1. Introduction

Copoazu (Theobroma grandiflorum (Wild. ex Spring) Schum) is a native cacao species composed of 35% pulp, 20% seed and 45% shell [1]. The pulp is the part with the highest commercial use due to its acid flavor and intense aroma highly appreciated [2,3]. It also has a high nutritional value, being a source of ascorbic acid (96-111 mg / 100 g), phenolic compounds (20.5 mg / 100 g) and considerable antioxidant activity (1.7-2.0 μM Trolox / g) superior to strawberry [4].

The seed, due to its active antioxidant substances content, the low percentage of theobromine and high content of unsaturated fatty acids (linoleic and oleic), has been qualified as a functional food [5]. Copuazú extracts has been found to reduce blood triacylglycerol levels, increase HDL cholesterol levels, improve plasma antioxidant capacity, improve glucose tolerance, cardiovascular disease, cancer, and diabetes [6].

According to [7] it is not possible to obtain specific data on the production and consumption of Copoazú, since its trade occurs mainly within the regions or distributed among small national producers.

Pulping is an indispensable stage for the integral use of copoazú. The pulping methods used are manual and mechanical. The first consists of separating the pulp from the seed and placenta using scissors, exposing it to microbiological contamination due to manipulation, in addition to the increase in the labor required, not recommended for the industry. Mechanical pulping is carried out using a vertical or horizontal pulping machine, which carries the pulp and seed through a mesh cylinder that has a rotating shaft with a pallet that generates the separation [1].

Enzymes are highly specific and efficient biocatalysts of a protein nature (intracellular and extracellular) [8]. Hydrolytic enzymes can degrade the plant tissues of fruits and vegetables [9]. This is the case of pectinases, widely used for juices extraction through the hydrolysis of pectic substances (a mixture of polysaccharides), composed mainly of polygalacturonan with methylated carboxyl groups [10] and hemicellulases capable of degrading complex structures such as hemicellulose, which forms non-covalent associations with cellulose difficult to break [11]. The food technology group of Embrapa studied the effect of applying pectolytic enzymes on the pulping yield of copoazú by evaluating two enzymes at different concentrations (100, 300, 500, and 750 ppm) obtaining yield percentages up to 60% in the treatments with 300 ppm added, concluding that enzymes are an alternative to improve pulp extraction process [12].

Fermentation is the phase where the aroma and flavor precursors of chocolate are developed [13]. The excess of pulp prevents normal development of the fermentation stage, where pulping is a decisive stage to guarantee the final quality of the chocolate [14]. In an experiment conducted by [15], it was possible to show that pulping involves a considerable reduction of important volatile compounds such as aldehydes, ketones, and alcohols during fermentation, confirming the importance of the pulp in the development of important compounds responsible for the desirable flavor.

The objective of this study was to evaluate different types of pulping using hydrolytic enzyme and the effect in the fermentation dynamics of copoazú seeds.

2. Materials and methods

2.1 Characterization, origin, state of thefruits and study site

The fruits were collected in the district of Agua Dulce in the municipality of Belén de los Andaquies, in the state of Caquetá, Colombia, at 280 m.a.s.l., with an average temperature of 28 °C, relative humidity of 87.2%, and annual precipitation of 3650 mm. Following the guidelines indicated in Resolution 1466 of December 03, 2014, the fruits were collected in their physiological maturity state when the peduncle easily detached from the fruit and the characteristic aroma became intense [16]. 220 fruits were collected per treatment, with average weights of 1020 g, 19.5 cm in length and 10.3 cm in diameter. They were transferred and selected in the agro-industrial transformation plant of Research Center Nataima of Agrosavia, Tolima, Colombia. Crushed and diseased fruits were discarded from the process. The fruits were washed and disinfected prior to the opening and grain processing, later they were characterized in the agro-food sciences laboratory, registering average pH values for the pulp of 3.8, soluble solids of 10.7 ° Brix and total acidity of 1.3% of acid expressed in citric acid content.

2.2 Pulping methods

Fruit opening and shelling were carried out manually, separating the peel and placenta from the mucilage and seed fraction, which was subjected to different pulping methods that are described below. Manual pulping (Ma) was carried out by separating the pulp attached to the seed using scissors. Mechanical pulping (Me) was carried out using a COMEK brand horizontal fruit pulper, with a processing capacity of 500 kgh-1. For the development of the enzymatic method (Ez), the Rapidase Liq plus, enzymatic preparation (DSM food specialties), derived from Aspergillus Niger strains and composed of the hydrolytic enzyme pectinases (exo- and endo-arabinases) and hemicellulases at 100 ppm was used leaving for 2 h at 30 °C in stockpot (COMEK, Colombia), with 40 rpm agitation and 50 gallon capacity under aerobic conditions, which was used as the prototype bioreactor. The combination of enzymatic and conventional methods such as enzymatic-mechanical (Ez-Me) was studied. At the end of the pulping phase, an external physicochemical characterization of the mass to be fermented was performed, analyzing it with respect to soluble solids (AOAC, 932.12), total acidity (AOAC, 942.15), and pH (AOAC, 981.12) [17]. The percentage yield was calculated dividing the individual weight of the pulp and the seed by the weight before pulping considering only the weight of the pulp and the seed, multiplied by 100.

