Introduction

The agricultural sector is one of the strategic areas of the Colombian economy despite its decreasing share in the Gross Domestic Product (GDP) in recent decades. It contributes to the national economy with job generation, with 15.7% of 22,104,000 jobs at the national level. Its contribution to GDP was 6.29% in 2018 (DANE, 2020, February 14; DANE, 2020, March 31) and its contribution to exports was 18.6% in 2019 (Contexto Ganadero, 2020; DANE, 2020, August 20); likewise, it plays a role in reduction of poverty and gender equity, among others. One of the branches of this sector is the sugarcane production of "panela", a traditional consumer product in Colombia. For 2019, the national agricultural production area of sugarcane was 5,345,794 ha, of which 239,873 ha or 4.49% of the total (EVA-UPRA, 2019) was used for panela production. This crop had a five-year fluctuation of agricultural area with a slight downward trend. The panela sugarcane is cultivated in 28 departments distributed in five production nuclei: The Occidental nucleus, whose main producer is Antioquia; the Western-Central nucleus, whose main producers are Caldas, Quindío, Risaralda, Cauca, and Valle del Cauca; the Southern nucleus, whose main producers are Nariño, Huila, and Tolima; the North-eastern nucleus, whose main producers are Boyacá and Santander; and the Central nucleus, whose main producer is Cundinamarca. Panela sugarcane crops are distributed in 511 municipalities, where the raw material is processed in approximately 18,000 sugar mills (registered), with 117 of these being the axis of the economy (MADR, 2019). The panela production in 2019 was 1,364,523 t, with an average yield of 6.41 t ha-1 (EVA-UPRA, 2019). More than 350,000 families participated in the production of panela and 287,000 direct jobs were generated (MADR, 2019). In 2018, only 7,654 t of panela (<1%) were exported, which indicates that almost all panela production is destined to domestic consumption (Agronet, 2020). In terms of panela consumption, Colombia ranks first in the world. For 2017, in Colombia, the estimated annual apparent consumption per capita was calculated between 19 to 22 kg of panela (Celis, 2017).

The Cundinamarca department is the major national producer of panela with 39,324 ha of sugarcane planted and 37,353 ha harvested, with a yield of 5.45 t ha-1, and 203,631 t of panela produced (EVA-UPRA, 2019). In Cundinamarca, the region with the highest production of panela is Gualivá. There, the most important municipality is Nocaima, which has 1,777 ha planted and harvested sugarcane, with a production of 10,662 t and an average yield of 6 t ha-1, which is somewhat less than the national yield average (EVA-UPRA, 2019).

At the national level, the panela sector faces limitations in the technical and economic aspects with negative consequences in the social sphere, which have been accentuating in recent years. The main cause is the fall in prices because of a saturation of the national market, which is almost the only demand field for this product. According to López (2019), the price of panela in June 2016 was approximately 2,800 Colombian pesos (COP) per kg, while in June 2019 it was 1,662 COP per kg, which makes a price reduction of approximately 40% in three years. According to Celis (2017), the annual demand per capita fell from 32 kg in 2002 to 19 kg in 2017 (approximately 40%), while the supply barely increased by 7% in 12 years, from 1,272,855 t in 2007 to 1,364,523 t in 2019. This situation is disadvantageous for producers because it generates a low profit margin. The low economic benefits are also due to the relatively low productivity of the crop, high unit production costs, low degree of differentiation, and reduced bargaining power at the producer level.

The difficulties mentioned above were approached, among others, by scientific studies. A reference sample of 17 studies during the last ten years, mainly undergraduate thesis, were found through Google and Google Scholar. These studies show a tendency to search for practical improvements of the disadvantaged situation in the panela industry via three main strategies: technological improvement of production, organic production, and exportation. One more strategy can be added to these, which is a creation of the producer association oriented towards marketing (Galeano & Marín, 2010; Román & Prieto, 2013; Melo Hernández, 2014; García, 2015; Guerrero & Escobar, 2015; Gutiérrez & Triviño, 2015; Cárdenas et al., 2016; Franco, 2016; Arcos, 2017; Arévalo, 2017; Castañeda et al., 2017; Galindo, 2017; Agudelo Retavisca, 2019; Betancourt, 2019; Bolívar, 2019; Díaz, 2019; Ruíz et al., 2019; Castaño & Ramírez, 2022).

