1. Introduction

With rapid technology and digital applications advancement, many concepts in industries have emerged [5,35,43]. Nowadays, the 4.0 industry and digital transformation are standard terms that stand out in a new industrial revolution [2,3,30]. Many companies are exploring this matter, but criteria and implications are still uncertain [4,10,25]. The technology implementation to achieve the concept of 4.0 industry, explanations, and the assertive methods for applying digital transformation remain unclear in the academic and industrial world [21,36,47]. Companies seek transformations today by adopting digital strategies that require new innovative and transforming technologies that enable cost reduction, rapid response to market changes, and easy adjustment to client demands, which increasingly look for services that anticipate their needs [11,29,32].

Therefore, general managers must consider digital transformation as a value chain problem [15,33]. Digital Technologies are progressively transforming every business with access to a wide range of digital systems that can manage their interactions with different actors in their networks [9,49,50]. Hence, new technologies have dramatically affected the current highly competitive corporate environment [19,37]. Moreover, digital technologies have transformed the way organizations and consumers interact and interchange value [26,38,39]. Consequently, the digitalization of enterprises' internal processes offers new and disruptive market opportunities to develop and launch innovations based on new corporate ideas [16,45].

Recent studies reveal highly correlated relations between innovation processes and company performance [18,22,41]. Thus, companies from different industrial sectors are starting to feel more pressure to adopt digital technologies, and there is an increasing fear that competitors will adopt such technologies by taking risks, opening doors to new business opportunities, and greater client satisfaction [8,13,14,52]. On the other hand, digital transformation will enormously affect the labor market. Previous studies reveal that half of the current job positions are subject to automation in the next 10 to 20 years [6,11,45]. Computers or computer-controlled machines can perform routine tasks following programmable rules. With the arrival of Artificial Intelligence, these daily tasks can also be endowed with cognitive behaviors like humans [1,7,24,27,44].

Therefore, computers can substitute routine cognitive tasks (like accounting) or daily manual tasks (like data classification). Soon, machines are expected to perform analytical tasks, interactive and non-routine manual skills (like administration or driving a vehicle) [17,31], according to the employment forecast from 2010 to 2020 prepared by the Labor Statistics Office and by occupational studies of [11,23,51]. It is estimated that approximately 47 percent of US employees face a high probability of automation (more than 70 percent), and machines will replace many of them in the next 10 to 20 years. In Germany, scientists came up with a lower rate of a 15 percent chance of re-placement based on a different approach in which they do not include total occupations; instead, they have individual tasks. However, the German study also shows alarming figures.

According to the World Bank, the approximate percentage of threatened jobs will be 77 percent in China, 69 percent in India and Ecuador, 67 percent in Bolivia, 65 percent in Panama, 64 percent in Argentina, Paraguay, and Uruguay, 57 percent average in industrial countries and 47 percent in the United States [5,11,32]. It is well defined that digital transformation has changed our lives and has become a way to achieve competitive advantages and differentiation in organizations; it is also a strategic means to create innovation and transfer technology and knowledge. However, the implications of process digitalization, construction of innovative capabilities, and the benefits of changes are unclear [20,48,52].

RPA- Robotic Process Automation has become one of the essential tools to perform a digital organizational transformation [57,58]. RPA is a technological imitation of a human employee to automate structured tasks quickly and profitably through structured software pieces known as digital robots [34,42,56]. Although the word "Robot" brings us visions of electromechanical machines, it is essential to note that RPA is not a physical robot but a software-based solution configured to perform repetitive tasks and procedures that used to be executed by humans [28,40,46]. This paper proposes a methodology that allows organizations to achieve a sustainable digital transformation using RPA- Robotic Process Automation and validates its impact on several practical exercises. This research reveals the influence and benefits of using RPA within business processes and defines a critical methodology to use RPA and build RPA centers of excellence within organizations.

