Introduction

The complexity of organizations, access to information, relationships with stakeholders, and the uncertainty of the environment have aroused great interest in generating improvements in strategic management. The objectives and decisions taken for production processes can have great repercussions on the organization's future. It requires an organizational strategic planning process that considers organizational characteristics and the uncertainty surrounding operations (Singh, 2020). Besides, resource constraints must be considered in rethinking strategies to ensure the sustainability of operations, customer focus, and organizational competitive advantage (Chaabane, Ramudhin, & Paquet, 2012; Rezvani & Fathollahzadeh, 2020). It is a necessity in developing environmentally sound practices, sound theories, sophisticated research methods, in which the interaction of conventional business models with government requirements for sustainable organizations stands out (Dentchev et al., 2018).

The growth of energy demand, consumer awareness about environmentally friendly products, and the need to act following environmental legislation (Gandhi, Thanki, & Thakkar, 2018) allowed the development and incorporation of green processes in organizations. Organizations began to include sustainable innovation processes in terms of production methods that extended the useful life of manufactured goods. However, the approaches implemented so far remain insufficient for sustainable production, which requires a radical transformation in the organizational strategic management models. Traditional strategic management models have focused on economic productivity and economies of scale (Fausti & Diersen, 2020). Hence, organizations that adopt a sustainable business model must develop internal structural and cultural capacities to integrate sustainability at the business level and into the organization's system (Schaltegger, Hansen, & Lüdeke-Freund, 2016), without neglecting stakeholder requirements. Tt is also important for each organization to recognize the environmental challenges, regulations and practices in the market (Vormedal, 2017).

Strategic management for sustainable production requires business models, production processes, and investment opportunities focused on sustainability (Barbieri & Santos, 2020). Strategic management for sustainable production can be defined as the formulation, implementation, and evaluation of decisions and actions related to environmental and socio-economic sustainability of the organization (Starik & Kanashiro, 2013; Starik, Stubbs, & Benn, 2016). Strategic management for sustainable production describes how to address sustainability issues without affecting the competitive advantage of organizations (Baumgartner & Rauter, 2017). Besides, sustainable strategic management involves a systemic view in which organizations depend on natural resources to carry out daily activities, and these activities have a direct impact on the environment (Williams, Kennedy, Philipp, & Whiteman, 2017).

When applying sustainable strategic management at the production level, organizations must rethink business models and manufacturing methods (Hallam & Contreras, 2016), to generate value for consumers through sustainable processes. It is also important to standardize environmental policies and regulations for all industry sectors. In some cases, the flexibilization of these policies reduces the intention of adopting sustainable production strategies (Alonso-Almeida & Rodríguez-Antón, 2020). However, the generation of value and competitive advantage within the organization cannot be neglected (Husgafvel, Watkins, Linkosalmi, & Dahl, 2013). Competitive advantage results from an organization's ability to develop the required activities at a lower price than its competitors, or to perform some activities in a unique way that creates value for the buyer (Porter, 1991). Competitive advantage is a state in which organizations can cope with the dynamics of the environment and continuously provide better products or services than their competitors (Li & Liu, 2014). Organizations can develop strategic management models to simultaneously improve competitive advantage and environmental performance (Agyabeng-Mensah, Ahenkorah, Afum & Owusu, 2020).

Several issues may be of interest in strategic management for sustainable products such as analysis of the levels of response capacity of organizations to the requirements of stakeholders, and the relationship between sustainable management strategies and competitive advantage (Ogunlela, 2018). Likewise, to identify the effects that business networks have on the adoption of sustainable management strategies, to differentiate resources and capacities required for the adoption of sustainable management strategies in regulated organizations and those that have advanced voluntarily (Bıçakcıoğlu, 2018). It also includes education, scenario analysis, assessment of strategies for sustainable production, smart manufacturing, integration of various links in the supply chain, employee engagement, and innovation (Olatunji et al., 2019).

