Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

Ciencia y Tecnología Agropecuaria

Print version ISSN 0122-8706On-line version ISSN 2500-5308

Cienc. Tecnol. Agropecuaria vol.20 no.3 Mosquera Sep./Dec. 2019 Epub Sep 10, 2019

https://doi.org/10.21930/rcta.vol20num3art:1590

Transformación y agroindustria

Texture, color and sensory acceptance of tortilla and bread elaborated with Maya nut (Brosimim alicastrum) flour to increase total dietary fiber

1Profesor asociado, Instituto Tecnológico Superior de Cintalapa, División de Ingeniería en Industrias Agroalimentarias. Cintalapa, México.

2Profesor-investigador, Tecnológico de Estudios Superiores de Ecatepec, División de Ingeniería Química y Bioquímica, Ecatepec de Morelos, México.

3Profesora-investigadora, Universidad Autónoma del Estado de Hidalgo, Instituto de Ciencias Agropecuarias. Tulancingo, México.

4Profesor-investigador, Tecnológico de Estudios Superiores de Ecatepec, División de Ingeniería Química y Bioquímica. Ecatepec de Morelos, México.

5Centro de Comercio SENA Regional Antioquia

Among ancestral underutilized crop species of high agroindustrial potential, the Maya nut (Brosimum alicastrum) is a source of protein, starch, and fiber. In this study, the effect of incorporating different proportions of Maya nut flour on the texture, color, acceptance, and total dietetic fiber of tortillas and white bread was assessed. Maize flour dough adhesiveness increased when Maya nut flour was incorporated (from 3.97 to 4.96 N), obtaining less hard but more cohesive doughs. Tortillas were more ductile, so they were more deformable (from 3.73 N to 4.84 N). Lower color differences were observed when 10% of Maya nut flour was employed (ΔE = 7.77 and 22.95 for tortilla and bread, respectively). Total dietary fiber content increased by 26 % in tortillas and 54 % in bread when 10 % Maya nut flour was incorporated. In contrast, detectable differences were observed by consumers in bread, especially regarding color development. Results indicate that 10 % of the Maya nut flour can be employed in tortillas and bread without affecting the texture properties; and despite changes in coloration, these were not considered important by consumers, and its use increases the total dietary fiber content. Replacement of the wheat flour with the Maya nut flour affected the texture of the bread to a greater extent due to the weakening of the gluten network, resulting in a harder texture and smaller crumb size, but with the improvement in the dietary fiber content.

Keywords coloration; fiber; maize; structure; wheat

Dentro de los cultivos ancestrales subutilizados que tienen un potencial agroindustrial está el ramón (Brosimum alicastrum), ya que su semilla es fuente de proteína, almidón y fibra. En este trabajo se investigó el efecto de incorporar harina de semilla de ramón en diferentes proporciones, evaluando su efecto sobre la textura, el color, la aceptación y el contenido de fibra dietética total de tortillas y de pan de caja. Las masas de harina de maíz aumentaron su adhesividad al incorporar harina de semilla de ramón (de 3,97 a 4,96 N), además de resultar menos duras, pero más cohesivas. Las tortillas fueron a su vez más dúctiles al ser más deformables (de 3,73 a 4,84 N). Las menores diferencias de color con respecto al control fueron observadas al incorporar 10 % de harina de semilla de ramón (ΔE = 7,77 y 22,95 para tortilla y pan de caja, respectivamente). El contenido de fibra dietética total aumentó en un 26 % en tortillas y 54 % en pan de caja al utilizar 10 % de harina de semilla de ramón. En contraste, para el pan de caja sí hubo diferencias detectables por los consumidores, sobre todo en el color desarrollado. Los resultados indican que se puede utilizar un 10 % de harina de ramón en tortillas o panes sin afectar las propiedades de textura; además, a pesar de los cambios en la coloración, no son considerados importantes por los consumidores, y su uso incrementa el contenido de fibra dietética total.

Palabras clave coloración; estructura; fibra; maíz; trigo

Introduction

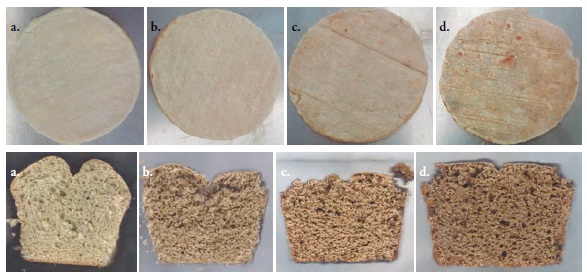

The main food sources of the ancient Mayan population was corn (Zea mays L., Poaceae) and Maya nut, Brosimum alicastrum Sw. (Moraceae); both species which were cultivated and used extensively as part of their daily diet (Ortiz, Azañon, Melgar, & Ellias, 1995; Peters & Pardo-Tejeda, 1982). However, currently the Maya nut is an underutilized crop species of high nutritional value, which has the potential to improve food security by providing a subsistence mean for producers, since it reduces the risk of loss due to environmental changes, price fluctuations, or diseases; furthermore, it also promotes sustainable agriculture by reducing the need for water or fuel and, above all, it preserves and celebrates cultural diversity (Lander & Monro, 2015). The use of underutilized species such as the Maya nut is limited by the lack of knowledge about its management and how it is prepared for consumption (Sánchez, Muschler, Prins, Solano, & Astorga, 2014). Boiled or toasted, Maya nut seeds are edible; these are eaten alone or with corn, honey or banana, or as fermented or hot beverages such as atole. Toasted and ground, the seeds are used as a substitute for coffee. Besides, from the milled seeds, black flour is used to make bread or tortillas (figure 1). The Maya nut seed is highly digestible, with a considerable content of tannins and fiber (Castro-González, Alayón-Gamboa, Ayala-Burgos, & Ramírez-Avilés, 2008), which makes it a source of functional ingredients, such as dietary fiber and antioxidants.

Recently, Maya nut seeds have gained commercial importance for two reasons. First, these are an alternative for food security due to their nutritional properties (Ramírez-Sánchez et al., 2017) and, second, because bioethanol can be obtained from the seeds (Olguín-Maciel et al., 2017). Maya nut seed starch has been proposed as a food ingredient, as raw material to manufacture biodegradable materials (Pérez-Pacheco et al., 2014) and for the production of thermoplastic materials (Ríos-Soberanis et al., 2016) to be used as excipients in the elaboration of tablets in the pharmaceutical industry (Moo-Huchin et al., 2015). Further, the oxidation of the Maya nut seed starch produces a lighter gel, which potentiates its industrial application (Pérez-Pacheco et al., 2016). Similarly, seeds contain a significant amount of phenolic compounds (gallic acid, chlorogenic acid, and vanillic acid) with antioxidant activity (Moo-Huchin, Canto-Pinto, Cuevas-Glory, Sauri-Duch, & Pérez-Pacheco, 2019).

A problem with industrialized products such as tortillas and bread is that the manufacturing process involves the transformation and refinement of corn and wheat, respectively, modifying its chemical and nutritional composition with the corresponding decrease or removal of dietary fiber as a prominent factor that must be considered in the compensation of nutritional food properties. Fiber has a vital physiological and nutritional role in human diet since it comprises a wide variety of chemical compounds with different physical characteristics. Each source of dietary fiber has intrinsic properties that are based on its composition and chemical properties, which in turn establishes the biological and fermentative properties of intestinal bacteria. This is carried out directly through catabolic regulation and indirectly through physical changes in the gastrointestinal tract environment (Lewis, Hall, & Van Soest, 2001).

Dietary fiber in corn consists mainly of cellulose, hemicellulose, and β-glucans, many of which are lost during the nixtamalization process due to the removal of the pericarp. The intensity of the nixtamalization process affects the concentration and composition of different fiber components, as well as its nutritional properties. The process of converting the corn into dough or flour decreases the insoluble fiber and increases the soluble fiber; moreover, the calcium hydroxide used as well as the thermal process hydrolyzes the insoluble fiber, which increases later during cooking due to the loss of moisture (Serna-Saldivar, 2015).

