Introduction

The sixth sustainable development goal (SDG) involves ensuring access to water and sanitation. Thus, clean and accessible water for all is an essential part of the world we want to live in, and there is enough fresh water on the planet to achieve this. However, due to bad economic management and poor infrastructure, millions of people -including children- die every year from diseases associated with inadequate water supply, sanitation, and hygiene (United Nations Sustainable Development, 2019).

Most of the population living in rural and peri-urban areas of developing countries depend on decentralized systems for the treatment of domestic wastewater, with conventional septic tanks (ST) being the oldest and most popular method for on-site wastewater treatment, given their favorable economic and functional features, such as simple design, low cost, easy installation, and minimal maintenance (Stazi and Tomei, 2018; Sharma et al., 2014). However, these devices have several inherent drawbacks, with the most significant being their limited treatment efficiency in terms of COD and TSS reductions for compliance with discharge or reuse requirements (30-40% COD and 55-65% TSS) (Nasr and Mikhaeil, 2013).

In light of the above, ST are usually sequentially combined with anaerobic filters (AF), in which the organic matter not removed in the ST is stabilized by microorganisms retained in the interstices or adhered to the support medium or biofilm in order to achieve a better effluent quality. This configuration (ST-AF, commonly called conventional system or CS), in addition to its simplicity, low cost, and easy operation, is highly accepted by environmental control bodies, mainly for small and dispersed populations, where there are few resources to build conventional sewer treatment systems (van Haandel et al., 2006).

Despite these advantages, these types of alternatives require larger reactors associated with high operating and construction costs. In addition, they sometimes demand a completely new structure, thus increasing the costs and resulting in greater space and maintenance requirements (Sharma et al., 2014).

Therefore, hybrid system (HS) strategies have been implemented, considering a wide range of technologies, i.e., from ST and AF to other combinations with up-flow anaerobic sludge blanket (UASB) reactors, activated sludge, reverse osmosis, and ultrafiltration, among others (Dorji et al., 2022; Fernández del Castillo et al., 2022; Vicuña et al., 2009).

Some examples of HS include:

i) The full-scale compact system developed by Sousa and Chernicharo (2005), called SISCOTE and composed of a modified ST (MST) and two hybrid anaerobic reactors operating in series, with removal efficiencies of 85-90% COD and 95% TSS;

ii) the full scale up-flow septic tank/baffled reactor (USBR) MST, built and tested in a small town in Egypt (Sabry, 2010), with removal efficiencies of 84% COD and 89% TSS;

iii) an MST followed by an up-flow AF, housed within a single cylindrical unit, designed for the in situ treatment of domestic wastewater (DWW), evaluated at laboratory scale by Sharma et al. (2014), which showed removal efficiencies of 86,3±4,9% COD and 91,2±9,7% TSS;

iv) an MST followed by an AF for the in situ treatment of the wastewater generated in a boarding school, with efficiencies on the order of 72,6% COD and 83,2% TSS (Sharma and Kazmi, 2015);

v) an isolated AF (IAF) system incorporating a waste heat input for wastewater treatment in buildings, tested at full scale in the Phitsanulok province of northern Thailand, with removal efficiencies of 61,3% COD and 67,7% TSS (Bouted and Ratanatamskul, 2018);

vi) the demonstration by Santiago-Díaz et al. (2019, 2021) of the potential of decentralized wastewater management in Mexico, through the use of a UASB-septic tank strategy for the treatment of municipal wastewater, finding that this system can be built with low-cost local materials and does not require sophisticated equipment (it is also an economical alternative due to the simplicity of the technology and its easy operation); and

vii) the HS comprising ST-AF, where the suspended biomass (present in the ST) is combined with adhered biomass (present in the AF) in the same reactor.

HS are compact, do not require large areas, and improve biological system performance. Additionally, these HS are also convenient in places where it is desired to increase the biological system's capacity without making substantial modifications involving civil works (Garrido Aranda et al., 2003; von Sperling and Chernicharo, 2005).

One of the aspects that defines treatment process efficiency is the hydrodynamic behavior of the reactors, which considers aspects such as the presence of dead zones and short circuits and the determination of the distribution of residence times (DRT) of the particles within the system (Levenspiel, 2004). However, in general, reactor design has focused mainly on aspects of biochemical process efficiency.

