1. Introduction

Surface water pollution is a serious problem for many developing countries. The main causes are industrial and domestic wastewater discharges that contain excessive concentrations of nitrogen, phosphorous, and organic pollutants into natural waters such as rivers and lakes 1. Unfortunately, one source of this type of pollution are starch factories, which are classified as polluting industries around the world 2. In Latin America, this issue is especially problematic due to the lack or low efficiency of wastewater plants to treat general wastewater. In many cases, this raw wastewater is discharged directly into natural water.

The potato represents one of the most important crops for the food sustenance of the world population but, at the same time, it is useful for diverse industrial processes and starch production. This starch is used as an industrial raw material in food, textile, chemical, medicines, and others 2,3. However, the starch production process requires a huge amount of water for to wash the feedstocks, perform the starch extraction process, and clean the pipelines and instruments. Most of the water that is used in the process is converted into wastewater 2. It is estimated that production each ton of starch will generate between 10-20 m3 wastewater discharge 3, containing organic products such as starch, proteins, amino acids sugars, and potassium 4.

The main concern arising due to this kind of process is that wastewater discharges from starch factories usually have a high organic load, which causes a drastic decrease in the amount of oxygen dissolved in natural water resources 2. Usually, wastewater from starch production contains chemical oxygen demand (COD) concentrations between 5000 and 50000 mg/L, biochemical oxygen demand concentration between 3000 and 30000 mg/L, and suspended solids concentration between 1000 and 5000 mg/L 3. Therefore, effective treatment of the starchy wastewater is critical.

Different kinds of processes can be used to treat wastewater from starch production. Both physicochemical and biological technologies can present good efficiencies. However, the biological process has gained a lot of attention in the last few years. Some reasons for this are that these processes present good efficiencies with low operation costs, and are sustainable and environmentally friendly technologies.

The aerobic process is a biological wastewater technology that has shown good efficiencies in the removal of conventional organic pollutants as determined by values such as chemical oxygen demand, biological oxygen demand, and nutrients in the typical concentrations of domestic wastewater affluents. Therefore, this process has been a focus in the treatment of domestic wastewater. However, biokinetic coefficients vary between different types of wastewaters. Table 1 shows the typical biokinetic coefficients values for activated sludge.

Table 1 Typical biokinetic coefficients values for activated sludge

| Description | Coefficient | Units | Value | |

|---|---|---|---|---|

| Range | Typical | |||

| Maximum specific rate of substrate removal | K0 | Day -1 | 2-8 | 4 |

| Endogenous respiration coefficient | ke | Day -1 | 0.03-0.07 | 0.05 |

| Saturation coefficient | Km | mg/L (COD- BOD5) | 40-120 | 80 |

| Performance coefficient | Y | mgSSV/mgBOD5 | 0.3-0.7 | 40 |

Source: Von Sperling and C. A. Chernicharo, 2005 5, M. & E. Inc et al 6

The biological process can be a potential tool to treat industrial wastewaters with specific characteristics, but the biokinetic coefficients (kinetic and stoichiometric coefficients) must be determined to optimize the scale applications of the process. The purpose of this study was to use an aerobic semi continuous reactor to determine the biological coefficients to treat wastewater from starch production and to evaluate the efficiencies of this process in the removal of a high concentration of potato starch.

2. Materials and methods

2.1 Experimental setup and operation

The aerobic reactor used in this study was constructed in acrylic with an effective volume of 4.0 L, overall height of 30 cm, and inner diameter of 15 cm. The system had quick-closing half-inch valves; one of these was located at the bottom of the reactor and enabled entry of the wastewater flow, while the other two facilitated the blowdown of the sludge. The incoming flow enterered using a peristaltic pump with a capacity of 6-600 RPM.

The reactor was completely mixed by a mechanical stirrer, and air was supplied by a fish tank pump through a plastic pipe in which stones were placed to generate fine air bubbles. This facilitated the transfer of oxygen to the microorganisms. The biomass used was of the suspended type. The schematic diagram of the reactor is given in Figure 1.

Source: Authors own creation.

Figure 1 Schematic representation of the aerobic system used during the experimentation (check the nomenclature part).

The reactor worked in a semicontinuous configuration; therefore, the system’s air supply, agitation, and peristaltic pump were activated with a digital timer for the different periods. The reactor worked for a total of 16 active hours and 8 inactive hours every day. The effluent from the system was collected in a sedimentation unit, where it was subsequently returned to the reactor. The purge was carried out directly from the aeration tank according to the age of the sludge from the experimental phase.

2.2 Inoculum

The system was inoculated with an aerobic sludge from a domestic wastewater treatment plant, called Aguas Claras, located in the municipality of Bello, Antioquia. The sludge presented good sedimentation characteristics and a low sludge volumetric index.