Figure 1. Maya nut seeds and its uses in traditional foods. a. Freshly harvested Maya nut seeds; b. Dry Maya nut seeds; c. Atole with Maya nut seed flour; d. Handmade tortillas with Maya nut flour.

As bread reaches a large part of the population and is widely accepted, it can be used as a carrier of bioactive compounds or other important nutritional components, so that other flours (derived from seeds, fruits, legumes, roots or tubers) can be considered for use as non-conventional raw material in its preparation (Sehn, Nogueira, & Steel, 2016). Bread fortification with different types of nutrients is a common trend that is expected to grow in the future. In some countries supplementation with dietary fiber is of particular importance due to the low dietary fiber consumed, despite the increase in knowledge about its value (Fechner, Scweiggert, Hasenkopf, & Jahreis, 2011).

Therefore, it is essential for the agroindustry to propose underutilized seeds as alternative sources of ingredients for the fortification of processed foods, taking advantage of the ancestral knowledge of its use as food. Accordingly, the aim of this study was to establish the effect of the incorporation of different proportions of Maya nut seed flour, replacing corn flour in tortillas and wheat flour in white bread, on the instrumental texture, color, and sensory acceptance properties, in order to increase the total dietary fiber content.

Materials and methods

Raw materials and preparation of tortilla and bread

The tortillas were made with nixtamalized corn flour (Hari-MASA®, Hari MASA S.A., Santa Catarina, N.L., Mexico), and the bread was elaborated with wheat flour (Selecta®, Molinera de México, S.A., Guadalupe, N.L., Mexico). The Maya nut flour was purchased from the Kishur Rural Production Society (Maya Oox®, Chocholá, Yucatán, Mexico), and it was used to replace different proportions of corn or wheat flour in the elaboration of tortillas and bread, respectively, in the following proportions: a) 0:100 as a control, b) 10:90, c) 20:80, and d) 30:70 of Maya nut seed flour: corn or wheat flour, on a dry basis.

For the preparation of corn tortillas, the flour mixtures were hydrated with water at a moisture content of 60%. Then, these were kneaded manually until complete the hydration of the flour mixtures formed a homogeneous mass; subsequently, these were stored in polyethylene bags with hermetic sealing and under refrigeration until their use within 24 h. The doughs of the different mixtures were used to make tortillas with a manual tortilla machine Monarca TT1 (Inmeza, S. A, Tlaquepaque, Jalisco, Mexico) equipped with a cutting cylinder of 135 mm with a thickness of 2.0-2.3 mm. The tortillas were cooked in a steel skillet heated to 290±20 °C, turning them after ca. 30 s for uniform cooking. The cooked tortillas were stored in polyethylene bags with an airtight seal until further analysis. A total of three batches of 1 kg of dough were prepared for each of the different treatments (0:100, 10:90, 20:80 and 30:70 of Maya nut seed flour: corn flour).

For the elaboration of wheat bread with different Maya nut flour mixtures, salt (1.2%), yeasts (1.2%), sugar (0.4%), vegetable fat (4.6%) and water (35%) were added. The manual kneading process lasted 30 min, allowing the dough to ferment for 40 min. The dough was again kneaded to eliminate the gas produced, and it was then divided and placed in molds for cooking at 200 °C for 40 min. The molds with the loaves were cooled to room temperature, demolded and stored in polyethylene bags until further analysis. A total of three batches of 1 kg of dough were prepared for each of the different treatments (0:100, 10:90, 20:80 and 30:70 of Maya nut seed flour: wheat flour).

Instrumental texture of dough, tortilla, and bread

The texture of the dough elaborated for corn tortillas and bread with different proportions of Maya nut flour was established using compression and penetration tests. For the compression test, an analysis of the texture profile of the raw doughs with different mixtures was carried out. A sample of fifty grams of dough was molded in a spherical shape and compressed with an acrylic cell of 4 cm in diameter in two consecutive cycles in a texture analyzer equipment Brookfield LFRA 4500 (Brookfield Engineering Laboratories, Middleboro, N.J., U. S. A.). Using the force-time curves the textural parameters were established in the following way: hardness (force necessary to reach a deformation), cohesiveness (internal joint strength that the body provides to the sample), adhesiveness (work necessary to overcome the attractive forces between the food surface and the surface of something else), and springing (ratio in which a deformed material returns to its original condition after the deformation force is removed), as reported by Szczesniak (1963) and Bourne (1978). For the penetration test, 50 g of molded mass in the form of a cylinder (5.0 cm in diameter by 2.0 cm in height, approximately) were penetrated with a 1.27 cm diameter spherical probe at a speed of 1 mm/s to a depth of 18 mm, in the same texturometer. Firmness (maximum force detected during the penetration) and adhesion strength (maximum strength detected when removing the probe from the sample) were calculated using the force-time curves (Flores-Farías et al., 2000). All analyses were carried out in quintuplicate for each treatment.

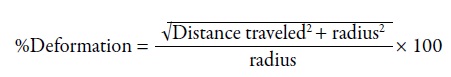

The textural properties of the tortillas made with different doughs were determined through the puncture test according to the method described by Sobral, Menegalli, Hubinger, and Roques (2001). Each tortilla was fixed in an acrylic cell with a 52.4 mm diameter chamber and perforated in the center with a 1.27 cm diameter spherical probe at a speed of 1 mm/s in the same texturometer up to a distance of 25 mm until it broke. From the force-deformation graphs the deformation force (maximum force detected at the breaking point) was calculated, and the deformation percentage was calculated using, on the one hand, the distance traveled by the probe to the breaking point, and on the other hand, the radius of the cell chamber as values of the legs of the Pythagorean theorem. The deformation percentage (hypotenuse) was calculated to establish the deformation capacity of the tortillas; five replicates were carried out per treatment, considering the radius as the original length and using equation 1:

The texture of the bread was established according to Gámbaro, Varela and Giménez (2002), using an analysis of the texture profile. The test was carried out using two slices of bread (15.0 ± 1.0 mm) cut from the center of the loaf to be compressed (40 %) in two consecutive cycles with a rest period of 5 s at a speed of 1 mm/s, and employing an acrylic probe 40 mm in diameter adapted to the same texturometer. The hardness (force necessary to reach a deformation), the cohesiveness (strength of the internal joints that provide the body to the sample), the springing (relationship in which a deformed material returns to its original condition after the deformation force is removed) and the chewiness (energy required to chew the food that will be swallowed) were calculated using the force-time curves (Bourne, 1978; Szczesniak, 1963). All analyses were carried out in quintuplicate per treatment.

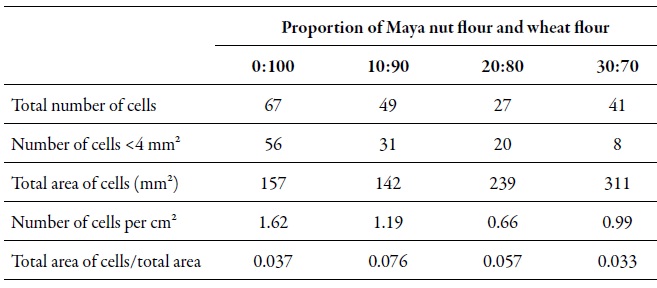

Crumb quality and bread volume

The crumb quality was established through image analysis. Slices from the center of the loaf were scanned at 600 DPI in an HP Photosmart Plus B210 scanner (HP Inc., Palo Alto, California, USA). The analysis was carried out in a sample area of 64×64 mm, taken from the center of the image. The image was analyzed with the Digimizer Image Analysis software (MedCalc Software, Mariakerke, Belgium), calculating the total number of cells, the number of cells smaller than 4 mm2, the total area of the cells, the number of cells per square centimeter and the cell area ratio between the total area, as reported by Paraskevopoulou, Provatidou, Tsotsiou and Kiosseoglou (2010). Bread volume was calculated by the linseed seed displacement method of the American Association of Cereal Chemists (AACC, 2014) in triplicate for each treatment.

