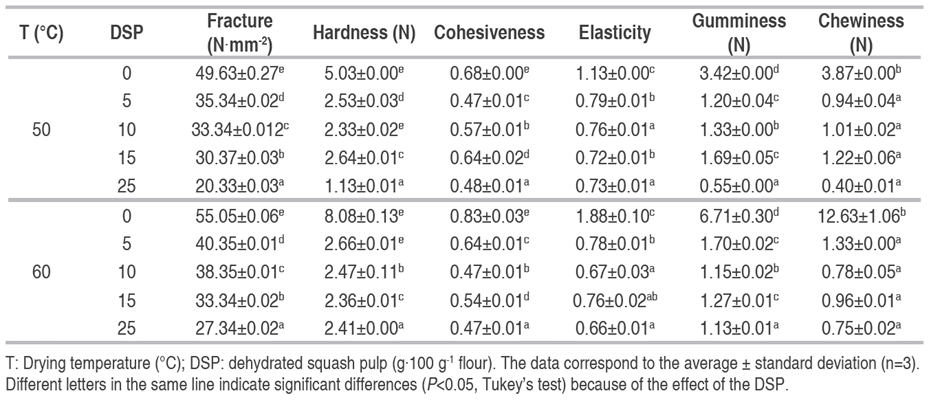

Texture analysis

Texture is an important part of consumer acceptance and is one of the criteria that defines pasta quality. According to the analysis of variance, both temperature and the DSP had a significant effect (P<0.05) on all the texture variables and the interaction of both factors. Results showed that elasticity and gumminess were higher in the control formulation (DSP-0) (Table 3). The formulations closest to this value were those corresponding to DSP-5 and DSP-15. The other formulations were significantly less elastic and did not show significant differences (Table 3).

Table 3 Dry spaghetti fracture stress and cooked spaghetti texture profile according to drying temperature and DSP addition level.

Regarding the fracture stress and hardness, all the values obtained for each of the formulations were significantly different, being higher in the control formulation (σfrac=52.34 N·mm-2 and hardness=6.56 N). The formulation that was closest to the control was DSP-5 (σfrac=37.84 N·mm-2 and hardness=2.59 N). Lastly, the cohesiveness was significantly different in all the formulations, whereby DSP-15 was the closest formulation to the control. In Table 3 shows more clearly the texture parameters evaluated for dried and cooked samples in the function of the percentage of DSP and drying temperature. Independently of the drying temperature, the incorporation of DSP produced a 37% decrease in the breaking force of the dried spaghetti. On the other hand, when the drying temperature was elevated from 50 to 60 °C, a noticeable effect in breaking force was noted, which could be due to an increase in the denaturalization of the proteins, promoting the reticulation of glutenine and gliadine with disulfide bonds. In other words, more disulfide bonds are formed at higher temperatures. This strengthens the network, resulting in the product's characteristic rigidity (Ogawa et al. 2015).

Regarding the elasticity parameter (Table 3), values of 0.67 and 0.79 were obtained, showing a decrease of 15% when the proportion of DSP increased. The remaining texture parameters, such as hardness, cohesiveness, gumminess, and chewiness, also decreased significantly with the increase of DSP. Aukkanit and Sirichokworrakit (2017) also reported that adding DSP increased hardness values and decreased cohesion and elasticity values. The added DSP is rich in fiber and lacks gluten; therefore, the spaghetti structure may be interrupted. Furthermore, electronic microscopies conducted on pasta with DSP showed an increase in the porosity of the transversal section due to the increase of DSP and an increase in the size of the pores, which causes a lack of continuity in the structure (López-Mejía and Morales-Posada 2020).

Additionally, the decrease of cohesivity of the spaghetti in the function of the percentage of DSP increase indicates that the structure's integrity was affected by the inclusion of fibers present in DSP, which yields a less compact structure. This behavior decreased gumminess, indicating the strength needed to break down the food to be ready for swallowing. On the other hand, the drying temperature did show a significant effect on hardness and cohesivity (Table 3). DSP-25 spaghetti dried at 60 °C showed greater hardness and breaking force. This is because the temperature caused the gluten network to increase in strength. However, the effect of drying temperature on hardness cannot be noted in cooking because water absorption diminishes the effect of temperature on the hardness of the spaghetti (Ogawa et al. 2015).

