I. INTRODUCTION

The Digital Twin (DT) concept has been developed to drive transformative processes across various industries. It involves creating a virtual representation of a system built from a combination of data models and sensor technologies, which enable the collection and processing of large amounts of data. The Digital Twin significantly improves predictive capability compared to existing technologies [1]. This results in enhanced decision-making through remote access and the creation of safer, more familiar working/operating environments that lead to increased production, reduced costs, and time savings in operations and maintenance [2]. Furthermore, it promotes a deeper understanding of systems and their operations, facilitates knowledge sharing across different contexts, and improves the learning experience, thereby increasing motivation and other positive outcomes.

The Digital Twin concept was first introduced by Michael Grieves in 2002 and formalized in 2011 [3]. Saddik [4] defined the Digital Twin as a virtual copy of an organism or a physical entity that enables information interoperability between the physical and virtual entities. According to Fu et al. [5], the Digital Twin can be a full life-cycle simulation of corresponding hardware, entities, or instances, for monitoring, evaluation, prediction, optimization, control, interaction, perception, and other applications. Tao et al. [6] defined the Digital Twin as a multiphysics, multiscale, and probabilistic simulation of a product that mirrors the life of its real counterpart. Thus, the Digital Twin has become a highly sought-after research area in academia, industry, and marketing, particularly in Industry 4.0. Considering its various definitions and uses, we conclude that the Digital Twin aims to link the real physical world to a virtual one. Three components are crucial to its design and development: the physical asset or object, its digital replica, and the bidirectional and synchronized relationship between the physical and digital assets [7].

The following are some noteworthy applications of Digital Twins (DTs) in different contexts. In 2019, Madni et al. [8] implemented physical vehicle DTs in a course offered by the Architecture and Engineering Systems program at the University of California. The system created an interactive feedback environment that allowed students to examine the vehicle, ask questions, and address concerns not as easily identifiable in a traditional classroom setting. In 2022, Erdei et al. [9] developed a digital replica of the cyber-physics and intelligent robotics laboratory, which includes the key elements necessary for 6-axis industrial robots to perform Point-to-Point (PTP), Linear (LIN), and Circular (CIRC) motions, thus reducing the costs associated with training and maintenance. Also, in 2022, Lin et al. [10] proposed an Internet of Things (IoT)-based intelligent learning environment named EduTalk; it was designed for programming education and enables students to build scientific projects by writing VPython programs to display 3D animations.

Interest in the integration of art and technology in the educational sector has been increasing over time [11]. Technology has enriched different artistic and cultural expressions, from interactive art to new digital media. The contribution is also observed in how these cutting-edge technologies serve the growth, control, and transparency in processes that involve machines or technological inputs [12] - [13]. For example, the art and technology laboratories "ATL" of the Departmental Institute of Fine Arts in Cali (Colombia) [14], with support from the Campus project (Centre for Innovation in Art, Technology, and Society) has four spaces containing various technological inputs to support prototyping processes of hardware and artistic elements. These spaces also lead the construction of artistic installations, the design and development of experiences in virtual and augmented reality, and the creation of digital products available to students and teachers interested in carrying out academic processes, applied research, and entrepreneurship in projects that involve the union between art and technology.

In this paper, we build a prototype of a digital twin of the ATLs of the Departmental Institute of Fine Arts in Cali (Colombia) to provide students, teachers, and the wider community with its benefits, enhance their interaction with the laboratory elements, and answer questions about its functionality. The prototype enables users to interact with and get information on the physical state of the laboratory, such as the availability of technological elements and their usage. Furthermore, by exploring the digital version of the selected space in real-time, users can gain insights into the laboratory.

The rest of the article is structured as follows: Section II explains the methodology used; Section III details the results of the prototype built; and Section IV presents the conclusions and future work.

II. METHODOLOGY

We use the Scrum development methodology [15], ideal for a small development team, to obtain the prototype quickly. The Scrum framework aims to deliver value in short periods, and it has three pillars: transparency, inspection, and adaptation. Its central component is the Sprint, which allows the project team to self-organize, focus on providing value in each delivery, improve forecasting, monitor progress, and project results [15]. Figure 1 shows the detail of the methodology used to build the components of the three layers of the architecture that support the IoT-ATL prototype.

