INTRODUCTION

Rutting is one of the main damage mechanisms of asphalt layers in asphalt pavements [1-13]. This phenomenon is the permanent vertical displacement or deformation that accumulates in pavement due to the repetitive passing of vehicles, which causes the formation of thin longitudinal depressions throughout the trajectory of tires (see Figure 1), together with the lateral dilation of the asphalt mixture [14]. This can generate structural or functional failures (serviceability level reduction in the roadway, accidents associated to hydroplaning or sliding in rainy days) in pavement, which can occur in any layer of the structure (subgrade, subbase, base and asphalt layer) [10, 15]. However, researchers such as [16-17] have demonstrated that the greater part of rutting occurs in the asphalt layer.

The overall rutting depth is composed of loss of materials, densification and lateral plastic flow [18]. According to [2, 6, 19-22], the phenomenon of rutting in asphalt mixtures occurs mainly because of densification during construction and the apparition of shear deformations during the useful life of pavement. [23] reports, based on studies conducted by AASHO (American Association of State Highway Officials) in 1962 and on real scale tests, that from the total of rutting the greater component is shear. A similar observation is found in [24-27]. [28-29] mention that permanent deformation in asphalt mixtures, measured in laboratory tests under cyclic load, occurs in three phases. On the first phase, deformation is rapidly accumulated as a product of densification in the asphalt layer caused by initial loads. In this phase, the aggregate in the mixtures helps to generate deformation mainly because of particle rearrangement caused by the densification of material (reducing air voids' content). On a second phase, the deformation rate is reduced and reaches a constant value. However, in this phase, microcracks begin to occur and the material starts to lose stiffness. With the continuation of cyclic loads, microcracks gradually propagate and join, forming macrocracks and giving rise to the appearance of the third phase, in which the rate of deformation increases and rapidly accumulates deformation. The first two described phases have been broadly reported by other researchers [30]. In situ, pavement rutting increases within the first years of operation and then stabilizes with time. In general, resilient deformation remains constant while permanent deformation is reduced with the number of load cycles [31]. [32] propose, based on the computer simulation on finite elements and on the studies carried out by [22, 33], four states in the generation of rutting: 1) densification caused by further traffic compaction; 2) apparition of shear deformations and a slip plane under the edge of the tire (hump initiation) as a combined product of the reduction in asphalt mixture shear strength with high pavement temperature and of the repeated action of traffic loads; 3) the critical global shear plane continues to slip, humps continue to develop, and permanent deformation increases up to a maximum rut depth; 4) continued instability ceases to result in an increase in rut depth, but instead results in a broadened rut basin as traffic wander compacts or moves the dilated portion of the mixture.

Understanding the way this damage mechanism occurs in asphalt pavement is a complex task. This is because there are multiple variables that influence its origination. Additionally, most studies on the subject are carried out within a laboratory and extrapolating these results to those obtained on a real scale increases the degree of complexity. Despite the broad number of studies carried out on the subject, there is not yet a definitive model that characterizes and predicts rutting resistance in asphalt mixtures in service. This article presents and describes, in summary, the most significant variables that influence the generation of this damage mechanism in asphalt mixtures. Likewise, the simplified equations most used for predicting the accumulation of permanent deformation in asphalt mixtures is presented. The information presented in this article can serve as a source for consultation for researchers that develop constitutive equations and regression models associated to the phenomenon of rutting in asphalt mixtures.

1. FACTORS THAT AFFECT RUTTING RESISTANCE

According to [34], rutting is mainly affected by three factors: mix (gradation, geometry and type of aggregate, and asphalt type and content), load (tire pressure, type of axis), and environment (temperature, moisture, precipitation). Predicting this phenomenon in asphalt mixtures is generally attempted by controlling its stiffness. In Table 1, the three main factors that affect rutting in asphalt mixtures are summarized.