Hydrodynamic aspects can be evaluated by tracer tests, in which an easily detectable tracer substance (which does not participate in any physical, chemical, or biological transformations that can alter the actual hydrodynamics of the fluid) with a known concentration is injected. Among the models used to evaluate hydrodynamics, the most applicable are the Wolf Resnick method, the axial dispersion model, and the model of complete mixing tanks (CMT) in series (Pérez and Torres, 2008; Hassanvand-Jamadi and Alighardashi, 2017). Authors such as Santiago-Díaz et al. (2021) have also applied a comprehensive analysis of a zeolite-packed up-flow baffled septic tank using tracer tests and mathematical modeling.

Although HS are presented as a promising wastewater treatment technology, there are few reported full-scale studies (Soroa et al., 2005). Thus, it is to continue with the research and application of these systems in order to respond to the need for more compact and more sustainable systems, as well as to reduce maintenance operations. Thereupon, this study presents the results of a pilot-scale evaluation of the performance of two wastewater treatment system configurations: (i) a conventional system (CS) involving a ST and an up-flow AF in separate units and (ii) a hybrid system (HS) involving ST-AF in a single reactor. This, from a perspective of both performance (COD and TSS removal efficiency) and hydrodynamic behavior.

Materials and methods

Area of study

The study was conducted in a university campus located at coordinates N 4°47'19,65" W 75°41'27,01", in the Central Mountain Range of the Colombian Andes, in the coffee-growing region, with an altitude of 1 465 meters above the sea level, in an urban area with intermediate climate (17 to 26 °C), and an average annual precipitation of 2 750 mm.

Characterization of the substrate

The raw wastewater (DWW) used as a substrate came from a building located in the Faculty of Arts (35 restrooms, one cafeteria, and three workplaces for painting, ceramics, and sculptures); and the inoculum came from the septic tank of the institutional wastewater treatment plant (WWTP), applying 40% of the useful volume of the reactors (Pérez et al., 2009). Table 1 shows the variables measured regarding the substrate.

Treatment system configurations and experimental conditions

Two system configurations consisting of septic tanks (ST) and an anaerobic up-flow filter (AF) were evaluated: (i) a conventional system (CS: ST followed by AF in separate units) and (ii) a hybrid system (HS: ST in the lower part and AF in the upper part of the same reactor).

The height of the AF, both in the CS and the HS, was 70 cm, and, as filling material, polypropylene rosettes of 186 mm diameter with a porosity of 95% were used (Balasundaram et al., 2014), placing 100 units on each filter. Figure 1 shows the evaluated CS and HS configurations.

The reactor volumes were: CS: 0,75 m3 (0,50 ST and 0,25 AF); and HS: 0,96 m3. Given that the porosity percentage of the rosettes was 95%, their incorporation in the reactors had little effect on their volume, leaving a useful volume of 0,74 and m3, respectively. These values were considered in the hydrodynamic analysis of the two systems.

Raw wastewater was fed by a distribution system with hoses, and, in order to improve the distribution of the AFs, a 1-inch PVC pipe with 0,5 mm perforations was installed at the bottom of the reactors. The hydraulic load was regulated using peristaltic pumps, ensuring the same initial HRT in both configurations (36 hours), which is based on studies conducted for the start-up of anaerobic systems with municipal wastewater in Colombia and Mexico (Méndez-Novelo et al., 2012; Orozco-Gaviria et al., 2014).

Considering that STs require HRTs between 12 and 24 hours, as well as the fact that, when AFs are used to treat ST effluents, HRTs are between 4 and 10 hours (Chernicharo, 2007), the operating strategy consisted of a progressive reduction of the HRT until the lowest value in each reactor with stable conditions was reached. This was done as the reactors responded favorably in terms of the COD removal efficiency and the behavior of the control variables (pH, TA, BA, VFA, buffer (BI) and alpha indices, and AI/AP ratio), in order to guarantee the conditions for metabolic equilibrium between the different process stages and, therefore, the adaptability of biomass to controlled substrate overloads (Pérez et al., 2009).

The BI corresponds to the relationship between alkalinity due to VFA and the total alkalinity; the alpha index is the relationship between BA and TA; and the AI/AP is the relationship between alkalinity due to VFAs and BA (Pérez and Torres, 2008). According to this criterion, the duration of each operating stage was variable (Table 2). Additionally, the COD and TSS reduction efficiencies were determined, and the temperature and pH were measured in situ.

Table 2 Operational conditions

* Includes stops due to the students' holiday period (absence of wastewater to feed the systems). **Does not include stops.

