1. Introduction

Electricity generation in Colombia is mainly based on hydroelectric and thermal power plants, which represent 60 % and 30 % of the entire generation in the country, respectively [1]. In general, power plants are located far from consumers, which increases transmission losses in power lines as well as prices per kWh charged to consumers.

In this country, 96 % of the population is connected to the National Interconnected System (SIN in Spanish). However, this percentage corresponds to only 52 % of the national territory; the remaining 48 % is mostly composed of municipalities and small towns known as Not Interconnected Zones (ZNI in Spanish). The electric power supply of the ZNI is provided by small diesel plants, photovoltaic (PV) panels or small hydroelectric power stations, which present service interruptions and involve higher generation costs than the SIN [1]. Nevertheless, these solutions can be optimized and synchronized.

These distributed generation networks, known as microgrids (MGs), are commonly based on non-conventional or renewable energy sources and small-scale systems. They have become a suitable option not only to provide electricity in remote areas but also to reduce the environmental impact of power generation. At present, a significant number of MG projects are being developed around the globe [2], which means it is a growing research area with high potential.

MGs can be located in almost any place that fulfills the environmental conditions for the implementation of their different energy systems (PV, wind or hydroelectric) to guarantee the supply to the loads, but their installed capacity cannot be greater than 10 MW. The analysis and design of MGs must consider the type and amount of energy sources and, for that purpose, the environmental conditions (i.e. information concerning the available resources) should be defined. Meteorological and weather databases can be used to complete this task. A second consideration is the estimation of loads that will be connected to the MG. The information about the loads should establish which of them require battery systems and other related constraints [3]. The behavior, costs and other characteristics of the MG can be predicted by simulating it. At present, several computer tools can be employed to design, plan and analyze MGs, e.g. ETAP, OPAL-RT and Sandia’s Microgrid Design Toolkit (MDT). However, HOMER (Hybrid Optimization of Multiple Energy Resources) Energy Plus has been most widely used and reported for designing and analyzing MGs [4-6]; besides, it offers several functions such as annual energy analysis, optimization and economic analysis. In this case study, HOMER Energy Pro is implemented to design and analyze the performance of two MGs: (MG1) a stand-alone PV and wind system with a diesel generator and (MG2) a grid-connected PV and wind system. The parameters of these energy systems are based on information about local weather conditions available in databases.

This paper is organized as follows: Section 2 explains the main concepts related to MGs and renewable energy sources. Section 3 is devoted to the description of the study cases and the implementation of the MG in the software. Section 4 presents the analysis of the results obtained with the software. Finally, the conclusions at the end provide an overview of the work.

2. Microgrids: concepts and components

A MG is defined as a small energy system or network at the distribution level that can operate in stand-alone or grid-connected configuration. The main elements of a MG are energy sources, storage systems and loads. [7]. The energy sources can be of any kind, i.e. renewable or no-renewable; however, a strong trend currently promotes the use of renewable energy sources because of the positive environmental impact that can be thus achieved. Photovoltaic (PV) arrays, wind turbines, biomass, and hydroelectric and diesel generators are the most common energy sources in MGs reported in the literature [8]. The selection of other components (such as inverters, protection devices, controllers and all the necessary equipment to manage the MG) depend on the type of energy source.

There are basically two types of storage systems: supercapacitors and batteries. The former are electrochemical capacitors capable of storing significant amounts of energy to be yielded in short periods. The latter are electrochemical devices composed of two electrodes separated by an electrolyte that work thanks to an electrochemical reaction; the most common types are lead-acid and lithium-ion batteries [3].

Two basic stages are necessary to design and plan a MG. First, the load is characterized and the requirements for the power supply are defined, e.g. voltage, current and consumption profiles. The second stage is sizing the energy sources and the related devices; the location of the MG is relevant for this purpose since it will define the possible energy sources [9].

3. Study cases and implementation in HOMER

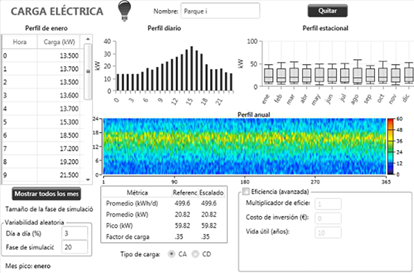

This work analyzes two different cases (MG1 and MG2) with the same load requirements using the Spanish language version of HOMER. Fig. 1 presents the load profile of a real building located in Medellín; it was obtained using a Fluke 435 power analyzer connected to the main electric board of the building during July and August of the present year.

The average load was entered onto the software, which takes such data as the basis to estimate the rest of the information for one year. This first part of the process enabled to establish that the building consumed 20 kW, a value to consider in the planning and design of the MG.

