INTRODUCTION

The apple is the fruit of the apple tree, which belongs to the Rosaceae family (Flores Gárate et al., 2015). Malus domestica refers to one of the species of the tree that defines the origin of the apple. It is known for its adaptability to a wide range of climatic conditions, diverse soils and various cultivation systems. The cultivation regions of Malus domestica include Europe, North America, South America, New Zealand, Australia, and Asia (Vigil Cannon, 2018).

From 2015 to 2019, global apple production averaged 84,722,560 tons (FAO, 2021). In South America, Chile, Brazil, and Argentina stood out as the top apple producers during the same period, producing an average of 1,719,909, 1,252,753, and 973,570 tons per year respectively. Colombia contributed an average of 3,523 tons to the global production, with the department of Santander as the country’s top producer (FAO, 2021). Despite these local production figures, Colombia heavily relies on imports, particularly from top producers of the region such as Chile (AGRONET, 2021).

This crop is known for being associated with a high requirement for cold hours. However, genetic modifications have expanded and diversified yields in regions with fewer cold hours, such as Brazil and Colombia. There are more than a thousand different varieties of apple, whose structural and physicochemical characteristics generate various alternatives for technological use. Among the apple varieties are Fuji, Gala, Golden, Red Delicious, Pink Lady, Ana and Granny Smith (Vigil Cannon, 2018). The characteristics of the fruit vary according to various intrinsic factors of the matrix such as the concentration of soluble solids, the percentage of acidity, the percentage of epicarp, the pH, among others, which define the state of maturity and other physicochemical and organoleptic factors of the fruit such as texture, color, flavors and odors (Corona Leo, Hernández Martínez, & Meza Márquez, 2020).

From the nutritional point of view, the apple represents a rich source of water (about 85 % of its total composition), soluble carbohydrates (fructose, glucose and sucrose) and insoluble carbohydrates (fiber); additionally, it presents within its composition micronutrients such as beta-carotene, tocopherol, folic acid and to a lesser extent ascorbic acid; in addition, the presence of potassium as its most representative mineral (Corona Leo et al., 2020; Pires et al., 2018).

Levels of consumption of apples worldwide are very varied. They are frequently consumed fresh and in foods which are subjected to low technological transformation such as jams, juices, compotes, jellies, and dehydrated products (Mignard et al., 2020). In Colombia, apples are primarily consumed fresh given the fact that more processed products are the often imported from powerful countries such as the United States and large apple producers such as Chile (Hernández Ruíz, 2017; Restrepo et al., 2014).

The market for dehydrated fruits in Colombia is in the process of development. Currently, products such as bananas, pineapples, and dehydrated uchuvas are available on the market, popularized due their intense flavors, bright colors, and long shelf life compared to their fresh counterparts (Fuentes Meléndez & Rondón López, 2019). However, the fried and/or dehydrated snack market typically only utilizes more conventional produce such as tubers (Potato, cassava and yam) or bananas, largely neglecting the use of other fruits (Chacón Orduz et al., 2017).

In Colombia, 59 % of the population consumes snack-type products within the context of entertainment, 38 % consume them in family gatherings and among friends, while the rest of the population does so to satisfy a craving or as a reward for a goal achieved throughout the day (Cámara de Comercio de Cali, 2018; Chacón Orduz et al., 2017). Therefore, dehydrated fruit products serve as a viable alternative for consumers (Ochoa Moreno & Ortigoza Micolta, 2018).

Immersion frying is a dehydration process commonly used in the food industry because it prolongs the shelf life of the products and confers pleasant organoleptic characteristics to the consumer’s palate (Torres et al., 2018). Among the pretreatments used in the preparation of snack-type products is the osmotic dehydration process, a technique that aims to decrease the initial moisture content in the fruits by means of mass transfer between the food matrix and a hypertonic solution (Acosta Castaño et al., 2020). This process consequently enhances specific flavors (Osorio Gutiérrez et al., 2020).

