1. Introduction

Nowadays, society expects much more from clothing than satisfying basic needs [1]. Clothes are used as advanced protective equipment and they are necessary to protect the user, in many different areas. Healthcare sector makes use of several protective equipment and most of them using textiles, as a barrier between the human body and the hazardous of the environment. Over the last years, a new range of materials and clothes for protect medical professionals and patients has emerge, improving the performance of each medical clothing [2].

Surgical scrub suits (SS) have been worn by health care workers in the operation room (OR) and for many other applications in healthcare outside the OR as a uniform. Clean air suits (CAS) are considered Class I medical devices according to the definition and classification rules of the Medical Devices Directive 93/42/EEC, amended by 2007/47/EC [3]. Clean air suit is defined as a “suit intended and shown to minimize contamination of the operating wound by the wearer's skin scales carrying infective agents via the operating room air thereby reducing the risk of wound infection” by EN 13795:2011+A1:2013 [4] and simultaneously as a Personal Protective Equipment (EPI) according with Personal Protective Equipment 89/686 EEC [5]. To work with protective clothing it is necessary to follow standard guidelines and respond to all performance requirements implied. The standard EN 13795 presents general protection performance requirements concerning properties which require assessment in CAS. As further characteristic of medical clothing, EN 13795 gives informative guidelines to consider the comfort of the users.

Minimize contamination is a vital question when related to medical clothing and infection control. A major part of the spread of potential infection can be stopped using the appropriate cloth system with the right textile materials. So it's necessary to select the most effective textiles to achieve protection on both patient and professional and cleanliness of the operating rooms and hospitals in general [6].

However, comfort of the professionals and patients has to be considered and the choice of textile materials has to be under the two mayor concerns: protection and comfort. Situations of clothing discomfort may appear to the user, decreasing its performance and increasing the stress and heat levels [7].

The thermal comfort is defined as the condition of mind, which expresses satisfaction with the thermal environment. It is a pleasant state of a human being that is psychologically, physiologically and physically in harmony with the surrounding environment [8]. Thermal interaction between man and environment is highly complex, because the person's perception of thermal comfort is affected by several parameters, such as air temperature, air movement (speed), humidity, clothing, activity level, mean radiant temperature (the average temperature of the walls, floor, windows) and many other factors. So, thermal comfort stands for the proper relationship between body heat production and loss. For that reason, thermal manikins can serve research and development in this field, because they are widely used for analyzing the thermal interface of the human body and its environment.

Therefore, thermal comfort is related to the sensations of heat or cold, moisture or dryness and influence the performance of textile products used near the skin [9].

Havenith [10,11], Oliveira [12,13] and Abreu [14] have been studying this issue proving how important are comfort and thermal properties since it affects directly the user’s performance at work.

Inside of OR, thermal comfort of medical clothing apparel is a very important parameter, since the lack of comfort can lead to thermal stress that influence the physic and psychological conditions of the surgeon, as the ability to maintain constant vigilance and concentration, which the correct surgical procedure is dependent [7,14]. Thermal comfort of the user of medical apparel depends on thermal properties and its adjustment to the environmental conditions in the OR during the surgery, among many other factors like design, size and fabric characteristics [15].

The excessively insulating and very low absorbent OR apparel result in the increase of skin temperature inducing a higher accumulation of humidity between OR staff skin and apparel, which can decrease thermos-physiological conditions of surgeons [16]. In other words, extremely insulating and low absorbent medical apparel will results in an increase of skin temperature, leading to a greater moisture accumulation between professional skin and clothing. To overcome this situation, surgical clothing needs to satisfy some comfort requirements: they should be breathable, loose fit, keep the user in fresh conditions and allow heat changes between the body and environment [17]. For health professional can achieve thermal comfort, the mean skin temperature should be between 33 °C and 34 °C and sweating or chills should not occur. In the way to study the thermal performance of surgical clothing, the aim of the presented study was to compare thermal properties between scrub and clean air suits using two different test methods, quantifying thermal properties such as thermal conductivity, using Alambeta and thermal insulation, using a thermal manikin.

Thermal manikins provide a good estimate of the total dry heat loss from the body and the distribution of heat flow over the body surface. In a standard environment, these measures can be used to describe the thermal characteristics of clothing.

The thermal manikin is an instrument for measuring the thermal insulation of garments and clothing ensemble. It is considered to be one of the most useful tools for evaluating thermal comfort of overall clothing systems. In comparison to other methods for measuring thermal properties of clothing, thermal manikin studies allow to investigate fully assembled clothing in the way these garments are supposed to be used (multi-dimensional), however without any influence of subjective interpretation of human testing or simply physical testing of the materials (bi-dimensional) [9].