Instrumental color

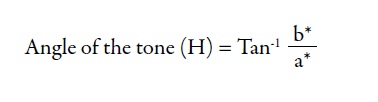

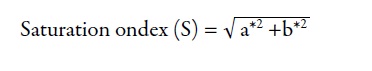

The instrumental color was measured using the CIE-Lab coordinates, employing the Color Analysis application for Android O.S. (Research Lab Tools, São Paulo, Brazil). The CIE standards of the application were a D65 Illuminant, which corresponds to daylight illumination, and a function of the angle of the observer of 2°. The results are the average values of the readings when rotating each of the samples 90°. From the CIE-Lab values, the hue angle (H) and the saturation index (S) were calculatedaccording to Little (1975), and using equations 2 and 3:

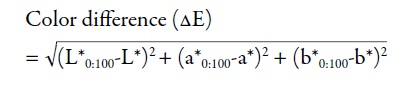

The total color difference was calculated according to equation 4 (Sivam, Sun-Waterhouse, Waterhouse, Quek, & Perera, 2011):

The results are the data of at least five replicas per treatment.

Total dietary fiber content

The total dietary fiber content was measured using the official test method 992.16 of the Association of Official Agricultural Chemists (AOAC, 1999), employing the test kit for total dietary fiber TDF100A-1KT (Sigma-Aldrich, Saint Louis, Missouri, U.S.A.). The samples of each of the tortillas and bread treatments (1 g) were subjected to enzymatic digestion with α-amylase, protease, and amyloglucosidase. Each sample was filtered and washed with distilled water at 80 °C. This solution was precipitated with 95% ethanol, filtered and dried, weighing the residue, and correcting the final calculation by subtracting the protein content (as total nitrogen by the Kjeldahl method), ashes and the control. This analysis was carried out in duplicate for each tortilla and bread treatment.

Sensory acceptance

A sensory acceptance test was carried out with potential tortilla and bread consumers. A hedonic scale of 10 cm long was used with an anchor at the left end marked "I dislike it a lot," and an anchor at the extreme right marked "I like it a lot." A total of 40 participants were recruited voluntarily, including students and staff of the institution Tecnológico de Estudios Superiores de Ecatepec (18 ♀ and 22 ♂, in a range age between 25 and 40 years). There was no previous sensory training as it was a consumer acceptance test. In the record sheet, information was only given on the incorporation of Maya nut flour to improve the fiber content of tortillas and bread. Samples were presented to consumers at the same time, randomly distributed and identified with three-digit random numbers. In the first session, the four samples of different tortilla treatments (¼ tortilla prepared the previous day, heated for 30 s at medium power in a microwave oven) were presented to the consumers. In a later session, four samples of different baked bread treatments were presented as buns (20 g), prepared the day before the test. The participants marked on the line their perception, between "I dislike it a lot" and "I like it a lot" in each attribute: color, aroma, texture, taste and general acceptance; rinsing with water was carried out between each sample assessment. The marks were converted to numerical values by measuring the distance in centimeters from the left anchor of the scale. As an acceptance criterion, the mean value was ≥ 5, which corresponds to the midpoint of the scale that corresponds to "I do not dislike it, nor I like it" (Clark & Johnson, 2002).

Experimental design and data analysis

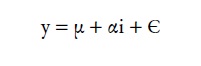

To evaluate the effect of the incorporation of Maya nut flour on the texture and color properties of tortillas and bread elaborated with different proportions of Maya nut seed flour, the model expressed in equation 5 was applied:

Where μ is the experimental average, αi in the maineffect by the incorporation of different percentagesof Maya nut flour: wheat or corn flour (0:100, 10:90, 20:80 and 30:70), and Є is the experimental error. The results of the analyzes, i.e., at least five reproducible trials per treatment, were analyzed using an Anova in the statistical software SAS version 9.0, and the difference between means was established with Duncan's means test (Der & Everitt, 2008).

The acceptance results were analyzed using a paired t-test, using the statistical software SAS version 9.0. The significance was established at p < 0.05 (Clark & Johnson, 2002).

Results and discussion

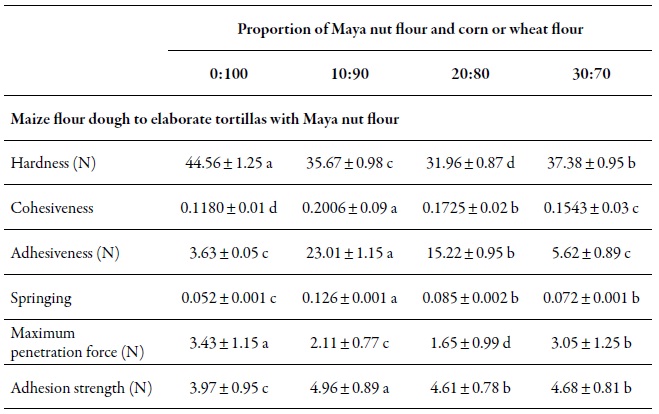

Instrumental texture of corn dough and tortillas

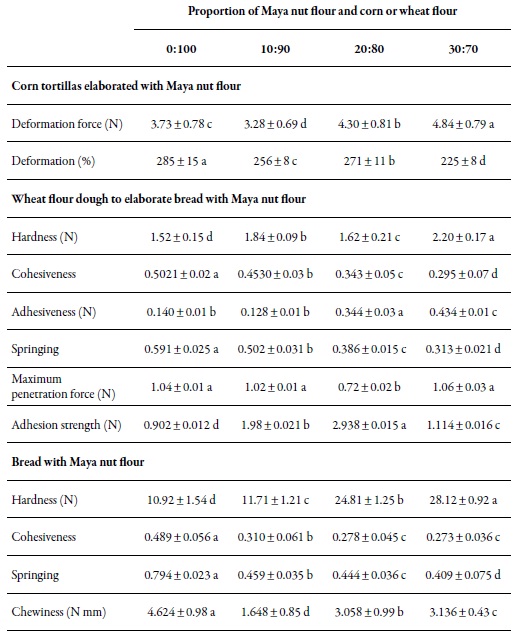

The incorporation of different proportions of Maya nut flour modified the texture of the dough and the tortillas elaborated with this dough. In the texture profile analysis test for the nixtamalized corn flour dough, the increase in the ratio of Maya nut meal significantly decreased (p < 0.05) the hardness of the doughs. On the other hand, the cohesiveness of the doughs was significantly (p < 0.05) higher at a proportion of 10:90, and the lowest cohesiveness was found in the control doughs without Maya nut flour. The same behavior was observed for the adhesiveness and springing of the doughs, in which the samples with the proportion of 10:90 were significantly (p < 0.05) the most adhesive and elastic. In the penetration test with the sphere, significantly (p< 0.05) higher values were obtained in the samples with Maya nut flour, and the lowest force was observed in the samples with a 30:70 ratio; the adhesion strength was significantly (p < 0.05) higher with the 10:90 ratio and the lowest was obtained with the 0:100 ratio (table 1).

In the tortilla texture test, the deformation force was significantly (p < 0.05) higher in the samples with the 30:70 proportion, followed by the 20:80 ratio, and the least deformable, were the samples with the 10:90 ratio. However, the samples with deformation percentages were significantly (p < 0.05) higher than the control samples without Maya nut flour, and the least deformable were the samples with a 30:70 ratio (table 1).

