Introduction

Vegetable beverages have been developed as substitutes for dairy beverages; soybean beverages are important due to their high nutritional value and wide range of health benefits. However, the presence of antinutrients such as trypsin inhibitors raises concerns from a nutritional point of view. Trypsin inhibitors cause low protein efficiency rates and pancreatic hypertrophy (Aderibigbe et al., 2021). Heat treatments more intensive than conventional pasteurization are needed to reduce or eliminate trypsin inhibitors due to their high thermal stability. Nevertheless, along with their reduction and degradation, the processed beverages show a reduction in soybean protein solubility kinetics that also serves as quality control for the presence of antinutritional factors in soybean-based products.

Emerging technologies such as high-pressure processing (HPP), electric pulses, and ultrasound for the inactivation of microorganisms and anti-nutritional factors are very expensive (Guerrero-Beltrán et al., 2009; Yuan & Chang, 2010; Vanga et al., 2020; Aderibigbe et al., 2021). Hydrocol-loids can be added to soybean beverages to improve their solubility, texture, viscosity, consistency, and syneresis (Yuan & Chang, 2010), and their effect on the gelling behavior of soybean beverage gels has been extensively studied; their thickening, stabilizing and/or gelling properties stand out. The function varies according to their molecular weight, structure, compatibility, gelling profile, dispersion, and hydration conditions that add value to food products (Rodríguez Sandoval et al., 2003).

Modified starches are widely used to improve the properties of food products, specifically to increase heat resistance, water retention capacity, viscosity, and to minimize the syneresis effect (Cho & Kang, 2022). We propose the use of three types of modified cassava starch as an alternative because of their low cost and function as a thickener and/ or stabilizer in foods. They have various uses in the food industry.

Starch modifications affect the quality and the application of a food matrix. Thus, it is necessary to study the sensory properties, structure, and stability of the product during storage. Its rheological properties must also be known during production, i.e., viscosity, shear strength, and physicochemical properties (Abbas et al., 2010). Some potato, cassava, and corn starches with high amylose content have been modified to achieve suitable physicochemical properties such as resistance to low or high storage temperatures, low pH, and opacity (Mahmood et al., 2017).

Three types of modified cassava starches were used in this study: octenyl succinic anhydride (OSA) with a substitution, crosslinked acetylated distarch adipate (ADA) starch and crosslinked-substituted starch (mixed). Different applications have been reported for these; for instance, the OSA modification changes its structure and emulsifying capacity (Gao et al., 2021). The latter depends on the degree of substitution, the size of the granules, the aggregation of the particles between the air/water interface, and the starch to oil ratio of the formulation in cassava, potato, rice, and wheat starches (Saari et al., 2016; Marefati et al., 2017; McNamee et al., 2018). OSA-modified starches have been used as carriers of bioactive food components (Wang et al., 2011) in dairy beverages using fermented whey (Imbachí-Narváez et al., 2018). They microencapsulate OSA and maltodextrins in the release of rose essential oils (Xiao et al., 2019; Partheniadis et al., 2020). Moreover, OSA starch is used in the cosmetics industry for its emulsifying capacity (León-Méndez et al., 2020). Modified acetylated distarch adipate (ADA) starch is used in foods as a bulking agent, stabilizer, and thickener (Ziçba et al., 2014; Partheniadis et al., 2020). It shows improved stability, hardness, and adhesiveness of the gels formed from it as well as swelling power, solubility, pasting temperature, gelatinization, and retrogradation enthalpy (Prochaska et al., 2009). It also improves the resistance to mechanical processes, temperature, and acidic pH with greater stability during storage. Hence, it is important to evaluate the effect of adding three modified cassava starches - ADA, OSA, crosslinked-substituted starch at different concentrations on the physicochemical properties of a fermented soybean beverage.