For several years, both state and private funding institutions encouraged organization of agricultural producers in associations. Within the framework of these actions, the Nocaima Panela Producers Association - ASOPROPANOC was created more than 17 years ago. Its members produce organic and conventional (traditional) panela according to the market demands. The commercialization carried out by this association is aimed at the national market through neighborhood stores, chain stores, final consumers of the same municipality and some health food stores, and at international markets through marketing agents such as Doña Panela® and Comerpanela®. The latter exports panela to Canada and the USA. According to Agronet (2020), the countries involved in the most of the panela exports (partially organic panela) from Colombia in 2018 were the USA with 2,379 t and Spain with 2,248 t.

The production and export of organic panela is one of the alternatives proposed to overcome the crisis in the panela industry. According to FEDEPANELA (2019), until 2019 there were 217 panela producers certified in organic production. Most members of ASOPROPANOC are certified in organic production by the BCS OKÖ GARANTIE certifying agency. The production of organic panela, guaranteed through third-party certification, has advantages and disadvantages for producers. The advantages are referred mainly to better prices for producers, access to new markets, better product quality for consumers, and reduction of negative effects on the environment, among others. The disadvantages, among others, are the monetary and temporal costs of conversion to the organic system, technological conversion of production, and standardization and improvement of product quality. Many traditional and conventional panela producers could become organic panela producers, but they have doubts about the benefits of switching to the certified organic production system. This study aims to provide empirical information that would help the producers to decide whether to produce certified organic panela by answering the following question: What are the technical, economic, social, and environmental implications of the organic panela certification?

The general objective of this study was to determine the technical, economic, social, and environmental implications of certified organic panela production as compared to its traditional (standard) production. The specific objectives deal with each technical, economic, social, and environmental implication. This research aimed to generate empirical information that supports and guides the transition from a traditional or conventional panela production system to a certified organic system.

Materials and methods

This study had a non-experimental design and operated mainly with descriptive data with explanatory additions. Thirty-two panela producers associated with ASOPRO-PANOC were studied; five were traditional producers and the remaining 27 were certified organic panela producers or were in the process of obtaining certification in organic production. This organization is located in the Nocaima municipality, Cundinamarca department of Colombia. This municipality is located to the northwest and 75 km from Bogotá D.C.; it has a total area of 69 km2 distributed in 21 townships. Its average altitude is 1,200 m a.s.l. and average air temperature is 24°C in much of the territory (Alcaldía de Nocaima, 2012).

The research was carried out in four phases. The first phase was based on a documentary study to define the dimensions (technical, economic, social, and environmental) and determine the analysis variables. The following variables were considered: 9 in the technical component, 14 in the economic component, 4 in the social component, and 3 in the environmental component. In this phase, the formats to collect field information were prepared. In the second phase, the field work was carried out, between July and September 2018, consisting of a census of the 32 ASO-PROPANOC producers through a questionnaire with 20 closed questions and 10 open questions. This census also included a questionnaire with 10 closed questions applied to 8 experts on the research topic of panela production. Additionally, during the census, observations were made about the farms and panela production, and tables of production costs were filled out. The third phase was the systematization and analysis of the information collected in the field through descriptive statistics. The fourth phase was the presentation and interpretation of results. In almost all the results, a comparative analysis was made between the certified organic production system and the traditional system (Ibarra, 2019).

Results and discussion

Technical implications

The technical aspects of certified organic production involve changes that must be applied both in the production of sugarcane for panela production and the transformation of sugarcane into panela. These changes are technological changes, improvements in the producer skills and technical knowledge, and improvements in the awareness of panela producers on panela production. According to Jordan (2015), the certification of organic products must be done according to established governmental standards, which must ensure the conservation of natural resources, avoiding residuality in the products obtained.

