1 | INTRODUCTION

Generally, the photovoltaics (PV) can convert the solar energy to generate electricity direct from the sun light by means of crystalline materials, multiple-junctions, or polycrystalline thin films. The polycrystalline thin films reduce the cost and materials needs because of the much lower materials usage, however polycrystalline thin films such as cadmium telluride (CdTe) have several potential advantages [1,2,3,4,5,6,7]. CdTe absorber layer has a high absorption coefficient, direct band gap 1.45 eV that significantly corresponds with the sun light spectra and long-term performance stability [8,9].

On one hand, the CdTe layer thickness reduction of solar cells is an attractive prospect due to limited availability and the rising price of telluride. Although, the CdTe solar cells have disappointed crystalline Silicon solar cells, but the CdTe cells is also simply manufactural by different techniques such as the closed space sublimation, molecular beam epitaxy, close-spaced sublimation (CSS) deposition, electrodeposition, spraying deposition, vapor transport deposition, screen printing techniques, Chemical bath deposition (CBD), vacuum evaporation, or CSS methods [10,11]. The efficiency of CdTe solar energy has increased but further gains in efficiency will continue to be beneficial over the past few years. The National Renewable Energy Laboratory (NREL) reports record efficiencies of 23.5% for cell efficiency; and 22.1% for module efficiency at the lab condition for cadmium sulfide/cadmium telluride (CdS/CdTe) solar cells that have increased by only 5.2% during the last 20 years [12,13]. Therefore, Improved efficiency helps to reduce the cost of the cells since the same area or number of panels can provide more energy.

On the other hand, single junction CdS/CdTe solar cells have relatively low efficiency because they can't absorb low energy photons. In order to overcome the limitations of their low efficiency, tandem solar cells can be used, where the complete solar cell induced by two sub cells [14,15,16,17]. Several different types of tandem solar cells have been experimentally demonstrated for better photon absorption and improved efficiency including III-V/Si solar cells [18,19], Perovskite/Si tandems [20], CdTe/CIS [21,22] and CIGS/CIGS [23].

In addition, the distributed Bragg reflector (DBR) is based on the fundamental principal of reflection and transmission of light at interface of multiple layered alternating dielectric pairs. The simplest DBR is composed of a stack of two different layers with different refractive indices. Recently, a CdS/CdTe solar cell based on Si/SiO2 DBR with conversion efficiency of 21.02% is presented [24].

In this work, we propose and investigate a polycrystalline cadmium telluride/silicon (CdTe/Si) solar cell based on SiO2 /TiO 2 DBR using calibrated simulations with experimental data of previous fabrication device. The aim of the numerical modelling is to check whether the CdTe/Si solar cell based on SiO 2 /TiO 2 DBR is working properly or not by using the SiO 2 /TiO 2 DBR. The paper is organized as follows. In section 2, we have described the device structure model and validation. The results and discussion are presented in section 3. In section 4, we finally conclude.

2 | DEVICE STRUCTURE MODEL AND VALIDATION

Generally, numerical analysis is a fundamental approach to predict of the solar cell performance and ensure the viability of the anticipated structure [2]. The efficiency of the proposed solar cell structure was modeled using the Silvaco ATLAS Device software package [25]. The fundamental and primary equations of interaction of optical and electrical during the solar cells operation and modeling are electrostatic potential, carrier densities, Poisson's equation, the continuity equations and transport equations. Poisson's equation relates the electrostatic potential to the space charge density as [25]:

where ψ, p and Є are electrostatic potential, local charge density and local permittivity, respectively. The continuity equations for electrons and holes are respectively defined by [25]:

And

where n, p, Jn, J p , G n and G p are electron concentration, hole concentration, electron current density, hole current current density, electrons generation rates and holes generation rates, respectively. R n and R p are the recombination rates and q is the magnitude of electron charge.

The drift current densities for holes and electrons based on energy balance transport model can be written as [25]:

where T n and T p represent the electron and hole carrier temperatures. The parameters μn and μp are the electron and hole mobilities respectively. The coefficients D n and D p are the thermal diffusivities for electrons and holes respectively. The rate of creation of electron-hole pairs as a function of position within a solar cell is [25]:

where s is the grid-shadowing factor, r(α) is the reflectance, α(λ) is the absorption coefficient, and 𝑓(λ) is the incident photon flux that is obtained by dividing the incident power density at each wavelength by the photon energy.

As mentioned above, solar cell operation is modeled by a set of coupled, non-linear, partial differential equations. The computer-aided design (CAD) produces numerical solutions of these equations by calculating the values of unknowns on a mesh of points within the device. An internal discretization procedure converts the original, continuous model to a discrete non-linear algebraic system that has approximately the same behavior. The set of partial differential equations, the mesh and the discretization procedure determine the non-linear algebraic problem that must be solved. The two-dimensional Silvaco ATLAS Device software is suitable for solving self-consistent these equations [25]. For higher accuracy in modeling of the mobility, recombination and carrier lifetimes; the concentration and field dependent mobility model, Shockley-Read-Hall recombination model and SRH concentration-dependent Lifetime were considered.