Based on that, this research aims to analyze trends in strategic management for sustainable production by considering periodicals of papers. For this purpose, the Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) methodology was adopted, as well as a bibliometric study for 442 publications retrieved from the Scopus database. PRISMA is a guide to study the structure of scientific publications and select those related to the topic of interest (Ng'eno et al., 2020). Bibliometric studies show trends in research and relevance of publications in a specific area of study (Ben-Daya et al., 2019). To meet the research goal, the research was divided into two phases: preparation and retrieval of information (construction of search equation, database consultation); application of PRISMA, and analysis of bibliometric indicators (quantity, quality, and structure).

The first part of the study deals with the methodological design used. Subsequently, research results are presented based on quantity, quality, and structure indicators. Finally, trends in research and conclusions on management tools for sustainable production are shown.

Materials and Methods

For the PRISMA methodology and bibliometric analysis, the Scopus database was selected as the main source of information to extract academic publications related to strategic management for sustainable production. Experts recognize Scopus as one of the best, most rigorous, and most complete bibliometric databases and repository for academic documents (Araújo et al., 2020; Fornacciari et al., 2017). It has around 22,000 information sources belonging to more than 5,000 international publishers (Khiste & Paithankar, 2017).

Based on the purpose of the research, we developed the following search guideTITLE-ABS-KEY (((sustainable PRE/4 production) OR (sustainable PRE/4 manufactur*) OR (sustainable PRE/4 fabrication) OR (green PRE/4 production) OR (green PRE/4 manufactur*) OR (green PRE/4 fabrication) OR (cleaner PRE/4 production) OR (cleaner PRE/4 manufactur*) OR (cleaner PRE/4 fabrication)) AND ((management PRE/3 strategy) OR (management PRE/3 policy) OR (management PRE/3 plan) OR (business PRE/3 strategy) OR (business PRE/3 policy) OR (business PRE/3 plan) OR (administration PRE/3 strategy) OR (administration PRE/3 policy) OR (administration PRE/3 plan)))

The PRISMA methodology seeks to evaluate, select, and synthesize high-quality original research relevant to a specific study area (Huang, Chen & Liu, 2020). PRISMA allows identifying different variables of interest in bibliometric studies, becoming the basis for mapping and trend analysis (López Belmonte, López Belmonte, López Núñez & Pozo Sánchez, 2019). After using the flow chart proposed by the PRISMA methodology (Moher et al., 2009), a total of 442 documents were obtained with which the bibliometric analysis will be developed (See Figure 1.).

Subsequently, a database was designed to analyze variables needed in the preparation, data retrieval, and elaboration of bibliometric indicators of quantity (Pareto's Law, Lotka's Law, and Solla Price Law), quality (Impact, h-index), structure (Co-occurrence and cluster). It is important to clarify that bibliometric studies are concerned with analyzing theoretical and practical contributions and the progress of publications in a specific area of study (Valenzuela, Merigó, Johnston, Nicolas, & Jaramillo, 2017; Vogel, 2014). Besides, advances in bibliometric methodologies allow efficient research on publications, contents, and relationships for large sets of documents to assess the status of an area of study, becoming a complement to expert opinions in specific academic fields (Du & Tang, 2014).

Lotka's law articulates the connection between authors and papers published in a field of study over a given period (See Equation 2.). This law measures the influence of authors and journals in the generation of academic documents (Abreu, Kimura, & Sobreiro, 2019; Kumar & Kushwaha, 2018; Silva et al., 2018).

Equation 1. Lotka's law

Where, A n = Number of academic documents corresponding to a certain number of authors; A 1 = Number of academic documents prepared by a single author; n 2 = Number of authors for whom Lotka's Law will be calculated.

De Solla Price's Law describe the exponential growth performance for academic production (De Solla Price, 1976; Kwiek, 2016; Yang & Meng, 2019), where documents rise with a regularity superior to other social processes and can be duplicated in periods of 10 to 15 years (See Equation 3.).