According to the analyses by the producers and technical assistants of FEDEPANELA, the labor involved in the sugarcane crop renovation and the technological package implemented in the organic system explain the higher productive margins achieved with said model, since the fertilization directly affects crop productivity (Osorio, 2007). The results referring to the two systems are presented below.

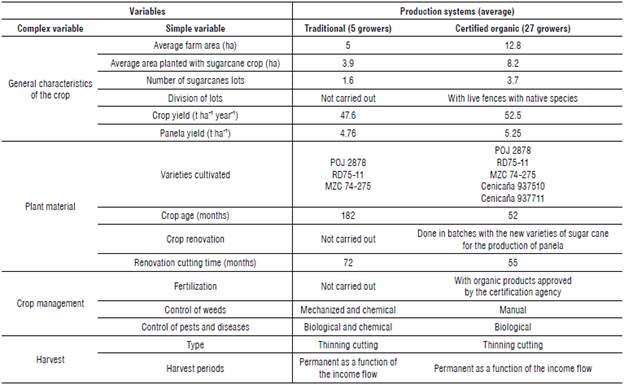

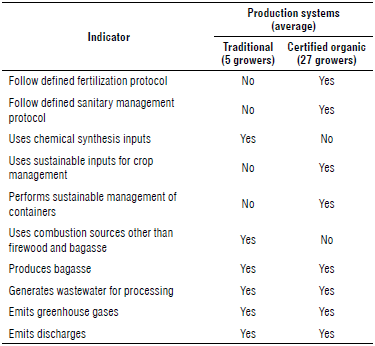

Sugarcane crop management for panela production

The difference between the production of the traditional crop system compared to that of the certified organic system is evident (Tab. 1). The most relevant difference consists in annual productivity, which is almost 0.5 t ha-1 (>10%). The most determining factors in improving productivity in certified organic systems relate to technological change, including introduction of improved varieties of higher yield, crop renewal, higher frequency of cutting, lower crop age, and organic fertilization. This change also implies a prior process of changing the production system from traditional to certified organic, which can take up to three years. Technological change also involves an increase in labor (days) and in cost of production (investment) per ha. These two aspects are detailed in the section corresponding to the economic aspects. Additionally, assistance and technical support by the certification entity must be included in the certified organic system. Technical support and certification promote establishment of a new production culture in growers that implies increase in personal discipline and greater environmental and social awareness.

TABLE 1 Technical aspects of the sugarcane production for panela under two systems: traditional and certified organic in the ASOPROPANOC (Nocaima, Cundinamarca).

Panela production

Compared to the traditional system, the production of certified organic panela suggests technological improvements and a change in the production culture as well as increasing environmental and social awareness of the producers. The technological improvement of the organic production begins with the change of to either an improved traditional stove or a "Cimpa", which has greater efficiency and performance (Rodríguez & Gottret, 1998; García & Cortés, 2011; Ramírez & Arenas, 2016). Logically, this costs more, which implies additional investment. According to Arévalo (2017), a determining factor in the panela making process is the technology innovation, especially, with the use of evaporators that improve the quality and safety of the panela product.

Another technological improvement is standardization of transformation and packaging process, which includes, among others, management of temperatures and dosages and use of stainless-steel trays and utensils. The foregoing activities ensure compliance with Resolution 779 of 2006 of the Ministry of Social Protection (Colombia) and other regulations for organic panela production, which include, among others, compliance with standards in infrastructure, facilities, equipment, materials and supplies, and personnel handling the product. The personnel linked to the production process must comply with regulations of protection, hygiene, and health elements as well as training requirements for their participation in a panela production unit.

An important factor in panela production is the temperature reached in the oven at the time of boiling of sugar honey ("punteo" in Spanish), where traditional ovens can reach temperatures of 116 to 122°C. This temperature can increase between 1 and 3oC when the altitude of the site is below 1000 m a.s.l.; Nocaima is located at 1200 m a.s.l.