The use of vacuum pressure in the process of immersion frying fruit slices involves the following: low oil temperatures, as for example in the frying of mango slices according to Acosta Castaño et al. (2020); improvement of quality parameters such as color, texture, and organoleptic qualities, as highlighted by Chong, Mazzitelli, and Quintero (2019) in the frying of Taro slices; and, lower fat content, as in the frying of white carrot (Arracacia xanthorrizha Bancroft) according to Calderón Marcillo (2019). It also reduces adverse effects on oil quality, preserves natural colors and flavors, and preserves most of the nutritional compounds in the food matrix subjected to the immersion frying process (Yaranga Oncihuay, 2019).

The objective of this work is to evaluate the effect of osmotic dehydration as a pretreatment on apple slices subjected to immersion frying, proposing the response surface methodology as an optimization method where the factors were driving force (∆T ), system pressure (P ), and immersion time (t) and the response variables were moisture content, fat content, and color change.

METHODOLOGY

Raw material

To carry out the research, the raw material, apples of the variety Malus domestica, were obtained from a local market located in Manizales, Colombia. The fruits were examined to verify that they were free of physical damage and any type of contamination. In addition, the following physicochemical parameters were determined:

Soluble solids content

For the determination of soluble solids, the official method 932.12 of the AOAC was followed (AOAC, 2021). An Atago-brand digital refractometer, model PAL-1 (0-53 %), was used.

Color análisis

For the color analysis, a Konica Minolta model CM-5 colorimeter measuring CIE-L* a * b* color space was used according to the methodology proposed by (Lillote et al., 2021).

Moisture content

The moisture content was determined by means of the official method 930.15 of the AOAC (AOAC, 2021) in a Binder-brand natural convection oven, model ED053-UL.

Osmotic dehydration

The apples were processed in an industrial Omega brand slicer, taking a slice thickness of 2 ± 0.2 mm; from each of them pulp fragments were extracted with a punch of 29.4 mm diameter. The cylindrical samples obtained were then immersed in a solution containing 45 % sucrose (C12H22O11) and 1 % citric acid (C6H8O7).

The dehydration process was carried out at 20°C and 40°C, evaluating the dehydration kinetics on the apple slices during the times (min) 0, 5, 10, 15, 30, 45, 60, 90, 120, 180, 240 by performing moisture analysis and determining the percentage of soluble solids.

The defined response variables for osmotic dehydration of apple slices are listed below:

Immersion frying

The immersion frying process of the dehydrated apple samples was performed in a piece of equipment with 7 liters of capacity for oil. The product/oil ratio was 6.67 g/L [15]. The oil used was a blend of refined soybean oil, vegetable oils, and palm oil with antioxidant tertbutyl hydroquinone (TBHQ).

The defined response variables for osmotic dehydration of apple slices are listed below:

Moisture content

For the determination of moisture content, the protocol noted above in the determination of moisture content in raw material was again proposed.

Color análisis

The magnitude of the parameters L*; a*; b* was quantified according to the protocol proposed in the color analysis for raw material. Subsequently the color change (∆E) was determined

with (1) (Obregón & Obregón, 2019).

The ∆ of each of the coordinates consists of the comparison between the samples subjected to a certain treatment with the standard sample that corresponds to the fresh sample according to the color analysis carried out on the fresh sample.

Fat content

The fat content was determined according to the official method 920.39 of the AOAC in a Centricol-brand Soxhlet extraction apparatus with a capacity for 6 flasks and a Binder-brand natural convection oven, model ED053-UL.

Sensory analysis of apple snacks

They were analyzed by means of a hedonic test, with a scale of 5 points (where 1=I dislike it a lot and 5=I like it a lot). For this test we had the evaluation of 100 consumer judges, according to the methodology proposed by NTC 3925.

Statistical analysis

Osmotic dehydration

In order to determine the osmotic dehydration time for the apple slices, an analysis of variance was performed with a multiple range test, which was then used in the evaluation of the response variables established for osmotic dehydration.