The texture of the dough to make tortillas is essential since the mass must have the proper consistency to adhere to the rolls of the tortilla machine and separate after cutting to be cooked (Gasca-Mancera & Casas-Alencáster, 2007). The type of starch affects the texture of the dough and the tortilla during its cooking. Starches are classified according to the length of the amylopectin chains and the ability of amylopectin to form crystals during gelatinization. Depending on the length of the amylopectin chain, the starches are classified into A, B, and C, forming different types of crystalline structures. Type C starches can form any type of crystal structure when gelatinized, while types A and B cannot do that (Hizukuri, 1985). The Maya nut seed starch is considered as a type C starch (Moo-Huchin et al., 2015), with an amylopectin content of 74.64% (Pérez-Pacheco et al., 2014).

In the corn dough during the process of making tortillas, irregular and swollen granules were observed; these act as a cohesive structure maintaining the mass structure together, which is a mixture of gelatinized starch and dispersed granules within the hydrated and denatured protein matrix (Gómez, Lee, McDonough, Waniska, & Rooney, 1992). Corn has a type A starch crystallization pattern typical of cereals, as during nixtamalization the heating and grinding causes only slight changes in the starch of the native corn. However, when the dough is transformed into a tortilla, the crystallinity of the native granules is affected by cooking (Campus-Baypoli, Rosas-Burgos, Torres-Chávez, Ramírez-Wong, & Serna-Saldívar, 1999). In this way, the Maya nut seed flour with a type C starch, in addition to modifying the texture of the dough, forms crystalline gels during cooking of the tortillas that affect the color. The incorporation of starch and proteins different from those of corn resulted in various types of interactions between these components when hydrating, kneading, and cooking the tortillas, improving the texture of the dough and the tortillas. The incorporation of Maya nut flour at proportions higher than 10 %, decreased the hardness and malleability of the doughs, being cohesive and more adhesive. The inclusion of proteins different from those of corn modifies the hardness of the tortillas (Chuck-Hernández et al., 2015), making them more resistant to deformation; this is what occurred in our research.

Instrumental texture of wheat dough and bread

In the wheat flour doughs, the incorporation of different proportions of Maya nut flour affected the textural properties of the doughs and the elaborated bread. The hardness of the wheat flour doughs was significantly (p < 0.05) higher when incorporating a 30:70 ratio of Maya nut flour, while the control samples showed the lowest values. In contrast, the control sample showed cohesiveness values significantly (p < 0.05) higher, and the lowest ones were found in the 30:70 proportion. The adhesiveness was significantly (p < 0.05) higher in the samples with a ratio of 20:80, and the lowest values were found in the 30:70 proportion. Finally, the 0:100 control samples were significantly (p < 0.05) more elastic, and those with the lowest springing values were those with a 30:70 ratio (table 1).

In the texture profile analysis test of bread, the samples with a ratio of 30:70 of Maya nut flour showed hardness values significantly (p<0.05) higher compared to the control that was increasingly lower. The textural parameters of cohesiveness, springing, and chewiness were all significantly (p < 0.05) higher compared to the control samples without Maya nut flour. In contrast, samples with a 30:70 proportion of Maya nut flour had cohesiveness and springing values significantly (p < 0.05) lower. The samples with a 10:90 ratio showed the lowest chewiness values (table 1).

Table 1. Texture properties of doughs and tortillas made with different proportions of Maya nut flour

a, b, c, d. Means with the same letter in the same line are not significantly (p < 0.05) different for the Maya nut flour proportion used.

Source: Elaborated by the authors

Table 1 (cont.) Texture properties of doughs and tortillas made with different proportions of Maya nut flour

a, b, c, d. Means with the same letter in the same line are not significantly (p < 0.05) different for the Maya nut flour proportion used.

Source: Elaborated by the authors

The addition of other proteins different from those of wheat flour causes a decrease in gluten content due to the substitution of these proteins by others that do not form the same structure of gluten; this, weakens the dough strength that was harder and more adhesive, but less cohesive (Paraskevopoulou et al., 2010). Similarly, other vegetable proteins affect the bread texture making it harder, due to the competition for free water with the gluten network (Mohammed, Ahmed, & Senge, 2012). Just as the proteins in wheat flour have a fundamental role in texture, starch also plays a critical role. The wheat endosperm contains type A and type B starches, and in a lesser proportion, type C starch (≈ 3 %), but after grinding, the predominant wheat starch is type A (varying between 50-87 %).

The proportion of starch from type A to type B affects the quality of bread products (Geera, Nelson, Souza, & Huber, 2006). During the bread dough mixing, wheat starch forms a surface for the union of gluten that decreases its adhesiveness, giving it a desirable consistency for handling, since bread dough is considered to be a structured foam consisting of gas cells dispersed in a protein-starch matrix with a humidity of ≈ 45 % (Maningat & Seib, 2010). Thus, when incorporating Maya nut flour with predominant type C starch, there was no counterproductive effect on the bread texture, as by gradually increasing the concentration of Maya nut seed flour in the bread replacing wheat flour, bread hardness increased with the concomitant decrease in cohesiveness.

Crumb quality and bread volume

Table 2 shows that the incorporation of Maya nut flour modified the bread structure. The bread volume was significantly (p < 0.05) higher (4,896 ± 0.257 g/mL) for the control (ratio of 0:100). The gradual incorporation of Maya nut flour decreased the bread volume in a staggered way, showing values of 3,166 ± 0.123 g/mL for the 10:90 ratio; 1,962 ± 0.101 g/mL for the 20:80 proportion, and 1,722 ± 0.203 g/mL for the 30:70 ratio. Wheat flour bread is a soft solid that has two phases: a fluid phase (air between the cells) and a solid phase (cell wall material). The number of cells and their size decreased with the incorporation of Maya nut flour, which explains the lower volume and the differences in texture observed. Figure 2 shows that the sample without Maya nut flour has a solid phase that is completely connected and homogeneous.

The volume fraction of the phases and the nature of their connectivity, which is the result of the formation of the cells during the bread-making process, establish the bread structure and its mechanical properties (Scanlon & Zghal, 2001). The interference in the formation of the gluten network by the Maya nut seed flour resulted in the decrease of cell expansion due to the gas pressure during fermentation, creating a more compact crumb structure. The bread cells without Maya nut flour were rounder and uniform with a thinner and smoother cell wall that was larger and more homogeneous (Angioloni & Collar, 2009). The incorporation of other flours in the bread decreases the amount of steam generated as a result of a higher water absorption capacity, reducing the bread volume and the number of cells formed with higher crumb firmness (Mohammed et al., 2012). The smaller volume and weight of the bread (related to a harder and less cohesive mass) concomitantly resulted in the development of bread with harder texture. The larger cells in the control bread without Maya nut flour are due to the elasticity of the gluten that allowed the expansion of the cells because of the gas pressure produced during fermentation and baking; a more elastic mass forms a softer and more elastic bread structure. Therefore, the incorporation of Maya nut seed flour in a proportion of 10:90 is the most recommended to minimize textural changes of the dough and the bread. This is because the texture is essential in the development of the bread structure, which is reflected in the crumb quality and bread volume.