Specifically, MG1 is composed of a PV system, a wind turbine, a diesel generator and a storage system; this MG is not connected to the conventional grid. MG2 comprises a PV cell, a wind turbine and a storage system connected to the conventional grid. The life span of both projects was set to 25 years, with an inflation rate of 0,58 %.

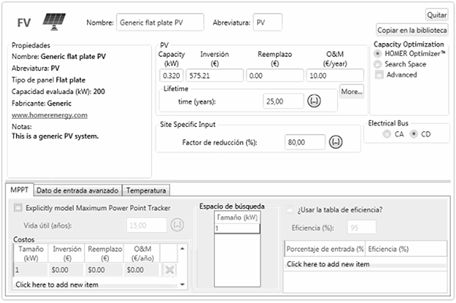

Both MGs use the same PV and wind systems. Their PV system is composed of Kyocera 320-Watt panels [10]. The price of each panel is EUR €575,21 (COP $1 995 978,7), and maintenance and operation costs were neglected. Fig. 2 is a screenshot the software’s interface and the main parameters required for the configuration of the PV system.

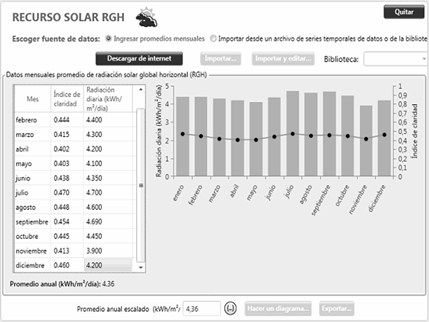

Solar radiation data were entered onto the software in accordance with the information available in [11]. The radiation profile is presented in Fig. 3.

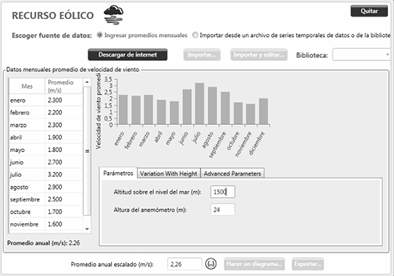

The wind system comprises 1.5-kW 2.2-m/s turbines, priced at €1 440 (COP $4 996 800) each [12]. As with the PV system, maintenance and operation costs were not considered. Fig. 4 shows the main characteristics of the wind system entered onto the software. Additionally, Fig. 5 presents a wind profile of Medellin in accordance with information available in [13].

3.1. MG1 settings and characteristics

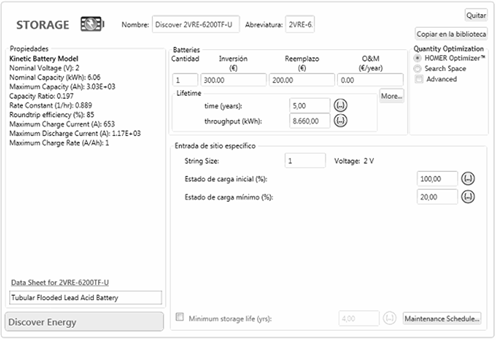

The first MG includes the PV and wind systems described above. The storage system consists of 6,6-kW batteries that cost €300 each and must be replaced at least every 5 years [14]. Fig. 6 shows the configuration of the storage system in the software. In addition, the required inverter amounts to €1 362,64 (COP $4 728 360,8) [15] and it must be replaced every 10 years. Fig. 7 shows the configuration of the inverter.

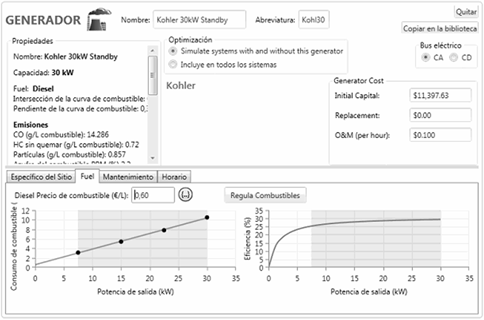

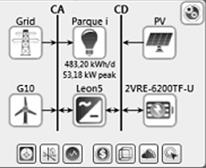

Furthermore, the diesel generator is a Kholer 30 kW-h plant [16]. Fig. 8 details the configuration of the generator, and Fig. 9 outlines the general scheme of the MG implemented in HOMER. As mentioned above, MG1 is configured to operate in stand-alone mode; therefore, all the components of the MG have been set.

3.2. MG2 settings and characteristics

The PV and wind systems of MG2, as well as its storage unit, are the same as in MG1. However, MG2 does not include a diesel generator and it is connected to the grid. Therefore, the cost of kWh must configured in accordance with the location and tariff set by the electricity provider (in this case, EUR €0,14/kWh or COP $500/kWh). The settings of the grid and the MG are detailed in Figs. 10 and 11, respectively.