Table 1 Factors that affect rutting in asphalt mixtures [19]

| Factor | Change in factor | Rutting resistance | |

|---|---|---|---|

| Aggregate | Surface texture | Smooth to rough | Increases |

| Geometry | Round to angular | Increases | |

| Size | Increase in maximum size | Increases | |

| Asphalt | Stiffness | Increase | Increases |

| Mixture | Asphalt content | Increase | Decreases |

| Air voids content | Increase | Decreases | |

| Compaction degree | Increase | Increases | |

| In-situ conditions | Temperature | Increase | Decreases |

| Stress or strain | Increase | Decreases | |

| Load repetition | Increase | Decreases | |

| Water | Dry to wet | Decreases |

1.1 Load

It has been broadly acknowledged that the accumulation of permanent deformation in asphalt mixtures increases with load magnitude [1, 4, 7, 12, 25, 34 - 44], and decreases with confinement pressure [45 - 46]. On the other hand, the type and form of vehicle tires influences the rutting phenomenon, given that the load distribution on the pavement is different depending on the tire used [27, 47]. [7] points out that, based on the analysis of damage mechanisms of multiple in-service pavements, trucks with simple or tandem load axis generate greater fatigue cracking than those that are tridem or greater. On the contrary, they conclude that the greatest vertical permanent deformations are generated by vehicles that distribute their load in tridem or greater axis.

The accumulation of rutting is also a function of load velocity. The greater the velocity, the less deformation in the asphalt mix [4, 48]. [3], conducting simulations in the finite element program ABAQUS and in real scale tests, report that the vertical deformation when a vehicle passes by at 20 km/h is twice as great as when it passes by at 90 km/h. [49] conclude that deformation caused by a vehicle at 10 cm/s is equivalent to that caused by 10 vehicles with the same load passing at 100 cm/s. [50] conducted simulations in ABAQUS for a pavement structure comprised of 17 cm of asphalt layer and 40 cm of base and subbase. They used the elasto-visco-plastic equation for simulations and concluded that the rutting phenomenon decreases in pavement if load velocity increases. Likewise, they observed an increase of 100% in permanent deformations when load velocity was reduced from 60 to 10 km/h.

1.2 Temperature

The behavior of an asphalt mix can be considered elastic at low temperatures and/ or high load velocities. At medium and high temperatures, elastic equations lead to underestimated pavement responses [51]. These materials display a visco-elastic or purely viscous behavior at high temperatures and/or when loads are applied at small velocities. Therefore, in general, the total deformation of an asphalt mixture under cyclic load is divided into one elastic component, a viscoelastic and a viscoplastic component. In general, the referenced literature reports that an increase in temperature generates a decrease in the stiffness of asphalt mixtures, increasing the susceptibility to the rutting phenomenon [1, 4, 12, 23, 34, 43, 45 - 46, 49, 52 - 58]. Therefore, rutting occurs mainly during the summer [59-61].

1.3 Density and Compaction

It is generally reported that an increase in density generates a decrease in susceptibility to rutting in asphalt mixtures [19, 31, 59]. According to [34], two samples with the same air content can undergo different responses to permanent deformation, given that void arrangement can differ when different compaction methods are used. [52] mentions that the construction of asphalt layers in cold climates may lead on occasion to low compaction densities in the mix, which results in a reduction in rutting resistance. [56, 62 - 63] report that the Marshall impact compaction method for asphalt mixtures within the laboratory is not suitable for evaluating the degree of rutting susceptibility in in-situ asphalt mixtures, given that in-situ compaction is done through kneading. [56, 64] compacted samples of an asphalt mixture using the Marshall method and the one recommended by SUPERAVE (gyratory compactor). They found significant differences in permanent deformation and resilient modulus measurements. Apparently, mixes designed through the SUPERAVE method offer more resistance to permanent deformation and stiffness than those designed through the Marshall method. [65] investigated the effect on resistance to permanent deformation by compacting three asphalt mixtures (of a similar volumetric composition) with four compaction modes: gyratory, vibratory, and roller. They concluded that the asphalt samples manufactured with a gyratory compactor and using a vibratory hammer in the laboratory generate more stiff mixes with greater resistance to permanent deformation compared to those compacted with a roller. This is perhaps due to the influence of confinement in molds used for compacting samples. According to [66], in situ, a great part of the accumulation of permanent deformation is due to an inadequate compaction of asphalt layers. In situ, the compaction method is different from that in the laboratory. The mixtures are compacted by kneading and the density achieved depends on multiple factors such as the weight and type of the compacting equipment, the boundary conditions, the stiffness of the platform, among others. In general terms, the tendency of the mixtures manufactured in the laboratory is to be stiffer and show greater resistance to permanent deformation than those compacted with a roller and in situ. As it was mentioned above, this might be caused by the confinement of the molds used to compact the samples in the laboratory [14, 65 - 66].

