Lemon balm (Melissa officinalis L.) is an essential and valued medicinal plant in national and international trade for its significant applications in the pharmaceutical and food industries. The genus Melissa is native to Europe and Asia, although it has also been found in the Mediterranean region (Abdellatif et al. 2021). It is a perennial plant belonging to the Lamiaceae family, measuring between 30 to 80 cm and presenting simple, quadrangular stems. Petiolate leaves characterize it, and when it reaches maturity, it exhibits a bloom with a color that can vary between white, pink, or blue (Waheed et al. 2019). This herb does not require much care and can proliferate, even in the wild, which allows it to spread worldwide (Kanatas et al. 2020). In Ecuador, as in Latin America, the practice of this crop occurs under altitudinal conditions from 1,800 to 3,356 meters above sea level (masl), tolerating an extensive range of conditions (low and high temperatures, low irrigation conditions, pests, among others), and adapting to humid temperate zones, warm and even in cold climates (Waheed et al. 2019).

On the other hand, Melissa is characterized by several therapeutic properties, which depend on the content and physicochemical compounds found in the final product. The therapeutic characteristics of this plant are in its leaves and are related to antioxidant, antimicrobial, anxiolytic, antidepressant, and anti-inflammatory properties (Sarkar et al. 2016). Fresh lemon balm herbs have been reported to contain phenolic compounds, l-ascorbic acid, carotenoids, flavonoids (rutin, luteolin, quercetin, cymaroside, and others), and terpenoids (Shamizi et al. 2022), which are responsible for such mechanisms. However, these depend on the post-harvest treatment given to the raw material.

With the above, lemon balm can be harvested anytime during its growth cycle. However, it is recommended to do so just before flowering for higher yield and operational quality (Avci and Giachino 2016). After harvesting, Melissa must be appropriately processed to ensure its quality and durability. Drying is one of the most common techniques for preserving aromatic and medicinal plants. The drying aim is to reduce the water content, decrease water activity, and prevent the growth of microorganisms and the oxidation of volatile components (Bonazzi and Dumoulin 2011; Shamizi et al. 2022). Conventional warm air drying typically involves low temperatures between 30 and 50 °C to protect active heat-sensitive ingredients (Argyropoulos and Müllera 2011). However, incorrect application of the method affects the quality of the dried product. For example, high drying temperature or prolonged drying time (DT) can lead to color deterioration and significant losses of essential oil (bioactive compounds) or other compounds (Arabhosseini et al. 2011). For this reason, it is common for producers to dry these plants in the shade to preserve the plant's chemical composition. However, at the industrial level, the drying process is affected by many factors, such as the size and composition of the feed, thermodynamic properties of the air, temperature, moisture, and dry air velocity (DAV) (Oyinloye and Yoon 2020). In the latter, temperature and DAV are the main parameters of this process, as they influence the drying kinetics and the dried product's physicochemical, microbiological, and sensory properties (Levate et al. 2020).

In the scientific literature, the application of drying in different medicinal plants has recently been studied (Ahmed and Langthasa 2022; Torki-Harchegani et al. 2016), but of these, a few studies deal with Melissa with applications on antioxidant activity, physicochemical, and microstructural properties (Argyropoulos and Müllera 2011; Shamekhi-Amiri et al. 2018; Shamizi et al. 2022). Therefore, the influence of tray drying on lemon balm and the quality properties of the product obtained is not well known, especially in developing countries. As a result, this has led to non-compliance with market requirements and, consequently, a lack of development in the tea industry. For this reason, this study aimed to evaluate the effect of tray drying parameters on the physicochemical, microbiological, and sensory properties of lemon balm to determine the best drying condition for bulk tea production. In the latter, different gradients of time, temperature, and drying air were tested through forced convection conditions. It's expected that the results obtained will allow a better understanding of the lemon balm drying process, which will be especially useful for the dehydrated industry.