2. RPA-robotic process automation

RPA can automate rule-based processes that involve routine tasks, structured data, and deterministic results, like transferring data from multiple input sources like email and spreadsheets to ERP and CMR systems [34,46,54]. Most RPA applications have been made to automate business services processes such as creating purchase orders, entering customer information to an ERP, creating service calls in customer service, creating sales orders, accounts, and data reconciliation, among others [12,34,42].

From an IT perspective, a "Robot" is equivalent to one software license. This robot is integrated into other IT systems through a front end and back end, unlike traditional software that communicates with other IT systems using back-end, so it is possible to integrate RPA with almost every software used by humans, regardless of its openness to third-party integrations [12,40]. According to the Robotic Processes Automation Institute (IRPA), RPA technology is not part of the information technology infrastructure of a company but is based on it [28,55].

Some characteristics that distinguish RPA from other automation technologies such as Business Process Management Systems (BPMS) are that RPA is located at the top of existing systems and accesses to these platforms through the presentation layer, so the programming logic of the underlying systems is not touched [12, 46]. Unlike the majority of the BPMs modeling packages, RPA software solutions do not require programming skills to configure the software interface [56,57]. RPA is configured to work simply by dragging, dropping, and linking icons. RPA does not create a new application or store any transactional data; therefore, a data model or database like BPMs is not required [28, 58].

3. Methodology

This section defines the crucial analysis phases to develop a successful RPA implementation within an organization.

3.1 Define Company Strategy

There are two principal methodologies a company can apply to implement RPA: top-down approach or bottom-up approach.

The Top-Down Approach: Top-down approach usually comes when the RPA initiative is conceived at a c-level, meaning this decision came and will be driven by top enterprise management. It is generally contained within a broader digital transformation initiative. Since this approach it's at a company level, there is the need to centralize RPA activities in a smaller structure that reports topping enterprise management, that is often called Center of Excellence (CoE), the group of professionals that integrate the CoE is experts in RPA and charge of:

Defining RPA standards and guidelines across the company

Manage RPA pipeline of opportunities

Prioritize processes

Build RPA automation

Deploy the automation to the production environment following security and IT requirements

This approach requires a broader orchestration and coordination effort to align all business units and different company departments; also, more strategic communication needs to go to all employees to motivate them to identify good automation opportunities.

The Bottom-up approach: it comes when RPA is initiated by a group of ground employees in the company; it is usually driven by either a department or cross-functional area, making the journey of building the RPA much more straightforward than the top-down approach, yet escalating the initiative to a company level could become challenging as it would require getting buy-in from a c-level. Although a small group of people can easily create the initiatives or proof of concepts, it is crucial to consider that alignment with IT and security is vital and would still need to happen to put automation in the production environment. Like any other software, RPA would need to be handled by the IT department.

If the company's readiness and reality do not fall into any of the approaches, a hybrid system could also be considered, selecting the best of the two. The most important thing to keep in mind, regardless of the process, is defining RPA strategy and journey and aligning with multiple actors like IT and security. After assessing and defining the company approach and strategy for RPA implementation, it is crucial to lay eyes on pipeline management. The pipeline will keep the initiative alive in the company. The channel could be handled by RPA leaders or CoE depending on the approach, but it is imperative to analyze processes and categorize them to understand benefits that each deliver and prioritize; accordingly, a dedicated resource or business analyst usually does this function.

3.2 Analysis ofpotential Areas for automation

As a second phase, it is essential to identify the potential areas of automation inside the company. Fig. 1 illustrates some susceptible processes to automate.

3.3 Processes identification and analysis

Fig. 2 illustrates the process identification and analysis flowchart that allows the incredible creation of technical guidelines with a robotics perspective and automated implementations.

A process is suitable for automation when the following fundamental conditions are met:

It is made up of highly manual repetitive tasks.

It is ruled-based.

It has standard electronic inputs in a readable format like excel, PDF, or Word.

It has a high maturity level with a low exception rate.

