1. Introduction

The time study is the quantitative component of the work study algorithm [1], which establishes the time in which a skilled worker performs an activity, following instructions, at a normal pace [2,3]. Its formal application arose at the beginning of the 20th century with Frederick Taylor [3], and, since then, it has become the foundation for several instances of process planning, management, improvement, and optimization [2,4-6].

There are several measurement techniques, such as the estimation of historical data, sampling, ratios and proportions, and the default time systems [1,7], but stopwatch time studies are still most widely accepted [3]. Despite originating in the manufacturing industry, these studies have widely disseminated in other sectors, mainly in healthcare [3,8], however, the literature review does not show more evidence of their application in the mining sector [3], where time plays an important role in the optimization of operations [9,10] such as loading and hauling [11], or the administration and performance of equipment, for which in some large-scale sites they have come to develop mining management systems (Dispatch) that use modern computing and data communication systems with global positioning systems to maximize fleet usage times [12].

Still, time studies not only measure the time required for the development of an activity, but also constitute to a much more complex undertaking, which starts by gaining a deep understanding of the processes before identifying the process elements and mechanisms through which they interact, the variables that may affect measurements, and intensively scrutinize data, to ultimately generate a reliable standard time for the measurement, management, and planning activities [2,4]. Therefore, if their application still remains complex in common industries, such as manufacturing and services, how much more could it be in underground mining, as this is one of the most risky production activities and demand developing extraction processes in inhospitable environments, wherein technological innovations are introduced in a different way than that for surface mining [9,11,13-15].

In this sense, the study seeks to broaden the understanding and implications of using stopwatch time studies to determine standard cycle times for the extraction processes at an underground mine located 4630 m above sea level, where the consistency of production speed is affected by the operational, geological, and geotechnical variability of the pits, but which, nevertheless, since 2010, has maintained a cycle time of 4.69 min/hole for its production schedules.

2. Methodology and related theories

Next, stopwatch time studies are described [1,4,16], with the adaptations that were required for their application in determining the cycle times of the underground mining extraction process under study:

2.1 Operation selection

The decision of operation selection depends on the objective pursued, such as improvements in the process, redesigns, introduction of new methodologies or technologies [4,7,10].

2.2 Pit selection

This step is not a part of the traditional time study, but it was instead incorporated because each pit offers different geological, geotechnical, and operational conditions [9,13-15]. Therefore, it is not enough to just select the operation, as we also need to generate strategies that would help us identify the pits where these operations will be assessed.

2.3 Operator selection

In the operator selection process, skills, experience, training, and commitment to the organization play an important role to ensure that workers continue performing consistently throughout the shift without feeling disturbed by the presence of an observer [2,4].

2.4 Attitude toward the worker

To secure the maximum possible level of engagement, everyone involved should be properly notified of the activities to be conducted. In the literature, this step has been lost over time, or left within the preparation phases of the time study. However, in this context, it acquires relevance because underground mining work must be conducted with minimum disturbance due to its associated risks [14,16].

2.5 Observer selection

This step is not mentioned in time studies because it is an industrial engineering practice [3]. Most studies only mention that the observer must have deep knowledge of the process and the ability to scrutinize the elements of the activity, guaranteeing the registration of information, as accurately as possible, without making judgments or altering the reality of the process [1,4]. However, both theory and practice show little evidence of the incursion of this engineering into underground mining operations due to the restricted access to these work areas [14,15]. Therefore, for this study, it was necessary to develop a strategy that integrates industrial and mining engineers into our team of observers, which expands the scope of industrial engineering processes to the underground mining operations.

2.6 Verification and breakdown of the working method

A time study cannot be conducted if the method is not standardized through procedures that contain all the information related to the process [14], which allow its components to be clearly visualized [2-4,8].

2.7 Cycle analysis

A cycle is defined as the time required to complete a production unit [2,4]. However, within the extraction context, where production results from the intervention of different areas such as drilling, blasting, geology, defining the cycle may not always be so obvious [11,15].

2.8 Number of observations

The following equation was used, for unknown population sample size (Eq. 1) [17]:

where:

2.9 Timing and data processin

Timing and data processing is the very act of measuring time. For this study, we used continuous timing, which consists of running the clock uninterruptedly for the duration of the study. The time readings of each element are the result of subtracting the reading time of that element and the time readings of the previous element. Sexagesimal digital chronometers and time control formats were used with the codes of the elements of the activity to be studied [2,4]. The data was downloaded into an Excel database, designed to detect inconsistencies in schedules and convert the seconds to a centesimal base. Likewise, we proceeded to eliminate times associated with strange elements which were separated for later analysis and replaced those values by the average obtained from the valid data in order to preserve the sample size [16].