2. Materials and methods

2.1. Clothing system

Two disposable and two reusable scrub and clean air suits were used in this study. All the clothing systems are currently used in operating rooms; all four are from different brands and have different materials/compositions. Table 1 shows the description of the studied clothing systems A and B. The clothing was stabilized in an adiabatic chamber before each test.

2.2. Alambeta

Alambeta measuring device (Fig. 1) measures transient and steady state thermo-physiological properties [18], which simulates, during a very small initial contact, the heat flux between skin and fabrics. Alambeta measures thermal parameters like, thermal conductivity, resistance, diffusivity and absorbance. When the sample is inserted, the measuring head drops down, touches the fabrics, the heat flow levels are processed and thermo-physical properties of the measured samples are evaluated. The measurement lasts for several minutes only. This equipment test the objective evaluation of warm-cool feeling properties of fabric. To simulate the real conditions of warm-cool feeling evaluation, the instrument measuring head is heated to 32ºC, which correspond to the average human skin temperature, while the fabric is kept at the room temperature 22ºC. Similarly, the time constant of the heat flow sensor, which measures directly the heat flow between the automatically moved measuring head and the fabrics, exhibit similar value (0,07 sec), as the human skin. Consequently, the full signal response is achieved within 0,2 sec. [9]. Warm-cool feeling means the feeling we get when the human skin touches shortly any object, in our case textile. Since this feeling strongly affects the choice of people when buying the clothes or home textiles, the objective assessment of this feeling became very important [19].

2.2.1. Thermal conductivity (λ)

Thermal conductivity is a property of materials that expresses the heat flux that will flow through the material if a certain temperature gradient exists over the material.

The measurement result of thermal conductivity is based on the following eq. (1):

The tested thermal properties are present in Table.2.

where:

P - heat power (W)

x - fabric thickness

A- area (m2)

ΔT- temperature gradient

The obtained results were treated statistically and the reproducibility of the different results, for each variable, was tested and analyzed.

Finally, selected softened samples of bed linen were evaluated by a dry thermal manikin to validate the conclusions.

2.2.2. Thermal diffusivity (a)

Thermal diffusivity is an ability related to the heat flow through the air in the fabric structure. The thermal diffusivity of the textile materials is the transcient thermal characteristic of textiles. It is expressed as eq. (2):

2.2.3. Thermal absorptivity (b)

The level of thermal absorptivity depends neither on the temperature gradient between the fabric and skin, nor on the measurement time.

Thermal absorptivity can be expressed as eq. (3):

where:

λ - thermal conductivity

ρ - fabric density

ς - specific heat of the fabric

This value just depends on the structure and composition of the material, particularly the surface properties. The lower the thermal absorptivity, the warmer the feeling during the short thermal contact of the skin with the fabric.

Since the thermal absorptivity is mainly the superficial property, its level can be changed by any superficial or finishing treatment, like raising, coating and softening [9]

2.3. Thermal manikin

The thermal insulation of clothing ensemble was measured using a thermal manikin, Fig. 2, with controlled skin surface temperature that simulates the wear. This thermal manikin, called “Maria”, is programmed to respond to the thermal environment as an average woman’s body; its size and configurations are similar to an adult woman. It is divided in 20 thermally independent sections and only sense dry heat transfer. Thermal manikin, positioned 0.1 m from the floor, was kept standing with their legs and arms held in vertical position without any motion. The skin temperature of all body was set, and during the test period maintained at 33 ± 0.1 °C. The tests were conducted in a climatic chamber where ambient conditions characteristic of an operating theatre were simulated, 20 °C ± 2 °C and 60% Rh. The climatic chamber can achieve temperatures around 15 °C to 35 °C and relative humidity around 35% to 85%.

Source: The authors

Figure 2 Thermal manikin: photo of nude thermal manikin used on tests (a) and software body picture of thermal manikin and color legend of body segments temperature (b).

Data acquisition started achieving stationary conditions after 60 min. During the acquisition period, the heat flux and the skin temperature of each body part record every minute. Thermal insulation ( IT ) was calculated according to global method, eq. (4), where Tsk [°C] is the mean skin temperature, T0 [°C] is the room temperature, Q [W/m2] the sensible heat flux of the manikin and fi the relationship between the surface area of segment i of the manikin [20]. This is the general formula for defining the whole body resistance and the one that best fits the definition of thermal insulation expressed [12].

Furthermore, global method is less susceptible to significant variations to calculate thermal insulation. The global method should be used for calculating thermal insulation of clothing for all manikin control modes, especially for thermal comfort regulation mode [15]

The effective clothing insulation ( Icle ), consisting of the difference between IT and Ia are calculated by the eq. (5), considering Ia is measured by operating the manikin nude.

For statistical data analyse the software “Action” was used. It was made the F-test of two variances at a 95% level of confidence. When p-value<0.05 then reject the two variances compared are equal.