Materials and methods

Materials

Soybeans were obtained from a local market in Bogotá. Modified cassava starches were donated by Poltec SAS (La Estrella, Antioquia, Colombia) as follow: starch with octenyl succinic anhydride substitution (OSA) (Gel®Lact), cross-linked acetylated distarch adipate (ADA) (Gel®Cream), and crosslinked-substituted starch, i.e., mixed starch (Gel®Lact XP). For fermentation, freeze-dried starter culture was used for direct inoculation with selected Streptococcus thermophilus and Lactobacillus delbrueckii subsp. bulgaricus and probiotic microorganisms Lactobacillus acidophilus and Bifidobacterium animalis subsp. Lactis (SACCO Lyofast SYAB 1).

Preparation of fermented soybean beverages

Soybeans with optimal physical quality (without defects) were carefully selected and soaked overnight. They were washed several times and shelled and subjected to precooking at boiling temperature in a 0.02% (w/v) bicarbonate solution for 15 min (Ziçba et al., 2014; Zheng et al., 2021). Wet grinding was carried out using a Blixer® equipment and water was slowly added according to one of the methods proposed by Zhang et al. (2012) with some modifications. Figure 1 shows the flow diagram of the preparation of the fermented soybean beverage.

The beverage was obtained by filtering and removing the solid residue (Okara) (Fig. 1). Sugar (5.5% w/w) and modified cassava starch were added according to the percentages used for each treatment with respect to the additional water, mixed and homogenized (APV Rannie, Lockerbie, United Kingdom) at 160 bars. The heat treatment was carried out at 85°C for 15 min according to the protocol proposed by Cui et al. (2021).

Soybean beverage fermenters

After the heat treatment, the beverage was cooled to 42°C, and a representative portion of commercial starter microorganisms and probiotics cultures (0.003% w/v) was inoculated into 100 ml of it (~4.97 ± 0.03 CFU/ml) and activated in an orbital shaker (Thermo Scientific, Solaris 4000). Ten ml were poured into flasks (200 ml) and incubated at 42°C in a Thermo Scientific 3911 incubator until reaching a pH of 4.5. It was then stored at 4°C for further analysis.

Physicochemical and rheological properties

A single concentration of cassava starch was considered for selecting the treatments. Three types of commercial controls were compared: soybean control (CS) (Toufree, Bogotá, Colombia), and two types of commercial fermented dairy beverages: CL1 (Yogo-yogo, Alpina, Sopó, Colombia), and CL2 (Pomar, Cajicá-Tabio, Colombia).

The physicochemical parameters of each treatment and control were evaluated. The quality parameters were pH, titratable acidity, apparent viscosity, syneresis, and total soluble solids. The pH was evaluated using a potentiometric method (AOAC 981.12) with a microprocessor-based pH meter (HANNA Instruments). Titratable acidity was determined according to the AOAC 947.05 using the volumetric titration method with a standardized 0.1 N NaOH solution. The results are expressed as a percentage of lactic acid. The soluble solids in the commercial beverage were determined according to the AOAC 22.019 using a refractometer calibrated at 20°C, and the result was expressed in Brix degrees. Syneresis was determined by centrifugation according to the methodology proposed by Joon et al. (2017). The test was performed in triplicate with a known weight of the sample for 10 min at 3500 rpm and 4°C. The supernatant was weighed and then syneresis was expressed as (g of supernatant/sample) x100 g of sample.

Apparent viscosity was established by a viscometer (Thermo Scientific® Haake Viscotester 550). A shear rate sweep from 0 to 80 s-1 (upward curve), followed by 80 to 0 s-1 (downward curve) was performed to assess the flow behavior of the commercial beverage and the treatments. Viscosity was measured in mPa s achieved at 80 rpm in triplicate. The power law was used to determine the rheological parameters of the fermented soybean beverage (Eqs. 1-2).

where t is the shear stress, K is the consistency index, n is the flow behavior index, and du/dy is the change rate of the shear velocity. Likewise, the viscosity n can be predicted using Equation 2 by the same power law, where e is the shear rate.

Each treatment was carried out in triplicate as well as the pH, titratable acidity, viscosity, syneresis, and contents of total soluble solids. Results were expressed as means with standard deviation.