First, we defined the DT components involving the selection and knowledge of the physical object to be emulated by identifying the scenarios to be digitized and studying the architecture required by the prototype. Second, we developed three sprints for the user stories (see Table 2) from the epics presented below. Each sprint included daily meetings, review meetings, and a retrospective at the end of each sprint. Finally, in the third step, the project was closed, including testing and feedback on the prototype.

A. Product Backlog: Conceptualization and Identification of Components

Epics. Users interested in the laboratory can interact and be informed of its availability status through real-time interaction with the prototype supported by DT. We defined the following epics to address these interactions: Epic 1: Interested users can know which technological elements are in the laboratory and which are available for loan. Epic 2: Users can know how the technological elements of the laboratory are used. Epic 3: Users can interact in real-time with the lighting in the laboratory spaces. Epic 4: Can users obtain updated information about the laboratory through the IoT-ATL prototype?

Description of the Art and Technology Laboratory (ATL) spaces. The ATLs [14] are in Cali, Colombia. The laboratories have three subdivisions: 1) Prototyping laboratory: space to develop industrial, mechatronic, and artistic prototypes required by the institution. 2) Virtual room: space to create digital products that include 2D - 3D design, illustration, and video game development. 3) Virtual training room: space to implement digital products and training using cutting-edge technologies such as virtual reality. The ATL technological elements defined for the IoT-ATl prototype are computers, laser cutter and engraver, CNC router, and cutting plotter, in addition to the laboratories lighting.

Architectures for the Design and Construction of Digital Twins. The Internet of Things (IoT) refers to the connectivity capability between the digital and physical world through the Internet connection [16]. Kranenburg [17] defines it as a dynamic global network infrastructure with self-configuration capability based on interoperable communication standards and protocols where physical and virtual "things" have an identity, physical attributes, and personalities. A critical requirement of IoT is that things connect to each other, thus the design of an architecture that guarantees their operations and communication [18] must be adaptive so that devices connect dynamically, and their communication is supported in any environment [19]. Several authors have proposed architectures such as social IoT (objects like the basis of human relationships) [20], service-oriented IoT [19], or special purpose IoT [21] Three-layer, four-layer, and five-layer architectures are the most common and widely considered for business, industrial research, and general applications [18] [21]

For the IoT-ATL prototype, we use a three-layer architecture [18], i.e., the perception layer is the physical one that includes acquisition cards with sensors or actuators that detect and collect information about the environment. Next, the network layer enables connections between smart objects, network devices, and servers. Finally, the application layer delivers application-specific services to the user.

Table 1 shows the mapping of the DT components with the identified and required elements and their location in the architecture defined for the IoT-ATL prototype.

Table 1 Component mapping.

| DT components | Identified - Required elements | Architecture |

|---|---|---|

| Physical object |

|

Perception layer |

| Bidirectional synchronized relationship between physical and digital assets | Connection protocol, Mosquitto server | Network layer |

| Digital replica of the physical object | Scenario programming in Unity and interaction programming | Application layer |

Prioritization of User Stories.Table 2 shows the user stories (US) with their respective requirements and prioritization.

Table 2 Organization of epics in user stories.

| Epic | ID US | User Story | Requirements | Priority |

|---|---|---|---|---|

| ¨1 | US-1 | As a user, I want to have a digital space where I can consult a list of existing and available items simultaneously. |

|

High |

| 2 | US-2 | As a user, I want to know how to use the technological elements available in the laboratory. |

|

High |

| 3 | US-3 | As a teacher and administrator, I want to have real-time control of the lighting in the laboratories without having to be physically present in them. |

|

High |

| 4 | US-4 | As a user, I want to interact in real-time with the physical components of the laboratories from a digital environment. | Connecting the digital environment with the real laboratory. | High |

B. Sprints

The sprints were conducted according to the 3-layer architecture of IoT. Sprint 1 was dedicated to the construction of the perception layer, Sprint 2 to the construction of the connectivity layer, and Sprint 3 to the application layer. The following section details the results obtained in each sprint.

