1. Introduction

The disc brakes are the essential elements to maintain maneuverability and, above all, safety in any vehicle (rotary or linear) and its occupants. Braking systems function by the friction to slow down the moving vehicle through mechanical contact between two surfaces (the disc and pad). Currently exists several types of brakes, according to the application, such as drum, band, disc, and conical. In particular, for the automotive industry, the most commons are the disc type in the front part and the drum type in the rear part [1]. Disc brakes differ from other types in that the applied force is normal to the disc track and not radial, as in drum and band brakes. Another particular characteristic is that the friction moment does not aid the actuation moment (self-energizing effect), as occurs in drum and bevel brakes. This phenomenon allows that slight changes in the coefficient of friction do not dramatically affect the braking force necessary to stop the vehicle. For example, a 30% variation in the coefficient of friction, which is a normal condition in humid environments, causes an increase of 50% in braking force; this occurs due to this type of brakes have been occupying an important place in the automotive industry, especially in the commercial/common vehicles.

The disc brake is the element attached to the wheel hub rotating at the same time with the vehicle speed, forming the mobile element of the braking system. Against the surface or friction area of the disc brake, the pads interact with which the vehicle is stopped thanks to the continuous friction that is established between the pads and the disc; During this process, the transformation of kinetic energy (accumulated in the vehicle due to its speed) into thermal energy is generated, which in many cases generates an increase in heat in the braking system. In this sense, it is common today for all four vehicle wheels to use self-ventilated disc brakes (with ventilation ducts). Fig. 1 shows the geometries and the principal elements of a self-ventilated disc brake.

During the braking process, different factors are involved in the effectiveness of the process, resulting thus the interest in knowing the influence of parameters/factors such as deceleration, kinetic energy, execution force, braking force, vehicle weight, surface in contact, the coefficient friction, coefficient of adhesion, vehicle aerodynamics, maximum braking force, road incline, distance and braking time applying mathematical or simulation concepts [2,4].

The disc brake is generally manufactured of gray cast iron from the early stages of vehicle development due to the ease of manufacture, good wear resistance, high thermal conductivity, and relatively low cost. However, notwithstanding these favorable properties, the corrosion behavior of cast iron is still a problem because it often contributes to the undesirable situation called brake judder phenomenon, that is, the appearance of stains on the braking track [5]. The first appearances of nodular cast iron date from the late 1940s in England and later in the United States, these materials were obtained by adding magnesium to the mixture present in the furnace, and thus, the formation of graphite nodules in its microstructure was achieved; which occurs during the solidification process. This fact was a great discovery because a material with high ductility and greater hardness could be obtained directly from the casting, avoiding any heat treatment and thus minimizing production costs. The gray cast iron material belongs to the family of graphitic cast irons that confer greater ductility, a property that gives excellent resistance to thermal shocks, with the ability to withstand deformations during excessive use. Likewise, it is an cast-iron with highest elongation capacity obtained by fusion in its ferritic grade or nodular quality; also, it can be bent, twisted, and deformed without fracturing, making it ideal to be used in the manufacture of vehicle parts exposed to impacts or wear [6]. Despite these advantageous mechanical and chemical properties, the corrosion behavior of cast iron remains a problem due to promote an undesirable phenomenon called hot/cold judder on the surface of the disc brakes [5].

Wear particles or debris are generated from the friction of the disc brake due to wear developed from the contact between the pad and the disc. Eriksson presented an explanatory model of the contact situation between an organic brake pad complex and a cast-iron disc; Osterle and Ostermeyer present similar results. From Fig. 2, metallic fibers or other hard particles (debris) are shown in the material pad, forming stable primary plateaus or patches, leading to the main part of the applied load in the contact pressure [7].

During the mechanical contact, friction and wear under the sliding contact parameters are determined at different test cases, from tests with simplified numerical and mathematical models. The torque contact is replaced with simplified models to full-field tests, where the system is tested under real conditions. Practical mathematical equations have been used across the years to estimate the dynamic and thermal behavior of the disc brakes. Generalities during the functioning of the vehicles (motorcycles, automobiles, trains, etc.) were selected by different authors to analyze the excellent behavior of the disc brakes and thus improve its performance. In this way, finite element analysis is applied to improve the mechanical components in the automotive industry [10].