Sensory evaluation

For the sensory test, the three types of starch (ADA, OSA, and mixed) were selected at 1.0% concentration and compared to a native cassava starch at the same concentration. Natural blackberry flavoring and blackberry red coloring (betanin E162) were added to all treatments. The sensory evaluation was carried out on the third day of preparation by 100 consumers. Participants were in an age range between 18 and 55 years old: 45 men and 55 women. Treatments were coded with three-digit random numbers (Kim et al., 2005). Participants were given instructions on how to perform the sensory test and a form where they were asked if they were regular consumers of non-dairy fermented beverages, allergic to soy-based products, or smokers; and if they had any disease that affected their senses. The sensory evaluation was made using a 1-7 hedonic scale categorized as follows: (1) dislike extremely; (2) dislike very much; (3) dislike; (4) neither like nor dislike; (5) like; (6) like very much; (7) like extremely. The evaluated parameters were general acceptability, texture, taste, smell, and color. Likewise, there was a blank space to indicate preference for any of the products and comments. The objective was to determine whether there are significant differences between the three modified starches and the native starch.

Statistical analysis

The experimental design was a 3Λ2 completely randomized factorial design with blocks (3 replicates per treatment); the factors were the type of starch (OSA, ADA, and mixed) and the concentrations of each modified cassava starch (0.8%, 1.0%, and 1.2%).

Levene's test was used to verify the homogenization of the data. This inferential test is applied to assess the equality of the variances of a variable calculated between groups or factors and to assess whether the variance in data is homogeneous under the null hypothesis. As an alternative hypothesis, if the data have a degree of significance of 0.05 or less, it is unlikely that the differences in the variations obtained in the samples come from a random sampling of a population with equal variances.

ANOVA was used to analyze the factors corresponding to each parameter using Model II to determine whether there was interaction. It was followed by the Tukey's test with a significance level of 5%. The statistical analysis was carried out with Rstudio statistical software and the results were expressed as mean ± standard deviation.

The unifactorial test between the treatments and commercial controls was conducted by ANOVA with a significance of 5%. The statistical analysis was carried out with the Rstudio statistical software, and the treatments were selected according to the mean ± standard deviation of the commercial controls.

The analysis of the sensory test was carried out using the non-parametric Kruskal-Wallis test, considering that the obtained data are non-continuous. The comparison between samples was made by non-parametric multiple tests for each evaluated parameter.

Results and discussion

Table 1 shows the results of pH, acidity, soluble solids, syneresis, and viscosity for each treatment. The syneresis and apparent viscosity results were statistically significant (P<0.05). The other response variables were not significant; however, pH and soluble solids did not show a normal behavior according to the Shapiro normality test and Wilks and Bartlett's homoscedasticity test. There is no evidence of variance homogeneity (P<0.05); therefore, the pH was taken as a range between 4.0 and 4.6, and the soluble solids were between 8.8 and 10.5. These variables underwent a descriptive statistical analysis.