If not fulfilling any of the above conditions, automating will not be the best option, but process improvement alternatives are advised.

3.4 Benefits and economic assessment

Once the process has been classified as a good fit for RPA, it is crucial to assess the benefit that automating that process will bring to the company and create a business case to understand the technology's investment vs. benefits and calculate the return of this investment. This would facilitate decision-makers to prioritize processes and get the most benefit from the pipeline. The below set of questions could help with initial process assessment, understand process complexity based on systems, process description, and pain points, and understand process hard and soft savings or benefits.

Benefit or complicated savings calculation would be equivalent to the sum of the Additional Benefits + Full Time Employee Benefit (FTE). A full-time employee equals the average time each employee dedicates to this activity per month * Number of employees supporting this activity monthly * Monthly Blended Rate (including benefits). Full-time Employee savings could also be calculated as Process Volume (# of items or transactions /month) * time spent per transaction in minutes* employees’ salary per minute. Once benefits are calculated, and an initial process assessment is performed, the processes need to be categorized based on complexity for automation (Could be classified in a range from 1 to 4 on a scale of complexity) and build the prioritization matrix shown below.

The last quadrant could be helpful to prioritize the RPA pipeline, but the user could potentially create their varying metrics displayed in the quadrants. Return of investment could be beneficial for decision making, process prioritization, and business case creation. To calculate the return of investment (ROI), the below information should be gathered (Table 2).

Recurring costs

Yearly Cost (When a human does the process)

Estimated Yearly cost with RPA (Process cost when is done by an RPA, this cost will be composed of: RPA support cost, RPA development cost, license, and infrastructure cost)

Total savings would be calculated as the difference between Estimated Yearly Cost with RPA- Yearly cost.

ROI would be calculated as Total savings / Yearly cost.

Best RPA candidates would be either processes located in quadrants "Quick Wins" or "Low hanging Fruits" or strategies with favorable ROI.

3.5 RPA implementation

There are some critical roles during the RPA journey which are responsible for executing, and these are:

Business Analyst (BA): Person in charge of doing process assessments, process mapping, handling conversations with the business, delivering design documentation, creating testing scenarios for user acceptance testing (UAT), supporting the development team in requirements or doubts that might come up.

RPA developer: Person or team in charge of delivering the robot to the business. These roles should cooperate in the subsequent phases to successfully implement RPA projects.

RPA can easily be integrated with tools such as OCR or AI algorithms during the implementation, so requirements like reading from PDF files, classifying data, predicting, and even natural processing language could be considered to enhance the RPA. Therefore, the more knowledge the roles of this type of technology have, the better the automation process will be adapted. The following sections show the RPA implementation roadmap.

3.5.1 Process Mining

Defining, a process model, implies lots of structuring work, e.g., relevant business activities and events must be identified and named, the order of these activities must be well defined, and business logic and critical activities must be specified within an organized and structured scheme. However, this discovery process can also be automated and oriented by a new "Process Mining" paradigm involving artificial intelligence, self-learn algorithms, simulation, and data science to extract knowledge and process structure. Process mining comes from using data mining on data generated while executing business applications. This way, design and extract the correct logic that depicts the business and optimize the process [25]. Process mining uses data to automatically build an as-is process model and improve the efficiency as well as speed in this critical step of the automation [23]. It can be questioned whether the process models obtained by process mining are equal to hand-crafted models regarding their quality because process mining can only be applied when an appropriate data log is available and may omit phrases that are not data-driven. Suppose your process discovery is supported by data, simulation, and mathematical analysis and is away from the employees' judgments. In that case, it can be a good candidate for process mining and possibly competent to develop a successful RPA.