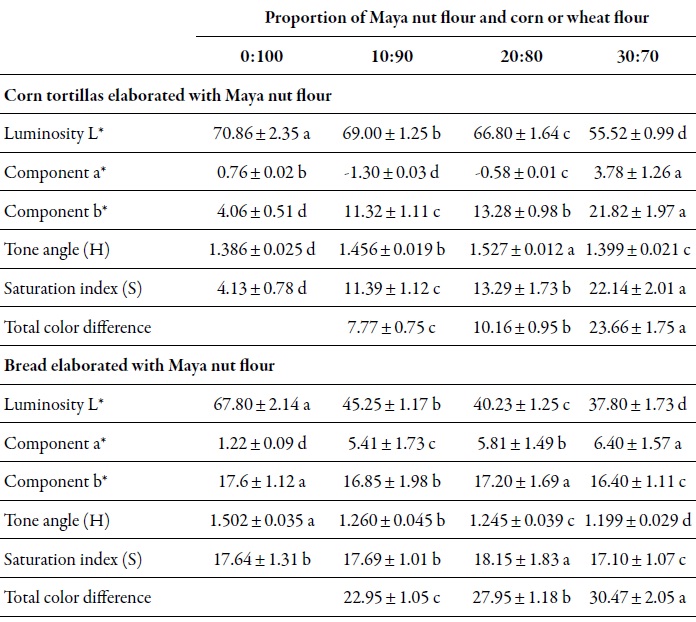

Instrumental color of tortillas

The incorporation of different proportions of Maya nut flour caused changes in the coloration of the corn tortillas. The samples with a 0:100 ratio were significantly (p < 0.05) brighter, while the gradual incorporation of Maya nut flour made the tortillas darker (lower L* values). For a* and b* components, i.e., the green-red and yellow-blue colorations, respectively, the samples with 30:70 ratio of Maya nut flour had significantly (p < 0.05) higher values, while the lowest green-red and yellow-blue coloration values were found in the control sample. The incorporation of different proportions of Maya nut flour increased the tonality (H) of the tortillas, showing the samples without Maya nut flour the lowest significant (p < 0.05) values. The same behavior was observed in the saturation index or color intensity (S), in which significantly lower values (p < 0.05) were found in the 0:100 samples (without Maya nut flour). Thus, the most significant (p < 0.05) difference in color compared to the control was found in the samples with the highest proportion of Maya nut flour, i.e., 30:70 ratio (table 3).

The color of the tortillas is the result of the content of carotenoids in corn, as well as the nixtamalization process. However, the incorporation of other proteins has a different effect on the color of corn tortillas, without causing variation, as is the case with beans (Cuevas-Martínez, Moreno-Ramos, Martínez-Manrique, Moreno-Martínez, & Méndez-Albores, 2010), or increasing the luminosity with soybean (Chuck-Hernández, Pérez-Carrillo, Soria-Hernández, & Serna-Saldívar, 2015). When Maya nut flour was incorporated, the color of the tortillas became darker and greenish, with a marked difference when using a higher proportion of Maya nut flour (figure 2).

Instrumental bread color

Using Maya nut seed flour caused changes in the color development of the bread formulated with different proportions of this flour. Luminosity was significantly (p<0.05) higher in the control samples, and lower values were observed in the samples with a 30:70 ratio of Maya nut flour. The color component a* or red-green was significantly (p < 0.05) lower in the control samples, and higher in the loaves with a 30:70 ratio of Maya nut seed flour. The bread without Maya nut flour had significantly higher values (p < 0.05) for b* or yellow-blue coloration and the samples with a 30:70 ratio showed the lowest values. The tonality values (H) were significantly (p < 0.05) higher in the control samples, and lower with a higher proportion of Maya nut flour. Color intensity (S) was significantly (p < 0.05) lower in the control samples, and with lower proportions of Maya nut flour (10:90). Thus, with higher rates of Maya nut flour in the bread formulations, the difference in color was significantly (p < 0.05) higher (table 3).

Color development in bread is different compared to the one observed in tortillas, due to the reactions of non-enzymatic darkening that takes place on the surface of the bread during its cooking. However, the replacement of wheat flour by other proteins makes the loaves darker, and the pigment content in these flours change the hue of the bread (Güemes-Vera, Peña, Jiménez, Dávila, & Calderón, 2008). The Maya nut seed has a high content of total phenolic compounds (Ozer, 2017), which results in a dark-colored flour that can interfere with the development of the bread color.

Table 3. Instrumental color of tortillas and bread obtained with different proportions of Maya nut flour

a, b, c, d. Means with the same letter in the same row are not significantly (p < 0.05) different for the Maya nut flour proportion used.

Source: Elaborated by the authors

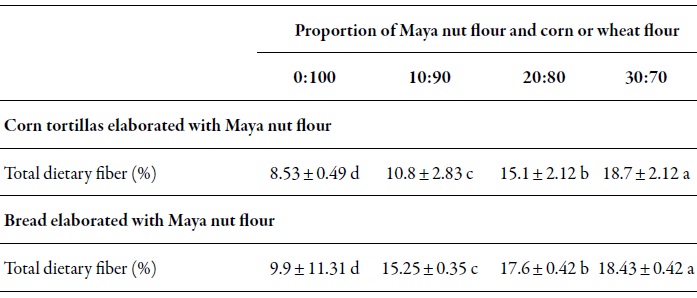

Total dietary fiber content

As expected, the incorporation of Maya nut seed flour increased the amount of total dietary fiber in tortillas and also in bread. With the 30:70 ratio of Maya nut seed flour, the fiber content was significantly (p < 0.05) higher in both tortillas and bread, in contrast to the control without Maya nut flour (table 4).

Table 4. Total dietary fiber content of tortillas and bread made with different proportions of Maya nut flour

a, b, c, d. Means with the same letter in the same line are not significantly (p < 0.05) different for the proportion of Maya nut flour used.

Source: Elaborated by the authors

Currently, one of the crucial problems to improve the nutritional quality of food is the increase in fiber consumption. Despite the recommendations in the daily intake of dietary fiber, consumption is generally below these levels, since dietary fiber reduces the risks of chronic illnesses such as heart disease and cancer, in addition to lowering the glycemic index and avoiding increases in blood sugar levels, parameters related to the prevention of diabetes; moreover, it also helps to regulate intestinal activity (Cho, 2009). The nejayote (residual water generated in the nixtamalization of corn) (Acosta-Estrada, Lazo-Velez, Nava-Valdez, Gutiérrez-Uribe, & Serna- Saldívar, 2014), as well as beans (Treviño-Mejía, Luna-Vital, Gaytán-Martínez, Mendoza, & Loarca- Piña, 2016), have been used in corn tortillas. In bread, fiber from peas (Pisum sativum), beans (Vicia faba L., Fabaceae) (Belghith-Fendri et al., 2016), oats (Avena sativa L., Poaceae) (Becceria, De la Torre, Sánchez, & Osella, 2011) or chia (Salvia hispanica L., Lamiaceae) (Verdú et al., 2015) have been used, only to mention some recent applications.

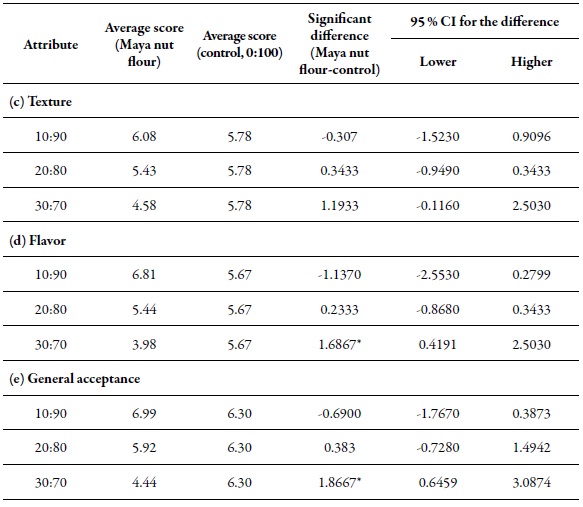

Tortilla acceptance test

The difference of means shows that the color of the tortillas with proportions of 10:90 and 20:80 were more accepted by consumers, without showing significant differences (p > 0.05) between these samples and the control. Samples with a 30:70 ratio were less accepted than the control samples with a score below 5 (Table 5a). Regarding aroma, no significant difference was detected (p > 0.05) between the control and the samples with proportions of 10:90 and 20:80 of Maya nut flour (table 5b). Interestingly, the texture of the tortillas was not significantly (p > 0.05) different between the control and neither of the treatments (table 5c). As for the taste of the tortillas, the samples with the highest proportion of Maya nut flour were significantly (p < 0.05) different (table 5d). Finally, the general acceptance of the tortillas was significantly (p < 0.05) lower for the samples with a higher proportion of Maya nut flour (table 5e), together with its low qualification in color, aroma, and flavor.

