1. Introduction

Bread is produced from wheat flour, rich in carbohydrates and fats, but in recent years, there has been a growing interest in improving its nutritional value [1,2]. The protein content in wheat varies between 11 - 12%, the partial elimination of this in wheat would mean the elimination of proteins in bread, so it is necessary to consider alternative sources such as cereals [3,4]. There are studies of bread making with substitution of different protein-rich food sources such as those from sesame seeds, flaxseed, soy, canola, quinoa, acha and bambara [5-8].

Recent presentations of bread substituted with other raw materials have been developed; for example, the use of potato flour, corn, green, banana, rice, mesquite, chickpea sprouts, hemp and sorghum [9-14]. Marchini et al. [15] propose to develop applications of wheat bread and lentils in the future. With a thick fraction of flour it is possible to provide a higher yield compared to unfractionated flour or finer fractions.

For example, quinoa that is especially recognized among these pseudocereals as a nutritious food due to its large number of protein levels (12.9-16.5%) than that of those present in other widely consumed cereal grains [16,17]. In addition, quinoa is best known for the quality of its protein, since it contains the ten essential amino acids in its structure, which correspond to daily consumption [18]. Another pseudocereal is cañihua, which is presented as a gluten-free product, which would avoid gluten-related disorders and issues of these associations such as celiac disease [19]. Cañihua has carbohydrates (63%), fats (7.6%), raw fiber (6.1%), ashes (4.1%) and proteins (18.8%), of which the main Protein fraction are albumin and globulin (41%) [20].

Another "novel" and "healthy" functional food ingredient, found in chia seeds that have gained increasing interest due to their unique nutritional properties [21], contains considerable amounts of carbohydrates (42,12 %), especially unsaturated fat (30.74%), dietary fiber (34.4%) and protein (16.54%) [22]. Furthermore, it contains antioxidants, minerals and vitamins [23].

Zegarra et al. [20] mentions that the main bread consuming countries in Europe with respect to per capita consumption are the United Kingdom (96 kg), Spain (77 kg) and Italy (65 kg), while in Latin America they are Chile (86 kg ), Argentina (49 kg), Peru (35 kg), and Brazil (31 kg), these data confirm that bread is a fairly preferred food in the family basket, presenting itself as an opportunity to introduce more nutrients and minimize problems suffered by celiac, without this significantly affecting the sensory characteristics of the final product. Therefore, the objective of the present study was to evaluate the inclusion of chia seeds in mixtures of wheat, quinoa and cañihua flour in order to increase the nutritional value of conventional breads with adequate sensory acceptability.

2. Methods and materials

2.1 Chemical composition of flour, seeds and bread

Wheat flour for baking, quinoa seeds and cañihua seeds were obtained from the market in the town of Nuevo Chimbote, Ancash, Peru (9 ° 7'27.01 "S and 78 ° 29'51" W). Chia seeds were harvested in Yungay, Ancash, Peru (09 ° 08 ′ 20 ″ S and 77 ° 44 ′ 40 ″ W). Moisture was determined by the gravimetric method in an oven (POL.EKO, model SLW-115STD, USA) with AOAC 931.04. Protein content was determined according to the Kjeldahl AOAC 2001,11 method in a kit (Foss-Labtec ™ LINE, China). The fat content was obtained in a grease extractor kit (Foss, model SOXTEC ™ 2043, China), using petroleum ether as a solvent according to AOAC 963.15. The ashes were calculated by incineration of the organic matter in a muffle (Thermo Scientific ™, Barnstead Thermolyne ™ model, USA), based on AOAC 972,15. The fiber determinations were carried out according to the NMX-F-090 method. 1978 in a FOSS unit (model Fibertec ™ 1023, China), which is based on the acid and alkaline digestion of the sample, obtaining a residue of raw fiber and salts that with subsequent calcination determines the raw fiber. Finally, the carbohydrate determination was made by difference: % Carbohydrates = 100 - (% Proteins +% Fats +% Ash +% Fiber +% Moisture).