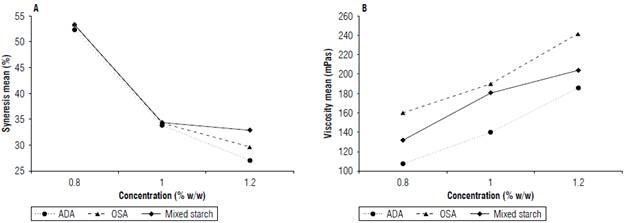

The Tukey's test was used to make multiple comparisons between the data collected on syneresis and viscosity (Tab. 1). First, the starch concentration had significant effects on syneresis (Fig. 3A) and presented higher syneresis with a 0.8% concentration (Fig. 2); second, there was no difference in syneresis for any starch at any concentration, except for 1.2%, at which it presented significant differences (P<0.05). From a more detailed analysis, 1.2% ADA starch had the lowest syneresis (27.08±1.72%) along with OSA starch at 1.2% (29.67±1.85%); they were considered similar as they did not present significant differences (P<0.05) but did have a significant difference compared to the treatment with 1.2% mixed starch (Tab. 1). There are other studies on milk beverages: Gomes et al. (2013) compares the physicochemical parameters of cow's milk, goat's milk, and a mixture of those two and obtained a syneresis similar to the one of this study. Likewise, Lobato-Calleros et al. (2014) use native starch and modified starches and pointed out a proportionally similar syneresis determined by the concentration. Furthermore, Imbachí-Narváez (2018) use ADA and OSA starches to make a fermented milk beverage; samples with OSA starch have less syneresis compared to those with ADA starch. According to the study, the syneresis parameter is higher than that of the last research and does not present a significant difference among starches; however, it depends on the concentration. We compared two matrices; therefore, starches tend to behave differently when the macromolecules in the food and their arrangement differ in proportions and conformations (Khurshida et al., 2021).

TABLE 1 Physicochemical properties of the fermented soybean beverage according to the type of starch (ADA, OSA, mixed starch) and starch concentration (0.8%, 1.0%, and 1.2%).

Treatments with acetylated distarch adipate (ADA), octenyl succinic anhydride (OSA), substituted cross-linked starch (mixed), fermented soymilk control (CS), and commercial fermented dairy beverages (CL1-Yogo-yogo, Alpina, Sopó, Colombia, and CL2-Pomar, Cajicá-Tabio, Colombia). Values with different lowercase superscript letters within a column are significantly different (P<0.05) from each other. Tukey's multiple comparison test was applied.

Different starches and hydrocolloids could be used as thickener to prepare soybean beverages (Santamaria et al., 2023). The results related to syneresis are lower as both starch and soybean concentrations increase (Peng & Guo, 2015; Huang et al., 2022) . Furthermore, the apparent viscosity is higher as both ingredients increase; however, the interface suspension between the aqueous phase and the starch is unstable (Huang et al., 2022). ADA and OSA starches have been applied to dairy beverages or plant-based substitutes; for instance, OSA starch has been compared with other modified starches at different concentrations (phosphorylated cross-linked starch and hydroxypropylat-ed starch) applied to liquid kashk (sour yogurt) for 60 d. Despite this study indicating a preference for the treatment with hydroxypropylated starch at high concentration at a sensory level, the TPA analysis revealed that the treatment with OSA starch had a better consistency, texture, and softening (Hosseini & Ansari, 2019). In a formulation of a soybean and quinoa-based yogurt with added ADA starch as a thickener (Huang et al., 2022) and in an almond yogurt (Devnani et al., 2022), due to the three-dimensional network formed by ADA, the resulting gel prevents water loss and is more consistent. It forms a fairly strong viscoelastic fluid that stably joins different structures. In the same way, OSA starch has been used as an encapsulator of bioactive components and as an emulsifier in colloidal systems of oil in water (Wang et al., 2023). According to the above, ADA and OSA starches can be used for different food matrices and purposes to provide various texture, consistency, and viscosity characteristics, so the results may depend on the properties of the base system (Gao et al., 2021).

FIGURE 2 Effects of syneresis on treatments with the three types of starch at a concentration of 0.8%: treatments with acetylated distarch adipate (ADA), octenyl succinic anhydride (OSA), and substituted cross-linked starch (mixed).

From another perspective, it must be taken into account that the syneresis, viscosity, and fluidity of the fermented soybean beverage are affected by factors such as homogenization by reducing the particle size, and heat treatment that allows the inactivation of microorganisms as well as the inactivation of proteins by changing their structural conformation (Zhang & Chang, 2022). The use of microbial strains and the fermentation process in which the gel is formed are related to the pH and isoelectric point of most proteins in a pH range between 4.4 and 4.6 (Verfaillie et al., 2023). These characteristics can be improved during and after fermentation by adding hydrocolloids.

Significant differences are evident in viscosity (Tab. 1), both for the type of modified starch, the concentration, and the interaction between factors (Fig. 3B). The treatment with 0.8% ADA starch presented lower syneresis with a shear rate of 80 s \ while the treatment with 1.2% OSA starch (241.73±12.34 mPas) resulted in the highest viscosity.