Source: Authors

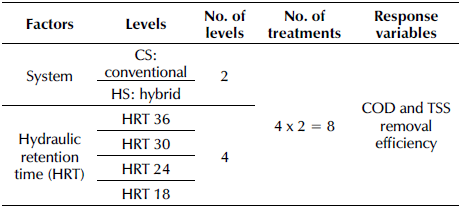

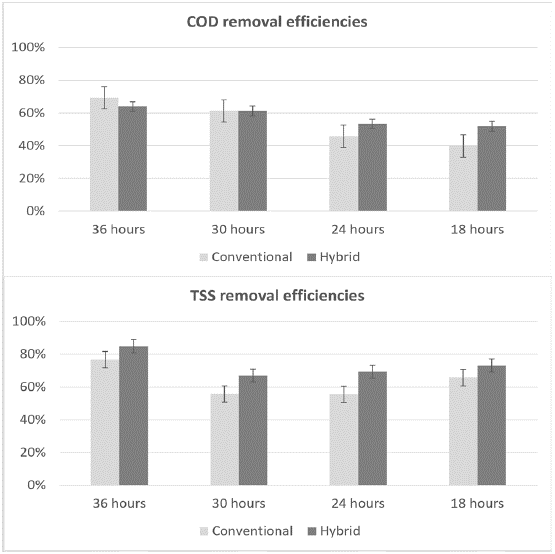

A multivariate factorial design was proposed in which eight treatments resulting from the combination of two factors were evaluated: the type of configuration (CS and HS) and the HRT (36, 30, 24, and 18 hours), as shown in Table 3.

Descriptive statistics tools were used to analyze the results obtained, including the average and the standard deviation. In the first instance, it was verified whether the assumptions of the analysis of variance were met for the response variables (COD and TSS removal efficiency), for which the Shapiro-Wilk and Levene tests were used with regard to the normality and homogeneity of variance, respectively. Additionally, to establish the significance of the factors evaluated for each of the response variables, as well as to examine factor interactions, an analysis of variance was performed based on the multivariate factorial model at a confidence level of 95% (a = 0,05). Statistical processing was performed with the Statistical Package for Social Science (SPSS) software.

Reactor hydrodynamic performance

To evaluate the hydrodynamic behavior of the two configurations and validate the real HRT with respect to the theoretical HRT, a hydrodynamic test was performed using sodium chloride (NaCl) as a tracer, which is not absorbed by sludge particles, has no inhibitory effects on anaerobic bacteria, and is not absorbed as a nutrient by microorganisms (Li et al., 2016). Equations (1) and (2) were used to calculate the tracer dose (Pérez and Torres, 2008), and the tracer injection was instantaneous.

where P represents the weight of the tracer to be added (kg); ∀ represents the useful reactor volume (m3); K represents the correction constant; Co represents the concentration (mg/L or g/m3); and I represents the degree of purity of the tracer (fraction of the unit).

The theoretical HRT was 24 hours, and, taking into account that the tracer test must last three times longer than the theoretical HRT, during which the concentration of the tracer is expected to approach zero, a period of 72 hours was considered, measuring conductivity every 20 minutes during the first 48 hours and then every hour until completing 72 hours. Table 4 shows the final value of P for each configuration according to these Equations.

Data analysis was performed by constructing tracer concentration and time distribution (E(t)) trend curves to determine the real or experimental HRT, and the Wolf-Resnick mathematical model, the axial dispersion model, and the complete mix reactors in series model were applied (Levenspiel, 2004; Pérez and Torres, 2008), with the objective of identifying the type of flow in each system and the presence of hydraulic phenomena such as short circuits and dead zones.

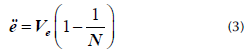

To evaluate the real HRT when compared to the theoretical one, the mean, variance, and standard deviation of the HRT were calculated according to the CS and HS reactor concentration results measured in known time intervals. Likewise, the mean residence time from the E curves was used to determine the hydraulic efficiency associated with a reactor's ability to distribute the flow uniformly within its useful volume, maximizing the pollutant contact time and optimizing its removal (Persson et al., 1999; Latrach et al., 2018). Equation (3) allows evaluating the effective volume and the number of complete mix tanks in series (Persson et al., 1999).

where V e represents the effective volume, and N represents the number of tanks in series.

Results and discussion

Substrate evaluation and experimental unit performance

Table 5 shows the physicochemical characteristics of the wastewater (influent), which is characterized by the temperature, pH, and VFA of the DWW. However, a high alkalinity and COD were observed, which allows classifying the substrate as having a medium to strong DWW concentration (Bureau of Sale Drinking Water, 2016), which may be associated with the fact that the wastewater comes from 35 sanitary batteries (without showers) that have water-saving devices. Additionally, wastewater is received from the washing of materials in the ceramic, painting, and sculpture workplaces. Lew et al. (2011) found similar values (COD: 1 576±376 mg/L) in Israel and elsewhere in the Middle East, which were caused by low per capita water consumption in these areas.