MATERIALS AND METHODS

Raw Materials

Lemon balm plants were collected before flowering at a farm in Otavalo, Ecuador. The leaves were separated from the stems, and visual impurities were removed. The plant material was stored at 2 °C in a refrigerator for subsequent drying trials. Before conducting the experiments, the lemon balm plants underwent a selection, classification, and disinfection process (sanitization with distilled water and white acetic acid). Finally, the lemon balm leaves went through a standardization process according to the method proposed by Buitrago-Zapata et al. (2018) to subsequently proceed to perform the drying process.

Drying method and construction of the drying curves

Lemon balm leaves were dehydrated in an electric convective tray dryer. The dryer has a design with a fan and four electric heaters and is equipped with temperature and air velocity controls. The dehydration process was carried out under the criteria of Tinebra et al. (2022), under the forced air-drying method. Initially, fresh lemon balm leaves had a moisture content of about 80%, but after the drying process, they reached a final moisture content of around 12%, which is the value recommended by NTE INEN 2392:2017 for storing dried Melissa. To elaborate on the drying kinetics, the Page model was used (equation 1), which is the most widely used statistical model to describe the drying process in plants.

Where κ is the drying constant (min-1), η the function coefficient and t is the drying time in minutes. In the model, MR represents the relative water content as a function of time and is calculated from equation 2.

In the equation 2, Mt represents the moisture content at time t, Mo is the initial moisture content, and Me is the equilibrium moisture (kg water. kg dry matter-1). However, since the values of Me are relatively low and do not affect the calculation, the equation can be simplified as equation 3:

Drying data were recorded at 0.5 h intervals until equilibrium moisture content was achieved for each drying condition, measured by constant product mass. This process was conducted to describe the thermodynamic effect of the drying process on the moisture content, which is responsible for the loss of volatile compounds and essential oils (loss of quality) of the raw material.

Experimental Desing

The operating parameters were selected according to the guidelines of Fiestas et al. (2014) as well as NTE INEN 2392:2017. The experimental phase was developed based on the research by Tinebra et al. (2022) through a randomized factorial design. The design was delimited and constructed, referencing the guidelines of Casler (2015) and Trujillo-Echeverria et al. (2020). The study variables were selected based on the scientific studies by Badmus et al. (2019), which report that the drying method and parameters significantly influence the quality of the raw material (as the final product). In particular, evidence suggests that i ) the same drying technique can produce different color changes according to the time-temperature-moisture gradient used for drying (Petikirige et al. 2022), ii ) quality parameters (e.g., physicochemical, sensory, nutritional, microbiological, functional, and other characteristics) may vary according to the characteristics of each product, and iii ) microstructural profiles may be modified as a result of enzymatic reactions, structural alterations and other reactions inherent to the operation (Bonazzi and Dumoulin 2011; Oyinloye and Yoon 2020). For this reason, physicochemical (including lead, cadmium, moisture, ash insoluble, and essential oil [EO] yield), microbiological (Escherichia Coli, Salmonella, Bacillus cereus, and Clostridium Perfringens), and sensory characteristics of lemon balm were taken as response parameters. The same treatments were used to construct the drying curves (Table 1). For the sensory analysis, the design was developed under nonparametric statistics given, the measurement characteristics, and assumptions of the model (normality and homoscedasticity). The experimental model and levels of the independent factors are given in Table 1.

The experimental design suggested 12 experimental units for two factors at four levels in triplicate. All the response data from the proposed experiments were expressed in a generalized polynomial equation, as shown in equation 4:

Where γIJK represents the response variable obtained from the k-th (k=1,…, n) replicate receiving the i-th level of A and the j-th level of B; n is the number of replicates for each of the AxB treatment groups; μ is the overall grand mean of γ; αi is the effect of the i-th level of factor A(∑i i =1, ..., a); βj is the effect of the j-th level of factor B(∑j j=1, ..., b); αiβj is the effect of the interaction between factors A and B; εijk is the random effect error attributable to the ijk-th individual observation.