The mathematical and numerical analysis theories have been used through the methodology shown in Fig. 3; note that gray or white steps could be applied, either through experimentation, simulation, or theoretical calculations that support the understanding of the behavior of disc brakes.

In general, CFD applications in the automotive industry have come a long way to influence the design of automotive components due to continuous advances in hardware and software (numerical techniques) to solve fluid flow equations [9-11]. The automotive industry's interest in CFD applications stems from its capacity to improve the automotive design (geometry), reduce product cost, and product life cycle times without a lot of experimental studies [12-15]. Therefore, the study of dynamic and thermal effects of disc brakes is an important field of research for manufacturers in the automotive industry.

The determination and selection of the geometric characteristics of the disc brakes depend on the load capacity and the operating conditions, which are essential factors to take into account in the initial design phase, accompanied at the same time by the type of fabrication material. In most cases, disc brakes designs must avoid overheating that appears between the disc and the pad due to friction during the braking process. In this way, the physical, mechanical, and chemical properties of the materials used affect the behavior and the braking efficiency [16-19].

In this review work, a Bibliometric analysis is carried out by extracting data from existing scientific publications on disc brakes in the Scopus database, with the primary objective of obtaining a general visualization of the growth over time of this important research topic for the automotive industry. The development of this work was achieved by measuring the contributions of different authors and journals overtime on characterization techniques, simulation employing finite elements, experimentation, and mathematical calculations; and thus, determine the most important sources and authors about the quality and quantity of the research. Likewise, results and technological trends in disc brakes worldwide are presented through the articles collected and analyzed using current statistical tools.

2. Materials and methods

2.1. Disc brakes

During the braking process, high temperatures on the disc brake surface could develop due to the mechanical contact between the disc and pad (responsible for braking). Note that the mechanical and chemical reactions appear as a function of the environmental and operating conditions, affecting the braking efficiency. Due to the composition of the brake pads, it is not easy to describe all tribochemical reactions in detail that could emerge. A typical phenomenon that occurs at low temperatures is the degradation of the phenolic resin, judder phenomenon, and others that comprise the oxidation of the metallic components of the braking system [20].

During normal and relatively light braking, the pressure force of the pad against the disc is approximately 5 kN, which results in a nominal pressure value on the surface of the pad around 1.2 MPa. The brake pad power dissipation easily exceeds 30 kW during hard braking, with high pressures around 10 MPa. These high energy densities result in very high surface temperatures, placing particular demands on the materials used in this kind of mechanical component [8].

2.2. Bibliometric analysis

The Bibliometric analysis was performed using the Bibliometrix library and BiblioShiny platform of the RStudio® software [21]. This software is one of the most used latest open-source programs developed to analyze and filter the most important scientific-literature fields on specific topics. Fig. 3 shows the principal workflow stages applied to the data analysis obtained. Also, the methodology proposed by García-León et al. was taking into account [22].

2.3. Data collection and information

The data were collected on September 29, 2020, directly from the scientific publications from Scopus database on disc brakes for documents published since 1964 with the following search equation: (("Brake*") AND ("Disc*") AND (("Analysis*"), because nowadays it is one of the most important databases to obtain information from scientific publications [23]. The Bibliometric analysis extracts quantitative information about publication metrics, geographic points, author collaboration, prominent research institutions, and journals [21]. The results of this analysis are used to expose the most recent ranking of a relevant topic across the time using explicit keywords. In this way, the keywords are used to consider the workflow shown in Fig. 4 because they cover a broad automotive industry. In this way, the subject field of the Scopus database includes relevant information about the publications such as title, abstract, author, keywords, total citations per document, affiliation, among others.