III. RESULTS

A. Prototype Architecture

Perception Layer. The components that make up this layer and interact with the other layers are defined considering their functionality and the elements available in the Laboratory [14]. IoT resources are used for the physical assembly of the prototype, as seen in Table 3.

Table 3 Elements used in the perception layer.

| Resource | Value | Feature |

|---|---|---|

| Acquisition board | Reference | ESP8266 (ESP-12E) NodeMCU |

| Actuator | Function | LEDs |

| Sensor | Type | Obstacle detection sensor KY-033 |

| Function | Detection of physical presence of a technological input | |

| Protoboard | Function | Base for circuit assembly |

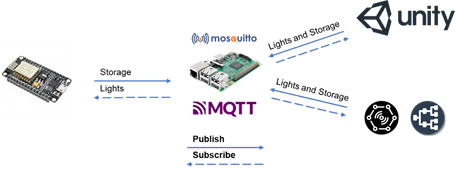

MQTT Protocol. It allows the prototype to connect as a subscriber and publisher to a broker initialized on a raspberry pi3. The broker is responsible for receiving and transmitting input/output data from the acquisition board. If a nearby element is detected, the broker sends a 1; otherwise, it sends a 0.

Obstacle Sensor KY-033 Connected to the ESP8266 System on a Chip. Its purpose is to detect the presence of technological equipment in the laboratory, which will provide the user with information about the existence of supplies.

ESP8266 System on a Chip. It has Ky- 033 obstacle sensors to detect the presence of technological equipment and LEDs to simulate the lighting fixture. The actuators (LEDs) are connected to the acquisition board on pins D0 and D1. In addition, the acquisition board is subscribed to some topics with information coming from the application layer that will provide the necessary information about the control of switching on or off the laboratory. Figure 2 (a) shows the physical assembly of the perception layer.

Network or Connectivity Layer. The Message Queuing Telemetry Transport (MQTT) communication protocol is used. This is a messaging protocol used for communication within an IoT environment that operates over the transport control protocol [22]. The protocol operates in a client-server system, where the server -called a broker- sends updates to MQTT clients [23]. The clients will not send messages directly to each other but through the intermediary broker. Each MQTT message contains a topic, organized in a tree structure, to which clients can subscribe or publish. For the developed prototype, a Mosquitto server was installed on a raspberry pi3 board that works as an intermediary broker for the MQTT clients, as seen in Figure 2 (b).

Application Layer. The visualization of and interaction with the real object are conducted using a "twin" developed in the Unity video game engine, the MQTT-DASH mobile application, and the MQTT-Explorer desktop application.

Unity. In this engine, a controller that allows users to move in space is implemented: a scenario that exemplifies the space of laboratories. We designed the scenario based on free models from the Unity Asset Store [24] and our own, elaborated with the Blender software. We added a futuristic theme to the prototype to increase the level of reception of the product among students. Figures 3, 4, and 5 compare the physical target with the designed replica. Figure 3 shows the entrance to the Hall where an animated character attends the user at the MQTT desk (see Figure 3(a)). The same animated character guides the user to visit the laboratories to make the connection with the broker (see Figure 3(b)) and enter the Hall (see Figure 4 (a)). Finally, in the laboratory management office (Figure 4 (b)), the user interaction starts with the lighting verification, as shown in Figure 7(a).

Figure 5 shows the virtual room and the prototyping laboratory, where the user verifies the lighting, the existence of the technological elements, and digital information on the use of each element.

Interactions.Figure 6 shows the server clients, for which it is necessary to create three topics: 1) Labs/Prototype (Topic for turning on the lights of the prototyping laboratory 1=on, 0=off). 2) Labs/Direction (Direction lab lights on topic 1=on, 0=off). 3) Storage/Prototype/PC1 (Prototyping lab PC1 storage information, whether the element is available or not).