The commercial patterns have different variations in terms of syneresis and viscosity (Tab. 1). The commercial control CS (fermented soybean beverage) had acidity, syneresis, and viscosity values similar to data reported for the treatments at a concentration of 1.0% for each starch. Furthermore, the commercial controls CL1 and CL2 (dairy-fermented beverages) reported higher acidity than fermented soybean beverages and showed a greater variability in syneresis and viscosity. Both the syneresis and the viscosity were significantly different in the dairy controls (Tab. 1). Commercial beverages have standardized processing. The two dairy beverages use different hydrocolloids; thus, their physicochemical and rheological parameters change according to storage conditions and shelf-life, mainly due to post-fermentation processes that influence the decrease in pH and increase in acidity and affect the percentage of syneresis, viscosity, and texture. When relating the pH and acidity values evaluated in commercial dairy controls, the pH of CL2 is lower than CL1 and the acidity is higher, which directly affects the rheological properties. The decrease in pH down to the isoelectric point of milk proteins (pH 4.4-4.6) of the formed gel in fermentation is due to the effect of the acidic medium and the increase in lactic acid. Thus, it results in leaching of the water retained within the gel and phase separation and causes the increase in syneresis and decrease in viscosity (Gomes et al., 2013; Peng & Guo, 2015; Yi et al., 2020). These commercial beverages show variability in terms of rheological properties, and there is no single standard that characterizes them.

FIGURE 3 Main effects of the inclusion of samples with acetylated distarch adipate (ADA), octenyl succinic anhydride (OSA), substituted-crosslinked starch (mixed starch) and its concentration on the fermented soybean beverage found in the evaluation of syneresis (A) and viscosity (B).

The soybean control (CS) is related to the values reported for the treatments with ADA, OSA, and mixed starch at 1.0%, also with 1.2% mixed starch. The CL1 control is related to ADA and OSA starch at 1.2%. Regarding viscosity, the CS is related to the OSA and mixed starch at 1.0% and ADA at 1.2%; while the CL1 control is related to the OSA 1.0% treatment, the CL2 control is more similar to the 1.2% mixed starch. The reported viscosity values are consistent for OSA starch (McNamee et al., 2018) and ADA (Kapelko-Zeberska et al., 2015). However, the rheological characteristics may vary for OSA according to the esterification grade of the hydroxyl groups at carbons 2, 3, and 6 in the starch glucose molecule (Sweedman et al., 2013; Ovando-Martinez et al., 2017). The increase in the number of OH groups substituted by OSA increases the native starch hydrophobicity and creates amphiphilic particles with different emulsifying degrees (Miao et al., 2014). The use of different modified starches depends on their structural characteristics that affect to a lesser or greater extent, rheological characteristics such as the acetylation and cross-linking degree of the ADA starch, as well as other types of chemical modifications such as distarch phosphate (E1412), acetylated starch (E1420), hydroxypropyl starch (E1440), hydroxypropyl distarch phosphate (E1442). Depending on the degree of substitution, the above starches are characterized by high solubility, high-temperature impact resistance, low susceptibility to retrogradation and syneresis, and paste viscosity (Bravo-Núñez et al., 2019). The ADA chemical modification in native starch affects the viscosity behavior according to the degree of its acetylation and cross-linking. A medium degree of acetylation (6%) results in high viscosity; but a low viscosity is caused by a high level of acetylation (12%) (Kapelko-Zeberska et al., 2015). In addition, the viscosity in the preparation of retrograded ADA presents a wide range of degrees of acetylation together with an increase in starch cross-linking (Khurshida et al., 2021).

Rheological properties

The apparent viscosity curve of a fermented soybean beverage is determined by adjusting the shear rate to between 0.01 and 80 s-1 (Fig. 4A). From our experimental data, an equation was obtained for each shear stress treatment as a function of the shear rate through the power law (Eq. 1), and rheological constants were predicted (Tab. 2). Under the same measurement conditions, the shear stress increased as a function of shear rate; the viscosity of the nine treatments was initially high, but it decreased rapidly as the shear rate increased (Fig. 4B).