Table 5. Mean value, significant difference and 95% confidence interval (CI) of differences in consumer ratings for corn flour tortillas elaborated with different proportions of Maya nut flour (n = 40)

* The value for the percentage (%) of Maya nut flour was significantly (p < 0.05) different from the equivalent control.

Source: Elaborated by the authors

Table 5 (cont.) Mean value, significant difference and 95% confidence interval (CI) of differences in consumer ratings for corn flour tortillas elaborated with different proportions of Maya nut flour (n = 40)

* The value for the percentage (%) of Maya nut flour was significantly (p < 0.05) different from the equivalent control.

Source: Elaborated by the authors

In the sensory evaluation, the acceptance of tortillas with Maya nut flour was good when the proportion used was below 30:70. In fact, the samples with a 10:90 ratio obtained acceptance ratings even higher than the control samples. If we relate these results with those of the texture and color of the dough and tortillas, we can establish that the total dietary fiber content can be improved (from 8.5 to 10.8 %) incorporating at least a 10:90 ratio of Maya nut flour, without affecting the sensory characteristics of the product. A ratio of 20:80 almost doubled the total dietary fiber content, but the scores obtained, although without statistical significance, were below the score obtained by the control. When using beans to fortify tortillas, Treviño-Mejía et al. (2016) indicated that the general acceptance for these tortillas was "I like it slightly” with a preference for whiter tortillas. The differences in the average score of the samples with Maya nut flour with a 10:90 ratio was not lower than a rating category below the control sample, with lower values for the lower confidence interval of 95% for the difference of means (Clark & Johnson, 2002).

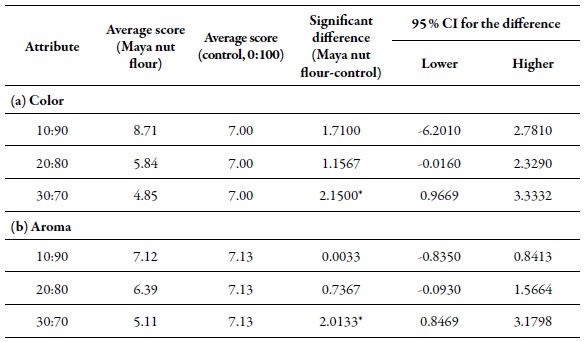

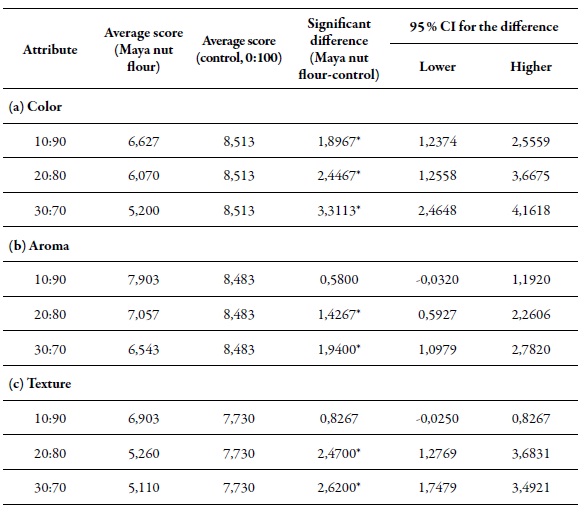

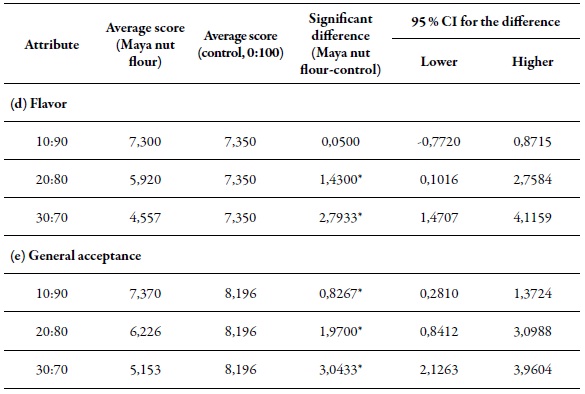

Bread acceptance test

In the sensory test of bread samples, further differences were found in the acceptance by consumers among treatments. Regarding the color of the loaves, all the samples had values significantly (p < 0.05) lower than the control (table 6a). Concerning the aroma, only the samples with Maya nut flour in a 10:90 ratio showed no significant difference (p > 0.05) with the control (table 6b).

The same acceptance behavior was observed for texture and flavor, in which the loaves with proportions of 20:80 and 30:70 were significantly (p < 0.05) less accepted than the control. The bread with a 10:90 proportion of Maya nut flour showed scores very close to the control concerning texture (9.90 and 7.73, respectively) and flavor (7.30 and 7.35, respectively) (tables 6c and 6d). Finally, the general acceptance of the bread samples with Maya nut flour was significantly (p < 0.05) lower compared to the control (table 6e).

Table 6. Average value, significant difference and 95% confidence interval (CI) of the differences in the ratings of consumers on the bread loaves elaborated with wheat flour and different proportions of Maya nut flour (n = 40)

* The value for the percentage (%) of Maya nut flour was significantly (p < 0.05) different from the equivalent control.

Source: Elaborated by the authors

Table 6 (cont.) Average value, significant difference and 95% confidence interval (CI) of the differences in the ratings of consumers on the bread loaves elaborated with wheat flour and different proportions of Maya nut flour (n = 40)

* The value for the percentage (%) of Maya nut flour was significantly (p < 0.05) different from the equivalent control.

Source: Elaborated by the authors

Nevertheless, the incorporation of Maya nut flour caused visible changes in the coloration of the bread, both instrumentally as well as sensorially. Consumers did not like the color developed during baking since all the samples were given lower grades than the control bread, which was also reflected in the general acceptance. However, for the aroma and flavor, the average score was very close and without statistical difference compared to the bread without Maya nut flour, despite the marked differences in instrumental texture, crumb quality and volume of the bread elaborated with Maya nut flour. Even the flavor showed values of preference close to 7, i.e., "I like it a lot." If we consider that incorporating a 10:90 ratio of Maya nut flour increased the total dietary fiber content by 50% (from 9.9 to 15.2 in the control and in bread with a ratio of 10:90, respectively), the awareness of consumers on the benefits of a fiber-enriched bread with an ancient Mayan crop (Dussol, Elliott, Michelet, & Nondédéo, 2017), could influence consumer appreciation; this is despite the fact that the evaluation sheet indicated that the bread contained Maya nut flour to improve the fiber content.

Conclusions

The incorporation of Maya nut flour did not modify substantially the texture properties of the doughs (related to handling during the process) nor of the tortillas or loaves, respectively. Although corn flour doughs with Maya nut flour were less hard, the cohesiveness increased, compensating the texture and becoming more elastic (deformable) tortillas. In wheat flour doughs the hardness increased with Maya nut flour, but the cohesiveness decreased, with the consequent compensation in the texture, which was reflected in more ductile bread (lower chewiness values). The use of 10% Maya nut seed flour showed to have the most acceptable texture values (with lower hardness and greater cohesiveness, or vice versa). The variations detected in instrumental color are not considered necessary by consumers since this attribute was not considered different from the control that did not have Maya nut flour. The increase in the total dietary fiber content increased by using 10% Maya nut flour in 26% for tortillas, and 54% for bread, being the most important feature in the nutritional improvement of these highly consumed and accepted foods without affecting their sensory acceptance.