Economic implications

Production and costs

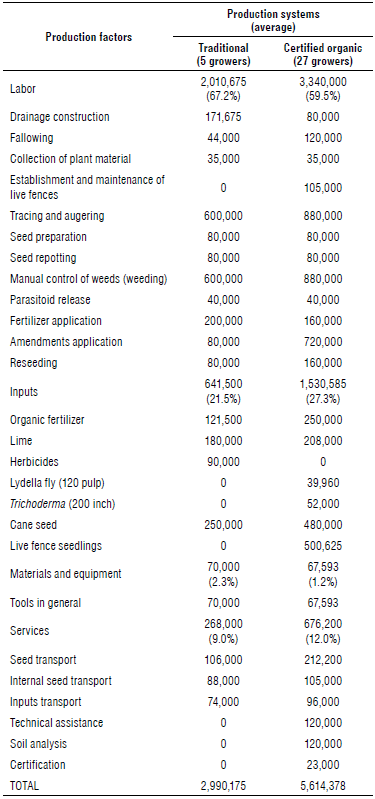

In sugar cane production, switching from the traditional production to the certified organic production implies an increase of 88% in the production costs per ha during the establishment phase (Tab. 3). In the following years, the cost of production decreased and then increased to just over 3 million COP (Tab. 5). For all factors of production, differences were found between the two systems, especially in labor expenses, establishment and maintenance of live fences, nutrition and health management. As for inputs, the differences consisted in the acquisition of improved seeds, mineral elements for fertilization, and health management. In services, the differences consisted in transportation, technical assistance, soil analysis, and certification.

TABLE 3 Production costs (Colombian peso) of sugar cane for panela in the establishment phase in two production systems: traditional and certified organic.

Note: For the calculation of costs, 2020 prices were used.

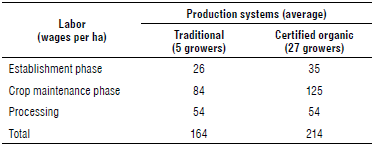

TABLE 4 Labor expenditure (wages per ha) in the production of 1 ha of sugarcane for panela (establishment - year 1 and maintenance - year 3): traditional system and certified organic system.

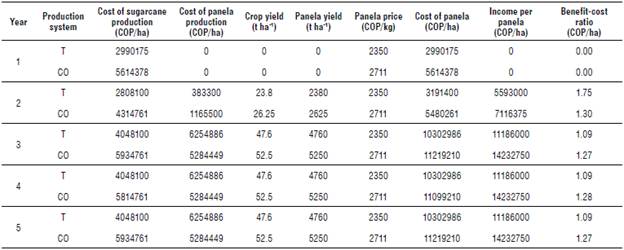

TABLE 5 Production costs of sugarcane and panela and profit margin (COP per ha): traditional (T) and certified organic (CO) production systems.

Note: COP - Colombian peso. For the calculation of costs, 2020 prices were used.

Regarding this last factor, the annual certification cost per farm is relatively affordable for the producers, given that the certification is done for a grower association and not for a farm. According to Ordoñez-Díaz and Rueda-Quiñonez (2017), small producers of panela must reduce costs within the production process to become competitive at the globalized market.

In addition, the traditional "trapiche" system employs people residing on the farm (family), while some manual operation tasks are done by contracted workers. The system of improved sugarcane mills receives cane to grind and hires workers for various activities (Ramírez & Arenas, 2016). According to Rodríguez and Gottret (1998), technology at this level represented about 29% of the total benefit generated in its productive activity and 13.1% reduction in the production cost. These data provide a quantitative reference.

As for the labor requirement in the crop establishment stage, given the increased activities compared to the traditional system, the certified organic production has a higher wage expense, approximately 39.5%. During the crop maintenance practices, the certified organic system requires 31% more labor than the traditional system. In the transformation phase for panela production, a correlative difference to yield appears, that is, although the transformation process becomes standardized, the organic system produces more panela per surface unit per year (Tab. 4). Logically, this generates higher costs but could be also considered as an opportunity for creating new jobs.