1.4 Aggregate and Asphalt

According to [67], gradation has a higher impact on minimizing rutting in asphalt mixtures when compared to improving or modifying the asphalt. According to [19, 68 - 69], aggregates with dense gradations and a coarse texture are desirable for controlling the rutting phenomenon. [70 - 71] mention that mixes manufactured with aggregates that have coarse gradations help to increase rutting resistance. However, [72] state that mixes manufactured with intermediate gradations have greater rutting resistance than those made with coarse gradations, because mixes using aggregates with coarse gradations are more difficult to compact. Apparently, the use of aggregates with greater particle size helps to reduce rutting potential in asphalt mixtures subjected to high load pressures [73]. An excess in the content of fine granular particles in the asphalt mixture can result in a significant reduction in rutting resistance [12,52,74]. However, [75] observed that, based on indirect tensile rests, there is an increase in permanent deformation resistance when the content of fine particles is increased between 2% and 10%. Additionally, they conclude that increasing the filler makes mixes more susceptible to moisture and, therefore, these tend to reduce their resistance to rutting when in the presence of water. [76] mention that asphalt mixtures manufactured with aggregates that have a high presence of sand particle sizes are more susceptible to the phenomenon of rutting. It appears that mixes manufactured with aggregates that have angular faces obtained through crushing processes develop less deformation under cyclic load than mixes manufactured with the same particle size distribution, but using aggregates with rounded faces [52, 74, 77 - 80]. A similar observation was registered by [9], but they clarify that the effect of fractured faces is greater as the asphalt is less stiff. [81] discovered, through a micro-structural simulation, that angular aggregates within the asphalt mixture generate a better interconnection of aggregates, which results in an increase in stiffness. [82,83] obtained the same conclusion by running a computer simulation with discrete elements method (DEM) in 3D.

In general terms, an increase in the accumulation of permanent deformation is reported as the air voids increase in the asphalt mixture. [12, 45, 84 - 85]. Asphalt mixtures increase their stiffness and, therefore, their rutting resistance as the content of air voids decreases and the content of particles with angular or fractured faces increases [19, 86 - 87]. [88] indicated, however, that a reduction in air void content, which is the product of an overuse of asphalt binder, increases the potential for rutting in asphalt mixtures. In other words, a reduction of air void contents actually reduces the potential for rutting, as long as said voids are filled with optimal asphalt contents and it is not an excessive increase, given that using excess binder produces important deformations [12, 34, 52, 74, 89].

Low viscosity asphalts generate less stiff asphalt mixtures, which are more susceptible to deformation under cyclic load [88, 90]. [91], based on Wheel Tracking type tests, observed that asphalts that are less penetrable and that have a greater softening point generate mixes less susceptible to rutting. [46, 70] concluded that increasing the PG range of asphalt generates mixes that are more resistant to the phenomenon of accumulating permanent deformations. In general, mixes that used modified asphalts display less rutting compared to those manufactured with conventional binders [11, 13 - 14, 34, 75, 92 - 101].

1.5 Tests and Equipment

The response to rutting in asphalt mixtures differs depending on the type of test performed. Likewise, there is no laboratory test that can accurately predict the response observed in situ [95, 102 - 103]. The most used laboratory tests for measuring permanent deformations in asphalt mixtures can be classified as:

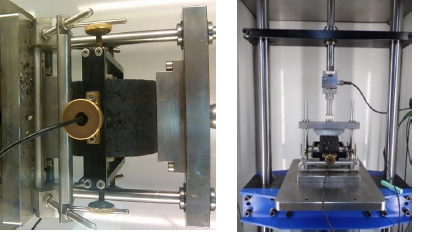

Uniaxial stress tests performed on unconfined cylindric samples under monotonic load, creep or cyclic (Figure 2).

Triaxial stress tests performed on confined cylindric samples under monotonic load, creep or cyclic. Cyclic triaxial tests are carried out by applying a constant confinement pressure and subjecting asphalt mixtures to conditions of stress similar to those produced by the passing of vehicles on the surface. An equipment that allows to conduct these types of tests is the AMPT (Asphalt Mixture Performance Tester, see Figure 3).