3. Results and discussions

3.1. Summary of publications and statistical results

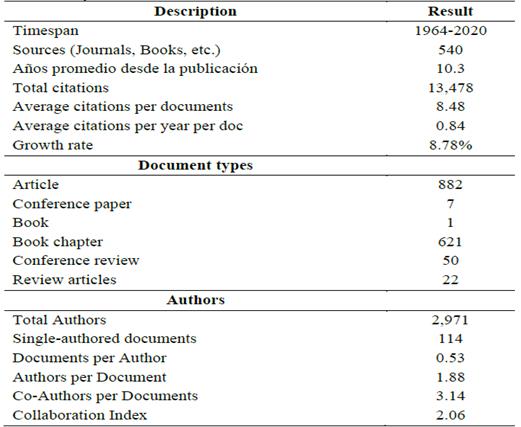

Table 1 shows the global database on the disc brakes, considering 1,584 different document types in the English language and the statistical results for the data used, according to the methodology proposed in Fig. 2.

3.2. Summary of publications

The analysis results of 1,584 documents show an annual growth rate of 8.78% from 1964 to 2020; this behavior is shown in Fig. 5. The study of automobile disc brakes has had significant growth since 2000. On the other hand, 55.7% of publications correspond to articles published in scientific journals, 39.2% articles published in conferences, and the remaining 5.1% correspondence to book chapters, business articles, conference reviews, and review articles.

3.3. Evolution of the use of keywords over the years

The keywords were extracted directly by the Bibliometrix tool, which analyzes the frequency of the appearance of each keyword in the publications; these keywords provide a general thought of the topics covered in the publications. For this analysis, the author’s keywords were used because they are more complete than keywords plus, which are automatically generated from the titles of the articles that are cited. Some keywords were analyzed through the evolution of the most representative across the years in four periods of time, at is presented in Fig. 6.

Source: Own elaboration.

Figure 6 Sankey diagram of the evolution of the principal keywords during four different periods of time 1964-2004, 2005-2011, 2012-2014, and 2015-2020.

On the other hand, Fig. 7 shows the 10 common keywords and the frequency of appearance according to the results obtained. The most frequent keyword is brakes, followed by friction and finite element analysis; these words appear in English because they are the most used language in publications. The interaction between the use and frequency of appearance between the keywords is shown in Fig. 8; notice that of the 2,377 keywords found, at least 20 words appear 9 times in publications, attributing a higher appearance after 2006.

The conceptual structure tries to explain the main themes and trends of the scientific world in a specific topic, what science talks about. Fig. 9 shows two conceptual groups (or themes) that were defined by the keywords used by the authors. These groups show a minimum group frequency of 2 per thousand documents and a minimum number of 9 repetitions per keyword. Cluster 1, (represented in red), concentrates 42.1% of the keywords used by the authors within the analyzed documents, where issues related to tribology such as wear, friction, coefficient of friction, vehicles, disc brakes, stress analysis, among others are studied. Also, cluster 2 (blue), 30.35% related to a thematic analysis by simulation of disc brakes; the remaining percentage represents keywords without interaction or little repeated with each other related to a common theme.

3.4. Importance of journals

Currently, the most important journals are they that bring the largest number of articles in the subject of disc brakes. In this way, according to Fig. 10, SAE technical papers and WEAR journal represent 17.7% of the total publications of 540 journals, which present quartile Q2 and Q1 respectively, representing a total of 3,062 citations (22.72%). On the other hand, the evolution of these two important journals is shown in Fig. 11, note that a high growth since 2000 with an increase in the number of publications in this topic. However, it is evident that the journal Acts of the Institution of Mechanical Engineers, Part D: Journal of Automotive Engineering, Advanced Research on Materials and Applied Mechanics, and Materials show an important contribution between the number of citations and hindex.

3.5. Relevant authors

Fig. 12 shows the behavior across the years of the 19 most relevant authors on the subject of disc brakes worldwide. Likewise, the largest number of documents per author is 3 per year, showing a significant rise in the subject by the authors since 2012.

Source: Own elaboration.