Although the production costs of the certified organic system are higher than those of the traditional system, these are compensated by its performance and price of the product. The yield of both the sugarcane crop and panela is approximately 10% higher, while the price is higher by about 15%. With these two elements, the average profit margin of the certified organic system is approximately COP 1,000,000 ha-1 per year compared to the traditional one, which generates approximately COP 400,000 ha-1 per year. The difference in the average annual profit margin per ha is 150%. The benefit-cost ratio for the traditional system is approximately 1.1, while it is approximately 1.3 for the certified organic system.

Commercialization

The traditional and certified organic panela systems have different product and marketing channels (Tab. 2). While the traditional system obtains a panela of a single type of presentation and of variable quality, the certified organic system produces a panela in two presentations, molds in 20 kg boxes and granules in polypropylene bags of 30 to 40 kg, with uniform quality guaranteed through certification and seal. Traditional panela is sold through two marketing channels: a producer takes it directly to the local market, where it has little bargaining power and generates additional transaction costs, or a producer takes it to an association of growers for sale. The certified organic panela is sold almost entirely by the grower associations, which already accumulates greater bargaining power and reaches national and international markets. The current difficulty of associations at the international markets is their small and constant volume of supply. Additionally, different qualities and markets also have different prices (Tab. 5). Certified organic panela costs on average 15% more than traditional panela. This is an interesting incentive for the producers, in addition to access to a less competitive market such as an international market. On the other hand, the market for organic products in Colombia is relatively small and slow growing. Due to the higher prices of organic products, an average Colombian consumer prefers to buy the conventional or traditional products. In the USA and European markets, the main destination for Colombian panela, prices for organic products are currently declining.

Social implications

Employment generation

As shown in Table 4, the certified organic sugarcane production for panela (214 d ha-1 year-1) requires an average of 31% more labor than the traditional system (164 d ha-1 year-1). While this implies an increase in the average wage requirement of just over 50 wages ha-1 year-1, it could mean the opportunity to generate new jobs in the area. However, this situation can produce two contrary effects. If there are farm workers searching for a job in the area, this system change could be advantageous, but if there is a labor shortage in the area, it can have a negative effect on production. Another possible effect could be the fluctuations in the wage price. According to Ordoñez and Rueda (2017), the phenomenon of rural-urban migration generates the need to create committees or societies that work together and guarantees the self-sustainability of the crop.

Producer protection

Producer protection refers to a social insurance, that is, health insurance, pension, and labor accident insurance. At the producer level, both the traditional system and the certified organic system are in similar conditions in terms of social security. Most employment contracts are informal; therefore, they do not include monetary contributions to health, pension, and insurance against labor accidents, although 40% of the producers surveyed were beneficiaries of the Identification System for Potential Beneficiaries of Social Programs (SISBEN in Spanish). However, at the level of certified organic panela producers, there is a tendency to improve this situation by formalizing fixed-term labor contracts with all legal obligations, although this is only in the case of administrators of panela farms (4 of 27 productive units). Additionally, the certified organic production, unlike the traditional system, commonly offers higher protection against physical injuries and occupational accidents, either through improved practices or appropriate protective equipment. Eighty percent of the operators who work in the mill of the certified organic system have a helmet, glasses, and overalls as well disposable masks and hats during the shaking, molding, and packing of panela, while those of the traditional system do not have these protective measures. Apart from protecting the producer, the personal protection measures mentioned above ensure delivering of a safe product. These aspects are also differentiating at the final product level.