Determination of response variables

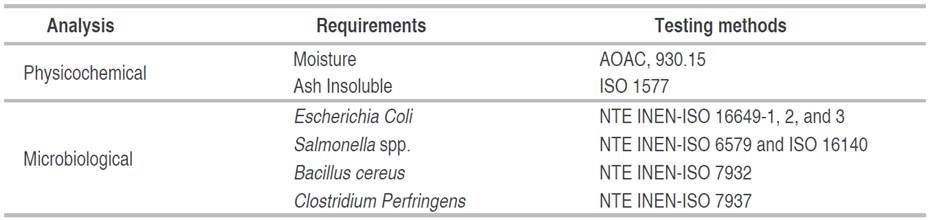

Determination of physicochemical and microbiological composition

The physicochemical and microbiological properties of lemon balm were evaluated in the raw material and the finished product. After drying, the samples were ground for further analysis. For the physicochemical analyses, samples of 0.5-5 g were weighed for each test. For microbiological analysis, the guidelines by Passafiume et al. (2021) were followed, preparing solutions 1:10. The solutions had 10 g of Lemon balm and 90 mL of sodium chloride solution. The samples were homogenized to identify the main microbial groups belonging to decomposition and pathogenic populations. Quantification was performed by plate count following ISO standards for each microorganism. The technical standard used for this process was NTE INEN 2392:2017. The methods used to quantify these components are detailed in Table 2. All the results of the physicochemical analyses were expressed on a dry weight basis (db), unlike moisture, which was expressed on a wet basis (wb).

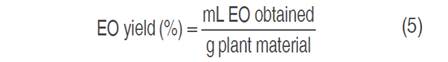

On the other hand, lemon balm EO was obtained by hydrodistillation following the approach proposed by Trujillo-Echeverria et al. (2020). The particle size for the extraction process was 0.3 mm, and the solute-solvent ratio was 1:15 (w v-1). The EO yield was calculated from equation 5:

Colorimetric analysis was performed to determine the color values of dried lemon balm. A Minolta model Chroma-400 digital colorimeter was used. Calibration of the colorimeter was performed with black and white mosaics before each measurement. The color parameters L, a*, and b* (brightness: L*, red/greenish: a*, yellowish/bluish: b*) were evaluated under the CIELAB system.

Sensorial evaluation

This research was evaluated under a sample of 102 consumers for each test. The number of panelists was selected according to the guidelines by Singh-Ackbarali and Maharaj (2014). The sampling used to select the consumer panel was stratified sampling (Kemp et al. 2011). To assess acceptability, the consumer had to at least: a) be of legal age, b) have no medical impairment, c) have consumed hot beverages at least once in their life, and d) their herbal tea consumption preference was hot tea without sugar. The methodology was employed from the hedonic rating scale (5 points) under the subjective parameters using the acceptability test type (Kemp et al. 2011; Saint-Denis 2018). The aspects being evaluated were flavor and aroma under the taster's appreciation (1: Dislike a lot, 2: I don't like, 3: Neither like nor dislike, 4: I like, and 5: I like a lot). These sensory attributes were chosen because they are decisive factors for buyers when choosing a product, first because of the positive impression (appearance, branding/packaging, color, flavor, texture, others) required to generate the product towards consumers and, second, for the mechanisms (psychological and physiological) it needs to influence the purchase decision (Chen and Lin 2018). This test aimed to improve or optimize the tea as a commercial product, based on knowing and perfecting the desirable aspects (liking scores) for the consumer.

Statistical analysis

All the results measured in the study were taken in triplicate and shown as mean ± standard deviation (SD) for quantitative data and as counts and percentages for qualitative data. The experimental results were subjected to Shapiro-Wilk and Levene tests to verify the normality and homoscedasticity of the data (population distribution). In this way, an analysis of variance (ADEVA) was carried out at 95% reliability, using a design with factorial interactions AxB. Only for sensory analysis, the Friedman test was used with a significance level of 5%. Differences of means were told significantly when P<0.05 for the Tukey test. The degree of fit for the model was determined using the coefficient of determination (R2) and the root mean square error (RMSE). The statistical software R v.4.3.0 was used for the analysis.