2.3 Fermentation

40 kg of mass were fermented in sweet wood crates (Melina Gmelina arborea), with dimensions of 70 cm high, 40 cm wide, 60 cm deep with 5 cm diameter perforations in the base and walls of the fermenter, to facilitate leachate drainage. During the fermentation phase, the temperature was measured at three points in the drawer, sampling daily at 200 g of mass, analyzing the interior of the almond with respect to pH (AOAC, 981.12) potentiometer (HANNA, USA), total acidity (AOAC, 942.15), humidity (AOAC, 920.151) by gravimetric method by drying using a dryer oven (GALLENKAMP, UK), following the parameters suggested by [18]. The cut-off test was developed on the last day of the phase, following the parameters outlined in NTC 1252 [19].

2.4 Statistical analysis

A completely randomized design was carried out, evaluating four different copoazu pulping methods in triplicate as shown in Table 1.

Table 1 Design of experiment

| Treatment | Method |

|---|---|

| 1 | Manual (Ma) |

| 2 | Mechanical (Me) |

| 3 | Enzymatic (Ez) |

| 4 | Enzymatic + Mechanical (Ez-Me) |

Source: The Authors.

The statistical analysis was performed using a one-way analysis of variance (simple ANOVA), and comparison between LSD means with a 95% confidence level. The STATGRAPHICS Centurion XV software version 15.1.02 was used.

3. Results and discussion

3.1 Pulping methods

The pulp yield of the evaluated treatments showed that the Ma and Ez-Me methods were the most effective in separating the pulp from the seed, with 65.71% and 66.8%, respectively (Fig. 1). Method Me recorded the highest pulp adhesion to the seed at the end of the stage, altering the seed yield. Also, it generated fractionation of 2.2% of the seeds with respect to the total mass. The combined treatment Ez+Me also reported 2.5% of broken seeds. These fractions had to be removed before the fermentation phase generating losses in the process.

The application of enzymes in food processing has been used to address multiple needs with high effectiveness. The use of pectinases in the transformation of fruits such as banana [20], mango [21] and pineapple [22] brought positive effects, in the optimization of processes and improvement of the quality of the finished product, which were reflected in rheological changes through reduction of the viscosity and clarification of the pulp, generating an increase in the total soluble solids content, total acidity and yield, which avoid the use of equipment and infrastructures of high investment. The release of interest products trapped in cell walls through the application of enzymes is another use studied linked to processing conditions and enzyme type or mixture due to the specificity of the active site to bind with the target molecule of the substrate [23].

The transformation processes intended to be carried out at industrial level must guarantee high profitability by reducing process costs with high yield. Ma was the most effective method for separating the pulp; however, production costs and high exposure to contamination are a problem for its industrial scaling-up [24]. This method also exposed the pulp to microorganisms affecting the physical and chemical fermentation development in agreement with previous results. These authors affirmed that the excess pulp prolongs the fermentation time of the copoazu seed [2].

The mass physicochemical characterization before fermentation process (Table 2) shows the results of Fisher's LSD multiple range test for the variables pH and acidity with a confidence level of 95%, forming two homogeneous groups between conventional and enzymatic treatments. The pulping methods with enzymes, achieved high removal of the pulp attached to the seed, finding an increase in the soluble solids content, titratable acidity, and a decrease in pH, results homologous to those reported by [25] when applying a crude enzyme extract from Aspergillus japonicus 586 in copoazu pulp. This behavior is generated due to the degradation of high molecular weight components such as cellulose present in the fruits cell wall, releasing compounds enclosed within the cells [26,27].

Table 2 Mass physicochemical characterization before fermentation process from the studied treatments.

| Pulping method | pH | Acidity (% citric acid) | Soluble solids (°Brix) |

|---|---|---|---|

| Ma | 3.79+/-0.34b | 1.31+/-0.13a | 10.7+/-0.55a |

| Me | 3.81+/-0.26b | 1.29+/-0.16a | 10.7+/-0.62a |

| Ez | 3.51+/-0.14a | 2.08+/-0.14b | 11.2+/-0.45b |

| Ez-Me | 3.52+/-0.38a | 2.04+/-0.18b | 11.3+/-0.43b |

* Values in the same column with equal letters do not vary significantly (P <0.05).