Consumer protection

In the food market, consumers consider product quality, price, and safety. In Colombia, the safety of panela is demonstrated through its INVIMA Registry (National Institute for the Surveillance of Medicines and Food, Colombia), which complies with current regulations of Resolution 779 of 2006 for panela productions. This registry allows the producer to sell its product, for example, in supermarkets. Only 1% of the traditional panela producers have INVIMA registry, while 100% producers of certified organic panela have it. Additionally, the latter have the organic certification that guarantees the non-use of chemical synthesis products in production. The INVIMA registry and organic certification give organic panela an advantage in quality over traditional panela; they allow access to more demanding markets with quality control and to specialized markets such as organic ones. The certification assures the consumer that the product complies with following parameters: i) prevents the degradation of natural resources, ii) protects the environment, and iii) is healthy for human consumption (Abarca & Sepúlveda, 2001).

Stimulus for collective action

According to Gómez (2018), collective action is the effort of two or more people to achieve a desirable result for the participating parties. In the case of the ASOPROPANOC organization, by marketing panela collectively, which is one of the main objectives of this organization, participation becomes more active and individual responsibility increases. The planning, organic production, certification, and marketing for export are carried out jointly by 90% of organic producers. These activities have strengthened the organization. Several of these cooperative activities occurred during the transition from the traditional system to the certified organic production. Traditional panela producers do not receive as many benefits as the "organic" ones, so their permanence in the grower association may be discouraged to the point of abandonment or diminishment. In the last 10 years, the association has increased from 10 members to 32 members because of the support provided to the association by FEDEPANELA, AGROSAVIA, and other entities to implement the organic production system.

Environmental implications

Contamination of the environment

The cultivation of sugarcane for panela, like many other agricultural activities, has effects on the environment. The negative effects are mainly related to the use of agro-inputs, especially those of chemical synthesis, due to their greater persistence and toxicity compared to organic inputs (Rodríguez et al., 2017). The use of chemical synthesis products, in the case of the traditional system, occurs mainly during fertilization and control of weeds and pests (Fonseca, 2002). The lack of management protocols for these inputs in the traditional system, creates a possibility of overdosing and contamination of surface and groundwater through inadequate discharges (Bernal, 2019). In the case of certified organic systems, handling of agro-input containers follows a protocol to reduce the environmental impacts (Tab. 6).

TABLE 6 Indicators of environmental contamination in sugarcane cultivation for panela in traditional and certified organic systems.

The transformation of sugarcane juice into panela requires energy; in this case, from combustion. In turn, production of panela generates gaseous emissions, discharges, and byproducts such as bagasse (Murcia, 2012; Ordoñez-Díaz & Rueda-Quiñonez, 2017). The bagasse produced during transformation serves, together with wood (firewood) and other materials, as fuel for the transformation process (Tab. 2). Additionally, washing of transformation equipment (troughs, "remillones" [utensil to remove foam], molding table, pan, bottoms, and installations) generates discharges in the crop area or areas near the houses in the case of the traditional system. In the certified organic system, these discharges are generally done in a water treatment system, which is a certification requirement to mitigate the environmental impact. Not all production units have a permit to discharge these residues (the exact data are not available). On this problem, ASOPROPANOC developed a project that implements a treatment system for wastewaters from the production process. Additionally, combustion of bagasse, firewood, and other materials, such as tires, in the case of the traditional system, generate greenhouse gas emissions. The most significant environmental impacts are evident during the stage of evaporation and concentration of juice, mainly due to the use of traditional stoves (Ordóñez-Díaz & Rueda-Quiñones, 2017).

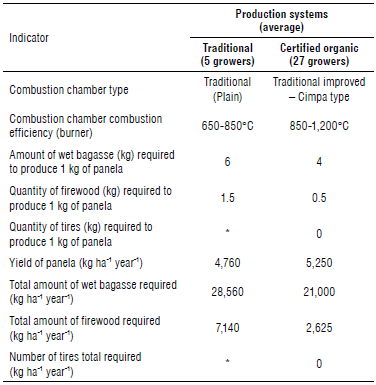

Use of combustible materials

The energy to heat the sugarcane juice and evaporate water comes from the combustion of bagasse, firewood, and, in some cases, vehicle tires (García & Cortés, 2011). The traditional system uses tires, while the certified organic does not. The efficiency of the combustion of bagasse and firewood depends on the quality or type of combustion chamber. These chambers could be traditional, improved traditional, or Ward-Cimpa. The traditional chamber generates less heat (Tab. 7) and produces more carbon monoxide (6-10% of CO); while the Ward-Cimpa generates more heat and produces less carbon monoxide (Guerrero & Escobar, 2015). This combustion efficiency also means that, in the certified organic system, less combustion material is required than in the traditional system.