3.5.2 RPA Process Design

After identifying processes suitable for automation and choosing the best candidates, the initial robot design is done based on information gathered during the initial process assessment by the business analyst. During this phase, process pieces are standardized, inputs and outputs are well defined, and a flowchart with all the robot needs to perform is created. Along this phase, business rules are defined, process exceptions and business continuity plans are mapped. Then all this information is consigned to an RPA deliverable called Process Design Document (PDD); this document contains all technical specifications of the robot and requires SME's (Subject Matter Expert) approval before transitioning it to the development team for the build phase.

3.5.3 Define a good Architecture of the solution

The capacity to support a holistic architecture that allows the sustainability of the robots is a fundamental issue in the success of an RPA project. Organizations need to evaluate capabilities in this area and evaluate the best options to put up the RPA ecosystem, especially if it is strategic to host the software in the cloud or on-premises infrastructure. All the architectures should ensure that new systems integrate seamlessly with the overall enterprise platforms. The IT area must establish a performance monitoring mechanism to manage and monitor the general RPA projects and establish maintenance and support protocols. Below in Fig. 4 is dis- played a typical architecture to develop an RPA under a holistic scheme.

3.5.4 RPA Development and Testing

Through this phase, the robot development begins, based on documentation gathered in previous steps and working sessions with the business. Deliverable of this phase will be the robot entirely built and running in a test environment. To move forward with robot deployment to a production environment, SME and team will have to go through User Acceptance Testing and approve the automation. A low complexity robot can take between 1 or 2 weeks to complete, a medium complexity one can take from 3 to 4 weeks, and a high complexity level might take 5 to 8 weeks. This time depends on the developer's expertise; the above numbers are standard for senior RPA developers. Complexity calculation is done by calculating the individual complexities of each process step considering the number of applications used in the process, the complexity level of each application, and the number of screens involved in the process. Points per function is a valuable technique for these calculations.

3.5.5 RPA Deployment and Sustain

After developing the robot and testing it in a controlled environment, the robot is deployed to a production environment; during this phase, required user accesses and infrastructure needed to work correctly in the production environment must be guaranteed. The technical team must monitor the robot's initial runs and add final adjustments if necessary. In the sustain phase, the robot works autonomously, and its operation is supervised to avoid failures and assure the process will be sustainable in the long run. Also, RPA documentation is delivered along with the business continuity plan so RPA errors and inconveniences can be handled in the future.