Figure 12 Impact of lead authors by documents and citations across the years.

The most representative authors on disc brakes, the total number of citations, publications, and the year of initiation of the research activity, are shown in Table 2. Notice that Belhocine A is the most relevant author with 38 publications and 256 citations, followed by Ouyang H, whit 882 citations and 21 publications. This reflects that the relevance of the publications is related to the quality of the journals and the impact of the article on the scientific community.

Fig. 13 shows the relationship in collaborative networks between authors; small collaboration groups can be observed, one of them is the orange one made up of Zhang I, Meng D and Yu Z, and the pink color Wang Y, Du Y, Ilu Y, and Zhang Y, the other groups are based on authors working in pairs or alone without collaboration on groups of articles.

3.6. Most important institutions

The 20 most productive institutions are shown in Fig. 14, taking into account the number of publications since 1964. These institutions are related to the number of publications per author and the frequency per affiliation; Thus, Tongji University is the institution where the most research related to disc brake analysis has been developed, with 55 publications, followed by Universiti Teknologi Malaysia with 29 publications.

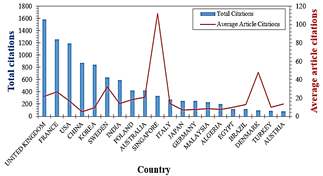

Taking into account the collaboration between and the institutions, Fig. 15 shows the most important countries around the world based on the frequency of appearance; notice that China is the most important country, because this country works together with several institutions worldwide and the number of authors with the same affiliation, so the frequency of appearance becomes greater. On the other hand, Fig. 16 shows the total and the average of citations for each country; it is evident that the countries with the most publications are not the ones with the highest average of citations; perhaps it is related to the fact of the quality and impact of the publications, which in most cases provide information about how improving the physical, mechanical and chemical properties of disc brakes

Considering the above, China is the most relevant country in the topic of disc brakes, the collaboration map between countries highlights trends and frequencies in networks worldwide, as shown in Fig. 17. Notice China's direct collaboration with South Korea, Japan, Australia, the United States, and the United Kingdom. In most cases, they are based on study agreements and analysis of the mechanical properties of disc brakes, mainly for the automotive industry.

3.7. Most cited articles

Of the 13,478 citations presented in Table 1, 21.51% correspond to 19 articles of the general total analyzed, as shown in Table 3. The researcher Ouyang H is the most cited in the disc brake analysis. Notice that only five articles are part of the Wear journal, one of the most important on this subject. Likewise, the relationship and percentages between the number of publications and citations in documents to date are presented at the end of the table, where around 529 (33.4 %) of the articles has not been cited yet, notice that the percentage of citation varies according to the quality and visibility of the publications.

5. Conclusions

The Bibliometric review study strongly depends on an adequate classification, quality, and distribution of the collected data; furthermore, due to the restriction of logical operators (use of accentuation in the authors' names) that are not recognized by the Bibliometrix library and BiblioShiny platform RStudio® software. However, the minimum margin of error is anticipated, with the editing and revision of during the import of the data.

The analysis of the keywords showed that various processes of analysis and evaluation of the performance of disc brakes had been developed and analyzed, showing strong influence in the automotive sector mainly. Likewise, in the 1,584 publications analyzed, 4.1% of the articles corresponding to 43.84% of the citations, whit great interest, and importance of the subject in the research subject.

Disc brake topic related to friction and computer science presented an annual growth rate of 8.78% from 1964 to 2020, where the main publications correspond to scientific journals in a 55.7%. These articles were published by a selected group of authors of China, India, and the United States of America according to the Bibliometric analysis due to the frequency of appearance and number of publications.

In order to implement a new material and geometry in the manufacture of disc brakes, the coefficient of friction must be relatively low. Still, the most important parameter is that stable, regardless of temperature, humidity, time of use, degree of wear, corrosion, the presence of dust and water jets from the road, etc. In addition to these properties, the requirements for long life and high comfort, i.e., absence of vibration, noise, and squeak, must be considered.