2.3 Composition of synthetic wastewater

Synthetic wastewater was prepared to simulate industrial wastewater from the potato starch extraction process. The concentrations of COD used were 500 and 1000 mg / L. The macro and micronutrients were added according to what was reported by Molina 7 for aerobic systems. The pH in the reactor was controlled by adding sodium bicarbonate into the incoming flow.

2.4 Operational Strategy

The reactor was operated for 126 days through 5 phases of operation that consisted of start-up and acclimatization and four subsequent phases which evaluated the variation of the sludge retention time (sludge age). Throughout the study, the kinetic and stoichiometric coefficients were determined, varying the sludge retention time between 20, 10, 8, and 4 days. The biomass concentration varied between 3040 and 610 mg/L and the F/M ratio varied between 0.36 and 1.70 1.92 gCOD / gVSS·d. Table 2 presents a summary of the experimental conditions used for the operation of the system

2.5 Analytical methods

Tests for COD, TSS, VSS, and SVI were done in the laboratory of the research group known as the Pollution Control and Diagnostics Group (GDCON), at the University of Antioquia, following protocols established in the Standard Methods 8. The GDCON laboratory is accredited by the Environmental Research Institute under the Ministry of Environment of Colombia (IDEAM) to carry out these analyses.

2.6 Aerobic biokinetic coefficients determination

The interaction between the growth of microorganisms and utilization of the growth-limiting substrate in a completely mixed activated sludge is based on the Monod model 9. This model is the most commonly used one for determining the biokinetic coefficients in biological processes, which can be expressed as 10

μmax is the maximum specific growth rate and Km is the saturation constant, which is numerically equal to the substrate concentration when μ=0.5μmax. The coefficients were determined based on the following assumptions:

The reactor volume is constant and completely mixed.

Influent COD concentration remains constant.

The synthetic influent wastewater does not contain microbial solids.

Steady-state conditions prevail throughout the system during the experimentation time.

According to Figure 2, the mass balance equations of both the biomass and substrate removal can be described by the following equations 11:

3. Results and discussion

The aerobic reactor used in the experimentation was operated under mesophilic conditions. The pH parameter (Table 2) was monitored every day to keep good environmental conditions for the microorganisms. The dissolved oxygen was always over 2 mg/L.

Potato starch could be a good carbon source when used as a substrate for biomass. However, the low water solubility and high potato starch concentrations in industrial wastewater may be a limiting factor for the aerobic process. Table 3 shows the pH variation through the experimentation time. The values show a tendency to remain between 7 and 8. The pH was controlled by adding 0.5 g of sodium bicarbonate. According to the literature, the pH in this biological process can vary while remaining close to neutrality. However, the pH in wastewater can fluctuate in the range of 6.5-8.5 16, which means that the environmental medium was suitable for the metabolic development of most microorganisms

Table 3 Reactor performance under start-up and steady-state conditions at four different ϴc.

| Parameter | Sludge retention time (days) | ||||

|---|---|---|---|---|---|

| Start up | 20 | 10 | 8 | 4 | |

| Operation period (days) | 01-66 | 67-82 | 83-94 | 95-107 | 108-119 |

| F/M ratio (mg CODmg/VSS day) | __ | 0.36 | 0.48 | 1.11 | 1.7 |

| Ph | 7.3 ± 0,3 | 7.4 ± 0.3 | 7.7 ± 0.3 | 7.5 ± 0.2 | 7.5 ± 0.3 |

| Aflluent COD (mg/L) | 478 ± 52 | 1081 ± 71 | 1074 ± 85 | 1108 ± 115 | 1038 ± 74 |

| Eflluent COD (mg/L) | 69 ± 20 | 22 ± 4 | 33 ± 5 | 90 ± 8 | 148 ± 11 |

| COD removal efficiencies (%) | 86 ± 4 | 95 ± 1 | 94 ± 1 | 94 ± 2 | 92 ± 2 |

Source: Authors own creation.

The sludge retention time was used as a controlling parameter throughout the experimentation. The reactor was operated applying different ϴc (Table 1). Therefore, the biomass concentration (mixed liquor suspended solids -MLSS) was changed for phases from 2 to 5 with average values of 3040, 2240, 1400 610 mgSS/L respectively. The biokinetic coefficients were determined at steady-state, a condition that was assumed to exist when biomass growth and COD removal were constant.

The biokinetic coefficient values were estimated through regression analysis of experimental data using the Lineweaver-Burk method as shown in Figure 3. The values obtained for 𝑘0 and 𝑘𝑚 were 1.8 1/day and 93 mg/L COD respectively. The graphic analysis of data shows a high regression coefficient with an R2 of 0.9596.