TABLE 7 Consumption of combustion materials (kg ha-1 year-1) in production of traditional and certified organic panela.

* No exact data available.

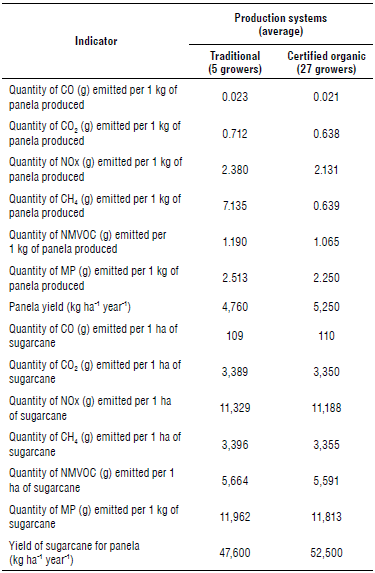

Greenhouse gas emission

The greenhouse gases generated during panela production (Tab. 8) include carbon monoxide (CO), carbon dioxide (CO2), nitrogen oxides (NOx), methane (CH4), and volatile organic compounds other than methane (NMVOC). The following factors differentiate the two systems: combustion technology (burner type), type of fuel material (bagasse, firewood, and tires) and its quantity, which, in turn, depends on the combustion technology. The new stoves generally have less heat availability than traditional stoves, mainly due to reduced fuel consumption (Castillo, 1996; Pandraju et al., 2021). The energy generation technology of the certified organic system, due to its greater efficiency, allows it to emit less greenhouse gases than the traditional system. Additionally, the non-use of tires reduces the amount of production of the greenhouse gases.

TABLE 8 Greenhouse gas emissions (kg ha-1 year-1) from the production of traditional and certified organic panela.

Note: Based on Ibarra (2019) and García et al. (2011). NMVOC - volatile organic compounds other than methane, MP - Particulate matter.

There is a reduction in greenhouse gas production when switching from the traditional system to the certified organic panela production system, especially in the transformation phase. For sugarcane production, the average reduction is from 5,975 g ha-1 year-1 to 5,901 g ha-1 year-1; while for panela production, the reduction is from 2,326 g kg-1 to 1,124 g kg-1 of panela produced.

Water consumption

The consumption of water during the panela production is oriented to washing of drawers, "remillones" (utensils to remove foam), bottoms, and other elements (Ubaque, 2013). The production technology also makes a difference in water consumption. The certified organic system consumes barely a quarter of what the traditional system consumes (Tab. 9). This implies savings in water costs and, potentially, in the production costs. Additionally, 97% of the productive units studied have a local aqueduct service, which does not measure consumption, which indicates that there is still no restriction on the use of this natural resource. This has a positive effect on production costs, since higher consumption does not necessarily lead to a higher cost of the water consumed.

Conclusions

The change from the traditional panela production system to the certified organic system has favorable technical, economic, social and environmental implications for ASO-PROPANOC's sugarcane producers. From the technical point of view, the change in the panela production system increases the productivity of sugarcane and panela due to the introduction of new genetic materials for the crop and the favorable change in production culture and environmental awareness of the producers. Economically, it implies higher production costs (investment), but also increases the net benefits due to improvements in the price for quality. Socially, it increases employment (wages), improves the physical safety of workers and the functionality of their organizations, as well as improving the quality of the product for consumers. And, from the environmental point of view, the use of combustible materials such as bagasse and firewood per kg of panela produced is reduced as well as the emission of greenhouse gases and the use of water.