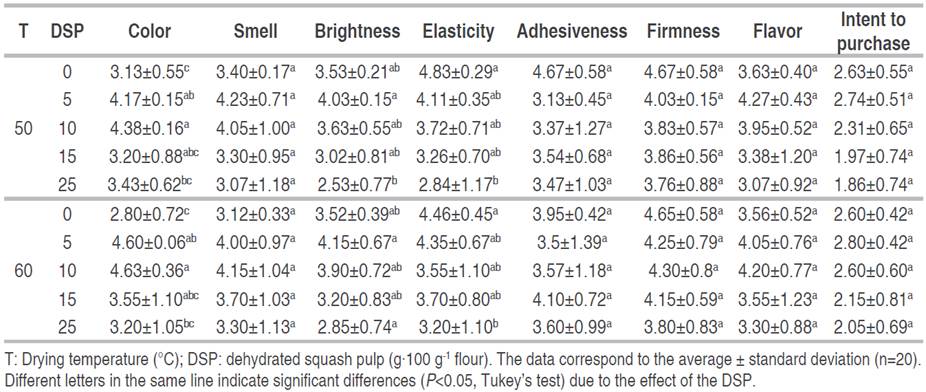

Sensory Acceptance

Sensory evaluation allows the possibility of using alternative raw materials for manufacturing new, enriched, available, and easily obtained food products. Besides having appropriate quantities of proximal composition, a new product must also have good acceptance. If the food is rejected based on its sensory qualities, its consumption will not be considered an option. According to the analysis of intersubject effects, temperature only affected the acceptance of flavor, while DSP affected the acceptance of color, brightness, elasticity, and flavor. The interaction of both factors only had a significant effect on flavor. This was higher in DSP-5 dried at 50 °C.

All formulations evaluated for sensory attributes obtained scores greater than 3, the minimum score for the attributes to be considered acceptable (Table 4). The attributes of color, brightness, elasticity, and flavor presented significant differences between the evaluated spaghetti formulations. The formulations that had greater acceptance in color, brightness, and flavor were DSP-5 and DSP-10. The DSP-5 and DSP-15 formulations had greater acceptance in terms of elasticity. Regarding consumers' intent to purchase, DSP-5 and DSP-10 came closer to category 3 (the consumer would buy), while DSP-15 and DSP-25 came close to category 2 (the consumer might buy). It is important to remember that 10 out of 20 evaluators considered that the samples should be evaluated at the temperature at which the spaghetti should be consumed. This was a technical limitation during the development of the sensory analysis, considering the small size of the sample (8 g) and the speed at which it cooled down.

According to the Pearson correlation test carried out, the products with good color acceptance also presented good scores for brightness (r=0.649; P<0.01) and <elasticity (r=0.406; P<0.01). It was also observed that the products with good adhesiveness presented good firmness (r=0.397; P<0.01). If the correlations are only analyzed regarding intent to purchase, the attributes that influenced the most were color (r=0.545; P<0.01), brightness (r=0.563; P<0.01), and elasticity (r=0.561; P<0.01).

CONCLUSIONS

Increasing the substitution of dehydrated squash pulp (DSP) from 5 to 25 g·100 g-1 primarily led to notable improvements in the product's dietary fiber and total carotenoid content. The incorporation of DSP not only enhanced the product's nutritional aspects but also could play a significant role in promoting human health due to its contribution of antioxidant pigments, such as beta-carotene. This precursor to vitamin A is essential for various bodily functions, including maintaining healthy vision, immune system support, and skin health, while also protecting against oxidative stress and reducing the risk of chronic diseases. This demonstrates the potential of DSP-enriched spaghetti as a valuable addition to a balanced diet. Moreover, increasing the proportion of DSP led to a reduction in cooking time for the spaghetti. It is worth noting that spaghetti formulations containing 5 and 10 g·100 g-1 of DSP exhibited superior sensory acceptance. Interestingly, consumers preferred pasta dried at 50 °C, highlighting that these DSP levels and drying temperatures are well-suited for creating spaghetti with enhanced nutritional attributes while maintaining taste and ensuring overall consumer satisfaction. Based on the results presented in this work, it is suggested that future studies concentrate on examining whether different varieties of squash or processing methods for Dehydrated Squash Powder yield varying nutritional profiles and sensory qualities. This exploration could offer consumers a wider array of options. Additionally, investigating consumer behavior and preferences in relation to pasta enriched with DSP may provide valuable insights. By focusing on these research domains, the full potential of DSP-enriched products to promote human health and sustainable food systems can be further revealed.

Finally, regarding the study's limitations, it would be crucial for future research to examine the impact of thermal treatments, including drying and cooking, not only on carotenoid retention but also on the formation of isomers that could influence their bioavailability. In addition, it is important to consider various strategies to improve the texture of the pasta, such as incorporating hydrocolloids to counteract the effects of adding dehydrated pumpkin pulp on the ultrastructure. This approach would make it possible to further increase the fiber and carotenoid content, while ensuring optimal sensory acceptance and superior cooking quality.