RESULTS AND DISCUSSION

Drying kinetics

Figure 1 shows the variation of moisture content of lemon balm leaves during the drying process at different temperatures and DAV. Initially, the process started with a moisture content of 80.25%, but during the first hour, the free water was rapidly evaporated by the action of heat (Figure 1). Approximately 2.5 h were required to reach equilibrium moisture content. In addition, the DT decreased when the air velocity increased from 1.5 to 3 m s-1, which means that at higher air velocities, the water evaporation rate from the food increased, reducing DT. Some studies have described that increasing temperature can decrease DT (Pasławska et al. 2020; Rudy et al. 2020); however, this study shows that the effectiveness of DAV in reducing DT has a significantly greater impact than increasing temperature alone. This is probably because, during the drying process, the surface water evaporates first since it is more affected by the DAV (Silverira et al. 2019). In such a way, with the elimination of surface water, heat stimulates the structure of the raw material by convection until it reaches the deepest parts of it (capillarity), which causes the drying rate to increase due to the diffusion of the liquid (which is more influenced by the temperature of the DAV), thus inducing the accelerated release of bound water in the product matrix (Chong et al. 2021). However, this reinforces the existence of a proportional relationship between temperature and DAV, although this behavior may also depend on other factors (dryer type, tray material, perforation diameter, raw material-tray interfacial contact, others) related to the drying process (Argyropoulos and Müllera 2011; Shamekhi-Amiri et al. 2018).

At this point, it is also worth mentioning that the increase in temperature and DAV shortened the convection drying time by approximately 44.44%. This result was comparable to those obtained by Łyczko et al. (2019) in Lavender leaves and Rudy et al. (2020) in Dracocephalum moldavica leaves, with a DT reduction of 43.75 and 45%, respectively, but higher than those reported for the lemon thyme (Pasławska et al. 2020). Nevertheless, it was observed that as the drying process progressed, the DAV decreased about the decrease in humidity but was compensated by the temperature gradient. This phenomenon could be explained by the Darcy-type pressure diffusion mechanism according to Fick's law (Łyczko et al. 2019).

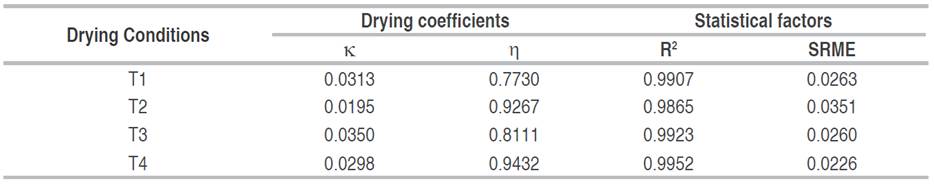

On the other hand, the results obtained from modeling using the Page model for the different drying conditions are described in Figure 2 and Table 3. In general, for all drying conditions, the RMSE values were relatively low (<0.04), while for R2 the values were high (>0.98). Treatment four showed the best results for the statistical model. The high values of the coefficients (R2 and RMSE) imply good predictive variability between the experimental data and the model. Therefore, the Page model has a good adaptation to predict the drying kinetics of lemon balm leaves. Several studies that address the modeling of the drying process of lemon balm leaves and other varieties, using various techniques, have reported similar results (Chua et al. 2019; Levate et al. 2020), demonstrating the reliability of the model.

Table 3 Results of the coefficients and constants of the Page model for lemon balm leaves' drying process (kinetics).