Table 5 Summary of evaluated influent physicochemical parameters

HRT 36 hours (n = 10); HRT 30 hours (n = 7); HRT 24 hours (n = 6); HRT 18 hours (n = 5).

Source: Authors

Throughout the experimental period, the reactors operated under environmental conditions in the mesophilic temperature range, as well as with pH values close to the ranges recommended for anaerobic digestion (6,5-8,0 units). As for alkalinity, an adequate buffer capacity was observed, given the predominance of bicarbonate alkalinity (Chernicharo, 2007).

Reactor performance

Table 6 shows the effluent characteristics of the two configurations (CS and HS) in terms of temperature, pH, VFA, TA, and BA. In general, both effluents reached higher alkalinity values than those of the affluent, which, according to Orozco-Gaviria et al. (2014), occurs because the system seeks to generate bicarbonate ions to reach equilibrium with buffer capacity.

Table 6 Summary of the control variables in the effluent of the conventional (CS) and hybrid systems (HS)

HRT 36 hours (n = 10); HRT 30 hours (n = 7); HRT 24 hours (n = 6); HRT 18 hours (n = 5).

Source: Authors

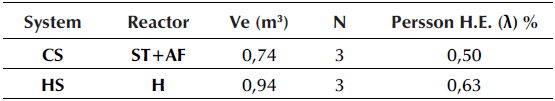

Figure 2 shows the COD and TSS reduction efficiencies in each of the evaluated operating stages, allowing to observe that efficiencies higher than 60% were achieved during HRTs longer than 36 and 30 hours for both the CS and HS and in the samples. For HRTs of 24 and 18 hours, although efficiency decreased overall, it was higher in the HS. It was observed that, in terms of the removal efficiency of both COD and TSS, the HS configuration exhibited a better performance under all of the evaluated operating conditions.

Source: Authors

Figure 2 Comparison of the COD and TSS removal efficiencies in the conventional and hybrid systems

From a statistical point of view, significant differences (p<0,05) were found between the HRTs of 36 and 18 hours in the removal of COD: (i) CS: 69,4±5,2 and 39,8±13,1%, respectively, which represents an efficiency reduction of 29,6%; (ii) HS: 64,0±5,4 and 52,0±16,8%, respectively, which constitutes an efficiency reduction of just 12% regarding the two HRTs. This indicates that CS was more susceptible than HS to a decrease in HRT.

Chernicharo (2007) reports COD removal efficiencies for the CS between 40 and 70% (for temperatures below 15 °C and above 25 °C), a range in which the results of this study fall, also coinciding with other studies, such as that by Méndez-Novelo et al. (2012) in Mexico with HS, in which removal efficiencies of 56% COD and 61% TSS were obtained while operating at HRs of 36 and 24 hours. In contrast, Pacheco and Magaña (2003) obtained low efficiencies in Mexico, in the order of 38%, when starting an HS in a continuous phase, due to the slow growth of the reactor biomass and the high affluent concentration variations (1 375-565 mg/L of COD). They also found that the higher the affluent concentration, the greater the removal percentage.

Other studies with anaerobic HS operated under different conditions exhibit higher efficiencies than those obtained in this study (Soroa et al., 2005; Sousa and Chernicharo, 2005; Sharma and Kazmi, 2015), possibly because the wastewater composition evaluated in this study includes waste from activities such as painting, ceramics, and sculpture, which can provide some potentially inhibiting substances to the microbial population responsible for the anaerobic digestion of the substrate.

Hydrodynamic evaluation of reactors

Figure 3 presents the CS and HS tracer concentration curves over time, and Table 7 shows the trend curve analysis through the relationships between the parameters.

An analysis of the CS and HS trend curves shows a dual or arbitrary behavior. According to Pérez and Torres (2008), plug flow occurs during the time elapsed from the tracer addition until it can be measured in the effluent and the curve changes from concave to convex. From this point and until a second inflection is observed in the descending curve, dual flow occurs. Henceforth, the flow is of mixed character. In this sense, the HS curve shows a greater predominance of plug flow than that of the CS.

According to the relationships between t/to and tp/to, there is a predominance of mixed flow in the systems, and large short circuits, with a value below 0,3, which indicates the probable direct passage of water between the inflow and outflow of the tanks.

