1. Introduction

One of the most relevant changes in today's agriculture is the transition from open field to greenhouse crops, the latter providing greater protection to plantations by avoiding the impact of climatic phenomena and ensuring crop quality and performance. This type of structure is usually designed to counteract adverse cropping conditions. However, it should be noted that each crop responds differently to the environment it has been exposed to, because light, temperature, humidity and other requirements vary depending on the case.

1.1. Effect of light and temperature on plant growth

The ability of plants to detect light and respond to it depends on their photosynthetic pigments and photoreceptors, which absorb light energy from different regions of the electromagnetic spectrum. One of the most well-known pigments is chlorophyll, which absorbs Photosynthetically Active Radiation PAR (400 - 700 nm) and provides the necessary energy for photosynthesis. In turn, photoreceptors detect slight changes in radiation. Through these molecules, plants respond physiologically and/or morphologically to changes in light composition. Among these photoreceptors, phytochromes mainly absorb red (600 - 700 nm) and far red light (700 - 800 nm), for which purpose they oscillate between two forms: The red absorbing phytochrome (Pr), which is inactive; and the far-red-absorbing phytochrome (Pfr), which is active and influences plant shape, color and flowering, together with seed germination, stem elongation and leaf expansion. The Pr/Pfr ratio is fundamental for the determination of these characteristics in the plant. At this point, it is important to clarify that the ability of light to modify plant morphology, known as photomorphogenesis, is a different process from that of photosynthesis [1-2].

Different researchers have reported that the relative amounts of red (R) and far red light (FR) significantly influence the morphology of plants. If the R:FR ratio is high, the plants tend to be low and have smaller leaf areas, whereas the opposite phenomenon occurs when the R:FR ratio is low, thus leading to more elongated stems [3,4]. Provided that conversion between Pr and Pfr is mediated by light, their balance can be modified through spectral filters for solar radiation or artificial illumination systems such as incandescent or fluorescent lamps with specific R:FR ratios [5-8].

As to the tomato crop, its elevated luminosity requirements make it necessary to provide 8 to 16 daily hours of light in order to reach adequate plant development and uniform fruit color. Contrastingly, low luminosity hinders flowering, fertilization and the vegetative development of the plant, while also reducing the absorption of water and nutrients [9]. Another factor that significantly influences the physiological processes of this plant is temperature, which allows an optimal development between 21-27°C during the day and 15-17°C overnight. When temperatures are above 36 °C, photosynthesis and respiration diminish and transpiration increases, thus resulting in deficiencies and physiological disorders in the plant. Temperatures below 8°C tend to minimize or halt growth and nutrient intake processes [10-13].

1.2. Greenhouse cover properties and formulation

Greenhouse cropping allows the creation of a suitable environment for the proper development of plants, by controlling the atmosphere generated inside, regardless of the geo climatic conditions of the zone and improving crop quality and profitability. A greenhouse performs as a physical barrier that protects crops from adverse weather conditions (rain, hail, frost, wind, and UV radiation, among others) and provides an appropriate microclimate for the optimal development of the plantation [14-16]. A greenhouse is actually a structure covered with plastic film between 80 and 200-micron thick, meeting certain physical, mechanical, optical and thermal properties. The optical properties of these materials include: Transmittance, which is related to the capability of a plastic film to allow the maximum transmission of visible light in the PAR region; and haze (turbidity), corresponding to the percentage of transmitted light that deviates more than 2.5° with respect to the direction of the incident light beam. Regarding these properties, plastic films can be classified as: Clear, through which objects can be clearly seen; and Broadcasters, which propagate the incident light in all directions. Visible light dispersion might be advantageous, since reducing shade inside a greenhouse promotes photosynthesis [17]. In turn, the thermicity of a film is its capability to stabilize temperature inside the greenhouse, either by reducing losses due to heat dissipation towards the outside during the night, or by avoiding overheating during high solar radiation days.

1.3. Formulation

Currently, the most widely used polymers in the manufacture of cropping greenhouse covers are: Low Density Polyethylene (LDPE), which exhibits good clarity and flexibility; Linear Low Density Polyethylene (LDPE), which is more resistant to Tension and Tearing and exhibits better Elongation than LDPE; Ethylene Vinyl Acetate (EVA), featured by high transparency, clarity and resistance to UV radiation; and Polycarbonate (PC), which has good impact resistance. The mixing of these polymers is widely used to enhance their properties.