Equation 2. De Solla Price's Law

Where, N = Magnitude related to the size of science; N 0 = Magnitude in time t = 0; b = Constant relating the growth rate with the already acquired size of science.

Bibliometric studies provide an overview of the latest developments in an emerging area of knowledge, which is of interest to researchers and practitioners (Ben-Daya, Hassini & Bahroun, 2019). Bibliometrics is an established technique for analyzing publication performance metrics and provides guidelines for future research (Muhuri, Shukla & Abraham, 2019). These metrics include descriptive indicators and network analysis (Donthu, Kumar & Pattnaik, 2020). Finally, the cutoff date for the analysis was the academic publications on strategic management for sustainable production available on Scopus until May 2020.

Results

Bibliometric Quantity Indicators

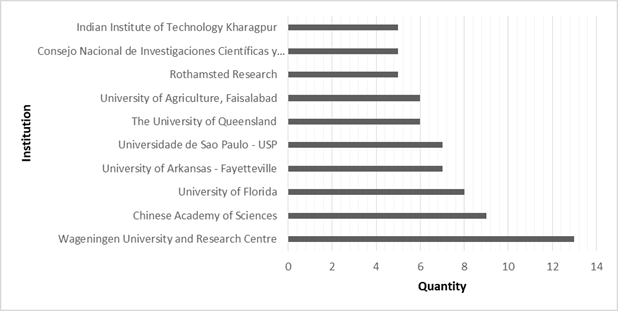

Figure 2. shows the documents published about strategic management for sustainable production from 1988 to 2020. The year 2020 is projected to end with approximately 77 publications. There is sustained growth in the volume of documents, and the relevance that the subject has acquired, which allows for the formulation of future research needs: social and environmental indicators that cannot be monetized (Silva & Guenther, 2018); environmental innovation for clean production (Fichter & Tiemann, 2020); articulation between the circular economy, government, industry, and education (Chen et al., 2020); policies for the adoption of sustainable energy sources in production processes (Zhou et al., 2020); bio-economic models for cost management in production processes (Kamilaris, Dewhurst, Vosough Ahmadi, Crosson & Alexander, 2020).

Source: Prepared by the authors

Figure 2 Number of publications per year about strategic management for sustainable production

Figure 3 shows the accumulated proportion of publications on strategic management for sustainable production, which has exponential growth behavior and shows researchers' interest in developing academic production around the subject. This behavior follows guidelines developed by (De Solla Price, 1976; Ferrer, 2020), in which scientific production grows with a much higher proportion than other social processes, being similar to biological and population growth. This growth can double in periods of 10 to 15 years.

Source: Prepared by the authors

Figure 3 Number of accumulated publications per year about strategic management for sustainable production

Figure 4 shows ten sources of information that have the most substantial amount of documents published in the area of study. The most representative source is the Journal of Cleaner Production (34 documents), which publishes documents in the area of clean production, technical processes, sustainable development, environmental assessment, sustainable products, corporate sustainability, corporate social responsibility, education for sustainable development, governance, legislation, and sustainability policy.

Source: Prepared by the authors

Figure 4 Sources of information with the number of publications in the study area

Another productivity indicator for information sources is Pareto's Law, where it is expected that 20% of the sources will publish 80 % of the documents. However, results showed that 72.7 % of the information sources publish 80 % of the documents. Dividing by quartiles the productivity of sources, results pointed that 7.6 % of sources publish 25 % of documents (Q1), 32.4 % publish 50 % (Q2), and, finally, 6 6% of sources publish 75 % of documents. Based on the information collected, there is no evidence of a source of information that significantly predominates in the Scopus database's records for publications on strategic management for sustainable production.