TABLE 2 Predictive data according to the power law model with experimental data for the treatments and commercial controls.

*The predictive model for CS was the 30 s-1. Treatments with acetylated distarch adipate (ADA), octenyl succinic anhydride (OSA), substituted cross-linked starch (mixed), fermented soymilk control (CS), and commercial fermented dairy beverages (CL1 -Yogo-yogo, Alpina, Sopó, Colombia, and CL2-Pomar, Cajicá-Tabio, Colombia).

Following the rheological model of the power law (Eq. 1), the consistency index (K), and the flow behavior index (n) were determined, and viscosity (Eq. 2) was predicted at 80 s-1 (Tab. 2).

The predictive model was applied to all samples with a shear rate in the 80 s-1 (Fig. 4A), except for CS, where 30 s-1 was used because the upper shear rates did not vary with the shear stress and kept constant, as shown in Figure 4A.

FIGURE 4 Treatments with acetylated distarch adipate (ADA), octenyl succinic anhydride (OSA), substituted cross-linked starch (mixed starch), fermented soymilk control (CS), and commercial fermented dairy beverages (CL1-Yogo-yogo, Alpina, Sopó, Colombia, and CL2-Pomar, Cajicá-Tabio, Colombia). A) Shear stress as a function of shear rate for treatments with 0.8% starch; B) Influence of shear rate on the viscosity curve for treatments with 1.0% starch.

The samples with the OSA starch had a higher consistency index (K) for all concentrations evaluated with respect to the beverages with ADA and mixed starches. The samples with OSA starch have higher consistency, viscosity, creami-ness and, therefore, a better texture. Similarly, mixed starch (crosslinked-substituted) has an intermediate viscosity and consistency index between the other two types of starches for each corresponding concentration. ADA starch exhibits a lower consistency index and, therefore, lower viscosity for each concentration. Moreover, all the samples presented a flow behavior index (n) less than 1 that is characteristic of pseudoplastic fluids (Chen et al., 2023).

Empirical data were converted into functions of viscosity. Viscosity curves are presented (Fig. 4B) according to the predicted data for К and n; viscosity decreased as the shear rate increased.

The concentration of modified cassava starch affects the fluidity of the fermented beverage by having more molecules suspended in the aqueous medium, as well as the different molecular interactions that can occur between particles. These intermolecular interactions directly affect the fluidity and viscosity when applying shear stress that influences their shear thinning characteristics (Chen et al., 2023). When comparing the shear stress of the nine treatments, an increase in the shear rate is evident and indicates that all the samples have pseudoplastic fluid behavior. This can be explained by the non-Newtonian behavior (shear-induced alignment) characteristic of lactic fermented beverages (Mitra et al., 2022) that is consistent with the viscosity results.

The intermolecular interactions are given first by the soybean proteins that are mainly globulins such as glycinin and beta-conglycinin. The nonpolar residues of these proteins face inward (hydrophobic), and the polar residues face outward (hydrophilic) (Jia et al., 2022). Furthermore, the starch has oil adsorption characteristics, and the aqueous phases improve with the modification octenyl succinic anhydride (OSA) because it acts as an emulsifier and stabilizer in the oil/water interface due to the particles and the stability of the drop (Marefati et al., 2017; Moraes Filho et al., 2019). This stability within the matrix is mainly due to soybean fatty acids and proteins with hydrophobic parts that prevent flocculation, rétrogradation, and the formation of starch lumps by electrostatic force between the particles. Moreover, acetylated distarch adipate (ADA) starch forms a three-dimensional network that increases the elasticity of the stable liquid system during storage (Kapelko-Zeberska et al., 2015; Partheniadis et al., 2020), so it has broader water retention capacities in the formed gel. When the soybean beverage is acidified by fermentation, it generally drives out the water retained in the gel at a low pH, but the three-dimensional network formed by ADA starch can retain water during storage due to cross-linking, and this contributes to preserve the quality of the product in storage.