Programming of Interactions. First, a controller is built for the user to interact with the IoT-LAB space and its facilities. Second, an access point is developed so that the user can communicate with the broker using the MQTT protocol. In this way, the user can publish and subscribe to the selected topics that achieve interaction with the real laboratory. There, the user can check the lighting status of the real laboratory (Figure 8(a)), modify it if convenient, and check the availability status of some technological equipment (Figure 7(b)).

MQTT Explorer - MQTT-DASH. Another way to visualize the interaction with the prototype is through the mobile application MQTT- DASH and the desktop application MQTT- Explorer. The user can review and interact with the status, thus enriching the interaction with the prototype.

B. Testing and Feedback

Two students, two professors, and the room administrator participated in the tests of IoT-ALT and verified compliance with the user stories. The defined and performed tests are described below:

US-1 Test. Real-time verification of existing and available elements in the laboratory according to US-1. Assessed variable: Existence and detection of the element in IoT-ALT. 1) The lab element can be seen in IoT-ALT if it is available. Figure 8(a) shows from the MQTT-Explorer desktop application that the prototyping lab computer was not detected and thus does not appear in IoT-ALT. In Figure 9(b), the input appears. 2) The lab item is NOT visible in IoT-ALT if it is not available.

Results. all users performed the test positively, i.e., the element was displayed if it was detected and not displayed when it was not available.

US-2 Test. Verification of the obtention of usage information when the element is present. Assessed variable: UI messages about the usage information of the elements present in the laboratory. 1) When entering one of the laboratories, the user can see messages that present specific details of the space, as shown in Figure 9(a). 2) When the user approaches the laser cutter and engraver, cutting plotter, 3D printers, and MAC computers, messages with relevant information about the input appear, as shown in Figure 9(b).

Results. All users observed unknown and relevant information about laboratories and specific inputs at the time of interacting with IoT-ALT.

US-3 Test. Verification of interaction with laboratory lighting. Assessed variable: Switching lights on and off in the management office and the prototyping lab, where the lighting actuators are located, from the IoT-ALT. 1) The user can turn the lighting in the management office on and off. Figure 7(a) shows the message to turn the lights on or off. 2) The user can turn on and off the lighting in the prototyping laboratory. Figure 7(b) shows the message to turn the lights on or off.

Results. All times that the five users interacted with IoT-ALT from the buttons presented in Figure 7, it was possible to turn on and off the lighting of the two spaces from IoT-ALT and it was reflected on the physical spaces, which was evidenced through a security camera.

US-4 Test. Interact in real-time with physical components of the laboratories from a digital environment. Assessed variable: connectivity and access to the IoT-ALT. 1) The user can connect to the IoT-ALT. Figure 3 shows how users connect to the IoT-ALT. 2) The user could interact with the IoT-ALT's different spaces, elements, lighting, and information. Figure 4 and Figure 5 present the digital spaces replicated in the IoT-ALT. Figure 7 shows the interactions with the lighting in the management office and the prototyping laboratory. Finally, Figure 8 shows how users can see and interact with the technological elements of the laboratory in real-time.

Results. All five users could interact with the physical space from IoT-ALT.

IV. CONCLUSIONS

DT implementation is a current challenge for both research and industry. This work identifies the necessary tools for rapid prototyping and the processes for a successful final product. The suitability of Scrum for digital product development -such as DT or video games- is debatable; however, it can be effective for small development teams with a focus on prototyping. Our technical evaluation shows the compatibility of MQTT communication protocols, Arduino acquisition cards, and the Unity game engine. In addition, the resulting replicas received positive feedback from users who were able to properly interact with them.

As future work, our goal is to enhance the immersive experience and interaction with laboratory equipment. This objective includes adding virtual reality to the prototype and incorporating more sensors for greater user interaction. With support from the UNITY-Things framework [25], we aim to determine the necessary roles for DT development teams. Additionally, using the collected data from the prototype, artificial intelligence algorithms will be applied to identify the laboratory's busiest times and predict the availability of laboratory equipment at specific times or schedules.