The productivity of information sources can also be evaluated through Lotka's Law (See Figure 5.) This law evaluates the quantitative relationship between information sources and their contribution to the strengthening of various study areas (Abreu, Kimura, & Sobreiro, 2019; Ruiz-Pomeda, Álvarez-Peregrina & Povedano-Montero, 2020; Kumar & Kushwaha, 2018). Information sources comply with Lotka's Law if the slope of the trend line approaches -2 and the determination coefficient approaches 1 (Rau, 2011). Thus, the individual productivity of information sources does not comply with the law because the slope is -1.61, and the determination coefficient is 0.6979. Thus, there is no source of information whose productivity is significantly higher than the other sources.

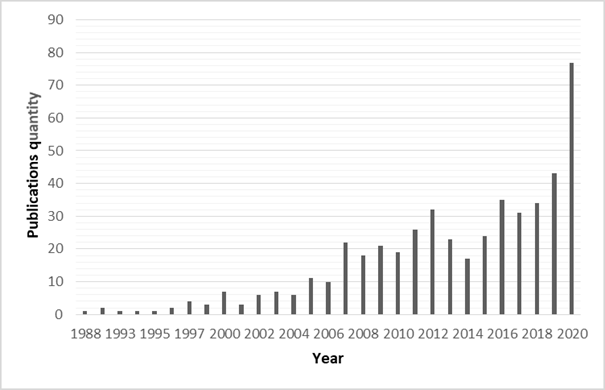

Another indicator to consider is the productivity by affiliation (See Figure 6.), which indicates the number of publications in the study area produced by 153 institutions. Of these, 69.9 % produced 80 % of the documents, in violation of the Pareto Law. For the quartiles, 13.61 % of institutions published 25 % of documents (Q1), 33.9 % published 50 % (Q2), and 62.7 % published 75 % (Q3). Thus, it is necessary to increase academic networks that strengthen research and academic production on strategic management for sustainable production, since the institutions in the first five places generate 10 % of documents. The institutions with the highest number of publications are Wageningen University and Research Centre (13), Chinese Academy of Sciences (9), and University of Florida (8).

Bibliometric Quality Indicators

Quality indicators assess reputation, visibility, and contribution to the development of an area of knowledge for academic information sources and researchers (Osterloh & Frey, 2020; Pluskiewicz, Drozdzowska, Adamczyk & Noga, 2018). Quality indicators analyze the quality of publications in a specific area of study, based on the impact factor by author or institutional affiliation, which allows differentiating the scientific value of publications (Friess et al., 2020). The impact factor is a dynamic index with the ability to find trends and fluctuations in the impact of publications and researchers during their careers and is recognized as a source of information that provides accurate and reliable data (Amjad, Rehmat, Daud & Abbasi, 2020). Similarly, there are other alternatives for evaluating the quality and impact of academic production such as the h-index (Hu, Wang, Ni & Liu, 2020; Li & Zhao, 2015; Sweileh, 2019), which measures quality based on the number of citations received per scientific article.

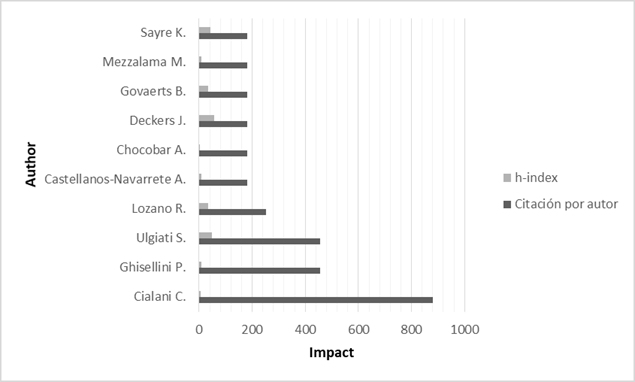

Thus, Figure 7 shows the 10 authors with the highest impact on the research topic and their h-index. The author with the highest impact on publications on strategic management for sustainable production is Catia Cialani, PhD. in Economics. Moreover, the Top 10 most productive authors do not coincide with the Top 10 authors with the highest impact. For example, Alan David Smith is the most productive author with a total of 4 publications on the topic of study; however, he ranks 513 in terms of impact with 11 citations per publication. Therefore, it is important to develop alternatives that allow for increased visibility of authors who are highly productive in the area of study.