In order to modify the response of the material to infrared radiation and ultraviolet light and thus generate suitable conditions for the crop, the formulations include additives aimed at managing the critical properties for their use in greenhouses (thermicity, photoselection and absorption and stabilization of UV light) [6,18]. According to the function performed by these additives, they are classified as:

UV stabilizers: They protect the film from the degradation caused by ultraviolet rays, thus prolonging its useful life.

UV absorbers: They are photo-selective additives that transform ultraviolet light and emit it in the form of a different radiation (e.g., red light) or heat, thus preventing the plants from being adversely affected by this radiation.

Mid-Infrared blockers (MIR 7000-14000 nm): They keep the radiation in question - which is emitted overnight by the soil and plants - within the greenhouse, thus preventing considerable temperature loses [17].

Near-Infrared blockers (NIR 700-3000 nm): They reduce the transmission of non-luminous solar thermal energy, thus preventing overheating when radiation is excessive.

Antistatics: They reduce static electricity, thus causing the film to attract less dust and, hence, preventing the decrease in light transmission.

Anti-drip: By increasing the surface tension of the material, this type of plastic film allows water to condense by forming a layer instead of drops, thereby reducing cryptogamous diseases, which are favored by dripping on plants [17].

Given that each species and cultivar provides a different biological response to the presence of additives in greenhouse cover films, the current research was conducted by growing tomato (Lycopersicon esculentum Mill.) seeds under controlled conditions in greenhouses with six (6) types of covering film additives. The influence of each film type was analyzed, focusing on the development of the vegetative phase of the plants. Special attention was given to the determination of root, stem and leaf length, as well the dry matter content of the plants. The results thus obtained were compared to the characteristics of plants cultivated in the open.

2. Materials and methods

2.1. Materials

The base polymer employed to manufacture the plastic films was LLDPE HANWHA 3304® (Melt Index 1.1 g/10 min; density 0.923 g/cm3; longitudinal tension 130; transverse tension 120 kg/cm2). The following additives were incorporated to the polymer matrix: UV Stabilizer (CLARIANT® HOSTAVIN 3326™); Medium Infrared Blocker (Hydrated Aluminum Silicate - Kaolin - surface area 20 m2/g; density 2.6 g/cm3; hardness 2.0 Mohs scale); UV Absorber (BASF® CGX UVA006™); Photoselective UV Absorber (BASF® SMARTLIGHT RL 1000™, which converts UV light into red light [635 nm] by luminescence); Near Infrared Blocker (MERCK® IRIODIN 215™, which reduces overheating without blocking PAR); Red Pigment Additive (BASF® IRGALITE 2BP™, color index 48:2); and Blue Pigment Additive (CLARIANT® HOSTAPERM A4R™, color index 15:0). The studied plants were grown from tomato (Lycopersicon esculentum Mill) seeds.

2.2. Cover film manufacture

The plastic films used for the experiment were manufactured by extrusion - blow molding, according to the procedure described by [19]. A total of six (6) types of additivated films were manufactured, with an average thickness of 200 μm. The trade names and concentrations of the additives used in the formulations are shown in Table 1.

2.3. Contruction of greenhouses

Six greenhouses were built per each manufactured film type. The structure types and their dimensions are detailed in Fig. 1. The experiment was conducted in the Bogota Plateau (4°46’59’’N, 74°02’42’’W): 2560 m asl; average temperature, 14 °C; annual precipitation, 600 - 1200 mm; relative humidity, 75%; daily average solar radiation, 4.2 kWh/m2. Twenty tomato (Lycopersicon esculentum Mill.) seeds were sown in each greenhouse. All the plants (including those grown in the open) were supplied the same amounts of water and nutrients. Pest control was carried out through a physical barrier (sodium chloride).

2.4. Measurement methods

Root, stem and leaf length were measured two months after sowing the seeds. Dry matter content was determined by drying the plant material in a BINDER® FD forced convection oven, at a temperature of 80 °C for 72 hours, after which the weight of the material was determined in an analytical scale. The temperature was recorded both inside and outside the greenhouses in afternoon of sunny days during the night, making use of PR-J-24 thermocouples. The characterization of the optical properties (haze and light transmission) of the cover films was performed according to the method described by Delgado et al. [19].

2.5. Experimental design

The experiment was conducted under a single factor, completely randomized experimental design with seven levels. The factors correspond to the evaluated plant attributes (root, stem and leaf length and dry matter content). The levels correspond to the cover film types (see Table 1). Film 1 was the control treatment, which contained UV stabilizer and medium infrared blocker. Five replicates were taken of the root, stem and leaf lengths, and three of the dry matter content.

The results were subjected to a one-factor ANOVA with 95% confidence, using STATGRAPHICS PLUS® 5.0. The Tukey HSD method was used for the contrast of means.