2.2 Rheological properties of the dough for bread formulations

The rheological properties of the dough for making the bread formulations were evaluated in an amylograph (Brabender, model 800250, Germany) according to the AACC 22-10 method; farinograph (Brabender, model 810161.001, Germany) according to the AACC 54-21 method and an extensograph (Brabender, model 860723, Germany) according to the AACC 54-10 method.

2.3 Bread formulation

The commercial wheat, quinoa and cañihua flours were obtained from the local market in Nuevo Chimbote, Ancash, Peru. Chia seeds of the Black variety were obtained from the Arequipa region, Peru. For each gram of formulated flour, the following was added: 0.01 g of enzymatic improver (Vitapan Soft Industria SA, Peru), 0.003 g of anti-mold (Vitapan Soft Industria SA, Peru), 0.02 g of salt (refined sea salt ≥ 97% NaCl, Emsal SA, Peru), 0.08 g of sugar (≥ 99.8% sucrose, Agroindustria San Jacinto, S.A.A, Peru), 0.05 g water, 0.02 g commercial dry yeast (Saccharomyces cerevisiae, Lesafre Ibérica, SA, Peru), 0.10 g butter (Laive, S.A., Peru) and 0.01 g emulsifier (Levapan, Peru). 13 different formulations of cañihua flour, quinoa flour and chia seeds were designed, according to Box-Behnken design, to substitute the wheat flour according to Table 1.

The ingredients were introduced in the Nova equipment (model K25, capacity of 40 kg), with two working speeds, the first one to mix the ingredients and the second one for the kneading process whose time depended on the league point or gluten in the dough. Once the kneading process was finished, the dough was divided in portions of 650 g to make the rounding with a resting time of 15 minutes, the portions were placed up to a maximum height of 3/4 parts of the rectangular mold previously spread with butter. The fermentation process was carried out in a Nova chamber (model CF MAX 1000), programmed at a relative humidity of 70%, temperature of 30°C for a time of 100 minutes. Afterwards, the molds are placed in a rotary oven (model CF MAX 1000) at a temperature of 140°C for 45 minutes. The baked bread was removed from the molds after being cooled to room temperature in order to be sliced, packed in polypropylene bags and finally stored at room temperature free of humidity.

2.4 Bread crumb texture and color

The texture of the breads were in a texture analyzer (Brookfield, model CT3-4500, USA) with a number 2 specimen (TA 4/1000) and a cylinder of 38.1 mm diameter and 20 mm height. The color of the samples were determined with the colorimeter (Konica Minolta, Chroma Meter CR-400, Japan) following the CIE-lab system, determining the parameters of L *, luminosity, a * (- green / + red) and b * (- blue / + yellow) in addition to the chromaticity (C *) and the hue angle (h °). The color of the crumb and rind was measured at the center of the slice.

2.5 Sensory evaluation

Fifty semi-trained panelists of both sexes, ranging in age from 19 to 25 years of age, evaluated all randomly coded sliced bread formulations. In the acceptability test, the attributes of color, odor, texture, taste and purchase intention were evaluated through a continuous scale with values between 0 and 5 (1 = I really dislike it, 2.5 = I don't like / I don't dislike 5 = I really like it). The samples were served on polypropylene plates, coded with random three-digit numbers, accompanied by a glass of mineral water and presented to the panelists.

3. Results and discussion

3.1 Chemical composition of flour, seeds and bread formulations

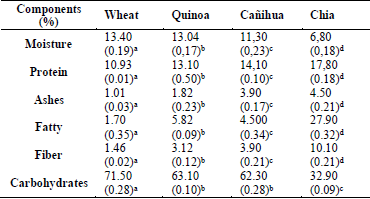

As expected, chia seeds had a high content of fat, protein, fiber and a low carbohydrate value compared to all the flours in Table 2, according to de Falco et al. [21] the level of fats in chia is between 19-23%, mainly consisting of α-linolenic fatty acid, protein contents between 19-23%, dietary fiber content between 18-30%, being higher than that of others grains (flaxseed, quinoa, amaranth) and finally the carbohydrate content is between 26 - 46%. Quinoa and cañihua flour compared to wheat flour had a higher protein and fiber content but a lower carbohydrate content [16,20].