Similarly, the relationship between the mean time and the theoretical time (tm/to), with a value <1, proves the existence of short circuits. In terms to the Wolf-Resnick, axial dispersion, and tanks in series models, Table shows the analysis of the two systems; the first section allows identifying the percentages of the reactor that behave as plug flow or as complete mixture, in addition to dead zones and short circuits, showing a very equitable dual behavior involving plug flow (52%) and complete mix (48%) at the CS outlet, as well as more dead zones compared to the HS, which exhibits a dual hydraulic regime, albeit with a predominance of plug flow (62%), thus confirming the trend curve findings.

Table 8 Application of the Wolf-Resnick, axial dispersion, and tanks in series models

Source: Authors

According to Levenspiel (2004), all reactors showed a dispersion number between intermediate (0,025) and large (0,200), which confirms the presence of PF and CM. According to the tanks in series model, the greater the number of tanks, the greater the tendency towards PF; and, with fewer tanks, there is a tendency towards CM. In short, the CS behaves like a completely mixed reactor (CMR) in a series of three, with a high dispersion coefficient and a dual regime and a predominance of plug flow (52%) and 5% dead zones. The CMR model showed a correlation of 88%.

The HS behaves as a CMR in series of three, with a high degree of dispersion and a dual flow regime with a greater predominance of plug flow (62%) than the CS (52%), without the presence of dead zones. There was also a higher correlation (91%) with the axial dispersion model. Similar results were found in the hydrodynamic evaluation at the end of the optimization of a full-scale AUFF (Pérez and Torres, 2008), as well as in studies conducted in Brazil (Baettker, 2015), evaluating different AF support media on a laboratory scale.

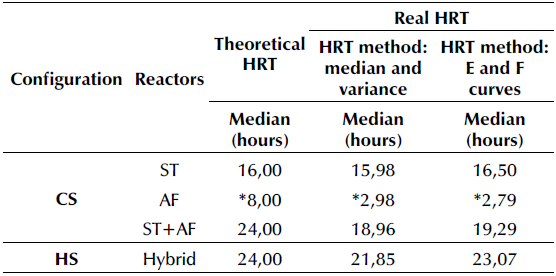

Table 9 shows the results of the estimation of real HRT for the systems, which indicate that the mean experimental or real HRT, calculated through the median variance and E curve methods, are similar. For the CS (ST+AF), the real HRT is 19,29 hours (in comparison with 16,50 for the ST and very close to the theoretical value of 16 hours), which means that, in this system, short circuits are mainly found in the AF, which have a real HRT of only 2,79 hours compared to the theoretical HRT of 8 hours.

Table 9 Estimated real HRT for the CS and HS

*These values were calculated as the difference between the HRT of the complete system (ST+AF) minus that of the septic tank (ST)

Source: Authors

This may be the cause of the low COD removal efficiency (45,9±19,7%) in the 24-hour HRT (insufficient wastewater contact time with the retained AF biomass). Thus, a large portion of the removal takes place in the septic tank (von Sperling and Chernicharo, 2005; Oliveira and von Sperling, 2008).

In the HS, the real HRT approaches the theoretical HRT with a difference of just 56,35 minutes, which guarantees a better performance of the HS with respect to the CS because the water mass has a longer contact time with the microorganisms responsible for removing organic matter. Table 10 shows that the HS also exhibits a greater hydraulic efficiency (0,63%) compared to the CS (0,50%) because, according to Persson et al. (1999), λ values > 0,75 indicate good hydraulic efficiency, 0,75 < λ <0,5 indicates satisfactory efficiency, and λ < 0,5 denotes poor efficiency.

Conclusions and recommendations

The evaluated wastewater shows adequate levels of pH and total and bicarbonate alkalinity, which guarantees a good buffer capacity in the systems. The alkalinity indices, as well as the operating variables, showed that the systems operated in a stable manner, without acidification due to the accumulation of VFA. However, the presence of paints and clay residues, among other additives used in painting, ceramics, and sculpture in the fine arts workplaces, can generate inhibitory effects on the process, which must be further evaluated.

In the conventional and hybrid systems evaluated, conformed by septic tank and anaerobic filters, the hybrid configuration had a better performance, with greater stability by better supporting the different hydraulic loads evaluated and achieving an 18-hour HRT removal efficiency of 52,0±16,8% for COD and 73,06±18,5% for TSS, in comparison with 39,8±13,1% for COD and 65,8±20,52% for TSS with the conventional configuration. Additionally, the hybrid system had lower performance variations as the HRT was reduced.

This hydrodynamic evaluation confirms the improved performance of the hybrid system, which is associated with a predominance of plug flow (62%) compared to the conventional system (52%), leading to a real HRT closer to the theoretical one, as well as to a greater hydraulic efficiency than the conventional system.