Source: Prepared by the authors

Figure 7 Number of citations in the top ten author about strategic management for sustainable production

However, to evaluate the impact by source or journal, Figure 8 shows the ten journals with the highest number of citations per publication in the area of study of strategic management of sustainable production. The journal with the highest number of citations per publication is Supply Chain Management, with a total of 114. In second place is the Journal of Industrial and Production Engineering, with a total of 97 citations per publication, followed by Interfaces with 88 citations per publication. However, there are differences between the most productive journals and journals with the highest impact. None of the top ten journals in terms of impact are in the Top 10 most productive journals. For example, the Journal of Cleaner Production has 34 publications in the area of study, but in terms of impact per publication, it is in 14th place, with a total of 54 citations per publication.

Bibliometric Structure Indicators

These indicators allow us to examine the structure and patterns of interdisciplinary collaboration and the overall evolving pattern of networks in a specific knowledge area (Hu & Zhang, 2017). Another alternative for analyzing the structure of academic networks is co-occurrence analysis. This analysis shows the number of publications in which two words appear together in title, abstract, or keywords (Det Udomsap & Hallinger, 2020). The smaller the distance between two terms, the greater the number of co-occurrences (Redeker, Kessler, & Kipper, 2019). However, the VOSviewer 1.6.10 software was used to construct the co-occurrence indicators. (van Eck & Waltman, 2014, 2017), which allows the construction and visualization of bibliometric networks.

Hence, Figure 9 shows the connection and clustering of the key terms' co-occurrences among the 442 publications analyzed in the Scopus database. From the total number of articles, 3850 keywords were obtained, of which 443 met the requirement of at least three occurrences. A total of 12325 links were generated, showing the relationship between two keywords. Thus, a Total Link Intensity of16525 was created. The keywords with the highest intensity are linked to the words with the highest occurrence. The intensity for the most representative terms is as follows: sustainable development (958), sustainability (652), sustainability (418), environmental impact (373), cleaner production (356), pollution control (345), environmental protection (336) and decision making (322).

In addition, a total of 8 clusters helped to define trends in research and knowledge evolution on strategic management for sustainable production: Cluster 1-management and models of sustainability to face climate change (21.67 %); Cluster 2-natural resources conservation (20.1 %); cluster 3 (19.2 %) methodologies, models and strategies of sustainable production; Cluster 4-circular economy and waste management in sustainable production (14.2 %); Cluster 5-energy sources management in productive processes (9.7 %); Cluster 6-education and water management (7.4 %); Cluster 7 (5.4 %)-risk and uncertainty management; and Cluster 8 (2.2 %)-public policies for sustainable production.

Cluster 1-Management and sustainability models to face climate change. The publications belonging to this cluster widely discuss how production models must migrate towards sustainable management models and alternatives to mitigate the effect of industrial operations on climate change. A common point is "Best management practices" that allow for increased production levels, reducing negative impacts on the environment (Choruma & Odume, 2019). The central objective of these measures is to generate policies to reduce energy consumption and carbon emissions through energy efficiency technologies (Castrillón-Mendoza, Rey-Hernández & Rey-Martínez, 2020); in addition, decisions and plans to extend the life cycle of products in a sustainable manner (Meng, Qian, Lou & Zhang, 2020).

Cluster 2-natural resources conservation. The documents belonging to this cluster highlighted the need to conserve natural resources without affecting competitiveness in production processes. The cluster allows for the sustainable manufacturing of high-quality products with good sales prices (Lagan, Mannan & Matsubayashi, 2007). In this way, it is possible to create strategic plans of sustainable management, oriented to the conservation of the environment, economic return and well-being of communities (Yakan & Baki, 2019), taking into account that the production processes affect mostly the energy and water resources (Wang et al., 2019).