Acknowledgment

This study was financed within the Project No. 666.18-PD “Techno-functional properties of the Maya nut (Brosimum alicastrum) seed flour and its effect on food texture,” of Tecnológico Nacional de México (TecNm), Mexico. The first author Domínguez-Zarate wishes to thank Consejo Nacional de Ciencia y Tecnología CONACyT, Mexico for granting the scholarship No. 606073 to develop his master’s degree studies.

REFERENCES

American Association of Cereal Chemists (AACC). (2014). Method 10-05.01. Guidelines for measurement of volume by rapeseed displacement. Saint Paul, Minnesota, EE. UU.: AACC International. [ Links ]

Acosta-Estrada, B. A., Lazo-Vélez, M. A., Nava-Valdez, Y., Gutiérrez-Uribe, J. A., & Serna-Saldívar, S. O. (2014). Improvement of dietary fiber, ferulic acid and calcium contents in pan bread enriched with nejayote food additive from white maize (Zea mays). Journal of Cereal Science, 60(1), 264-269. doi:10.1016/j.jcs.2014.04.006. [ Links ]

Angioloni, A., & Collar, C. (2009). Bread crumb quality assessment: A plural physical approach. European Food Research and Technology, 229(1), 21-30. doi:10.1007/ s00217-009-1022-3. [ Links ]

Association of Official Agricultural Chemists (AOAC). (1999). AOAC Official Method 992.16 Total dietary fiber enzymatic–gravimetric method. Official Methods of Analysisof AOAC International (16.a edition). Washington, D. C., EE. UU.: AOAC International. [ Links ]

Beccerica, S., De la Torre, M. A., Sánchez, H. D., & Osella, C. A. (2011). Use of oat bran in bread: fiber and oil enrichment and technological performance. Food and Nutrition Science, 2(6), 553-559. doi:10.4236/fns.2011.26079. [ Links ]

Belghith-Fendri, L., Chaari, F., Maaloul, M., Kallel, F., Abdelkafi, L., ... Ghribi-Aydi, D. (2016). Wheat bread enrichment by pea and broad bean pods fibers: Effect on dough rheology and bread quality. LWT-Food Science and Technology, 73, 584-591. doi:10.1016/j.lwt.2016.06.070. [ Links ]

Bourne, M. C. (1978). Texture Profile Analysis. Food Technology, 32(7), 62-66, 72. [ Links ]

Campus-Baypoli, O. N, Rosas-Burgos, E. C., Torres-Chávez, P. I., Ramírez-Wong, B., & Serna-Saldívar, S. O. (1999). Physiochemical changes of starch during maize tortilla production. Starch/Stärke, 51(5), 173-177. doi:10.1002/ (SICI)1521-379X(199905)51:5<173::AID -ST AR173>3.0.CO;2-B. [ Links ]

Castro-González, A., Alayón-Gamboa, J. A., Ayala-Burgos, A., & Ramírez-Avilés, L. (2008). Effects of Brosimum alicastrum and mixtures on voluntary intake, nutrient digestibility and nitrogen balance in sheep fed tropical pastures. Animal Feed Science and Technology, 141(3-4), 246-258. doi:10.1016/j.anifeedsci.2007.06.033. [ Links ]

Cho, S. (2009). Functional and dietary fibers: an introduction. En S. S. Cho, & P. Samuel (Eds.), Fiber Ingredients Food Applications and Health Benefits (pp. 1-6). Boca Raton, EE. UU.: CRC Press. [ Links ]

Chuck-Hernández, C., Pérez-Carrillo, E., Soria-Hernández, C., & Serna-Saldívar, S. O. (2015). Functionality and organoleptic properties of maize tortillas enriched with five different soybean proteins. Cereal Chemistry, 92(4), 341-349. doi: 10.1094/CCHEM-07-14-0154-R. [ Links ]

Clark, R., & Johnson, S. (2002). Sensory acceptability of foods with added lupin (Lupinus angustifolius) kernel fiber using pre-set criteria. Journal of Food Science, 67(1), 356-362. doi:10.1111/j.1365-2621.2002.tb11410.x. [ Links ]

Cuevas-Martínez, D., Moreno-Ramos, C., Martínez-Manrique, E., Moreno-Martínez, E., & Méndez-Albores, A. (2010). Nutrition and texture evaluation of maize-white common bean nixtamalized tortillas. Interciencia, 35(11), 828-832. [ Links ]

Der, G., & Everitt, B. S. (2008). A Handbook of Statistical Analyses using SAS (3rd edition). (pp. 99-109). Londres, Inglaterra: Chapman & Hall/CRC. [ Links ]

Dussol, L., Elliott, M., Michelet, D., & Nondédéo, P. (2017). Ancient Maya sylviculture of breadnut (Brosimum alicastrum Sw.) and sapodilla (Manilkara zapota (L.) P. Royen) at Naachtun (Guatemala): A reconstruction based on charcoal analysis. Quaternary International, 457, 29-42. doi:10.1016/j.quaint.2016.10.014. [ Links ]

Fechner, A., Scweiggert, U., Hasenkopf, K., & Jahreis, G. (2011). Lupine kernel fiber: Metabolic effects in human intervention studies and uses as supplement in wheat bread. En V. R. Preedy, R. R. Watson & V. B. Patel (Eds), Flour and Breads and their Fortification in Health and Disease Prevention (pp. 463-474). Londres, Inglaterra: Academic Press. [ Links ]

Flores-Farías, R., Martínez-Bustos, F., Salinas-Moreno, Y., Kil-Chang, Y., González-Hernández, J., & Ríos, E. (2000). Physicochemical and rheological characteristics of commercial nixtamalised Mexican maize flours for tortillas. Journal of the Science of Food and Agriculture, 80(6), 657-664. doi:10.1002/(SICI)1097-0010(20000501)80:6<657::A ID-JSFA576>3.0.CO;2-J. [ Links ]

Gámbaro, A., Varela, P., & Giménez, A. (2002). Textural quality of white pan bread by sensory and instrumental measurements. Journal of Texture Studies, 33(5), 401-413. doi:10.1111/j.1745-4603.2002.tb01356.x. [ Links ]

Gasca-Mancera, J. C., & Casas-Alencáster, N. B. (2007). Addition of nixtamalized corn flour to fresh nixtamalized corn masa. effect on the textural properties of masa and tortilla. Revista Mexicana de Ingeniería Química, 6(3), 317-328. [ Links ]

Geera, B. P., Nelson, J. E., Souza, E., & Huber, K. C. (2006). Composition and properties of A- and B-type starch granules of wild-type, partial waxy, and waxy soft wheat. Cereal Chemistry, 83(5), 551-557. doi:10.1094/CC-830551. [ Links ]

Gómez, M. H., Lee, J. K., McDonough, C. M., Waniska, R. D., & Rooney, L. W. (1992). Corn starch changes during tortilla and tortilla chip processing. Cereal Chemistry, 69(3), 275-279. [ Links ]

Güemes-Vera, N., Peña, R., Jiménez, C., Dávila, G., & Calderón, G. (2008). Effective detoxification and decoloration of Lupinus mutabilis seed derivatives, and effect of these derivatives on bread quality and acceptance. Journal of the Science of Food and Agriculture, 88(7), 1135-1143. doi:10.1002/jsfa.3152. [ Links ]

Hizukuri, S. (1985). Relationship between the distribution of the chain length of amylopectin and the crystalline structure of starch granules. Carbohydrate Research, 141(2), 295-306. doi:10.1016/S0008-6215(00)90461-0. [ Links ]

Lander, T. A., & Monro, A. (2015). Conservation of Brosimum alicastrum, an underutilized crop and keystone forest tree species; a potential win-win for conservation and development in Latin America. Biodiversity and Conservation, 24(8), 1917-1930. doi:10.1007/s10531-015-0913-9. [ Links ]