Fig. 1 shows the cross-sectional views of the previous experimentally - fabricated CdTe solar cell type (Glass/ITO/ZnO/n - CdS/p-CdTe/Al), tandem CdTe/Si solar cell (Glass/ITO/ZnO/n - CdS/p-CdTe/n-Si/p-Si/Al) and tandem CdTe/Si solar cell based on SiO 2 /TiO 2 DBR as proposed to achieve higher efficiency. The device parameters for the simulations are similar to that mentioned in Ref. [2] and are given in Table 1.

FIG. 1 The cross-sectional views of the previous experimentally-fabricated CdTe solar cell (Glass/ITO/ZnO/n-CdS/p-CdTe/Al), tandem CdTe/Si solar cell (Glass/ITO/ZnO/n-CdS/p-CdTe/n-Si/p-Si /Al) and tandem CdTe/Si solar cell based on SiO 2 /TiO 2 DBR.

TABLE 1 The device parameters of solar cell for the simulations.

| Parametrics | CdS | CdTe |

|---|---|---|

| m * n/m o | 0.171 | 0.25 |

| m * p/m o | 0.7 | 0.7 |

| Dielectric Constant Є/ Єo | 10 | 9.7 |

| Electron Affinity [eV] | 4.3 | 4.28 |

| Electron Mobility /j, e [cm 2 /Vs] | 350 | 500 |

| Hole Mobility μh [cm 2 /Vs] | 50 | 60 |

| Electron/Hole Density n, p [cm -3 ] | 1016 | 1014 |

| Band Gap Energy E g [eV] | 2.42 | 1.45 |

| Effective Density of States N C [cm -3] | 2.4 x 1018 | 8 x 1017 |

| Effective Density of States N V [cm -3 ] | 1.8 x 1019 | 1.8 x 1018 |

TABLE 2 The comparison between the experimental results of open circuit voltage (VOC), short circuit current density (JSC), fill factor and cell efficiency with the simulated ones for conventional cell.

| Parametrics | Conventional cell | Simulated cell |

|---|---|---|

| Voc (mV) | 985 | 988 |

| Jsc (mA/cm 2) | 22.2 | 22.14 |

| Fill factor | 0.830 | 0.823 |

| Efficiency (%) | 18.12 | 18 |

In brief, the conventional cell consists of substrate of glass, 50 n indiu-tin-oxide (ITO), 50 nm CdS and 300 nm CdTe. The device parameters of proposed tandem CdTe/Si solar cell based on SiO 2 /TiO 2 DBR are same as tandem CdTe/Si solar cell except that the three pair of SiO 2 /TiO 2 served as DBR with their refractive index 1.46 and 2.25, respectively. The geometric thickness of each layer is d = λ/4n, where n is the real refractive index and X is the light wavelength that travelling inside the DBR material.

It is worth noting that the simulations are calibrated and tuned using experimental value measured. Table 2 compares the experimental results of open circuit voltage (VOC), short circuit current density (JSC), fill factor and cell efficiency with the simulated ones. As seen, the simulated results are quite close to the experimental data [2].

3 | RESULTS AND DISCUSSION

Figs. 2 and 3 show the voltage dependent current density and output power for tandem CdTe/Si solar cell and conventional CdTe solar cell under global AM 1.5 conditions, respectively.

FIG. 2 The voltage dependent current density for tandem CdTe/Si solar cell and conventional CdTe solar cell under global AM 1.5 conditions.

FIG. 3 The voltage dependent output power for tandem CdTe/Si solar cell and conventional CdTe solar cell under global AM 1.5 conditions.

As seen, The obtained open circuit voltage, short circuit current density, fill factor and conversion efficiency of tandem CdTe/Si solar cell are 1000 mV, 37.2 mA/cm2, 0.94 and 23.5% under global AM 1.5 conditions, respectively. In comparison to conventional CdTe solar cell with 18% efficiency, a 30% relative enhancement in the conversion efficiency value for tandem CdTe/Si solar cell.