As well as the calculation of R and RMSE in this study, it was observed that the parameters κ and η of the Page model increased as the temperature and DAV varied. In particular, the increase in η was related to the rise in DAV, while κ was related to the temperature gradient, as explained by other studies (dos Santos et al. 2017; Levate et al. 2020). However, this could also be explained by the fact that the parameter κ affects the external drying conditions and the parameter η on the internal drying conditions. In fact, from what has been reviewed, this would be the first study that demonstrates that DAV is related to the internal conditions of the drying process. However, more studies would need to be conducted to confirm this hypothesis.

Determination of physicochemical and microbiological composition

Before proceeding to the dehydration of fresh lemon balm, physicochemical and microbiological characterization of the samples of the treatments was carried out. By operational standardization, i.e., based on diameter, all samples were classified with the following characteristics: leaf width averaged 2.8±0.12 cm, leaf length 3.91±0.6 cm, petiole diameter 0.13±0.2 cm, and petiole length 2.58±0.98 cm. Leaves were heart-shaped with toothed margins, green foliage, and a characteristic lime, lemon, or grapefruit aroma. Such attributes were essential to developing the dehydration process, and their results were like those reported in other research (Buitrago-Zapata et al. 2018).

In contrast, the results obtained for the physicochemical characteristics of fresh and dried lemon balm are presented in Tables 4 and 5. Fresh lemon balm leaves presented the highest values in humidity, ash, and aw (Table 4), while the highest values in EO in dried Melissa leaves. On average, after the drying process, the moisture had a value of 11.05±0.53% (wb), the ash content was determined at 0.38±0.09%, the aw was established at 0.49±0.57, and the EO yield was 1.18±0.07%. The values above were within the range requested by NTE INEN 2392:2017 and other studies (Argyropoulos and Müllera 2011, 2014). Significant differences (P<0.05) existed for both factors and interactions in moisture, % EO, and ash, but no differences were found for aw and factor B of ash (Table 5).

For fresh leaves, moisture fluctuation was attributed to sample handling, post-harvest resting time, sample collection, and storage methodology (Padilla et al. 2018). The variation in ash is due to the degree of soil contamination by limestone, dicalcium phosphate particles, and pesticides, which could directly impact this quality parameter. Although, the variations could also be related to specific crop processes, i.e., postharvest and storage, to name a few (Gordanić et al. 2021; Németh-Zámboriné et al. 2019).

In the case of the factors, the a0 and b0 levels proved to be the most appropriate parameters to achieve lower moisture, aw, and ash but better EO yields (Table 5). Regarding moisture and aw, the increase in temperature resulting from higher drying velocity reduces the moisture content, aw, enzyme activity, and DT (Chasiotis et al. 2021). However, the variation in ash content after tray drying is due to the reduction of contaminants (soil, dust, stones, others) resulting from the disinfection process, although it may also be related to the presence of trace contaminants of earthy and environmental material, which are difficult to remove (Mukherjee 2019; Garba and Oviosa 2019). On the other hand, the differences in EO content are believed to be during vapor extraction, where the evaporated water and other volatilized substances are expelled from the drying chamber (Trujillo-Echeverria et al. 2020). Nevertheless, there are other factors, such as the solute/solvent ratio, particle size, solvent polarity, and interfacial contact between the plant matrix and the mechanism performed by the solvent to break the cell walls to extract these compounds, which may be related to the increased yield and higher concentration of lipophilic secondary metabolites (Dulo et al. 2023; Sridhar et al. 2021; Trujillo-Echeverria et al. 2020). Despite this, variations in all compounds of dehydrated lemon balm would be subject to operational variations [including variability of time, DAV, temperature, drying method, and industrial design, among others] (Argyropoulos and Müller 2014), morphological and physiological variations of the crop [e.g., the origin of samples, sowing and harvesting time, fertigation, irrigation, and crop rotation] (Gordanić et al. 2021; Németh-Zámboriné et al. 2019).