3. Results and discussion

3.1. Optical Properties of the films

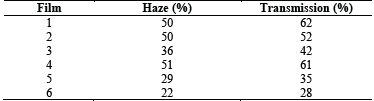

According to the results shown in Table 2, films numbers 1, 2 and 4 generate more intense PAR inside the greenhouses because they have relatively higher percentages of haze and transmittance than the other films. This condition may favor the microclimate generated inside, thus positively influencing plant growth.

It can be clearly seen that film 4 has the highest haze and transmittance properties. This is probably associated to the amount of kaolin used in its formulation (5phr), which is lower than those of the other formulations. On the other hand, both the blue and red pigmented films (Films 5 and 6) exhibited low transmittance and light diffusion records.

3.2. Greenhouse thermicity.

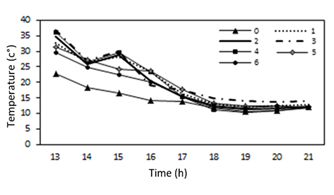

During sunny days, the temperatures registered from 1:00 to 4:00 pm inside the greenhouses were 6º C above the outside ambient temperature. There was a gradual decrease in this difference from 5:00 pm to 9:00 pm (see Fig. 2), after which thermal inversion takes place: the temperature inside is lower compared to that of the outside (see Fig. 3). The dissipation of heat from the inner side of the cover films towards the outside of the greenhouse is evident through heat transmission (convection) and medium infrared radiation MIR (black body).

In order to minimize radiated heat loss, all the evaluated films contained MIR blocker (hydrated aluminum silicate) at an amount of 8 phr, except for film 4, which was formulated with 5 phr. And precisely this greenhouse exhibited the highest thermal reversion, i.e., its temperature was the lowest in the early morning hours, which can be clearly attributed to the MIR blocker (see Fig. 3).

Although the incorporation of the near-infrared blocker (IRIODIN 215®) into Film 4 was intended to prevent overheating inside the greenhouse (especially in sunny days), no such blocking effect was observed due to this film type. The temperature inside the corresponding greenhouse was among the highest ones from 1:00 to 4:00 pm (see Fig. 2). The main cause of this null blocking effect is the elevated transmittance of Film 4 (61%), resulting, in turn, from its formulation, which contained a lower amount of kaolin (5 phr) when compared to the other cover films. There is a close relation between the transmission of light into the greenhouse and increasing temperatures. The greenhouses with higher haze and transmittance characteristics (Films 1, 2 and 4) exhibited higher temperatures during the afternoon, while those additivated with red or blue pigment (numbers 5 and 6) had lesser transmittance values and, hence, lower internal temperatures. On the other hand, increased plant stress levels resulting from higher temperatures hinder transpiration and photosynthesis, while they increase respiration and biomass production [16]. As it can be observed in Fig. 5, the plants grown in greenhouses with higher haze and transmittance features reached the highest dry matter content records.

3.3. Effect of film type on the development of the vegetative phase of tomato plants.

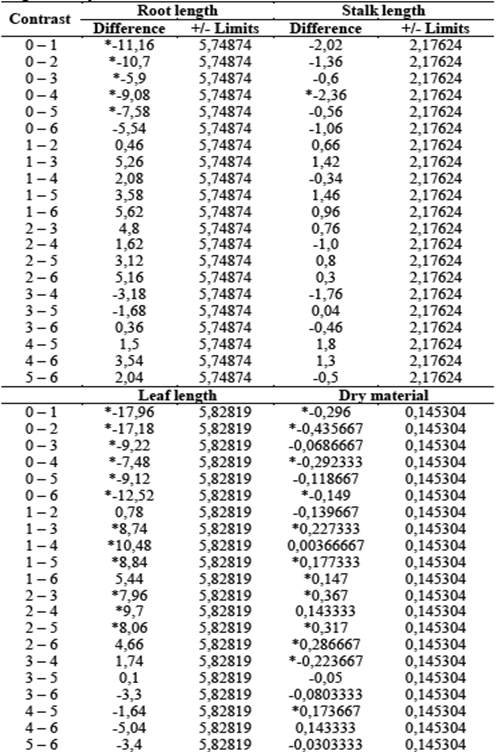

The statistical ANOVA shown in Tables 3 and 4 reveals a significant difference between the vegetative development of the tomato plants grown in greenhouses and those cultivated in the open, which exhibited lesser growth (Figs. 4, 5, 6 and 7). This is mainly due to the advantages offered by cultivation under controlled conditions in greenhouses, where it is possible to mitigate the factors that hinder the optimum development of the plants, thus protecting them against drastic fluctuations in temperature, UV radiation and humidity, among others.