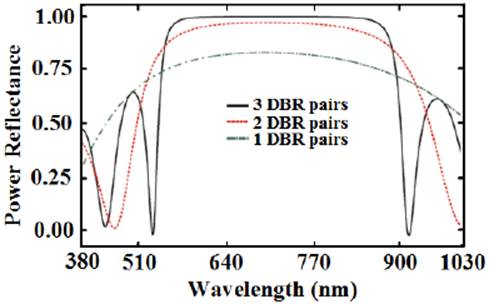

Although metallic BRs can act as electrodes but they suffer from a lack of light transparency, whereas dielectric DBRs have high light transparency. In order to achieve better performance, we optimize tandem CdTe/Si solar cell with three pair of SiO 2 /TiO 2 DBR. By increasing the number of DBR pairs, large power reflectance values can be achieved due to the periodic nature of the DBRs. The 100% power reflectance at a certain wavelength can be approached with an infinite number of DBR pairs. On the other hand, the required number of DBR pairs to achieve a given reflectance value at certain wavelength decreases with increasing refractive index contrast of the stack of two different layers. The refractive index contrast for SiO 2 /TiO 2 DBR is 0.79. Therefore, we optimize the number of SiO 2 /TiO 2 DBR pairs. Three different values of pairs, as 1, 2, and 3, are used for this purpose. Fig. 4 shows the power reflectance comparison of the SiO 2 /TiO 2 DBR as a function of number of pairs. It is evident that the maximum power reflectance value increases as the number of pairs increases from 1 to 3, whereas a flat stop bandwidth is formed for 3 SiO 2 /TiO 2 DBR pairs. The values of maximum power reflectance and stop bandwidth are 99.97%.

Fig. 5 shows a comparison between output power characteristics of different structures of solar cells including tandem CdTe/Si with three pair of SiO 2 /TiO 2 DBR, tandem CdTe/Si and conventional CdTe cells under global AM 1.5 conditions. The tandem CdTe/Si with three pair of SiO 2 /TiO 2 DBR shows the maximum output power of 45 mW/cm2 under global AM 1.5 conditions. As can be observed, the output power value of tandem CdTe/Si with three pair of SiO2/TiO2 DBR increased about 25% and 55% compared to that of the tandem CdTe/Si and conventional CdTe solar cells, respectively.

FIG. 5 The comparison between output power characteristics of different structures of solar cells including tandem CdTe/Si with three pair of SiO 2 lTiO 2 DBR, tandem CdTe/Si and conventional CdTe cells under.

In order to investigate whether the carrier lifetime effect was present when the carrier lifetime of CdTe increased, the performances of the tandem CdTe/Si with three pair of SiO 2 /TiO 2 DBR with different carrier lifetime were also examined. Except carrier lifetime, all parameters are kept as same in these simulations. Figs. 6-9 show comparison of the open circuit voltage, short circuit current density, fill factor and conversion efficiency as a function of carrier lifetime of CdTe under global AM 1.5 conditions, respectively.

FIG. 6 The comparison of the open circuit voltage as a function of carrier lifetime of CdTe for tandem CdTe/Si with three pair of SiO 2 /TiO 2 DBR structure under global AM 1.5 conditions.

FI G 7. The comparison of the short circuit current density as a function of carrier lifetime of CdTe for tandem CdTe/Si with three pair of SiO 2 lTiO 2 DBR structure under global AM 1.5 conditions.

FIG. 8 The comparison of the fill factor as a function of carrier lifetime of CdTe for tandem CdTe/Si with three pair of SiO 2 /TiO 2 DBR structure under global AM 1.5 conditions.

FI G 9. The comparison of the conversion efficiency as a function of carrier lifetime of CdTe for tandem CdTe/Si with three pair of SiO 2 /TiO 2 DBR structure under global AM 1.5 conditions.

It is evident that the carrier lifetime of CdTe has a strong effect on the conversion efficiency. Since all carriers generated in the depletion region will be physically collected at higher lifetimes, the conversion efficiency improve with increasing the carrier lifetime. The improved open circuit voltage, short circuit current density, fill factor and conversion efficiency of tandem CdTe/Si with three pair of SiO 2 /TiO 2 DBR were 1.2 V, 39.5 mA/cm2, 0.95 and 28.5% under global AM 1.5 conditions, respectively.

4 | CONCLUSION

In this paper, we propose and investigate a polycrystalline cadmium telluride/silicon (CdTe/Si) solar cell based on SiO 2 /TiO 2 distributed Bragg reflector (DBR) by using calibrated simulations with experimental data of previous fabrication device. By inserting the SiO 2 /TiO 2 DBR, the conversion efficiency is increased by about 25% compared with the conventional CdTe/Si solar cell with similar dimensions. Furthermore, the carrier lifetime of absorber layer can provide improved conversion efficiency of device about 15% compared with the conventional solar cell. With optimized carrier lifetime, a signiicant enhancement in short circuit current density and output power was noticed with maximum cell efficiency up to 28.5% under global AM 1.5 conditions. The results approve that the polycrystalline CdTe/Si solar cell based on SiO 2 /TiO 2 DBR seems to be the most optimal choice for converting the solar energy in high efficiency photovoltaics systems.