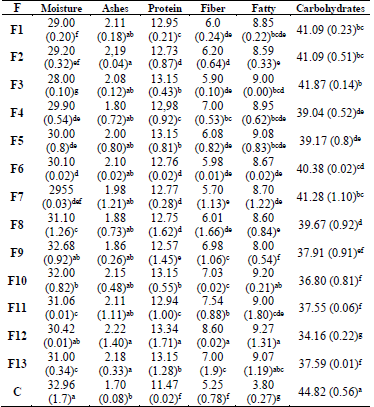

Table 3 shows the proximal composition of the formulations incorporated with quinoa flour, cañihua flour and chia seeds, showing a significant increase (p <0.05) in the levels of ash, fiber, fat and protein, as well as decreased carbohydrate content compared to the control. In general, white bread is low in minerals and must be supplemented to meet the daily requirements of most elements [24]. F12 ranks first in protein, ash and fiber content, second in fat content and lower in carbohydrate content compared to all formulations. As expected, the control formulation had the lowest content of ash, protein, fiber, fat and the highest content of carbohydrates. Jimenez et al. [25] replaced wheat flour with bean, chia and amaranth flour, whose products obtained (breads) had significant contributions of protein, lipids and fiber. Abou et al. [26] incorporated chia seeds at levels of 2, 4, 6 and 8% in sliced bread, providing amino acids such as isoleucine (0.8%), lysine (0.93%), valine (0.95%) and aspartic (1.69%). It is important to point out that the presence of chia seeds also contributes to the final product with omegas-3 fatty acids, such as linolenic acid [27]. Amaranth, chia and quinoa seeds contain proteins that have biological and functional properties that provide nutritional benefits due to their reasonably well-balanced amino acid content [28].

3.2 Texture and color

In Table 4, the texture analysis was represented by chewiness (mJ) and in all the formulations there were no significant differences (p<0.05) between them nor with respect to the control, which would indicate that the addition of flour of quinoa, cañihua and chia seeds in the added proportions do not increase the hardness of the crumb in a notorious way, so it can be stated that the energy for the loaves to disintegrate is not far from the control bread [20]. Generally, the addition of flours such as chestnut, flaxseed, sacha inchi increases the hardness of the crumb in bread formulations [29,30]. The addition of up to 20% of cañihua flour in wheat flour allows to maintain good properties with respect to texture and nutritional [31].

Table 4 Texture and color of the formulations.

F: Formulation, T: Texture, C: Control.

Sourse: The Authors.

In terms of color, significant differences were found for baked breads with respect to the brightness in the crumb (Lm*) and crust (Lc*) of the bread (p<0.05). The presence of carotenoids, chlorophyll and lignin in quinoa, cañihua and chia seeds can influence the final color of the formulations. The color in bread is the result of complex chemical reactions between proteins and carbohydrates during the baking process [32-34]. It has been evidenced that in the formulations whose proportions of quinoa were greater the yellowish color was more pronounced [35]. As described by Gilabert [36] a color difference of more than 5 units between the crust and the crumb indicates that consumers can perceive significant differences with visual observation.

Chromaticity values (Cm *) showed a gradual increase from 19,990 (control) to 20,780 (F3) for the crumb. On the other hand, the crust chromaticity (Cc *) of the formulations is lower than that of the control bread and did not show a significant difference with the formulations (F2, F6, F9 and F12). The control showed a high chroma due to its brightness; this color parameter is lost due to the incorporation of cañihua flour [20].