Table 3 Analysis of variance for root, shoot and leaf length and dry matter content.

Source: The Authors.

Table 4 Tukey HSD multiple comparison analysis for root length, stem length, leaf length and dry matter content.

* It denotes a statistically significant difference with 95% confidence.

Source: The Authors

Source: The Authors.

Figure. 6 Analysis of means for root length (a), stem length (b), leaf length (c), and dry matter content (d).

Below is the analysis of the effects of each one of the additives incorporated into the polymeric matrix on the development of the vegetative phase of the studied tomato plants:

UV stabilizer Hostavin 3326™: This component was included in all the studied cover films. Its function is to prevent polymer degradation (yellowing of the film) and the consequent reduction in the transmission of PAR. Said effect was not perceived in the present study.

Hydrated aluminum silicate (kaolin): Thermal function additive, the effect of which is analyzed in section 3.2.

UV absorber CGX UVA006™ (film 2): The plants grown under this cover showed a similar growth μmic to that obtained with the control film, although they grew slightly larger due to the higher PAR transmittance of this material. The results show that the reduction in the UV radiation received by the plants inside the greenhouse resulted in a small increase in length and dry matter production by the plants [20]. Leaf length was significantly greater with respect to Films 3, 4 and 5, whereas dry matter content was higher than that obtained with Films 3, 5 and 6 (see Table 3).

UV absorber: SMARTLIGHT RL1000™ (film 3). The growth of the plants grown under this cover was lesser than that of the control treatment. As a result of the presence of this additive in the film, it can be inferred that, by converting the UV radiation absorbed by the film into red light, the R: RF ratio and, consequently, the morphology of the plants was affected. This resulted in lower plants with smaller leaf area [3-4]. Light transmission was also affected by the presence of this additive, thus bringing about lower PAR transmission to the inside of the greenhouse and, hence, hindered plant development. Provided that the current research contemplates only the vegetative development of the crop, these results suggest the need to carry out further studies to establish the general incidence of this additive on tomato cultivation and the moment of the life cycle when it exerts greater influence.

Given that, the variation in the amount of red and far red light received by the plants in the greenhouses is likely to affect plant growth and morphology, further studies are needed to quantify the R: RF ratio and its effect on the vegetative growth of tomato plants.

Near infrared blocker: IRIODIN 215™ (Film No. 4). The thermal analysis of the current results is discussed in section 3.2. The plants cultivated under this cover exhibited longer stems, a characteristic that is favored by the elevated PAR transmission that features this material. Dry matter content was significantly higher when compared to that registered under films 3 and 5, while leaf length was lower than that obtained with films 1 and 2 (see Table 4).

Red pigment: IRGALITE 2BP™ (film 5). The growth of the plants under this cover was lower with respect to the control, which is attributable to its lower transmittance properties (see Table 2). As in the case of the UV absorber, an increase in the amount of red light received by the plants inside the greenhouse modified the R:RF ratio, which is responsible for the shape, color and flowering of the plants. In this specific case, stem elongation and leaf expansion were affected.

Blue pigment: HOSTAPERM A4R™ (film 6). The comparative analysis of means shows that the plants grown under this cover produced less dry matter than both the control and treatment 2, an effect that is associated to low PAR transmission (see Tables 2 and 4).

4. Conclusions

As expected, the plants grown outdoors registered lower growth parameters than those grown in the greenhouses. This is mainly due to the mitigation of the adverse effects of infrared radiation and ultraviolet light by the covers. With respect to the control film, the incorporation of photo-selective additives did not positively influence the vegetative growth of the plants.

The incorporation of the mid - infrared blocker in the formulations prevented the night temperature inside the greenhouses from dropping drastically below the external temperature. Just as well, it was observed that by decreasing the concentration of kaolin, there was greater thermal reversion in the structure. On the other hand, the greenhouses covered with materials featured by greater haze and transmittance properties reached higher afternoon temperatures, which demonstrates the close relation between the amount of light allowed into the greenhouse and its temperature. With regards to dry matter content, the increase in temperature inside the greenhouses was found to increase biomass production.

PAR was found to exert a greater influence on the growth of tomato plants red and far - red radiation, which indicates that the vegetative growth of the tomato plants was mainly influenced by photosynthesis. Although the effect of photomorphogenesis was found to be weak, a slight decrease in leaf length and foliar area was appreciated under high R: RF ratio values.

Complementary studies are necessary to determine the influence of the photo-selective additives and the near infrared blocker during the flowering and harvest of this crop.