Cluster 3-methodologies, models, and strategies of sustainable production. The cluster summarizes the different models, methodologies, tools, and strategies created in industrial sectors to adopt sustainable production processes. Firstly, it is important to approach lean manufacturing as a continuous improvement system that optimizes the use of natural resources in production processes and generates competitive advantages in organizations (Yadav et al., 2020). It also highlights eco-innovation as an alternative for clean production and transition to a circular economy in organizations (Prieto-Sandoval, Mejía-Villa, Ormazabal & Jaca, 2020). All this allows for the strategic management of "Green Supply Chains," in which all links and stakeholders make cooperation decisions to operate in an environmentally friendly manner (Giri, Mondal & Maiti, 2019).

Cluster 4-circular economy and waste management in sustainable production. Cluster 4 publications seek to reincorporate components into production processes and extend the life of manufactured goods. A management alternative is circular economy, which allows balancing economic growth, organizational sustainability, and environmental protection (Chen, 2020). However, these management alternatives must be accompanied by tools for evaluating a product's environmental impacts during all stages of product life. Among these tools is Life Cycle Assessment (Esmaeilzadeh, Asgharipour & Khoshnevisan, 2020). It is also necessary to have government policies and regulations that encourage eco-innovation and adoption of environmental management strategies to compete in global markets (Rahman, Billah & Hack-Polay, 2019).

Cluster 5-energy sources management in productive processes. Cluster 5 documents address the impact of energy sources on the adoption of sustainable production processes. Therefore, in a competitive environment, energy policies can change priorities, decisions, and investments in production (Zhou et al., 2020). Decisions include changes in physical infrastructure and investment in technology that improves energy efficiency and reduces greenhouse gas emissions (Liu, Sabbaghi & Khalili, 2009). The use of renewable energy sources contributing to the sustainable management of production processes is also highlighted (Manolis, Zagas, Karetsos & Poravou, 2019).

Cluster 6-Education and water management. The publications belonging to this cluster consider education and social characteristics key elements in the management ofresources used in sustainable production, especially water resources. There are productive processes with a high water demand; however, it is possible to create policies for efficient and low-cost water resources management (Ganora, Dorati, Huld, Udias & Pistocchi, 2019). Policies include the use of predictive models to improve time efficiency of water use in production processes (Darbyshire, Crean, Dunn & Dunn, 2019). Besides, these policies involve education for sustainability through the exchange of information and knowledge among stakeholders (Matzembacher & Meira, 2019).

Cluster 7-Risk and Uncertainty Management. Cluster 7 brings together strategy documents for managing risks and uncertainty associated with sustainable production processes. In complex industrial contexts where natural resources limit production processes' capacity, it is necessary to create risk management strategies that include measures of adaptation and resilience to change (Tan, Benjamin, Cayamanda, Aviso & Razon, 2016). The most common risks are financial, technological, and supply chain risks, for each of which a mitigation strategy must be created to reduce the effects of risk on productive processes (Ngan, Promentilla, Yatim & Lam, 2019). Each of these risks is associated with a process of uncertainty that must be taken into account in strategic planning and decision making at the organizational level (Zeng et al., 2018).

Cluster 8-Public policies for sustainable production, the publications belonging to cluster 8 agree that organizations adopt sustainable production processes if there are public policies that leverage their adoption. It includes scale production, low-interest rate credits, and tax exemptions (Wang et al., 2019). However, in some industrial sectors, these policies are still in their infancy and need to be adapted to new technologies and sustainable development objectives (Mak, Xiong, Tsang, Yu & Poon, 2020). Furthermore, these policies require accounting and evaluation tools that highlight the potential for sustainable production practices (Pacini, Lazzerini & Vazzana, 2011).