4. Experimentation

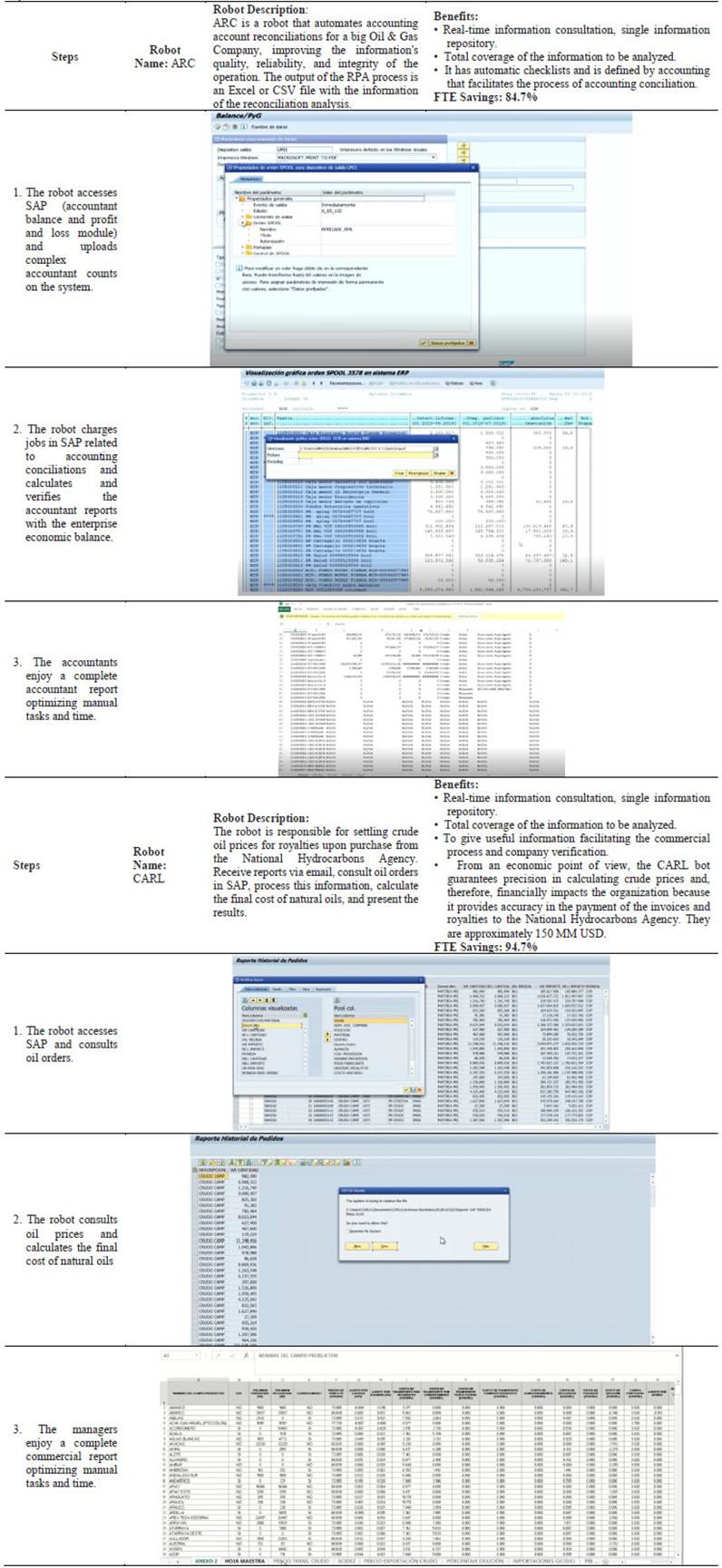

This section presents the results of implementing Robotic Process Automation - RPA in different areas using the previously defined methodology. First, ARC was developed, a Robot that automates accounting conciliations for big Oil & Gas companies, improving the information's quality, reliability, and integrity of this process, which is very sensitive and critical. The automation compares and automatically reconciles the economic values that a company has registered with its bank movements, it classifies the accounting books, and confronts the bank statements. Second, CARL was developed, a robot responsible for settling crude oil prices for royalties upon purchase from the National Hydrocarbons Agency. This process is too critical due to managing a large quantity of data and a small mistake can cause a considerable loss of money. For this reason, it may be precise and secure. Table 3 below presents all the outcomes of the experimentation.

5. Conclusions

The methodology proposed in this document brings together the fundamental elements to perform RPA in any organization, ensuring articulation of crucial factors and agents to achieve successful implementations that transform and create value within organizations. This methodology comprises structured phases that must not be replaced to ensure all the objectives when automating an industrial or organizational process. The proposed methods illustrate how to implement RPA projects according to different organizational structures. Therefore, it is essential to carry out detailed analyses of these components before deciding the appropriate model for each company.

It is important to note that each RPA project deserves individual and independent investments that may be subject to financial consequences for organizations. Also, organizational change is a determining factor in the success of new technology implementation that affects job positions and overall companies. For this reason, it is necessary to design training and transition mechanisms to transmit the RPA knowledge and benefits to the employees.

The experimentation of this research reveals how the most latent concern in employees and company personnel is the fear of losing their jobs due to digitalization. Although all their jobs are assisted and transformed, metrics and studies reveal how robots free up large amounts of time associated with employees' repetitive tasks, allowing them to use these free hours for innovation-framing business and continuous improvement. The results of this study show the enormous impact of RPA over the digital transformation of an organization and strongly argue that this tool will be decisive for corporate changes in organizations that are adapting to industry 4.0 and the new digital era.