The values of the shade angle for the crumb (h°m*) of the formulations presented lower values with respect to the control and at the same time presented significant differences (p<0.05), for the crust (h°c*) the formulations also presented lower values than the control (p<0.05), values close to 90° equivalent to a yellow color with a slight inclination to red color. In general, the color of the crumb is related to the color of the flours [21]. The color of the crust ranges from intense golden brown at the top to slightly golden brown, due to Maillard's reactions and the caramelization of sugar [37].

3.3 Rheology

The farinogram establishes the behavior of the flour during the bread making process (Table 5). It shows the elasticity and plasticity of the dough when it is subjected to continuous mixing at constant temperature [38]. The results show that for the water absorption parameter (ABS) the substitutions (62.93 - 65.5 BU, Brabender Units) presented significant differences (p<0.05) with respect to the control (25.5 BU), the presence of proteins especially quinoa and cañihua could compete for the absorption of available water in the masses [39]. Flours that exhibit ABS values of less than 55% are not recommended for baking since it does not allow the development of essential phenomena to obtain quality products [30].

The dough development time (DDT) represents the time required for the development of gluten, so that the stronger the flour, the longer the unwinding time [40]. Therefore, in the substitutions it reached a DDT (3.87 - 3.29 min) before the mass produced by the control flour (4.03), which reflects low curves that correspond to a flour that weakens, whose characteristic lacks a good development of gluten when increasing the volume of the dough. The stability of the mass (S) follows a decreasing trend (4.19 - 2.19 min); Magaña-Barajas et al. [41] point out that a good quality bakery dough is one whose stability values are between 10 to 15 min, however the results presented indicate lower values, which suggests that wheat flour corresponds to a weak dough flour (soft wheats), therefore the greater the substitution, the stability is lost, which means that the gluten weakens and loses strength. Due to interactions, mainly wheat gluten proteins and other ingredients of the raw material, the addition of gluten-free quinoa flour, cañihua and chia seeds decrease the aptitude of wheat flour for the development of dough (DDT). The tolerance index (MTI) provided information on the tolerance of the mass, the formulations presented values between 110 and 125.3 UF (Farinographic Units), higher than the control (100 UF) (p <0.05), this is due that as the percentage of flour increases, the weakening of the dough increases [42].

The amylographic properties (Table 6), with respect to the starting temperature of gelatinization (70.57-71.70 °C) did not show significant differences between the formulations and the control (p <0.05); however, for the gelatinization temperatures, significant differences (p <0.05) with respect to the control (90.02 °C), in a close temperature range (88.0 - 89.93 °C), did occur. The paste formation temperature depends on the starch concentration, while the gelatinization start temperature is related to the nature of the interactions between the starch components [43]. The maximum gelatinisation in the formulations (728.33 - 861.76 AU, amylographic units) was significantly lower than the control (878.0 AU) (p <0.05). These differences were due to the substitution of flours and seeds that conferred to the final product compounds such as proteins, lipids and fiber (Table 2), this interfered with the solubilization and hydration process of wheat flour starch. Švec et al. [44] studied the amylographic properties of wheat flour, quinoa, cañihua, mixture between quinoa / wheat flour and cañihua / wheat flour in proportions of 10/90 and 20/80, determining that the maximum gelatinization temperature was found between 88 - 94 ° C for all the samples.

Rodriguez et al [30] found significant differences with respect to the maximum gelatinisation for wheat flour (1249 AU) with different levels of substitution of extruded sacha inchi cake (630 - 986 AU). Recent studies indicate that one way to improve the rheological properties of breads based on wheat flour substituted with other protein sources such as lentil flour depends on the granulometry, since a coarse fraction can provide higher yields compared to unfractionated flour or to flours with finer fractions [9].