4. Simulation results

The MGs described in Section 3 were analyzed using HOMER Energy Plus, and simulations allowed to evaluate the viability of the projects and different aspects of their operation.

4.1. MG1 simulation results

The software allowed to analyze different possibilities to implement the MG according to load requirements and information about the energy systems set during the configuration. As a result, MG1 must be composed of a PV system of 504 PV modules, a wind system of 59 wind turbines and a battery pack of 152 units. In addition, 9 inverters are required in the DC bus. Fig. 12 summarizes the total cost of the project and information about each system. In turn, Table 1 presents the summary of greenhouse gas emissions produced by the diesel generator.

The PV system made the greatest contribution to this MG: an annual production of 206 292 kWh. During the day, generation was observed to reach 130 kW, which guarantees a correct charge of the battery pack for nighttime operation. The charge of the batteries exceeds 50 % most of the year, which contributes to a limited use of the diesel generator. Thus, MG1 can save resources and avoid the emissions of greenhouse gases. The inverters will operate constantly because the power of the MG is mostly provided by the PV system. As for the wind system, each turbine contributes to the MG with 20 W during the day, but production is reduced to 5 W at night. Overall, this MG generates 31,241 kWh a year. In general, the renewable systems in MG1 supply 94,4 % of the power, while 5,6 % is provided by the diesel generator.

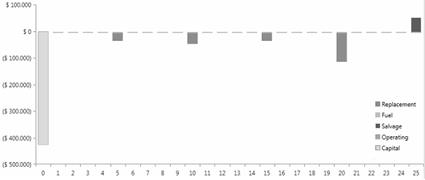

An economic analysis allowed to calculate the cash flow and profitability of MG1 shown in Fig. 13. Values below the zero line represent losses or costs of the project. High investment costs can be observed at the beginning, when batteries are replaced every 5 years, and when inverters are replaced along with the wind generators in years 10 and 20. At the end of the project, the return on investment rose to EUR €56 024,23.

4.1. MG2 simulation results

In the second case, MG2, the software allowed to analyze different possibilities to implement the MG. As a result, 391 PV panels, 7 inverters, 3 wind turbines and 73 batteries are required. The cost summary is shown in Fig. 14.

The operation of the grid is also characterized according to the configuration of the MG. In this way, the software calculates the energy that can be bought from the utility company or sold to the grid. However, since Colombia is currently developing regulations for that commercial activity, such data will not be considered. Fig. 15 presents the monthly consumption of the MG from the grid.

As in MG1, the PV system has a significant influence on the operation of MG2. In this case, 87 % of the generated power is provided by the PV system, which corresponds to 159 307 kWh per year. Additionally, Fig. 16 details the operation of the storage system and the way batteries are charged since noon and then discharged quickly. This indicates system oversizing introduced when the software tries to optimize the MG. The configuration of the system can therefore be manually changed to reduce the number of batteries.

The contribution of the wind system is limited because it provides less than 1 kW to the MG. Consequently, it can be replaced with more batteries or the conventional grid. In general, renewable sources supply 72 % of the electricity in MG2, while 18 % is taken from the grid. At last, the economic analysis of the cash flow in Fig. 17 indicates that the return on investment the project will reach EUR €7 131,65 in year 25.

5. Conclusions

Two different MG configurations were analyzed using the software HOMER Energy Plus, which is one of the most widely employed computer tools to study MGs at present. The load of both MGs corresponds to a real building located in Medellín. Therefore, local weather conditions were considered as well.

The option HOMER Optimizer in the software was activated to provide the best possible configuration of each energy system in the MG. The first case considered renewable energy sources and a diesel generator but in stand-alone configuration. The second case also considered renewable sources but in grid-tied configuration. Both cases show that the PV system makes a relevant contribution to generated power. However, the results of the wind system reveal its limited influence on the MG, which may be caused by unsuitable wind profiles for the wind generator technologies available in the software. Nevertheless, the simulations indicate that both cases are technically viable but not economically feasible because of their excessively high implementation costs. Future studies can implement MGs that do not supply electricity for all the load but only a part of it. In addition, MG projects should consider the option of selling excess electricity to reduce the time of the return on investment. Such alternative was not considered in this work because its regulatory framework in Colombia is not yet defined.

The software employed in this study is a useful tool to analyze the main operation characteristics of MGs. Different cases and types of energy sources can be examined and information can be easily entered. However, data related to energy sources (i.e. PV system, wind, diesel, and conventional grid, among others) must be as accurate as possible. In this way, the results of the simulation will enable to define the viability, the return on investment and other relevant aspects to design and plan MGs.