2.10 Mean observed time (MOT) calculation

The mean observed time (MOT) results from the sum of the mean times of each of the elements of the activity (Eq. 2) [2,4]:

where:

Ei = mean time of component i.

2.11 Normalized time (Tn) calculation

It consists of adjusting the MOT to the worker's performance using Eq. 3 [6,16]:

where:

FV = factor for evaluating the work rate of the operator.

To date, there is no consensus on this assessment, which in some cases is left to the discretion of the analyst [4]. However, for greater objectivity, we decided to use the Westinghouse assessment system, which assesses the performance of the worker starting from the algebraic sum of the unit to the percentage qualifications of each factor shown in Table 1 [16].

2.12 Standardized time (Te) calculation

It results from adding additional time for personal needs and to let operators recover from fatigue to the normalized time (Eq. 4) [4]:

The allowances were added from those proposed by the international labor organization (ILO), Table 2 [4].

Fig. 1 summarizes the adaptations described:

3. Results for the case study

3.1 Results from the application of the stopwatch time study

The operating unit under study is a polymetallic deposit of silver (Ag), gold (Au), lead (Pb), zinc (Zn), and copper (Cu), which are contained in argentype galena, sphalerite, chalcopyrite, and tetrahedrite; from intermediate to low sulphidation, located in veins of variable behavior, which in some cases tend to bifurcate (branch out) and in others to become strangled. The extraction process begins with the fragmentation of the rocky material, where the mineral ore is found located in veins. Then, the extracted ore is transported by winches to a vertical infrastructure (ore pass) where it is stored and awaits the mining trucks. This entire process is organized into cyclical activities that include drilling, blasting, maintenance, cleaning, transportation, and filling. This study focused on the drilling activity, as it sets the rate of production.

Still, maintaining the speed of this activity is complicated due to the variability of pit conditions. In addition, generating individualized cycle times would be a difficult option to sustain in practice. Given this situation, it was decided to determine cycles for pits grouped under certain parameters, which were determined in consensus by general management, mine management, safety, industrial hygiene, mine services, planning, geomechanics, and management control (Table 3).

Following these parameters, nine pits met the conditions and were selected for the study.

The strict safety conditions in underground mining require skilled, duly trained, and motivated workers who can work at a high level of concentration and commitment to avoid unfortunate accidents. In this sense, all company crews comprise of skilled workers.

The additional consideration that was taken into account was to assign workers with more than five years of experience in the company to the nine previously selected pits, under the premise that the more the experience, the greater is the ability to be confident before the observer, without altering work rhythm. Then, all stakeholders, from managers to operators, underwent training sessions focused on sharing all aspects related to the study and answering questions.

The team of observers also went through an induction process that lasted one week, where aspects of health and safety, extraction process, and time study were aligned. After that, each observer was assigned to each of the nine pits through a work schedule, which included collecting information in day and night shifts, with their corresponding breaks, and office work to monitor progress and information processing.

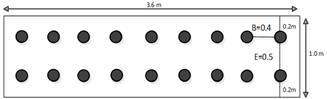

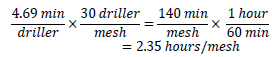

The extraction process was duly documented, updated, and socialized. Drilling was conducted in teams having a driller and an assistant, who mostly operated manual rotary percussive drilling machines using water and compressed air (Jackleg). The activity consisted of drilling holes on the points of the meshes that have been previously painted on the rocky surface in the direction of the veins (Fig. 2):

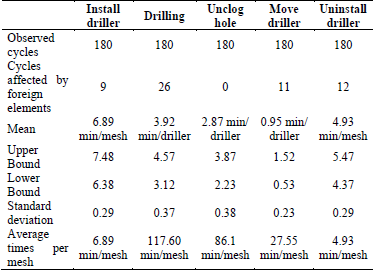

The perforation is described in thirteen steps, which were grouped and coded into five components to facilitate the identification of the start and end times (Table 4) and differentiated them from foreign elements.

The analysis of the cycle denoted an error in the units, which had been expressed in min/hole. This is accepted because the process produces tons of fragmented rock per shift (Tm/shift), and the blasting measures its production in fragmented tons per drill (Tm/drill). Since this tonnage not only depends on the type of explosive, but also on the drilling efficiency of the drill, everything shows that this was the reason why the cycle was set in minutes per hole (min/hole). However, as we can see in the component analysis in Table 4, drilling does not advance by hole but by mesh (min/mesh), and, since drilling sets the process rate, the correct cycle units are min/mesh.