3. Results

3.1. Alambeta

Fig. 3 shows thermal properties of tested clothing. Thermal conductivity is a property of materials that expresses the heat flux that will flow through the material if a certain temperature gradient exists over the material [21]. Scrub suits have higher conductivity than CAS. SS B with 33% cotton in its composition has higher conductivity than polyester, that’s why SS B has higher conductivity than CAS D. Scrub suits have higher diffusivity than clean air suits. This property represents heat propagation velocity of material, so SS will diffuse the heat faster than CAS.

Source: The authors

Figure 3 Thermal properties of clothing measured on Alambeta: condutivity (a), diffusitivity (b) and absoptivity (c)

Source: The authors

Figure 4 Heat loss from body section of manikin dressed with CAS (a) and SS (b).

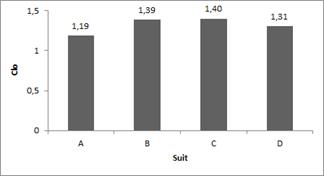

Thermal absorptivity is a warm-cool feeling parameter and represents instantaneous heat flow that appends when two bodies, with different temperatures, come into contact. This value just depends on the structure and composition of the material, particularly the surface properties. The lower the thermal absorptivity, the warmer the feeling during the short thermal contact of the skin with the fabric [19]. Single-use SS and CAS have the same absorptivity value and it is lower than for reusable SS and CAS. Each material that can absorb and conducts heat well, will remove the heat from the skin and make the user feels fresher [22].

3.2. Thermal manikin

Fig. 4 shows the heat loss from manikin body segments. According to Hensel cited in [21], the higher is the heat flux loss from the skin to the environment, the faster the temperature will drops and more intense is the freshness feeling. So a material that could absorb and conduct heat well, will remove heat from the skin and give the sensation of being a “coolest” garment. Hence, heat loss is closely related to thermal insulation, they are inversely proportional parameters. In this particular case, as expected, unclothed parts like feet, hands, forearms and face have higher heat loss.

Through heat loss values, total ( IT ) and effective clothing thermal insulation ( Icle ) can be calculated. In Fig. 4 can be seen that SS A have the lower thermal insulation, the difference between single use SS and CAS (A and C) is around 0,032 m2.°C/W and for disposable ones (B and D) it is around 0,012 m2.°C/W. However, the difference between SS and CAS is significant when we compare SS A with CAS C, and there is also a significant difference between scrub suits A and B.

Source: The authors

Figure 5 Total thermal insulation and effective clothing insulation of scrub and clean air suits.

When the effect of air layer thermal insulation is removed ( Icle ), clothing thermal insulation decreases but shows the same behaviour. For A suit, can be observed a decrease around 73%, about 58% and 57% for B and C, respectively, and 61% for D.

Thermal insulation of clothing can also be expressed in clo values, Fig. 5. The higher the value of clo, the greater is thermal insulation. Clo value of 1 is defined as the amount of clothing required to a human being at rest to be comfortable at room temperature of 21 °C [16]. The differences between clothing clo values are statistically significant (p-value < 0,05), except between suits B and C (p-value > 0,05), Table 3. So, the differences of wear SS B or wear CAS C can’t be perceived. SS A has the closest clo value of 1, meaning that for the user, the more thermal comfortable suit, according to clo value is SS A.

4. Conclusion

This study was performed to compare thermal properties between scrub suits and clean air suits made of woven and nonwoven fabric. In this study we present two types of tests to measure the thermal properties and performance of fabrics. Thermal properties of fabric were measured on Alambeta and thermal insulation of clothing was carried on a thermal manikin, in a controlled air and humidity conditions, according with OR atmospheric conditions.

Regarding to fabric thermal properties there is no suit that responds with good behavior to all properties measured. Reusable SS and CAS have similar conductivity, but for diffusivity values, they behave differently. Thermal manikins provide a good estimate of the total dry heat loss from the body and the distribution of heat flow over the body surface; these measures were used to describe the thermal characteristics of clothing to understand the comfort experience for the user. Clothing thermal insulation differences are statistically significant (p < 0.5) which means the user will perceive thermal differences when using different scrub suits.

Thermal insulation of clothing, it is dependent upon their specific design, size and fabric characteristics, particularly air permeability that allows heat exchange between skin surface and environment.

When thermal insulation is to be measured using a thermal manikin it’s necessary to evaluate the fabric properties, design and clothing fitting to the manikin and external air and humidity conditions.

Comfort is an important matter when it comes to personal protective equipment or medical uniforms and it must be considered when it comes to the user personal activities at work, when developing new equipment it is imperative to offer the user a good comfort experience, and for that it is necessary to test several properties for comfort, like the thermal properties evaluated in this study.