Diametral or indirect tensile tests performed under cyclic load or creep. The load is applied vertically by compression in the diametral plane of a cylindrical specimen of the asphalt mixture (Figure 4).

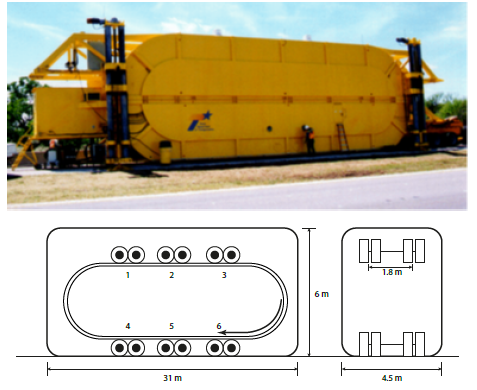

Wheel-Track or small-scale deformation type tests. The samples in these tests are prefabricated beams, and, in these, deformation of an asphalt mixture is measured in function of the number of applied cycles (Figure 5). Some examples of the equipment most used throughout the world to perform these types of tests are APA (Asphalt Pavement Analyzer, AASHTO TP 63), Wheel-Track from Hamburg, and the French Pavement Rutting Tester (FPRT).

Simple shear tests, applying of creep, cyclic and dynamic load. Samples are similar to those used in diametral tests.

X-ray tomography tests. In this test, an asphalt mixture can be described at a micro-mechanical level in 3D by analyzing air voids and form, texture, and configuration of the aggregate. Likewise, it is possible to obtain an estimate of the asphalt binder's stiffness within the asphalt mixture and the stiffness between particle contacts. A more detailed description of these types of tests can be consulted in [105].

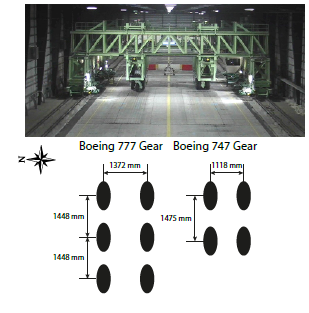

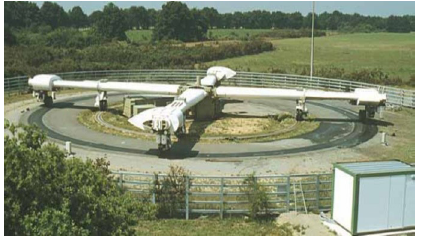

Full scale tests (Figure 6-8). These offer a good representation of field conditions, given that this method ensures the simulation of the pavement system of and the loads that it will actually have to support on its structure, along with the lateral movement of vehicles and the use of real velocities for load application. These tests require designing and constructing tracks that can be longitudinal or circular. In these circular tracks, the loaded tire velocity is limited to centrifugal force [106]. The main disadvantage of this type of technology is that it requires the construction of real scale costly structures and using sophisticated instruments and equipment for measuring and calculating deflections and stresses, as well as for the moisture control of every layer of pavement [11].

A detailed description of these tests can be consulted in [14].

2. EQUATIONS FOR PREDICTING PERMANENT DEFORMATION

The generalized equation for determining useful life affected due to rutting in asphalt mixtures is the following [111]:

N f is the number of load cycles required for the mix to fail due to rutting, εz is the vertical deformation in the mix and k1 and k2 are parameters obtained through regression.

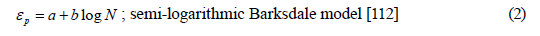

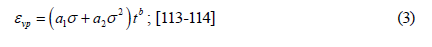

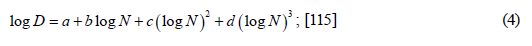

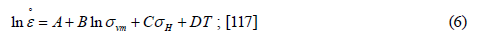

Other simple equations obtained through regression that can be consulted in the referenced literature are presented below.

ε p is the axial deformation, Nis the number of load cycles, α and b are parameters obtained through regression.

εvp is the axial visco-plastic deformation, t is the load time, σ is the creep stress, α 1 , α 2 and b are parameters obtained through regression.