With this clarification, the calculation that the same company uses to determine the tonnage produced, which is obtained from the dimensions of the mesh, the efficiency of the shot, and the specific weight of the mineral, made sense. This same error was caused in the time study conducted in 2010 by the company which had concentrated only on timing drilling and ignored the presence of other elements, thus generating a biased cycle time. This fact supports the importance of separating cycle analysis as a different step to which careful attention must be paid in a production context.

Regarding the number of observations, n = 384 was obtained. However, due to operational conditions and the decision of the mining specialists, the sample was reduced to 180 observations, assuming an error e = 7.3%. This decision is understandable in underground mining operations, where safety is a factor that always takes precedence over all others.

Table 5 summarizes the information obtained after timing the elements, considering that each cycle includes 30 holes, 30 unclogging operations, and 29 drilling movements:

Therefore, the MOT for the process is 243.07 min/mesh. Then, with approval from the drilling and blasting equipment, the performance of the operators was evaluated, obtaining an average valuation factor of 102% (Table 6).

Finally, with the intervention from the industrial hygiene, the allowances were determined in 34% (Table 7).

Finally obtaining Tn=247.93 min/mesh and Te=332.23 min/mesh.

3.2 Impact on production planning

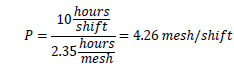

Production (P) with initial cycle (mesh/shift):

Production (P) with new cycle (mesh/shift):

Then, if 0.8 Tm is obtained per hole (data provided by mine), then:

Therefore:

This means that under the conditions presented, an additional 58.91 Tm are required from the process and the worker, which exceeds what can be produced in a normal shift. Likewise, the detail in the calculations shows the important role that cycle time plays in planning and managing processes.

4. Discussion

The biggest question that companies have when they want to introduce improvement methodologies, techniques, or tools, is how to adapt them in practice [18]. This is the main reason why many of them are not implemented or, worse still, result in forced implementations, letting loose a series of peculiarities that hinder the achievement of the same results in other industries. Through this study, it was possible to detect three stages that must be incorporated into the stopwatch time study technique, in order to determine standardized times for the underground mining extraction process. Starting with the selection of the pits because, in this context, it is not enough to determine the activities for assessment, but also where they will be assessed. Unlike other processes, extraction activities are repeated cyclically, moving through pits with different characteristics [9,13-15], which may change work rates, thus making standardization complicated. However, it was seen that a viable alternative is to standardize the cycle to groups of pits that behave under certain parameters, thus reducing the cycle rhythm oscillations.

The other crucial stage to carry out the implementation was the selection of observers, due to the shortage of industrial professionals with deep knowledge of underground mining operations and the restricted nature of the sector, which by concentrates mostly on personnel directly involved in the extraction sector. However, with the integration of mining engineers, this aspect was overcome, managing to properly identify and delimit process components. Finally, dedicating a stage to exclusively assessing the cycle [14] was successful as the complex configuration of the underground extraction process forces each area to measure production based on its contribution to the process. Hence, drilling advances its production based on the number of drilled meshes, while blasting sees it in tons of rock fragmented per drill. Still, in the end, through operational calculations, it is possible to converge these different units on the main production unit, which are tons of fragmented rocks. Here, the detailed analysis of the stopwatch time study technique [3], allowed us to understand that the correct units of the cycle were min/mesh, and not min/hole. In fact, for many years, this error biased production projections generated over demands on the process.

5. Conclusions

Through this study, we were able to identify the considerations and stages that should be taken into account, when implementing the stopwatch time study to determine cycle times for an underground mining extraction process. However, strict security measures, the restricted access to the exploitation areas, the variability of the conditions of the pits, and the very configuration of the processes constitute a big challenge for the adequate implementation of the technique. However, the thoroughness with which the methodology analyzes the activities unveiled an error in process cycle units used, the presence of random elements within the drilling that had been ignored in previous measurements, and foreign elements that affected 28 observations. These foreign elements corresponded to execution issues identified in ancillary tasks of the drilling process, which is the critical process that sets production rates. Likewise, the study also proved the need for fair cycle times, due to their impact on production planning, and the demands on the process and the worker. Therefore, the limitations of the underground mining extraction context should be seen as an opportunity to continue researching strategies for adapting process management tools and techniques to this operational reality that, like any other, also seeks to improve business competitiveness.