As a result, the effect of drying parameters is inversely proportional to the physicochemical content of horticultural products. The drying process has a positive effect on increasing the shelf life of lemon balm (Bonazzi and Dumoulin 2011). The glass transitions produced by the drying process affect the quality of dehydrated foods (Badmus et al. 2019). Suitable conditions of temperature and DAV allow for obtaining desorption isotherms in equilibrium within the drying process (Chakraverty and Singh 2014). This means that a given variation of the temperature- DAV-drying time gradients can cause proportional changes in the physicochemical characteristics of the dehydrated food (determined as a hygroscopic solid), which would directly affect the quality and specifics of the final product (e.g., nutritional content, rehydration, and enzyme activity to name a few).

According to Tukey's test at a 95% confidence level, dried Lemon balm physicochemical compounds content was partially significantly different between treatments, except for the a w, which is directly related to the isothermal process of the drying process. Consequently, treatment T4 offers the best characteristics for the final product, demonstrating that, as with the factors, these characteristics are related since their behavior lasts until the end of the process.

Microbiological analysis

Table 6 shows the total bacteria count in fresh and dried lemon balm leaves. The results show that the bacteriological count value was within the range requested by NTE INEN 2392:2017 (Table 6). No significant differences were found. In the raw material, the presence of pathogens was attributed to the use of organic fertilizers such as cow (or another animal) manure or the use of contaminated water for cultivation (Gómez-Ramirez et al. 2021). However, the lack of controls in the harvesting, post-harvest, storage, and transportation process could also be related to these microorganisms or, even worse, to foodborne diseases (Gallo et al. 2020; Gil et al. 2015).

On the other hand, the absence of microorganisms is attributable to the drying process, which reduces the percentage of moisture and free water necessary for the proliferation and survival of microorganisms (Tinebra et al. 2022). However, the disinfection and sanitization process before drying may have also contributed to the reduction of the microbiological load. Now, although the product is within the parameters by the standard, precautions should be taken with Bacillus cereus because it is a highly resistant pathogen; it is present in dust, as well as in the soil, being able to survive in pH media of 4.9-9.3 and even saline solutions of 7%. In addition, it can develop without problems under temperatures from 4 to 48 °C, so it must be kept under quality control in storage to avoid contamination or exposure to bacterial diseases in the consumer (Gil et al. 2015). This should also be considered with other microorganisms since they are characteristic pathogens of these foods.

Color Characteristics

Table 7 shows the results of the average color of the dried leaves of lemon balm. The results were like those obtained by Argyropoulos and Müller (2014). The color analysis was done as additional information to the test of acceptability since it is an essential parameter in consumer decision-making during purchase (Chen and Lin 2018). In addition, the influence of the drying process on the physical characteristics (color of the final product) of the dehydrated lemon balm was studied to evaluate the impact on the technological quality of the final product.

In this study, the lightness value decreased (P<5%) with increasing drying temperature. a* and b* of the surface of dried lemon balm leaves decreased significantly (P<0.05), which was attributed to non-enzymatic browning (Oliveira et al. 2016). Greater color degradation was observed at temperatures above 45 °C and dry air velocities below 1.5 m s-1, indicating undesirable color changes. The color parameters are improved by increasing the rate of dry airflow due to the increased interfacial contact of the solid with the temperature and the accelerated evacuation of the condensate in the drying chamber.

In general, changes in the color properties of a dried food depend on several physicochemical alterations during the drying process. For example, during food processing with heat treatments, color change is assumed to occur by different processes, such as pigment degradation, ascorbic acid oxidation, and Maillard reaction (Sturm and Hensel 2017). In this study, the color alteration was affected by carotenoid degradation and chlorophyll transformation in lemon balm leaves.