Another property studied was extensography (Table 7), under a break time of 60 minutes for the masses. The resistance of the mass (R) was analyzed in all the formulations (1410 - 740 BU) including the control (1451 BU), which presented significant differences (p <0.05) as well as for the maximum resistance (M) in the formulations (752.67 - 1512.33 BU) and control (1640 BU) (R <M), as expected, a greater substitution of wheat flour requires a lower energy A (cm2) to stretch the formulated masses. The maximum extensibility (E) did not present significant differences between the control and F8, F9, F6 and F7. Stikic et al. [38] points out that the addition of 20% quinoa seeds had a positive effect on the rheological characteristics of the dough. Chemically it would be assumed that the gluten network that is formed in the dough by disulfide bonds of gluten proteins are capable of compensating for the addition of 10 or 15% of quinoa seeds without changing the mechanical properties of the dough.

3.4 Sensory analysis

The appearance attribute determined that the F3 formulation (4.22) obtained the highest preference score and did not present significant differences with respect to the control (4.2), F4 (4.2), F10 (4.0), F7 (4.0), F8 (3.98) and F1 (3.92) (p <0.05). It can be inferred that those formulations with a substitution level between 24.5% and 28.5% total (F9, F13, F3, F2, F12, and F11) are not preferred by the panelists. Regarding the flavor attribute, the formulations F3 (3.78), F7 (3.67) and F4 (3.51) presented a higher score than the control (3.78), the inclusion of quinoa, cañihua and chía increased the preference for panelists.

Stick et al. [38] points out that breads made with 10% and 20% quinoa seeds obtained an excellent rating and were given 4.98 and 4.88 points, respectively (scale 1-5, representing extreme dislike and liking). In texture there is also a favorable score for formulations F7 (3.49), F3 (3.48), F10 (3.13), F11 (3.02), F4 (3.00).

Color F3 (3.67), Control (3.32), F2 (3.25), F7 (3.23), F11 (3.15). Odor F3 (3.51), F7 (3.47), F10 (3.40), F4 (3.24), F8 (3.32) were the highest scores. Finally, for the color attribute, the F3 formulation did not present a significant difference with respect to the control (3.32) (p <0.05), this result can be contrasted with that presented by Sayed-Ahmad et al. [45] who, by fortifying wheat flour with chia flour, obtained darker breads without significantly affecting their global acceptability.

However, fortified bread showed better values than the control in terms of sensory profile, whose mean obtained scores between 3.4 and 3.7 on a scale of 1-5. In general, the F3 formulation presents attractive scores for attributes studied (p <0.05) (Fig. 1), this is an essential requirement for the development of a new product. A physical view of the formulations presented are shown in Fig. 2. Food fortification is one of the most popular strategies today to achieve products that are characterized by presenting components that promote health benefits, including functional foods [46-48]. Chia seed seeds mucilage have been shown to be included in bread for their ability to substitute fat while preserving quality attributes and making them healthier foods [49].

Chia seeds could substitute flours of up to 6% to obtain functional bread for consumers, with good acceptability and high-quality nutrients [26]. Arisaca et al. [50] indicated that it is possible to include significant amounts of quinoa, cañihua, maca and linseed flour in the bread formulation, up to 15.5% of substitution, without presenting sensory rejection, notably improving the nutritional qualities and meeting the requirements nutritional.

The acceptability found in this work is also reflected in the elaboration of other products, for example the mixtures of wheat flour with quinoa have been a viable option to improve the nutritional, durability and sensory properties of hamburgers [51].

4. Conclusion

The inclusion of chia seeds (2%) in mixtures of wheat flour (75.5%), quinoa (7.5%) and cañihua (15%) show significant acceptability in relation to the attributes of appearance, flavor, color, odor and texture with respect to the control of bread (p <0.05). With a significant nutritional contribution of proteins (13.15%), fiber (5.9%), fats (9.0%) and carbohydrates (41.87%). The color analysis for the crumb showed darkening in the formulations. However, this did not influence their acceptability. The rheological propertiesm (amylographic, farinographic and extensographic) showed that when wheat is substituted, the dough formed tends to weaken due to the effect of gluten substitution and expansion during the fermentation of the dough. The different substitutions were verified to present satisfactory results in relation to the nutritional and sensory aspects.