Evolution of Trends in Research on Strategic Management for Sustainable Production

An analysis was carried out accounting for the evolution of research trends on the subject of strategic management for sustainable production over the last 32 years (See Figure 10), based on the 442 documents retrieved from the Scopus database. Thus, changes in trends are influenced by changes in regulations, evolution in environmental impact assessment systems, and modification in production practices in the period analyzed. In the years between 1988-1995, studies focused on traditional cultural systems that respect the fair use of natural resources and can be replicated in sustainable production processes. However, these traditional techniques must be adapted to new approaches for strategic, political, economic, and social management (Mountjoy & Gliessman, 1988). They also involve the need to rethink manufacturing processes, material use, and design for the environment (Miller & Moore, 1994). They also consider integral strategic management of natural resources that simultaneously guarantees sustainable production and biodiversity conservation (Thompson & Welsh, 1993).

In the period 1996-2003, research took the risk and impact assessment into account to provide information to decision-makers in the organization so that the greenhouse effect problem could be included in management strategies (Pipatti, 1998). Similarly, several publications were made on the implementation of Environmental Management Systems derived from an awareness of sustainable development and reconciliation of productive processes with ecosystem conservation (Pun, Hui, Lau, Law & Lewis, 2002). In addition, cleaner production is conceived as a preventive environmental management strategy for industrial operations (Van Berkel, 2000).

For the years between 2004-2011, publications increased interest in green practices manufacturing, which consider resource consumption and environmental impacts derived from processes, products, and management, which implies modifications in manufacturing methods (Tan, Li, Liu, & Li, 2008). In addition, the extension of the product life is highlighted by the creation of economic incentives and markets for recycled goods, which allows better environmental and economic performance in organizations (Brouillat, 2009). The above creates a set of objectives, drivers, and challenges for sustainable manufacturing, such as changes in strategic management, corporate values, and commitment of senior management (Koho, Torvinen & Romiguer, 2011).

Finally, in the period from 2012-2020, the progress in adoption towards sustainable practices became slower, indicating the need for more concrete guidelines that would allow organizations to act strategically, successfully, and sustainably (Baumgartner & Rauter, 2017). Therefore, the adoption of clean production tools received more interest, which can be seen as a preventive approach to environmental problems and impacts in manufacturing processes, promoting sustainable innovation in business, industry, and services (Ghisellini, Ji, Liu, & Ulgiati, 2018). It also facilitates the use of Life Cycle Costing, Life Cycle Assessment, and Social Life Cycle Assessment studies. The publications also highlight the importance of strengthening entrepreneurship and innovation systems as key actors in the adoption of cleaner production (Fichter & Tiemann, 2020).

Discussion

We used PRISMA and bibliometric analysis as a methodology that allows the scientist to study tendencies and interactions between multiple research outputs in a specific study area. Bibliometric analysis is one of the five meta-analysis' categories. Also, bibliometric is a tool to assess the quality of scientific production. Our analysis includes three approaches: (a) descriptive (Productivity indicators indicators), b) evaluative (Quality indicators), and c) historical (Co-occurrence and cluster). These approaches show the growing interest in publications about strategic management for the adoption of sustainable production practices. Furthermore, bibliometric analysis allows identifying trends in research such as intangible benefits in sustainable production, access to entrepreneurship and innovation ecosystems, circular economy, Green Supply Chain Management, sustainable energies, and bio-economic models of valuation.

Based on the foregoing, the structure of economic sectors determines the need to develop sustainable production practices and clean manufacturing processes. These practices help to rethink resource allocation (Chen & Zhao, 2019). Also, the structure of economic sectors has a key effect on the treatment of natural resources and it allows to mitigate environmental impacts resulting from strategic decisions in organizations. In addition, manufacturing organizations see sustainable production as an alternative to reduce waste and costs (Yaqub & Lee, 2019). Thus, sustainable production practices reduce water consumption and improve energy efficiency in various manufacturing activities (Naqvi et al., 2019).