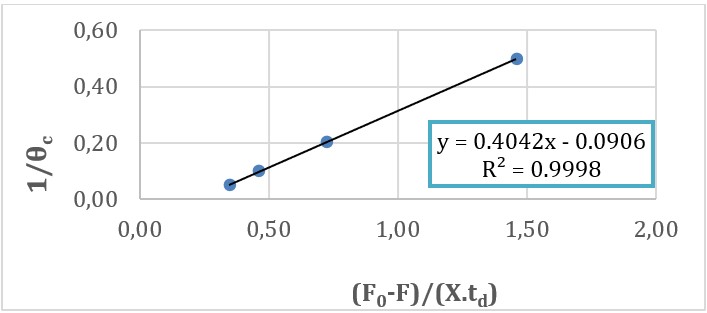

In the same way, the Y and 𝑘𝑒 coefficients were estimated through the graphical analysis of experimental data, as shown in Figure 4. The Y and 𝑘𝑒 values obtained were 0.4 mgSSV/mgCOD and 0.09 1/day respectively. In this case, the graphic analysis of data shows a good fit with a regression coefficient where the R2 was 0.9998 .

It is important to mention that the biokinetics coefficient values obtained for starch removal are similar to those for domestic wastewater reported in Table 1. The constant 𝑘𝑚 represents the affinity of the biomass for the substrate. In this case, the high values of this constant mean a high affinity of the microorganisms for the starch. This could be because starch is a highly biodegradable substrate, and the reactor had a good performance at the COD concentration of 1000 mg/L. However, the reactor was operated at a high HRT (24 hours), which means that if the COD load changes the starch removal efficiency could change as well 17. A study on starch wastewater treatment reported by Wang and collaborators 1) showed that aerobic system efficiency is affected by HRT. They proved that at high HRT, such as 24 hours, the reactor had efficiencies up to 96.5% but when the HRT was low (HRT = 6 hours) the efficiencies decreased considerably.

Figure 5 shows the behavior of the F/M ratio vs ϴc. The F/M ratio decreases when ϴc is higher and vice versa. Therefore, this graph describes the way the F/M ratio changes with the ϴc variation through the experimentation time. It is important to note that the reactor had a strong variation in biomass concentration (mixed liquor suspended solids) under the effect of ϴc decrease and, as a consequence, the ratio of F/M rose considerably during the experimentation time, as can be seen in Figure 5.

Source: Authors own creation.

Figure 5 Graphic representation of a) the behavior of F/M vs the variation in the ϴc. b) variation of system efficiency vs the variation in the ϴc.

On the other hand, the efficiency of the system is strongly affected by the F/M ratio. When the F/M ratio is lower the efficiency of the system increases. This good efficiency in the system occurs because, when the ratio F/M is lower, the biomass is in high competition for the substrate, which may not be enough for the microorganism. Therefore, there is higher efficiency in the system. However, it is important to note that the system dynamics can change if the cell residence time is too high. At a low F/M ratio the presence of nematodes and rotifers predominates, but if the cell-residence time continues to increase, the biomass decreases to the point that is not possible to find active cells through microscopic observation (Figure 6 c). In this case, system efficiency decreases dramatically. Therefore, when determining biokinetic coefficients, the system never reached this critical condition. The reactor was operated under a steady-state with active biomass.

(Source: own elaboration).

Figure 6 Change in the microbial structure under the effect of ration F/M variation.

However, when the F/M ratio increases, the system efficiency decreases (Figure 5b). This drop-in efficiency is associated with low concentration of the biomass, despite its greater biological activity. In this case, there is a change in the sludge microbial structure whereby dispersed bacterial populations, free ciliates, and flagellates predominate (Figure 6 a-c ).

These changes in the biological structure also affect the system's operation. When the F/M ratio is lower, the SVI is good, and the sludge has good sedimentation characteristics with SVI values below 100 mL/g 7. However, when the F/M ratio is higher the SVI is also higher (>100 mL/g). Therefore, the sludge does not have good sedimentation characteristics, which is a consequence of the presence of dispersing biomass.

The oxygen consumption rate was also monitored through the experimentation phases under the ϴc variation. Figure 7 shows the values for the OCR for the experimental test in each ϴc and the theoretical calculation.

4. Conclusions and recommendations

The aerobic process can be used as an alternative to treat wastewater from starch extraction. The biokinetics coefficients showed good values for starch removal, which are close to the coefficient values of domestic wastewater treatment. This similarity arises because starch is an organic substrate with high biodegradability. However, it is important to consider the effect of the organic load when the aerobic system is going to be applied as the only process to treat this kind of wastewater. This is due to the fact that the starch wastewater has a high COD concentration; therefore, a high HRT is needed to obtain good efficiency, as was the case in this study.

Consequently, it is suggested that future research should evaluate the maximum starch load which can be applied to the system without losing efficiency, and also, to evaluate whether there is a change in the biokinetics values when this load increases. However, the results obtained in this research are a good basis for the application of biological processes to treat wastewater from starch production.