Source: The Authors.

3.2 Fermentation parameters

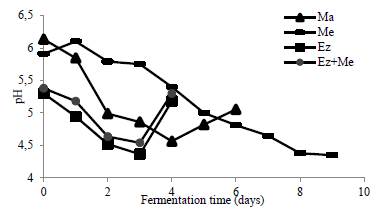

Temperature is a determining variable to estimate the evolution of fermentation, achieve 45 ° C during the first 48 hours of this phase allows the death of the embryo, permeabilizing the shell and allowing access to fermentation products which transform biochemical and sensory grain quality [28]. The effect of pulping on the dynamics of copoazu fermentation is shown in Fig. 2, finding the peak temperature for enzymatic treatments on day 2 of the fermentation, while for conventional treatments, it was visualized on the fourth and fifth days. This increase in temperature is generated by exothermic reactions of yeasts and proteolytic enzymes in the hydrolysis of sugars and pulp proteins. The mass generated during the enzymatic treatments presented high substrate content, the breakdown of cell walls releases compounds from the pulp and increase its availability to transform during fermentation process. The analysis of variance presented significant differences for the variable temperature. The LSD Fisher test (P<0.05) for multiple ranges showed two homogeneous groups corresponding to the enzymatic and non-enzymatic treatments. The development of the chemical variables was recorded in Figs. 3 and 4, reporting the behavior of the total acidity and internal pH of the seed during fermentation. Significant differences were recorded in the analysis of variance for total acidity and pH during fermentation with a confidence level of 95%, being reflected in the reduction in time for enzymatic treatments.

Source: The Authors.

Figure 3 Internal acidity profile of the seed during the fermentation of copoazu.

The physical and chemical profiles during the fermentation showed differences in the dynamics of the enzymatic treatments compared to the conventional treatments. The hydrolytic activity of the enzymes generated chemical changes such as the increase in the soluble solids content and the acidification of the medium through the release of acid molecules and simple sugars [28], increasing the availability of substrate required for the development of beneficial microbiological consortia that interact during fermentation, reducing the fermentation stage from six to four days and promoting the generation of aroma and flavor precursors.

The development of acidity for enzyme treatments showed its maximum point on day 3 of the fermentation, being inversely proportional with the lowest pH values and indicating an accelerated development of the phase concerning the dynamics found in fermentations when conventional methods was carried out.

The upward behavior of the internal acidity of the seed during the first days of fermentation and its subsequent decrease was generated from the conversion of ethanol to acetic acid and the migration of compounds from the seed coat to cotyledon [29]. pH values between 5 and 5.5 are indicative of the good quality of the fermented grain [30], values recorded by the Ma, Ez and Ez-Me treatments on their last day of fermentation, and for the enzymatic treatments it was six days before, achieving a reduction in the time due to the previous pulping process using enzymes.

The physical fermentation index is reported in Table 3, finding the highest fermentation value for pulp treatment Ez with 85% well-fermented grains and 0% of unfermented grains. Polyphenolic compounds such as anthocyanins hydrolyze to anthocyanidins, and then, these are polymerized together with simple catechins to form complex tannins [30], chemical phenomena that accelerate in contact with air, and generated caramel-colored pigmentations in well-fermented grains that were reported in the physical fermentation index, finding the lowest values of well-fermented grains in treatments previously subjected to the Ma, Ez, Ez-Me.

Table 3 Physical fermentation indices of the copoazú seed.

| Pulping method | Well fermented grains (%) | Insufficiently fermented grains (%) | Unfermented grains (%) |

|---|---|---|---|

| Ma | 81+/-1,0b | 19+/-2,0a | 0+/-0a |

| Me | 59+/-0,5a | 41+/-0,5b | 0+/-0a |

| Ez | 85+/-1,5b | 15+/-1,0a | 0+/-0a |

| Ez-Me | 81+/-1,0b | 19+/-0,5a | 0+/-0a |

* Values in the same column with equal letters do not vary significantly (P <0.05).

Source: The Authors.

4. Conclusions

Manual pulping is an effective technique for copoazu, however high labor costs and handling make it industrially unviable. Enzymatic pulping method as a biotechnological technique is effective for separate pulp and seed. The use of enzyme increases substrate availability in the mass before fermentation process and generates a positive effect on the physical and chemical dynamics during this stage. Enzymes is a viable alternative for implementation at industrial level it also allows the use of pulp and seed, reduce the fermentation time, and generate desired characteristics in the final product. Enzymes is a promising alternative to be incorporated into copoazú pulping processes in remote areas, where it is produced, without requiring investment in industrial machinery.