Sensory analysis

The general acceptance of all treatments with modified starch could be differentiated with respect to the native starch that had a lower acceptability score (Fig. 5B). Both the sample with OSA and the mixed starch differed completely in texture from the native starch. This attribute was judged correctly by consumers, who expressed that the sample with native starch had a very liquid, non-creamy texture, whereas the samples with OSA and mixed starch were very creamy, viscous, full-bodied, and had texture. Additionally, most of the consumers said that the samples with ADA starch were very fluid and not very consistent. There were no significant differences between the treatments for smell. The OSA and mixed starches differed in flavor from the native starch. The latter was judged as a rather acidic and fermented taste, related to unpleasant flavors, while the OSA and mixed starch samples were rated as pleasant with a dairy flavor or similar to dairy drinks or traditional yogurts. ADA starch had a neutral dairy connotation with a lack of flavor or increased sweetness, although the same amount of sweetener and strawberry flavoring were added to all treatments in order to mask the characteristic soybean flavor. There was no marked difference between samples regarding color. This is consistent because the same dye at the same concentration was applied to all the treatments.

There was no difference between the treatments with modified starches for general acceptance in the test scores (Tab. 3). Even though most of the consumers preferred the sample with OSA starch (Fig. 5A-B), some rated the OSA starch beverage as a 7 (24 participants) on the hedonic scale; however, most of them gave it a 5 or 6 (27 and 29 participants). For the sample with mixed starch, the distribution was between 5, 6, and 7 (21, 32, and 28 participants). There were 43 participants who liked the product with ADA starch. Finally, general acceptance was rated 4 and 5 for the product with native starch.

TABLE 3 Means of acceptability according to the score given by consumers.

Different superscript lowercase letters within the same row indicate statistical differences (P<0.05) according to the Kruskal-Wallis test. The standard error value was 0.1 (SE=0.1; n=100) forali parameters and treatments evaluated.

When reporting the sensory analysis with parameters such as syneresis and viscosity (Tab. 2), the observations of the consumers agreed with the texture results of the OSA and the mixed starch samples. They referred to a beverage like yogurt with characteristics of creaminess, consistency, and viscosity. While the ADA sample had a fluid and low viscous connotation that agrees in a certain way by having a viscosity (Tab. 2) lower than the beverages with OSA and mixed starch. Equally, the sample with native starch was perceived as quite liquid, as if water had been added to the product that corresponds to the high syneresis reported (Tab. 2). The solid phase precipitated and separated from the liquid phase even though the sample had been homogenized before the sensory analysis. Some consumers stated that the sensation in the mouth was quite smooth to the palate; but, in general, they did not observe the presence of lumps or grit in the samples, so the particle size in all samples was similar and homogeneous. Finally, regarding the appearance, one of the physical characteristics observed in the samples with OSA starch (Fig. 2) was the fragility of the structure of the granules that leads to soft texture on the palate, just like the one with mixed starch. ADA starch has a granular morphology (Fig. 2), with a more compact and resistant appearance that may not be creamy or consistent from the sensory point of view. However, as previously analyzed, it may maintain itself longer without changing the syneresis, viscosity, and consistency during storage.

Conclusions

The addition of modified cassava starches at different concentrations does not directly influence the pH, acidity, and soluble solids of fermented soybean beverage. These parameters depend on the conditions of the fermentation process.

The treatments with less syneresis were ADA and OSA starch at 1.2% with no significant differences compared to the control dairy beverage (CL1). The treatment with the highest viscosity was the OSA 1.2% with a value of 241.73±12.34 mPas. Finally, the more similar treatments to the control soybean beverage (CS) for both syneresis and viscosity were OSA, mixed starch at 1.0%, and ADA at 1.2%.

The function for each treatment was predicted by the power law rheological model, and the fermented soybean beverage had a pseudoplastic behavior with a flow index of less than 1, similar to dairy products. Furthermore, the consistency index (K) depended on both the concentration and the type of modified starch.

The sensory analysis indicated a preference for the samples with OSA starch; however, the treatment with mixed starch could have similar properties and was also sensorially acceptable to consumers.