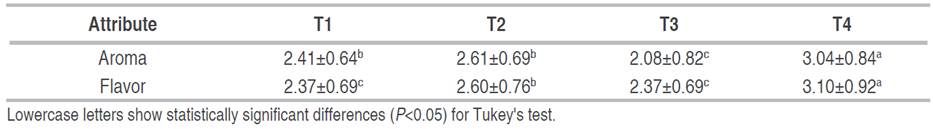

Sensory analysis

A sensory analysis of the dehydrated lemon balm tea was conducted by a panel of 102 consumers. Most of the participants were men (63%). The mean age of the participants was 31.64±14.78 years (range: 19-60). Table 8 shows the scores obtained for each attribute evaluated. Throughout the experiment, the descriptors that consistently scored the highest in terms of aroma and flavor were "neither like nor dislike" and "I don't like," while the phrases "I like a lot" and "I like" received the lowest scores. It was found that various consumers had varying degrees of acceptability for lemon balm teas, with a statistically significant difference (P<0.05) observed. The tea samples that consumers liked the most were those of the T4 treatment. The obtained results were like those obtained by da Silveira et al. (2022). When compared to other types of tea, the sensory analysis of lemon balm tea is a subject that has been studied truly little. No additional studies that evaluate the sensory aspects of lemon balm were discovered.

Table 8 Consumer acceptability scores of lemon balm tea in its organoleptic aroma and flavor characteristics.

Despite these, it is believed that the differences found would be related to various compounds (polyphenolics, antioxidants, flavonoids, and others) and the formation of aromatic substances (Wang et al. 2022), which combine synergistically to produce good aroma and flavor. In this regard, Tang et al. (2020) reported that the attributes of sweetness, bitterness, and astringency were related to the content of polyphenols, flavonoids, amino acids, and triterpenes. The results obtained would support these findings, as the EO content was high, suggesting a direct relationship between these factors. In addition, in the tasting sessions, consumers mentioned descriptives such as lemon aroma, citrus aroma, herbal aroma, fruity aroma, sweet flavor, bitter flavor, and sour flavor, among others, which would agree with such findings. Nevertheless, other factors responsible for modifying the sensory attributes to consider are crop characteristics, dehydration processes, and preparation of tea (Cárdenas-Mazón et al. 2018).

Lastly, it would be important to conduct more studies to support this hypothesis and increase the consumption of lemon balm tea, especially since lemon balm has been reported to have many beneficial activities for the human body (Petrisor et al. 2022).

CONCLUSION

The findings obtained in this study show that drying parameters have a significant impact on the overall quality of lemon balm and the drying process. Samples dried at 45 °C and 3.0 m s-1 achieved lower moisture, aw, and ash but higher EO yields. The high values obtained in EO were attributed to the particle size (0.03 mm) and the solute-solvent ratio (1:15 w v-1) used in the hydrodistillation process. No like this, crop-specific processes (crop management, postharvest, storage, and food processing, among others) can alter the physicochemical, microbiological, and sensory characteristics of Lemon balm. From the sensory point of view, when the temperature exceeds 45 °C and the dry air velocity is below 1.5 m s-1, there is a decrease in lightness, color degradation occurs, and enzymatic reactions alter the a* and b* parameters of the instrumental color. The T4 treatment has resulted in the most preferred tea among consumers. In the drying process, it was observed that temperature has a greater effect in the initial stages of the process, which allows the surface water of the feed matrix to evaporate at a faster rate, while DAV stimulates the internal structure of the raw material by capillarity and diffusion, thus increasing the drying rate and significantly decreasing the drying time. In fact, when the DAV is increased from 1.5 to 3.0 m s-1, the DT decreases by approximately 44%, something that does not happen with increasing temperature alone. Page's model demonstrated an excellent ability to predict drying kinetics under various drying conditions (RMSE <0.04 and R2 >0.98). The findings of this study provide a theoretical basis for optimization of the drying process and improving the quality of the final product. The future perspective is to continuously improve the drying process of herbs, fruits, and vegetables through the optimization of the drying parameters and non-invasive technological systems or chemometric models (predictive algorithms) that allow monitoring or controlling the physicochemical, microbiological, and sensory quality of the final products. More research is needed on the interaction of bioactive compounds and sensory attributes to obtain products with high-quality pharmacological effects oriented to the final consumer.