On the other hand, manufacturing organizations face challenges such as severe environmental regulations, social development campaigns and growing responsiveness among stakeholders. These challenges are forcing organizations to implement a cooperative approach and create a permanent partnership with third-party logistics providers to successfully take advantage of the shared capabilities of both companies (Govindan et al., 2019). In this way, the environmental weight can be decreased through outsourcing as a result of more efficient processes and/or more up-to-date technologies (Tamás, 2018). This is accomplished by using equipment that help to decrease the amount and volume of hazardous waste; and also diminish final disposal costs (Hakiki et al., 2018).

In addition, the use of technological developments such as Big Data and Smart Manufacturing allows identifying the attributes of interest related to sustainability production that generate value for manufacturing organizations (Ren et al., 2019). Furthermore, the integration of Industry 4.0 and the circular economy requires the reconfiguration of production processes, redesign of business models and commitment of stakeholders to manage the value chain in a sustainable way (Garcia-Muiña et al., 2018). It is essential for organizations creating long-term strategic actions that allow them to visualize trends related to sustainable production; change the organizational structure; strengthen the culture and the sustainable behavior in employees; and respond to new environmental market demands.

Conclusions

As evidenced throughout the document, PRISMA methodology and bibliometric analysis are useful tools for assessing quality, relevance, trends, and gaps in research in various areas of knowledge. This evaluation requires the use of a set of descriptive and historical indicators to obtain an integral vision of scientific production, which include: quantity indicators (Pareto's Law, Lotka's Law and Solla Price Law), quality indicators (Impact, h-index) and structure indicators (Co-occurrence and cluster). The results show a substantial increase in the interest of the scientific community in strategic management for sustainable production; however, there are differences between authors and more productive sources for those with higher impact. These differences reflect the need to create and improve the means of dissemination for academic results.

As a contribution of the research is the analysis of co-occurrence and cluster, this analysis showed the articulation between publications, generation of networks, and the evolution of knowledge. In this way, eight clusters were identified that group public policies, educational requirements, tools, models, and strategies of sustainable production in manufacturing industries; to guarantee efficient management of natural resources, industrial waste, risks, reincorporation of materials, and extension of the useful life of the product. The clusters are Management and models of sustainability to face climate change; natural resources conservation; methodologies, models and strategies of sustainable production; circular economy and waste management in sustainable production; energy sources management in productive processes; education and water management; risk and uncertainty management; and public policies for sustainable production.

Strategic management for sustainable production has been a topic of study and high impact for organizations in the last 30 years. However, in the last decade, a change in consumption characteristics and environmental regulations for manufacturing organizations occurred. This change contributed to the creation, transformation, and adoption of production methods that allow for the optimization of resources, the reduction of environmental impacts, and the conservation of competitive advantage in organizations. Currently, this study identified the following research trends: environmental innovation, circular economy, Green Supply Chain Management, sustainable energies, and bio-economic models of valuation. The above can only be fulfilled if there is a real commitment from top management to incorporate sustainable production tools into the objectives, methods, strategies, and decision-making process in the organization.

As in other study, this study has some obstacles and restrictions. First, we studied the amount of citations but this impact indicator is time-dependent. This means that more citations values may be related with earlier publication periods. As well, the addition of latest documents reduces the amount of publications, searches and citations, affecting impact indicators. Secondly, the Scopus database was used as the only source of information. We suggest using other alternatives such as JSTOR, Taylor & Francis, Web of Science, Nature, and Google Scholar to obtain a holistic view of the research area's behavior, as long as duplicate records are avoided. Also, bibliometric indicators were selected to analyze the evolution of academic publications on strategic management for sustainable production. Other non-traditional bibliometric indicators should also be considered, such as co-citation, international impact, webometrics, altmetrics, geographic diversity analysis, editorial impact, and prediction indicators. The choice of indicators to be used depend on the area ofknowledge, taking into account that the inclusion of recent papers reduces the number of citations, affecting impact indicators. Despite these limitations, we consider that our work provided the basis for future research on strategic management for sustainable production and bibliometric analysis.