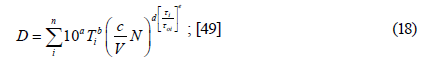

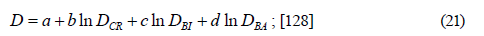

D is the displacement, Nis the number of load cycles, α-dare parameters obtained through regression.

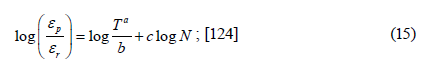

α and c are parameters obtained by regression.

is the permanent deformation rate, σ

vm

is the vertical stress in compression, σ

H

is the horizontal stress in compression, T is the temperature, A-D are parameters obtained through regression.

is the permanent deformation rate, σ

vm

is the vertical stress in compression, σ

H

is the horizontal stress in compression, T is the temperature, A-D are parameters obtained through regression.

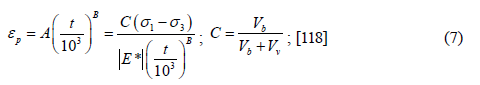

A is a coefficient that depends on the volumetric composition of the mixture, B is a coefficient that varies between 0.14 to 0.37, V b is the asphalt content in volume, V is the void content in volume, |E *| is the dynamic modulus, o1 is the vertical stress, σ 3 is the confining pressure.

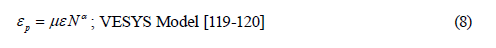

µ is a constant of proportionality between the permanent and the resilient deformation, ε is the permanent deformation for the first 200 load cycles, α is a parameter that takes into account the decrease in the deformation rate with N.

q is the deviator stress, α and b are parameters obtained through regression.

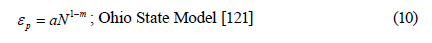

1 -m is an exponent which is a function of temperature.

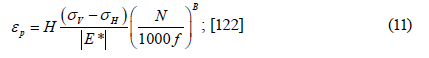

σ v and σ h are vertical and horizontal stress, respectively, f is the load frequency (20 Hz suggested), B is a parameter that depends on the volumetric composition of the mixture (0.25 suggested), H is a coefficient that depends on the asphalt content (115 suggested).

y is the displacement, α and b are parameters obtained through regression.

α and b are parameters obtained through regression.

εo, p and ß are parameters obtained through regression.

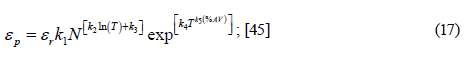

εr is the resilient deformation, α-c are parameters obtained through regression.

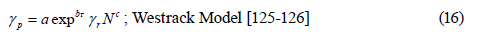

Yp is the critical permanent shear strain, y r is the resilient shear strain, T is the shear stress, α, b, c are parameters obtained through regression.

%AV is the air void content in percentage, ki are parameters obtained through regression.

D is the displacement, Vis the speed load, T is the shear stress, α-e are parameters obtained through regression.

α-d are parameters obtained through regression.

α-c are parameters obtained through regression.

D, D CR , D BI and D BA are the total displacement, measured in the asphalt wearing surface, in the asphalt intermediate layer and in the asphalt base layer, respectively, a-d are parameters obtained through regression.

3. CONCLUSIONS

This study described the main variables that influence the phenomenon of rutting in asphalt mixtures. Likewise, it presents the most used equations for modelling said damage mechanism. Considering the literature reviewed, the following was concluded:

The main causes of the generation of this damage mechanism in flexible pavements are increasing the number and magnitude of cyclic loads and reducing their velocity, increasing temperature in the area, reducing the degree of compaction in the mix, manufacturing mixes with high air void contents and high fine particle contents, using soft asphalts or asphalts with low stiffness, using excess of aggregates and inadequate asphalts, executing a defective constructive process, and using support layers with low stiffness.

The mathematical equations used for attempting to predict the accumulation of permanent deformations developed in in-situ asphalt mixtures, as well as within the laboratory, generally focus on relating permanent deformation with the number of load cycles. However, the greatest deficiency of these mathematical relations is they are not capable of predicting, using a single equation, the deformation that an asphalt mixture will undergo when subjected to different load magnitudes and environmental conditions. This is because regression parameters for said equations are not constants for the material but rather state variables (changing with the type of test, geometry of samples, border conditions, volumetric composition of mixes, etc.). Few equations simulate aspects associated to durability (climate effect, aging, among others) and to the compaction process of asphalt mixtures (within the laboratory and in situ).