Immersion frying

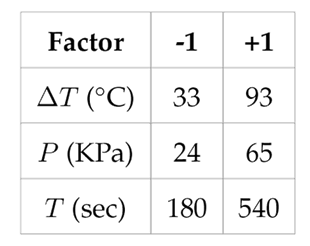

To determine the most statistically optimal immersion frying process of the apple slices, a response surface analysis was employed using a rotatable composite central design methodology. The data was then analyzed using the Statgraphics Centurion XVI software, where a 3-factor control system, ∆T (°C), P (absolute kPa), and t (s) was proposed. Relating ∆T accor-ding to (2).

This generates an array of 20 treatments (Chavez Salazar et al., 2017). Each response variable (Y) is generally estimated with (3).

Here, β i , from i: 0-9, corresponds to the coefficients estimated by each response variable analyzed based on the behavior of the temperature, immersion time, and pressure of the sys-tem during the process. The statistical optimization takes into account the effects and changes observed in each treatment on the response variables which emerged during the immersion frying process.

RESULTS

Raw material

Soluble solids concentration (17.13±1.00 ºBrix), moisture content (80.99±0.59 %), and color coordinates L* (24.23±0.98), a* (25.12±1.12), and b* (10.26±0.34) were determined. Measurements were performed in triplicate on different apples, randomly taken from the batch desig-nated for experimentation.

Osmotic dehydration

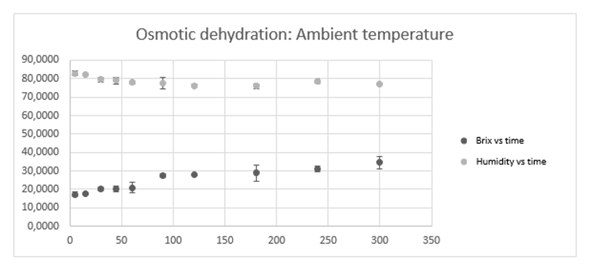

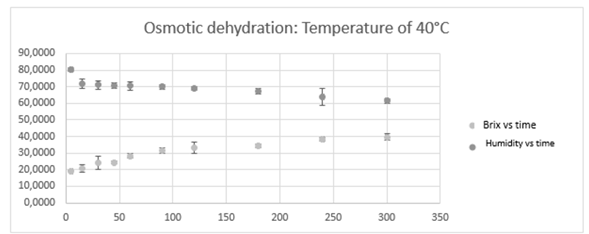

According to the results obtained, the osmotic dehydration process generated significant changes in the moisture and soluble solids content in the apple slices. Results revealed an increase of soluble solids in the matrix at 240 min of this process. Parallel to this, the moisture content decreased when the dehydration process reached the 240 min mark, at which point the maximum content of soluble solids within the matrix was achieved according to dehydration kinetics (See Figure 2 and Figure 3 ). In the analysis of variance conducted at both operating temperatures, p-values below 0.05 were obtained, thus inferring that the temperature and the immersion time are significant in the process. Additionally, a multirange test was administered which determined that there are significant differences between the temperatures and the time at which osmotic dehydration influences the composition of the samples, namely that a minimum time of 240 minutes at a temperature of 40°C is necessary to reach the máximum concentration of soluble solids in the dehydrated slices.

Similar results were reported by Estrada et al. (2018) who concluded from their study on processes of osmotic dehydration of mango and guava pieces that a sucrose solution at a concentration of 40 % w/w and a temperature of 80ºC is the best dehydration treatment for this type of food matrix. On the other hand, Osorio Gutiérrez et al. (2020) conducted dehydration processes using three different formulations of solutions (a solution with refined sugar, a sucrose solution-Jamaica extract, and an emulsion of Hi-Cap chili oleoresin starch and sucrose) in apple slices obtaining an increase in the mass transfer mechanisms at a temperature of 40ºC for the three formulations, further defining the constant immersion time of 120 min.

Immersion frying

The immersion frying process of osmotically dehydrated apple slices was performed considering the system pressure, immersion time, and driving force. The following response variables were analyzed: color change, moisture content, and fat content. Physically, the apple slices underwent a change that contributed to the sensory evaluation (taste, texture, and aroma) of palatability of the product; in addition to the shelf life of the product under standard conditions, that is, without requiring refrigeration or other conditions that preserve the conditions of the fresh fruit over time for the consumer.