Lewis, B. A., Hall, M. B., & Van Soest, P. J. (2001). Interaction between human gut bacteria and dietary fiber substrates. En G. A. Spiller (Ed), Dietary Fiber in Human Nutrition (3rd edition) (pp. 271-276). Boca Raton, EE. UU.: CRC Press. [ Links ]

Little, A. C. (1975). Off on a tangent. Journal of Food Science, 40, 410-411. [ Links ]

Maningat, C. C., & Seib, P. A. (2010). Understanding the physicochemical and functional properties of wheat starch in various foods. Cereal Chemistry, 87(4), 305-314. doi:10.1094/CCHEM-87-4-0305. [ Links ]

Mohammed, I., Ahmed, A. R., & Senge, B. (2012). Dough rheology and bread quality of wheat-chickpea flour blends. Industrial Crops and Products, 36(1), 196-202. doi:10.1016/j.indcrop.2011.09.006. [ Links ]

Moo-Huchin, V.M., Cabrera-Sierra, M.J., Estrada-León, R.J., Ríos-Soberanis, C.R., Betancur-Ancona, D., ... Pérez-Pacheco, E. (2015). Determination of some physicochemical and rheological characteristics of starch obtained from Brosimum alicastrum Swartz seeds. Food Hydrocolloids, 45, 48-54. doi:10.1016/j.foodhyd.2014.11.009. [ Links ]

Moo-Huchin, V. M., Canto-Pinto, J. C., Cuevas-Glory, L. F., Sauri-Duch, E., & Pérez-Pacheco, E. (2019). Effect of extraction solvent on the phenolic compounds content and antioxidant activity of Ramon nut (Brosimum alicastrum). Chemical Papers, 73(7), 1647-1657. doi:10.1007/s11696-01900716-x. [ Links ]

Olguín-Maciel, E., Larqué-Saavedra, A., Pérez-Brito, D., Barahona-Pérez, L. F., Alzate-Gaviria, L., ... Tapia-Tussell, R. (2017). Brosimum alicastrum as a novel starch source for bioethanol production. Energies, 10(10), 1574, doi:10.3390/en10101574. [ Links ]

Ortiz, M., Azañon, V., Melgar, M., & Ellias, L. (1995). The corn tree (Brosimum alicastrum): a food source for the tropics. En A. P. Simopoulos (Ed.), Plants in Human Nutrition (pp. 135-146). Basilea, Suiza: Karger. [ Links ]

Ozer, H. K. (2017). Phenolic compositions and antioxidant activities of Maya nut (Brosimum alicastrum): Comparison with commercial nuts. International Journal of Food Properties, 20(11), 2772-2781. doi:10.1080/10942912.2 016.1252389. [ Links ]

Paraskevopoulou, A., Provatidou, E., Tsotsiou, D., & Kiosseoglou, V. (2010). Dough rheology and baking performance of wheat flour-lupin protein isolate blends. Food Research International, 43(4), 1009-1016. doi:10.1016/j.foodres. 2010.01.010. [ Links ]

Pérez-Pacheco, E., Moo-Huchin, V. M., Estrada-León, R. J., Ortiz-Fernández, A., May-Hernández, L. H., ... Betancur- Ancona, D. (2014). Isolation and characterization of starch obtained from Brosimum alicastrum Swarts seeds. Carbohydrate Polymers, 101, 920-927. doi:10.1016/j.carbpol. 2013.10.012. [ Links ]

Pérez‐Pacheco, E., Estrada‐León, R. J., Sauri-Duch, E., Bello‐Pérez, L. A., Betancur‐Ancona, D., & Moo‐Huchin, V. M. (2016). Partial characterization of starch obtained from ramon (Brosimum alicastrum Swartz), oxidized under different conditions. Starch, 69(5-6). doi:10.1002/star. 201600233. [ Links ]

Peters, C. M., & Pardo-Tejeda, E. (1982). Brosimum alicastrum (Moraceae): uses and potential in Mexico. Economic Botany, 36(2), 166-175. doi:10.1007/BF02858712. [ Links ]

Ramírez-Sánchez, S., Ibáñez-Vázquez, D., Gutiérrez-Peña, M., Ortega-Fuentes, M. S., García-Ponce, L. L., & Larqué-Saavedra, A. (2017). El ramón (Brosimum alicastrum Swartz) una alternativa para la seguridad alimentaria en México. Agroproductividad, 10(1), 80-83. Recuperado de https://www.revista-agroproductividad.org/index.php/agroproductividad/article/view/943/802 [ Links ]

Ríos‐Soberanis, C. R., Estrada‐León, R. J., Moo‐Huchin, V. M., Cabrera‐Sierra, M. J., Cervantes‐Uc, J. M., Bello‐Pérez, L. A., & Pérez‐Pacheco, E. (2016). Utilization of ramon seeds (Brosimum alicastrum swarts) as a new source material for thermoplastic starch production. Journal of Applied Polymer Science, 133(47), 44235. doi:10.1002/app.44235. [ Links ]

Sánchez, D. V., Muschler, R., Prins, C., Solano, W., & Astorga, C. (2014). Diversidad de especies vegetales alimenticias en la microrregión de Cacahuatique Sur de El Salvador: un enfoque en especies comestibles subutilizadas y conocimiento local. Agroecología, 9(1-2), 101-109. Recuperado de https://www.revistas.um.es/agroecologia/article/view/300681/216101 [ Links ]

Scanlon, M. G., & Zghal, M. C. (2001). Bread properties and crumb structure. Food Research International, 34(10), 841-864. doi:10.1016/S0963-9969(01)00109-0. [ Links ]

Sehn, G. A. R., Nogueira, A. C., & Steel, C. J. (2016). Non-conventional raw materials for nutritional improvement of breads. En C. M. Rosell, J. Bajerska, & A. F. El Sheikha (Eds.), Breads and its Fortification. Nutritional and Health Benefits (pp. 248-272). Boca Raton, EE. UU.: CRC Press. [ Links ]

Serna-Saldivar, S. O. (2015). Nutrition and fortification of corn and wheat tortillas. En L.W. Rooney & S. O. Serna- Saldivar (Eds.), Tortillas Wheat Flour and Corn Products (pp. 29-64). Saint Paul, EE. UU.: AACC International. [ Links ]

Sivam, A. S., Sun-Waterhouse, D., Waterhouse, G. I. N., Quek, S. Y., & Perera, C. O. (2011). Physicochemical properties of bread dough and finished bread with added pectin fiber and phenolic antioxidants. Journal of Food Science, 76(3), H97-H107. doi:10.1111/j.1750-3841.2011.02086.x. [ Links ]

Sobral, P. D. A., Menegalli, F. C., Hubinger, M. D., & Roques, M. A. (2001). Mechanical, water vapor barrier and thermal properties of gelatin based edible films. Food Hydrocolloids, 15(4-6), 423-432. doi:10.1016/S0268-005X (01)00061-3. [ Links ]

Szczesniak, A. S. (1963). Classification of Textural Characteristics. Journal of Food Science, 28(4), 385-389. doi:10.1111/ j.1365-2621.1963.tb00215.x. [ Links ]

Treviño-Mejía, D., Luna-Vital, D., Gaytán-Martínez, M., Mendoza, S., & Loarca-Piña, G. (2016). Fortification of commercial nixtamalized maize (Zea mays L.) with common bean (Phaseolus vulgaris L.) increased the nutritional and nutraceutical content of tortillas without modifying sensory properties. Journal of Food Quality, 39(6), 569-579. doi:10.1111/jfq.12251. [ Links ]

Verdú, S., Vásquez, F., Ivorra, E., Sánchez, A. J., Barat, J. M., & Grau, R. (2015). Physicochemical effects of chia (Salvia hispanica) seed flour on each wheat bread-making process phase and product storage. Journal of Cereal Science, 65, 67-73. doi:10.1016/j.jcs.2015.05.011. [ Links ]

Received: February 13, 2019; Accepted: June 07, 2019

text in

text in