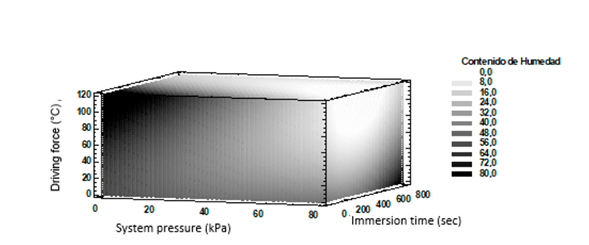

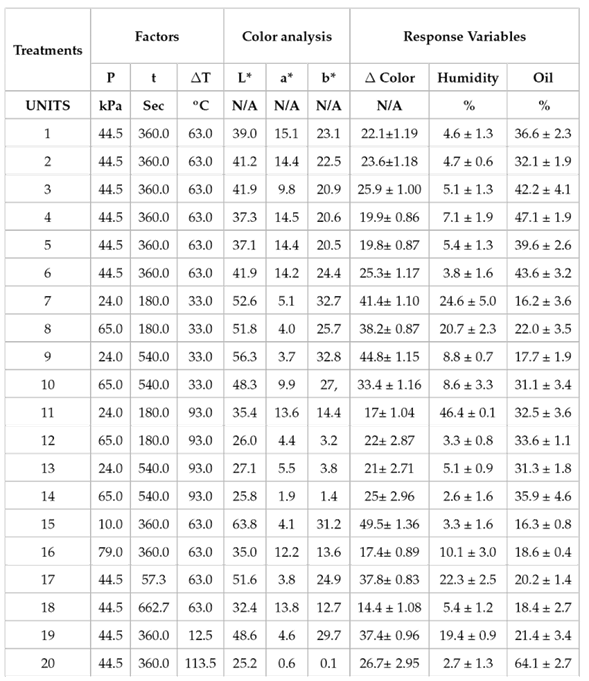

The mean values with their standard deviation and the ANOVA of the quality parameters of the fried apple slices as a function of the factors ∆T (°C), P (kPa absolute), and t (s) are shown in Table 2 and Table 3 respectively. Likewise, Figures 4, 5, and ?? present the behaviors in three dimensions of the response volumes of each quality parameter depending on independent variables or factors.

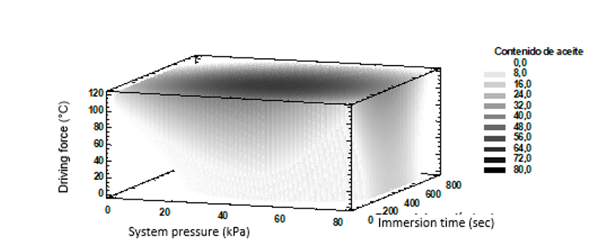

The behavior of the color change (∆E) presented significant differences with respect to the driving force ∆T (main effect) and independent term (constant) (see Table 3), fluctuating in average values between 17 and 49.5 (See Table 2). As Mendoza Hurtado and Mendoza Borges (2015) noted, there are certain ranges of appreciation of color changes: negligible (0,0 < ∆E < 0,5), slightly perceptible (0,5 < ∆E < 1,5), remarkable (1,5 < ∆E < 3,0), appreciable (3,0 < ∆E < 6,0), and very appreciable (∆E more than 6.0). Following this categorization, all simples of the 20 experimental treatments have very appreciable color changes. In Figure 3, it is evident that in the range of ∆T greater than 40°C, P greater than 40 kPa, and t below 800 s treatments with smaller color changes are presented.

According to the study by Pillajo et al. (2019), which involved vacuum immersion frying of mashua chips, the color behavior of the chips is mainly determined by the temperature of the frying medium. On the other hand, Acosta Castaño et al. (2020) point out that temperature is the determining variable in vacuum immersion frying of mango chips because the color change is mainly disturbed on the b* parameter. Consequently, the frying process at subatmospheric pressures with lower oil temperatures generates an alternative in the improvement of the organoleptic qualities related to the visual component of the product.

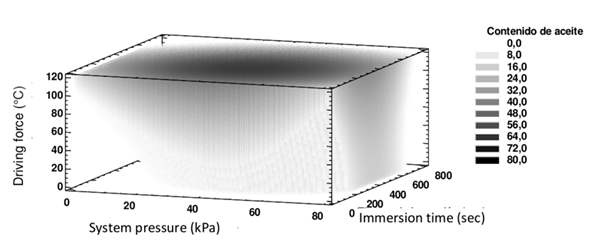

Regarding the moisture content, the parameters with significant differences as represented in Table 3 were the independent term (constant) and the immersion time (main effect); this parameter fluctuated between 2.6 % and 46.4 % (See Table 2). Likewise, according to Arrazola et al. (2021) the moisture contents of fried products, such as potato and yam, are 1.5 % to 3 % moisture, which aligns with some of the results presented in Table 2.

Table 3 ANOVA for osmo-dehydrated apple slices subjected to immersion frying

* Statistically significant parameter (p< 0.05)

Source: Own elaboration

Figure 4 illustrates low humidity in the apple snacks when subjected to pressure values above 20 kPa, driving force below 40°C, and immersion times below 600 s. It should be noted that some of the values of the response surface fall outside the range of average fluctuations; this may be due to the processing conditions in addition to the structural and chemical charac-teristics of the apples. However, Trejo Escobar et al. (2019) posit that the effect of the pressure and the immersion time of the potatoes in the fryer significantly affect the moisture content, concluding that the best operating conditions are sub-atmospheric pressures and low oil tem-peratures.

Regarding fat content, the most influential variables were the independent term (constant), ∆T (main effect and square effect), P (square effect) and t (square effect) (see Table 3). Additionally, the average values of fat content ranged between 16.2 % and 64.1 % (see Table 2). In Figure 5, the areas representing lower fat contents in the apple snacks correspond to system pressure values (20-60) kPa, driving forces above 80°C, and immersion time (100-600) s. The above behavior may be due to the osmotic dehydration pretreatment effect on the apple sli-ces. Some authors have reported results in the same trend: Gallon Bedoya (2017) in frying by vacuum immersion in potato, Acosta Castaño et al. (2020) in frying by vacuum immersion of mango, and Arteada Medina et al. (2019) in frying processes by vacuum immersion of lulo, where the matrices when subjected to a frying process at sub-atmospheric pressures generate products of low fat content and of more favorable organoleptic characteristics, typical of snacks such as the texture and/or crunchiness of the product.

Immersion frying with the use of low pressure differentials acts as a method of transformation and conservation of fried slices. However, the technique enhances its effect in matrices with low humidity (Dehghannya & Ngadi, 2021), which is the reason why osmotic dehydration stands out as a suitable technique for reducing water on apple slices. Furthermore, the technique allows for the formation of a film around the matrix, a phenomenon that prevents molecular disintegration and losses in frying operation yields, as reported by Arshied et al., (2021) in the osmotic dehydration of apple cubes.

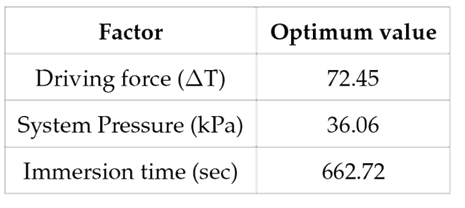

Finally,Table 4 summarizes the optimal values of the process conditions in obtaining apple snacks by vacuum immersion frying, where the moisture content, color change, and fat content are minimized with an impact of 3.0 each.

CONCLUSIONS

Osmotic dehydration as a pretreatment prior to immersion frying is a technique of interest for enhancing the organoleptic characteristics and the evaluable physicochemical characteristics or quality parameters of the final product, as well as for the preservation of the frying medium.

Taking into account the optimal values for frying determined from this course of study, ∆T (72°C), pressure (36 kPa) and time (663s), vacuum frying can be considered to be an agroindustrial transformation process suitable for dehydration in the production of fruit snacks since, by modifying the pressure of the operating system, the use of high temperatures in the oil is reduced. Monitoring system pressure and osmotic dehydration during the vacuum frying process of fried apple slices proves to be beneficial in terms of the enhanced sensorial value of the product as well as its increased shelf life.